Patents

Literature

201 results about "P-dichlorobenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

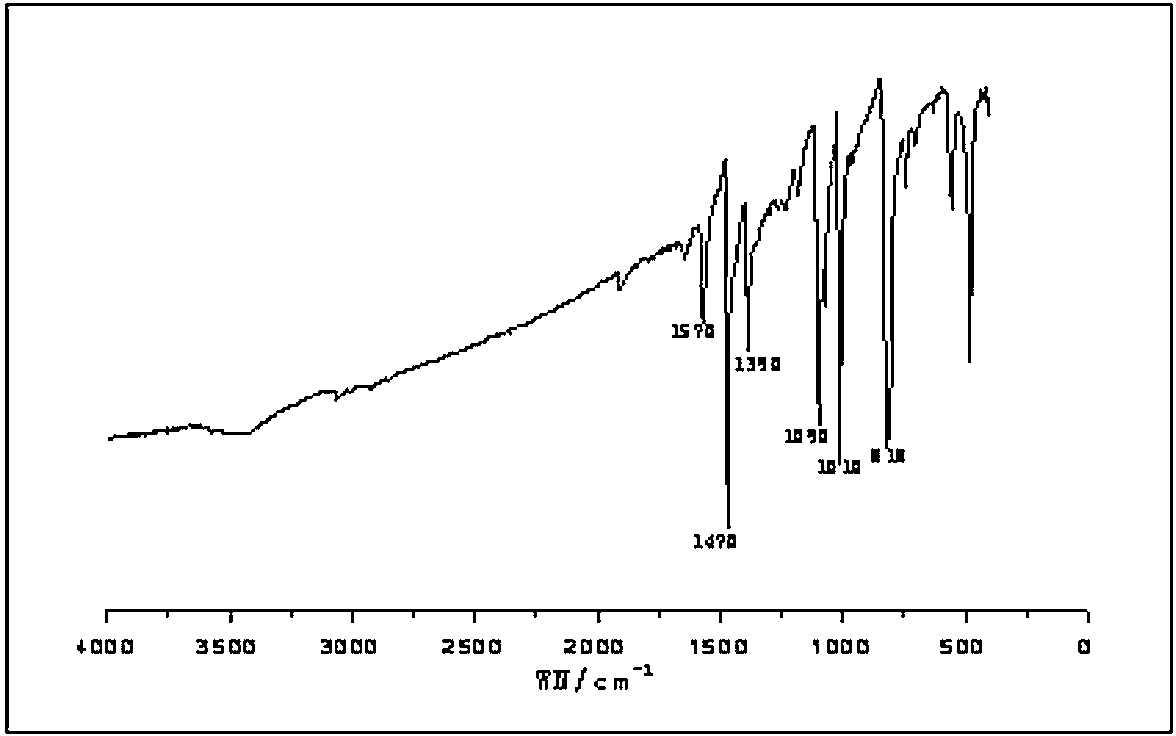

Para-Dichlorobenzene p-Dichlorobenzene p-DCB PDB Paramoth Para crystals Paracide Dichlorocide. ... 1,4-Dichlorobenzene (1,4-DCB, p-DCB, or para-dichlorobenzene, sometimes abbreviated as PDB or para) is an organic compound with the formula C 6 H 4 Cl 2. This colorless solid has a strong odor.

