Four-purpose valve for single hydraulic prop

A single hydraulic prop and hydraulic cavity technology, applied in props/supports, mining equipment, earth-moving drilling, etc., can solve the problems of poor unloading capacity, internal leakage of hydraulic cavity, hidden safety hazards, etc. The effect of large discharge capacity and enhanced safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

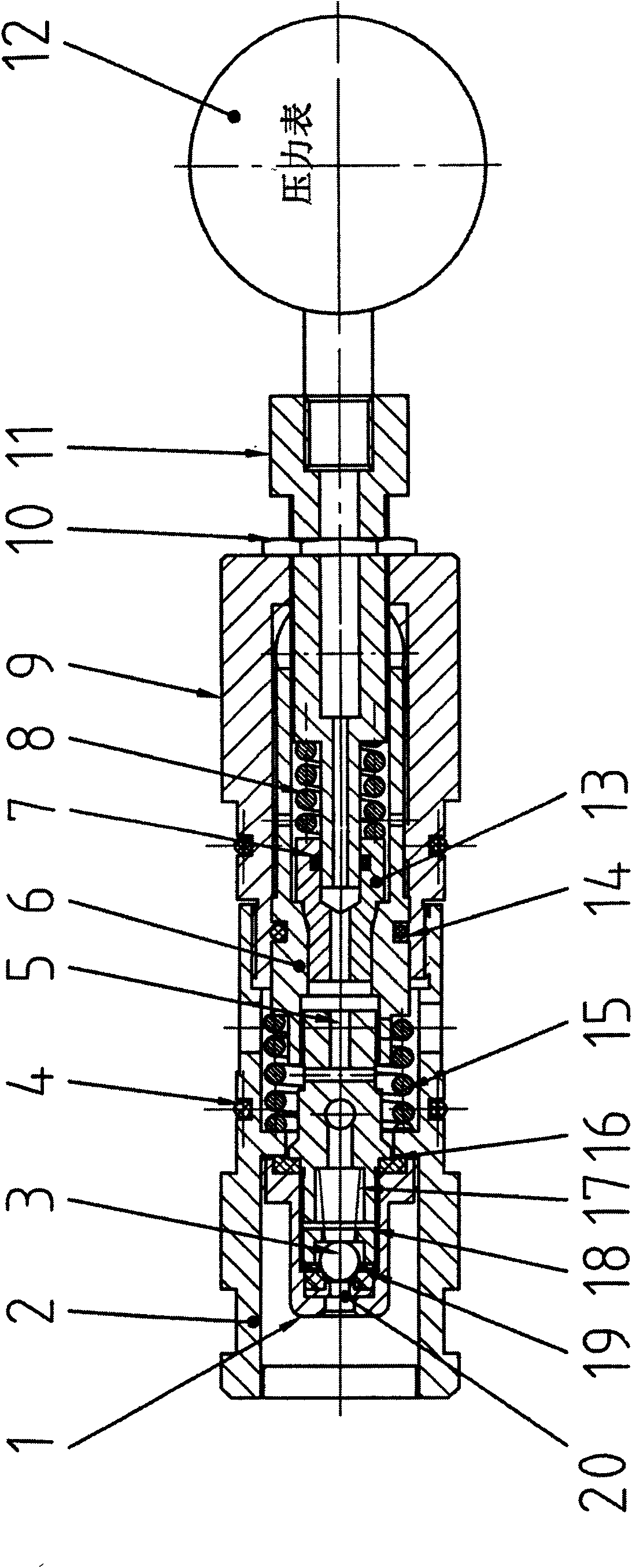

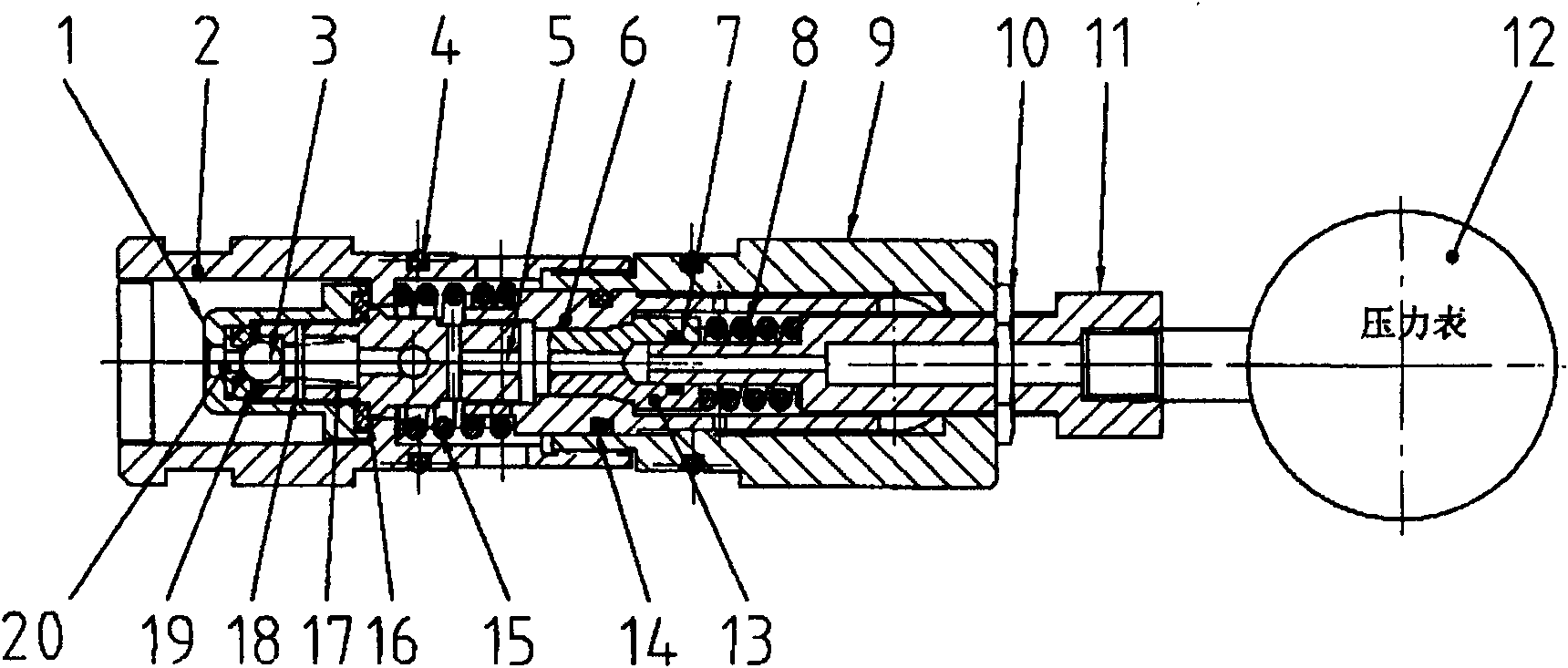

[0011] In the figure, the left valve cylinder (2) and the right valve cylinder (9) are tightened, installed in the three-purpose valve hole of the single hydraulic prop, and sealed by the O-ring (4) to prevent liquid leakage. Oil injection valve body (1), limit sleeve (20), check valve seat (19), steel ball (3), compression screw sleeve (18), conical spring (17), connecting screw rod (5) The liquid injection device of the four-purpose valve uses a special liquid injection gun to complete the liquid injection through the liquid injection hole on the oil injection valve body. Oil injection valve body (1), connecting screw rod (5), valve sleeve (6), unloading valve pad (16), unloading valve spring (15) constitute the unloading device of the four-purpose valve, push the valve sleeve to the left, compress the unloading valve spring, A gap is formed between the unloading valve pad and the sealing surface on the left valve cylinder, and the hydraulic fluid leaks out. Liquid introduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com