Prestress construction method for combined steel beam

A construction method and prestressing technology, applied in the processing of building materials, construction, building components, etc., can solve the problems of difficult construction of prestressed tendons, limited prestressing of section steel, large deflection of large-span construction, etc., and achieve the improvement of concrete prefabrication rate , The area of the pre-pressing area is increased, and the effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

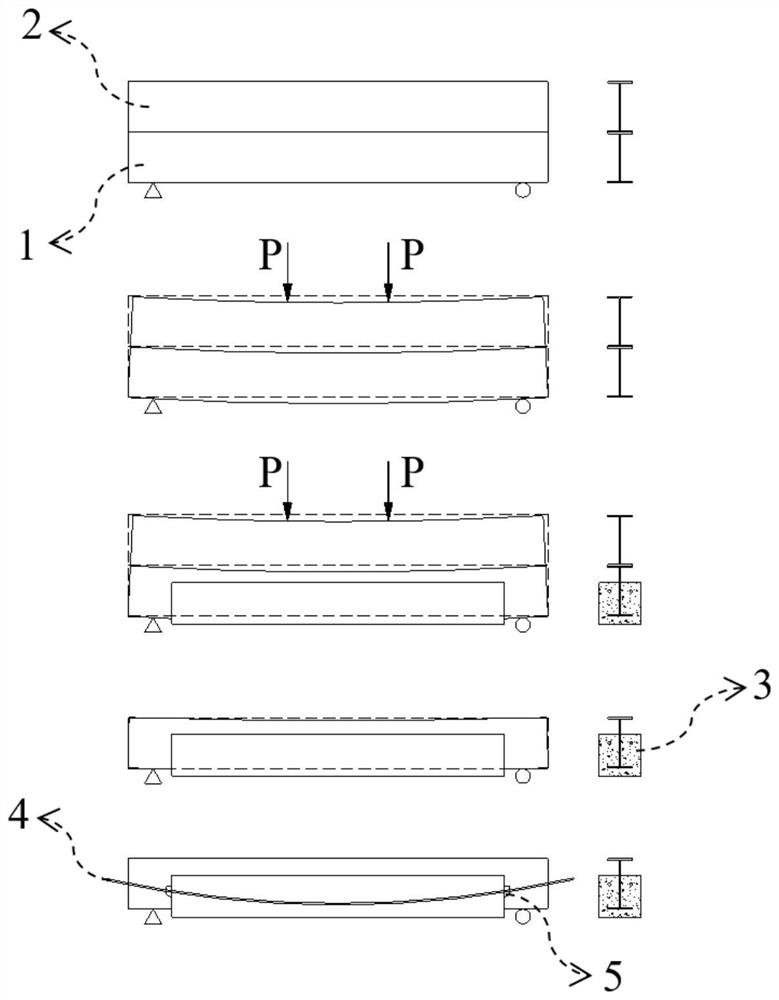

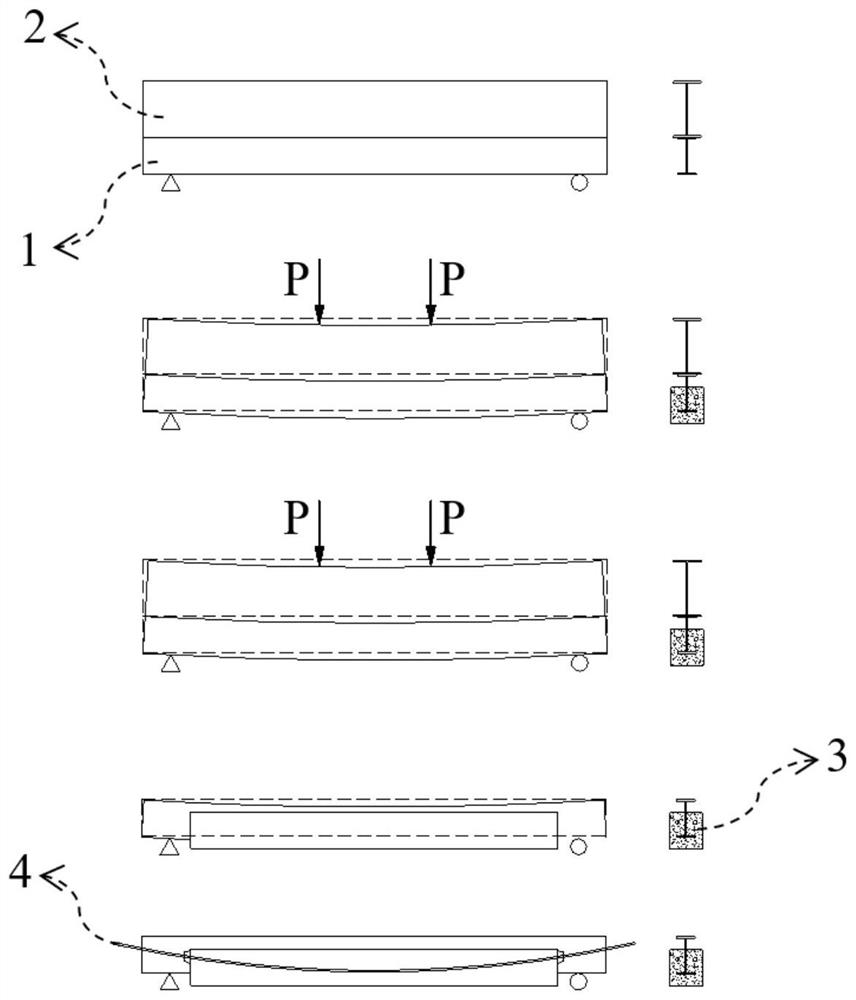

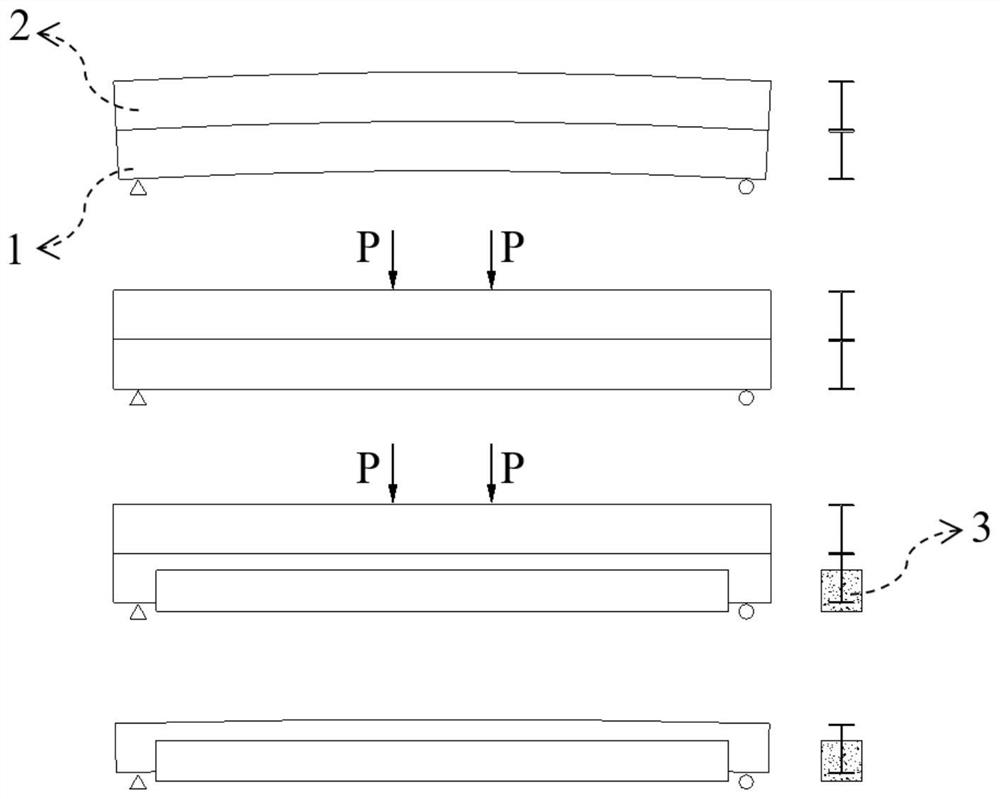

[0036] refer to Figure 1 to Figure 5 , the mixed prestressed composite beam includes prefabricated composite beam and cast-in-place concrete 6, the prefabricated composite beam mainly includes the lower section steel 1 and the precast concrete 3 poured on the lower section steel 1, and the mid-span prestressed tendon 4 is stretched in the precast concrete 3, correspondingly The lower section steel 1 adjacent to the prefabricated composite beam is connected at the end with spacing. The cast-in-place concrete 6 is poured above the lower section steel 1 and between the adjacent prefabricated composite beams, the mid-span prestressed tendon 4 extends and extends into the cast-in-place concrete 6, and the ends are fixed.

[0037] In this structure, the mid-span prestressed tendon 4 is stretched from both ends of the precast concrete 3 under the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com