Preparation method of recyclable lightweight graphene sponge oil absorbing material

A graphene sponge and oil-absorbing material technology is applied in the field of preparing light-weight graphene sponge oil-absorbing materials, which can solve the problems of cycle performance degradation, affecting product service life, and inability to further improve oil absorption, and achieves widening of layer spacing and higher ratio of oil absorption. The effect of surface area improvement, oil absorption rate and oil absorption improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

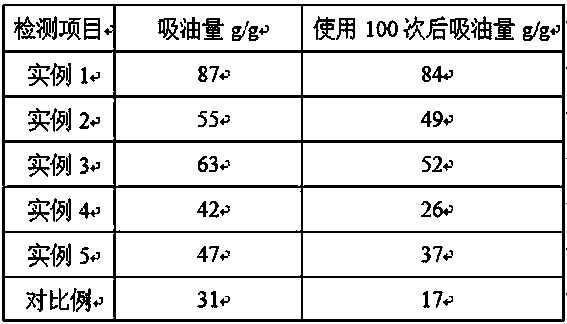

Examples

example 1

[0022]In parts by weight, take 60 parts of graphene oxide, 10 parts of sodium polystyrene sulfonate, and 150 parts of water in turn, mix them into a beaker, stir and mix them with a glass rod for 5 minutes, and ultrasonically React for 60 minutes, filter to obtain No. 1 filter residue, and wash No. 1 filter residue with deionized water for 5 times, then transfer the washed No. 1 filter residue into a vacuum drying oven, and vacuum dry at a temperature of 100°C and a pressure of 80Pa To constant weight, pretreated graphene oxide is obtained; according to the mass ratio of 80:1, the iron salt solution with a concentration of 0.05mol / L and the pretreated graphene oxide are mixed and poured into a three-necked flask, and the ultrasonic frequency is 50kHz, and the temperature is Under the condition of 45°C, after ultrasonic impregnation for 60 minutes, filter to obtain No. 2 filter residue, and dry the obtained No. 2 filter residue at a temperature of 110°C to constant weight to obt...

example 2

[0024] According to the mass ratio of 80:1, the iron salt solution with a concentration of 0.05 mol / L and graphene oxide were mixed and poured into a three-necked flask, and ultrasonically impregnated for 60 minutes at an ultrasonic frequency of 50 kHz and a temperature of 45 ° C, and then filtered to obtain No. 2 filter residue, and the resulting No. 2 filter residue was dried to constant weight at a temperature of 110°C to obtain a dry impregnating material; the obtained dried impregnating material was transferred to a tube furnace, and the reducing Under the protective state of reducing gas, the temperature was slowly programmed to rise to 1000°C at a rate of 4°C / min. After the reduction reaction was held for 3 hours, it was cooled to room temperature with the furnace, and the material was discharged to obtain the raw material. The hydrochloric acid solution with a fraction of 10% was mixed according to the mass ratio of 1:20, ultrasonically impregnated for 60 minutes at an ...

example 3

[0026] In parts by weight, take 60 parts of graphene oxide, 10 parts of sodium polystyrene sulfonate, and 150 parts of water in turn, mix them into a beaker, stir and mix them with a glass rod for 5 minutes, and ultrasonically React for 60 minutes, filter to obtain No. 1 filter residue, and wash No. 1 filter residue with deionized water for 5 times, then transfer the washed No. 1 filter residue into a vacuum drying oven, and vacuum dry at a temperature of 100°C and a pressure of 80Pa To constant weight, pretreated graphene oxide is obtained; in parts by weight, 40 parts of pretreated graphene oxide, 120 parts of absolute ethanol, 15 parts of (N-amidino) dodecyl acrylamide, 4 parts Polyethylene glycol derivatives, 0.02 parts of catalyst, firstly pour the pretreated graphene oxide and absolute ethanol into the reactor, stir and disperse with a stirrer at a speed of 800r / min for 60min, then turn on the heater of the reactor, at a temperature of At 70°C and a rotating speed of 600...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com