Construction method for prefabricated perforated type filling module of ribbed cast-in-place concrete floor slab

A construction method, concrete technology, applied in the direction of construction, building structure, building material processing, etc., to achieve the effects of reducing energy consumption, reducing noise transmission, and overcoming impact noise interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

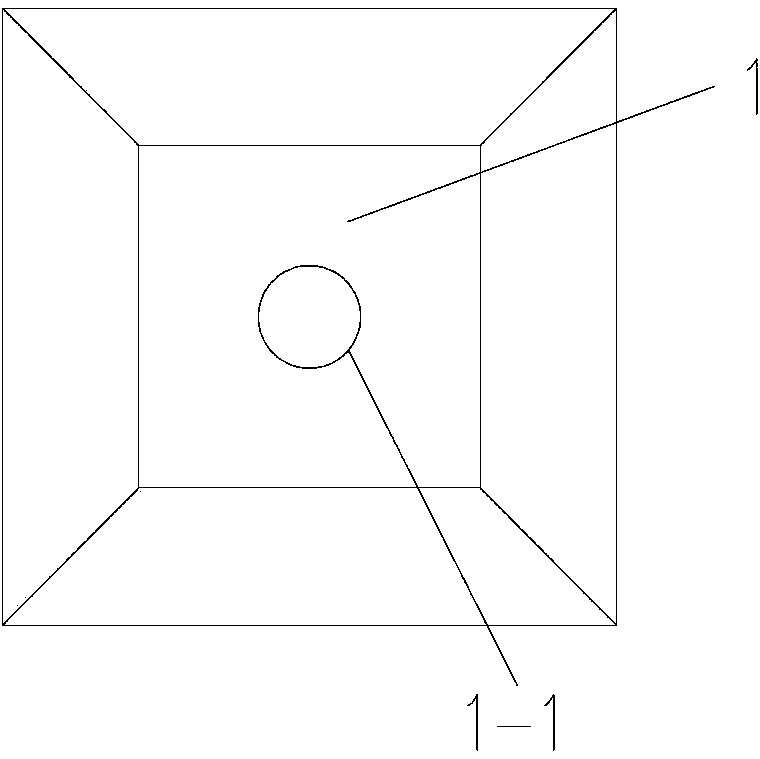

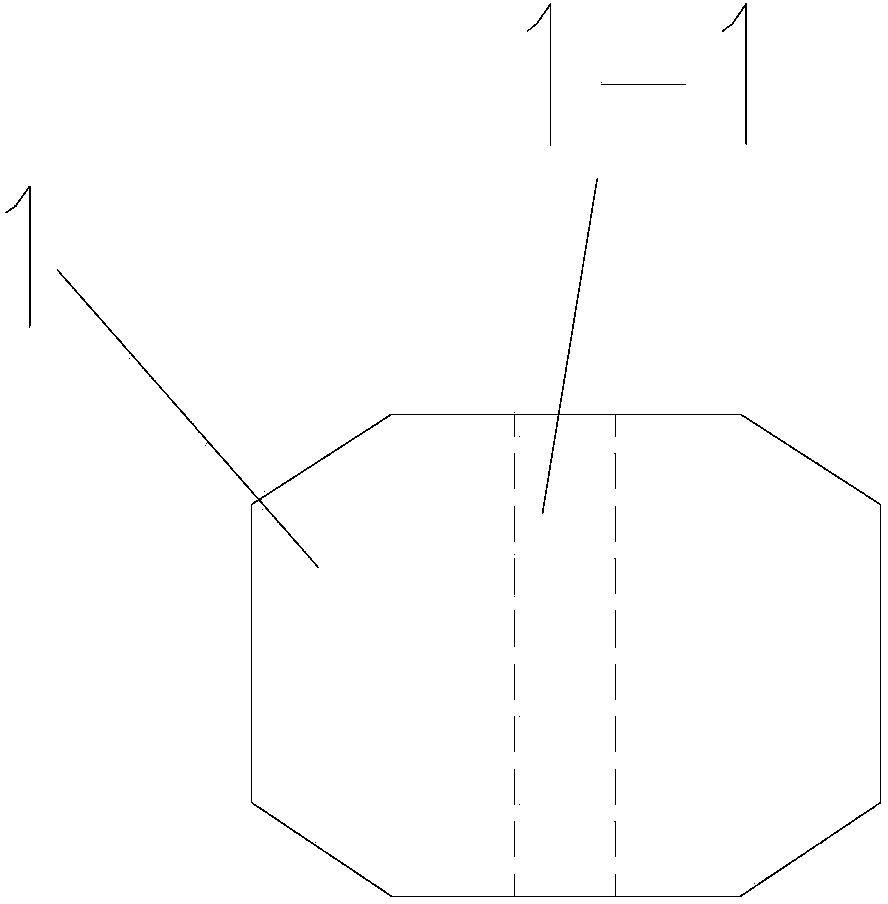

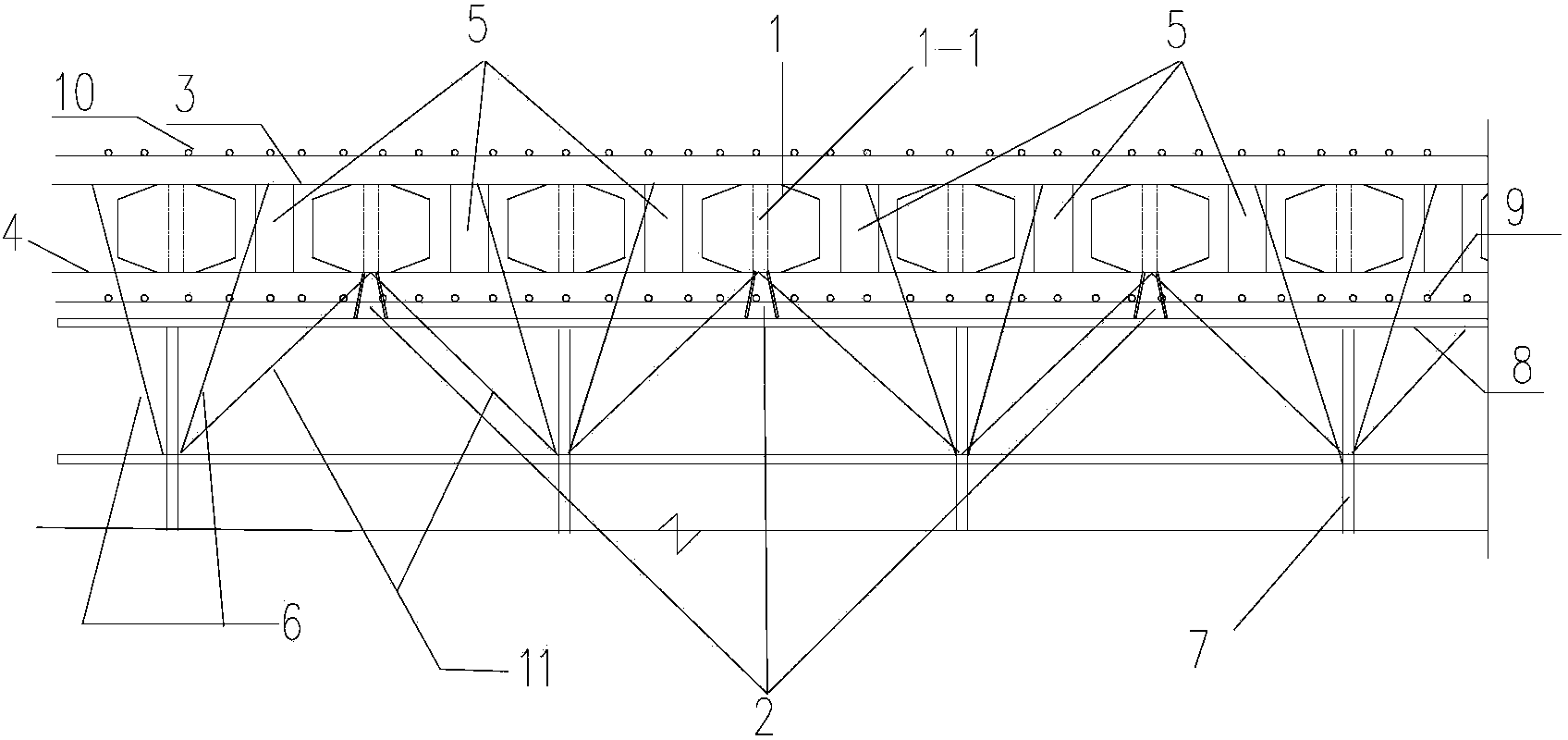

[0049] (1) set up formwork support frame body 7; (2) install the bottom template 8 of floor slab on described formwork support frame body 7; (3) tie two-way bottom row steel bar 9 on described bottom formwork 8; (4 ) Bind the bottom row of transverse rib beam reinforcement and the bottom row of longitudinal rib beam reinforcement of the rib beam 5 along the horizontal and vertical intervals on the two-way bottom row of reinforcement bars 9 and the bottom row of horizontal rib beam reinforcement bars and the bottom row of longitudinal rib beam reinforcement bars The top row of transverse rib beam steel bars and the top row of longitudinal rib beam steel bars are bound to form multiple squares; (5) two high-foot pads 2 are placed in every other square; (6) each The longitudinal support reinforcement 4 is installed in the row of grids, and the height of the longitudinal support reinforcement 4 is higher than the high foot block 2; the first double-strand U-shaped iron wire 11 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com