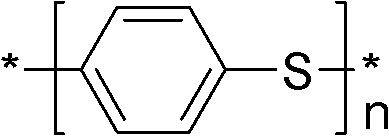

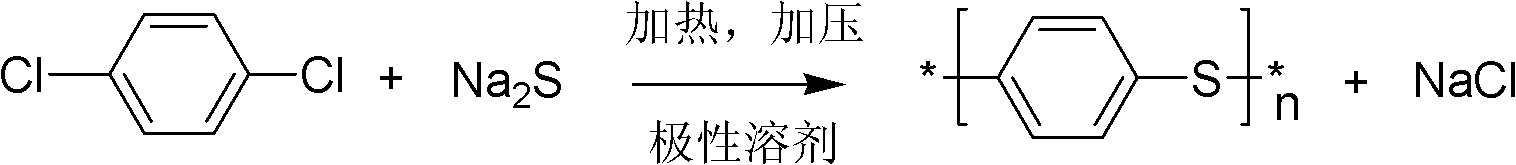

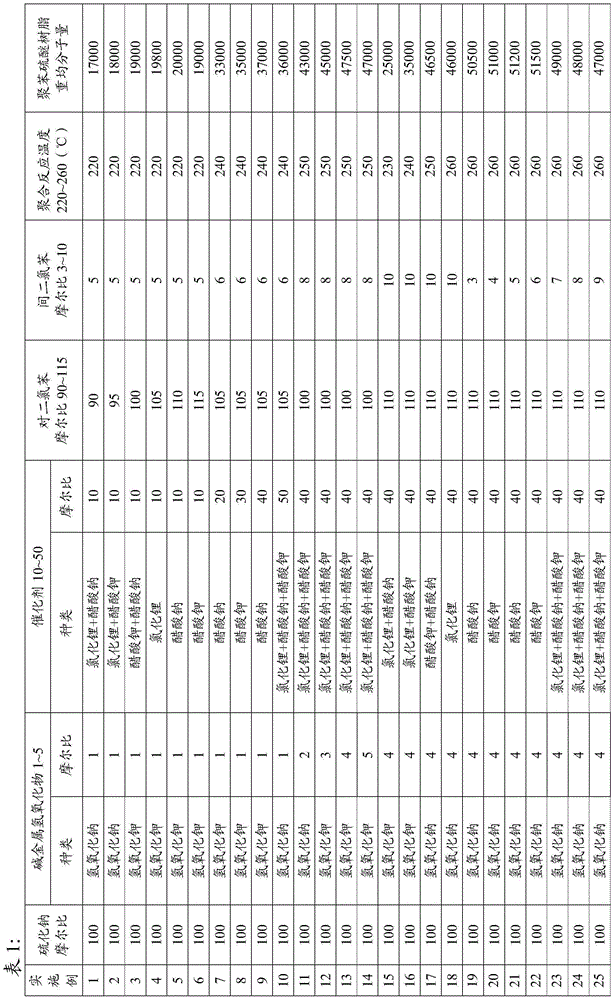

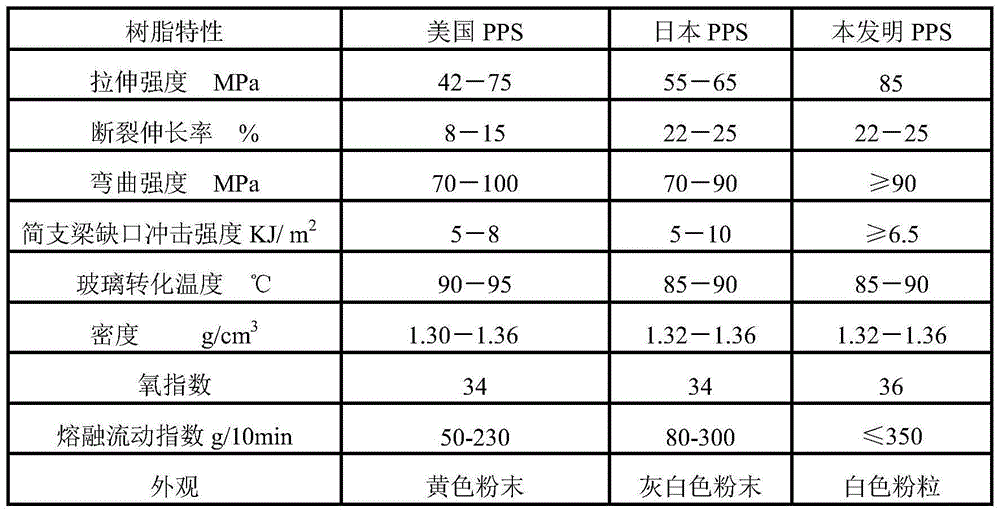

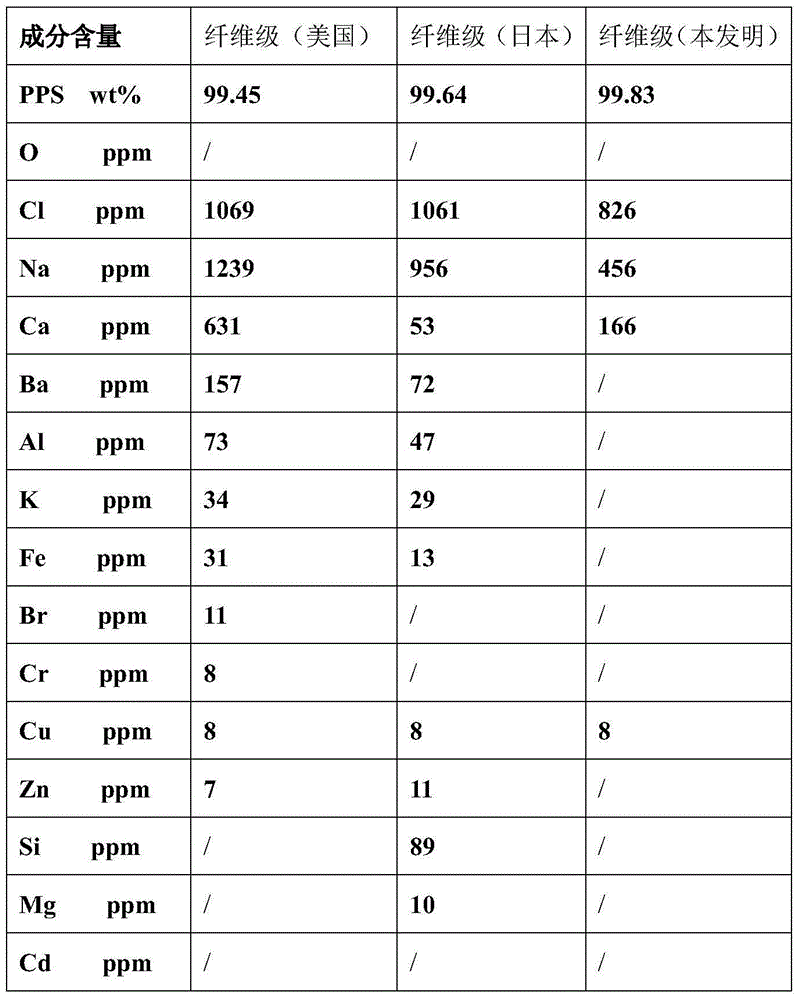

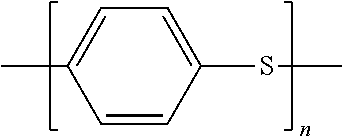

Method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin

ActiveCN103073720AThe average molecular weight is largeMolecular distribution index is smallMonocomponent synthetic polymer artificial filamentFiberPolymer science

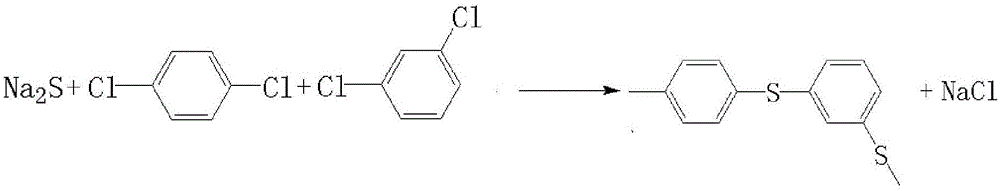

The invention discloses a method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin. According to the invention, sodium sulfide and p-dichlorobenzene are adopted as raw materials; N-methyl pyrrolidone, N,N-dimethyl acetamide, and the like are adopted as solvents; under the existence of a basic salt, through a four-step method comprising pre-polymerization, polymerization, chain