Loading shuttle car for docking with automatic guiding transport vehicle

A technology of automatic guidance and shuttle vehicles, which is applied in the field of shuttle vehicles, can solve the problems that cannot meet the requirements of use, insufficient space, and the transportation equipment cannot fully meet the docking of automatic guided transport vehicles, etc., to achieve the reduction of the number of docking equipment and the ingenious and reasonable design concept Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

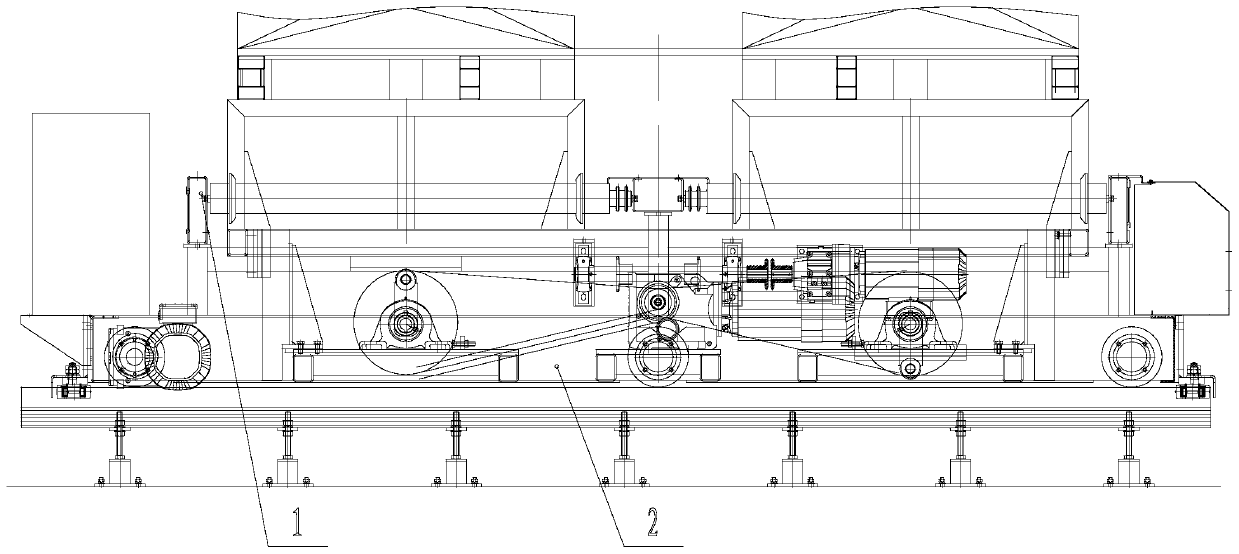

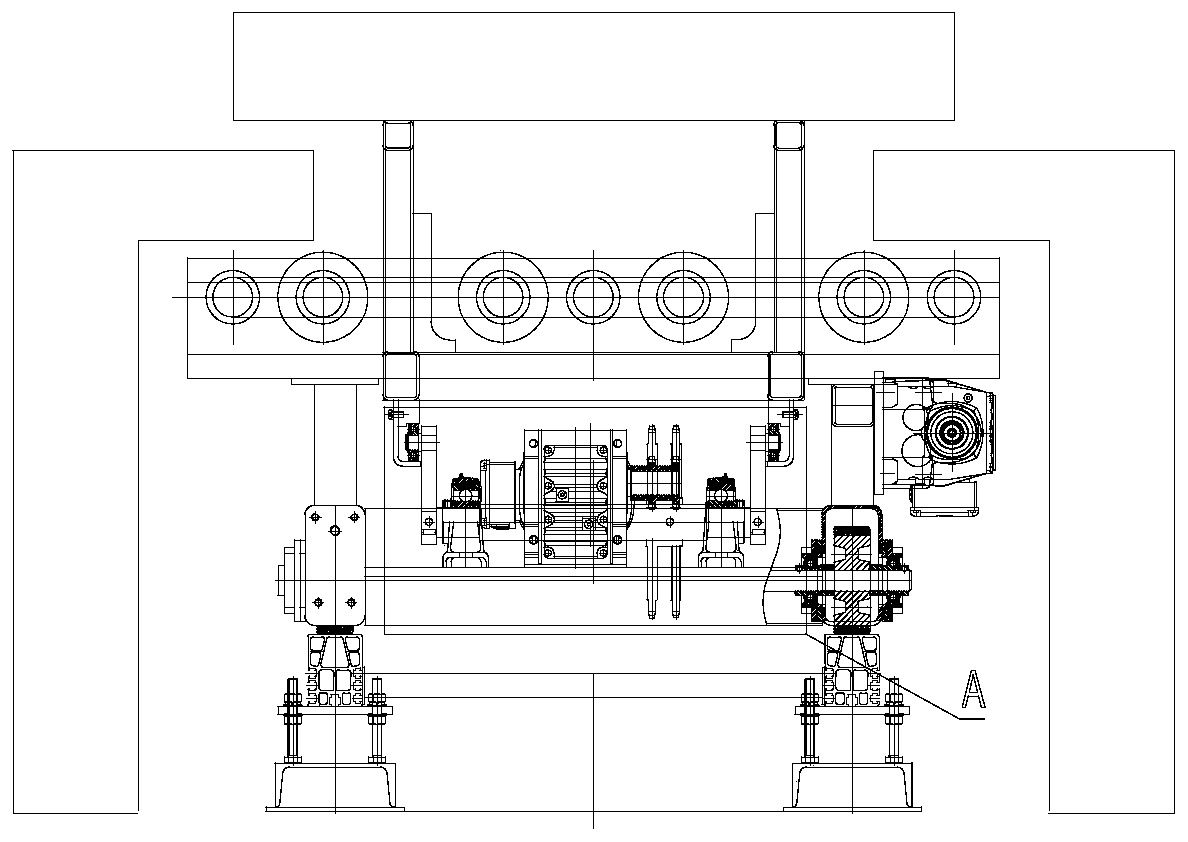

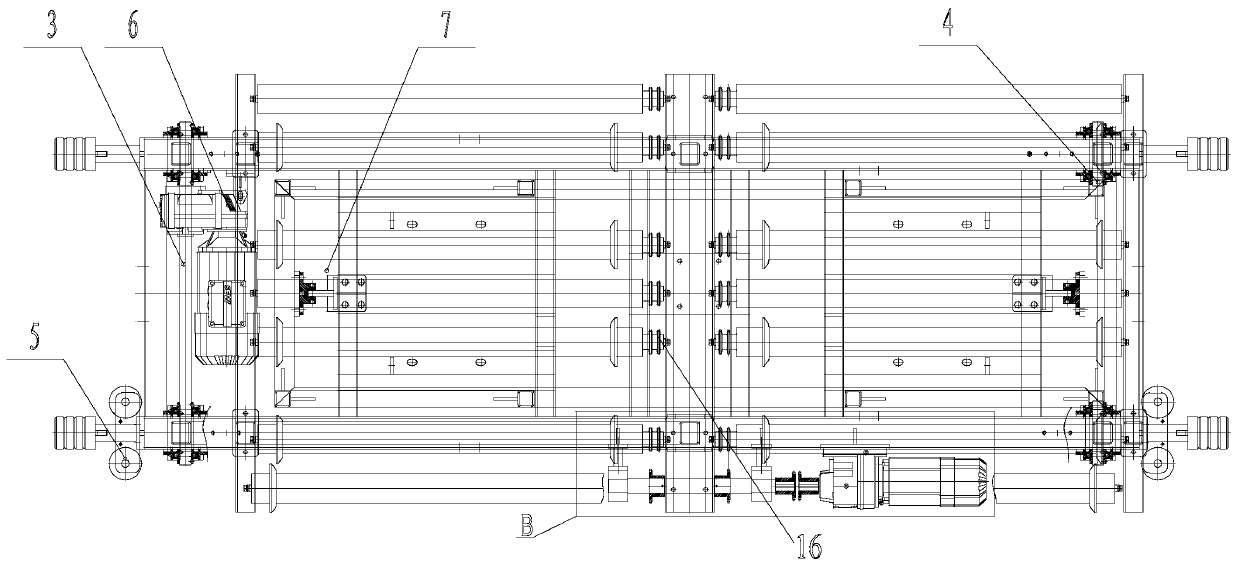

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] Figure 1~5 , including roller conveyor 1, shuttle car bottom frame 2, driving shaft 3, driven shaft 4, horizontal wheel set 5, horizontal running motor 6, guide column 7, curved rod 8, transmission sprocket 9, output shaft 10, Lifting drive motor 11, roller conveyor drive motor 12, first sprocket 13, drive shaft 14, second sprocket 15, driven sprocket 16, etc.

[0015] Such as Figure 1~5 As shown, the present invention is a shuttle car for docking automatic guided transport vehicles, including a shuttle car bottom frame 2 that is movably arranged on a track, and a drive shaft 3 is installed on one end of the shuttle car bottom frame 2 along the length direction, and the other is A driven shaft 4 is installed at one end, and the drive shaft 3 is driven by a horizontal running motor 6 installed on the bottom frame 2 of the shuttle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com