Novel downhole pipe

A new type of well pipe technology, applied in construction, drinking water installations, water supply installations, etc., can solve the problems of water pollution, ductile iron pipe corrosion, high cost, etc., achieve high ring stiffness and strength, improve overall life, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

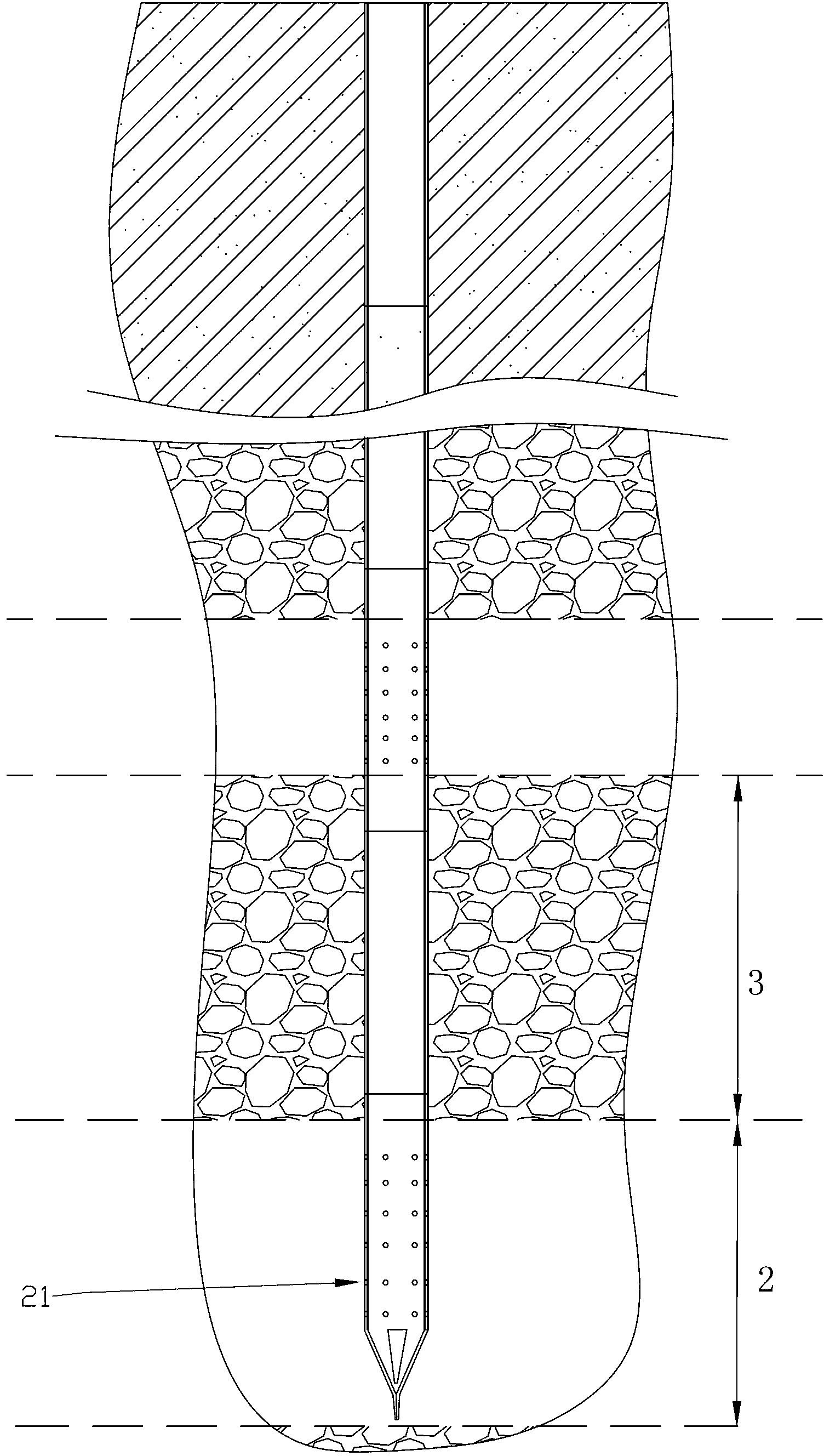

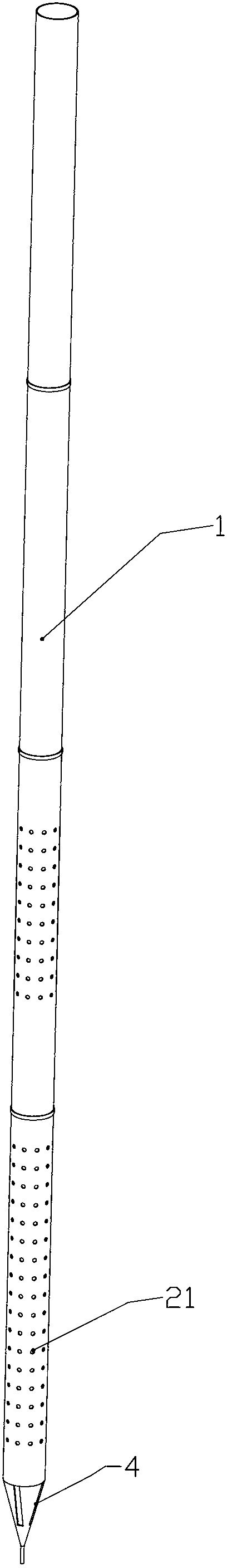

[0016] Such as figure 1 , figure 2 As shown, a new type of downhole pipe, the base of the downhole pipe is a PVC injection pipe, and the multi-section injection pipes are thermally welded to form an integral downhole pipe 1. The heat welding is carried out on site when going into the well, and has a weld 11. According to the situation of the groundwater layer, at least one section of seepage hole 21 is provided on the pipe wall of the downhole pipe to form a seepage section 2 for matching with the groundwater layer, and the rest has no seepage holes to form an isolation section 3 for connecting with the rock layer and the groundwater layer. The rock and soil layers are matched; the lower end of the downhole pipe is cut, gathered, and welded to form a cone-shaped 4 shape, and the lower end of the cone is convenient for downhole operations.

Embodiment 2

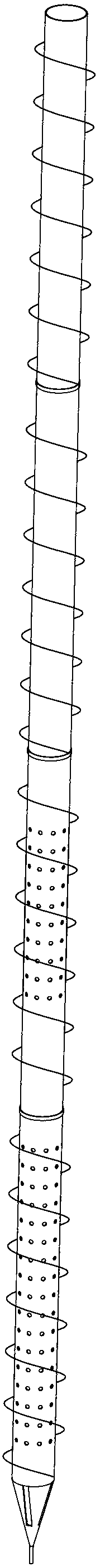

[0018] Such as image 3 As shown, the difference from Example 1 is that the base of the downhole pipe is a plastic-steel coiled pipe, and the water seepage holes in the seepage section avoid steel reinforcement ribs. The structural strength of this solution is higher than that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com