extension and end-capping, the high-purity low-color fiber-grade polyphenylene sulfide resin is synthesized. By adjusting process parameters, polyphenylene sulfide average molecular weight and distribution index can be effectively controlled. Also, purification process can be simplified, and metal ion embedding can be reduced. Resin slice color is reduced, resin processing stability is improved, and resin performance is improved.

Owner:CHINA PETROLEUM & CHEM CORP

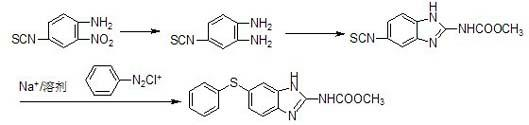

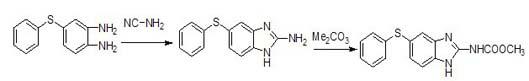

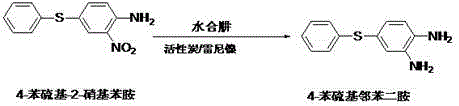

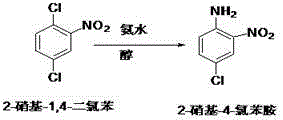

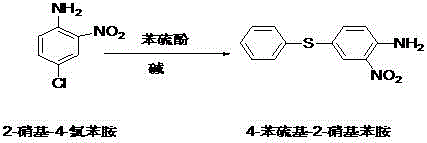

Preparation method for anthelmintic benzimidazole fenbendazole

InactiveCN102241635AOperational securitySuitable for industrial productionOrganic chemistryFenbendazoleAnthelmintic drug

The invention discloses a preparation method for anthelmintic benzimidazole fenbendazole. The method is characterized in that: p-dichlorobenzene is used as a starting raw material which is subjected to nitration, amination, condensation, reduction and ring-closure reactions so as to obtain fenbendazole (the content of the final product being 98% to 101%). The novel preparation method has the characteristics of a simple and highly efficient process and safe operation, and is suitable for industrial production.

Owner:JIANGSU BAOZONG & BAODA PHARMACHEM

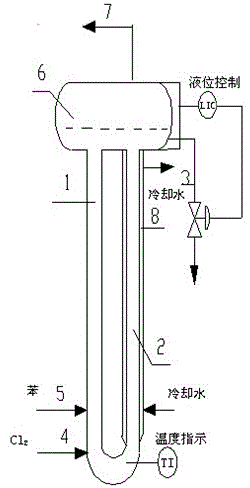

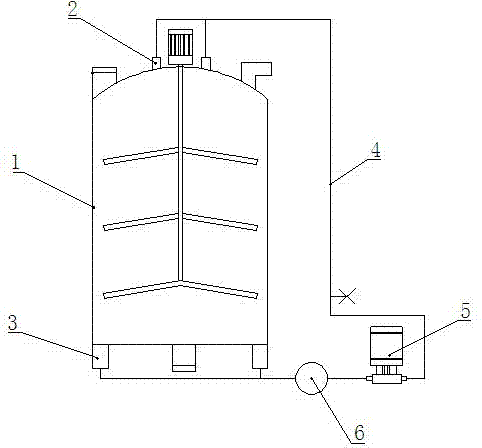

Method for preparing chlorobenzene, p-dichlorobenzene and o-dichlorobenzene in benzene chlorination

ActiveCN103819307AQuick responseIncrease production capacityHalogenated hydrocarbon preparationChlorobenzeneReaction temperature

The invention discloses a method for preparing chlorobenzene, p-dichlorobenzene and o-dichlorobenzene in benzene chlorination, and relates to a preparation method of chemical raw materials. The method comprises the following steps: continuously introducing dry benzene and chlorine with a high activity and high p-dichlorobenzene selectivity catalyst into an outer circulation reactor, wherein the benzene and chlorine need sufficient retaining time, reacting at a set temperature to prepare p-dichlorobenzene, obtain o-dichlorobenzene at the same time and co-produce chlorobenzene, preparing dichlorobenzene by using the outer circulation reactor and taking the benzene and the chlorine as raw materials and metal sulfide as a catalyst, at the same time co-producing chlorobenzene, forming circulation of the materials through the introduced nitrogen and generated hydrogen chloride as power so as to obtain good stirring for prompting mixing, diffusion, heat conduction and mass transfer of the reactants. The method is rapid in reaction speed, high in capacity, large in ratio of p-dichlorobenzene and o-dichlorobenzene, free of polychlorobenzene byproduct, and high in flexibility and operation flexibility as the ratio of the chlorobenzene to the dichlorobenzene in a product can be adjusted according to demands.

Owner:LIAONING FANGDA ENG DESIGN CO LTD

Synthetic method of m-dichlorobenzene

InactiveCN101696151ASolution to short lifeImprove conversion rateChemical recyclingHalogenated hydrocarbon preparationAutomatic controlGas phase

The invention discloses a synthetic method of m-dichlorobenzene which is obtained by transposition in the presence of a catalyst by taking o-dichlorobenzene and / or p-dichlorobenzene as raw materials. The catalyst is a composite catalyst comprising a solid phase catalyst and a gas phase catalyst, wherein the solid phase catalyst is aluminum trichloride or halide of transition metal, and the gas phase catalyst is anhydrous hydrogen chloride or other anhydrous halogen acids. The raw materials have no limitation of water, have arbitrary ortho-para proportion and react under normal pressure; the solid catalyst has long service life, and the gas catalyst can be recycled after gas-liquid separation and has high conversion ratio; and the synthetic method can be used for large-scale industrial production. The process realizes the automatic control easily and has energy saving, safety, environment protection and low cost.

Owner:JIANGSU EQUALCHEM

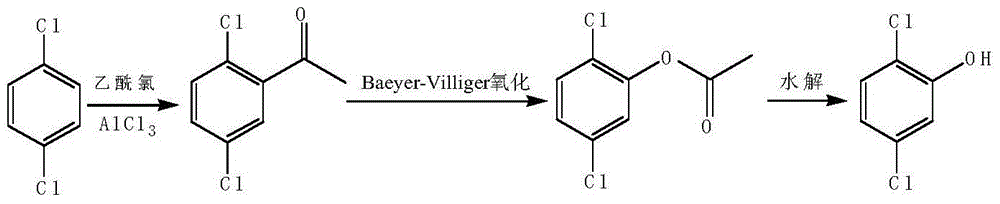

Preparation method of 2,5-dichlorophenol

InactiveCN104591973AThe synthesis process is simpleShort routeOrganic compound preparationCarboxylic acid esters preparationHydrolysisPeroxide

The invention discloses a preparation method of 2,5-dichlorophenol and relates to the technical field of pesticide intermediate synthesis. The preparation method comprises the following steps: with p-dichlorobenzene as a start raw material, performing a Friedel-Crafts acylation reaction between the p-dichlorobenzene and acetyl chloride in the presence of aluminum trichloride to obtain 2,5-dichloroacetophenone; performing a Baeyer-Villiger oxidation reaction between the 2,5-dichloroacetophenone and a peroxide in the presence of a catalyst at room temperature to obtain 2,5-dichlorobenzene acetate; and performing a hydrolysis reaction between the 2,5-dichlorobenzene acetate and inorganic aqueous alkali in a reflux condition to obtain 2,5-dichlorophenol. The preparation method disclosed by the invention has the characteristics of simple synthesis process, short line, low production cost and high yield; and moreover, with less quantity of generated three wastes and high environmental protection property, the preparation method is more suitable for large-scale industrial production.

Owner:ANHUI XUELANG BIOTECHNOLOGY CO LTD

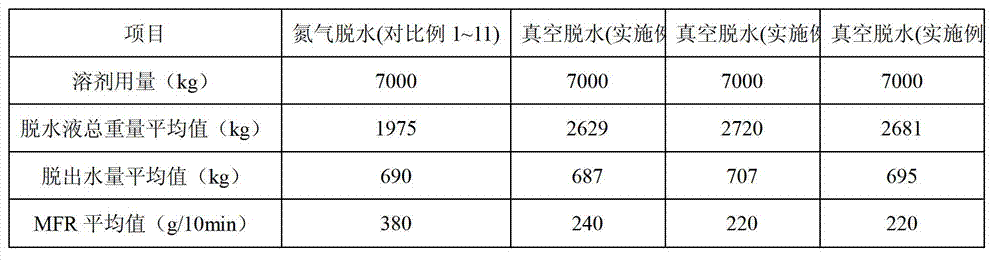

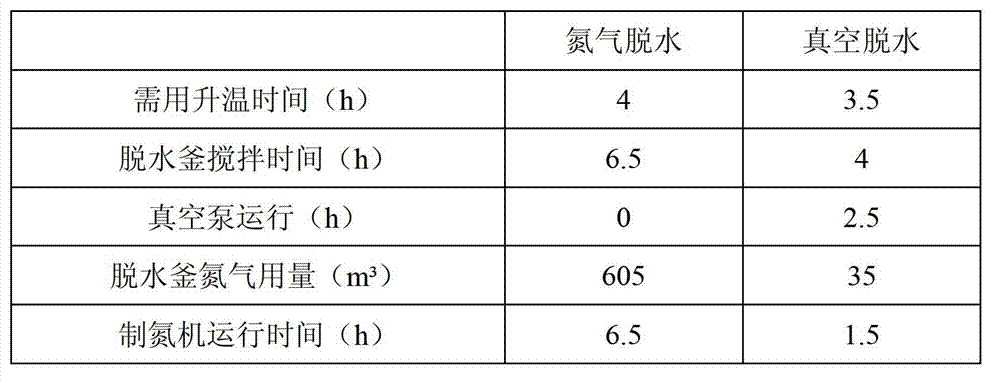

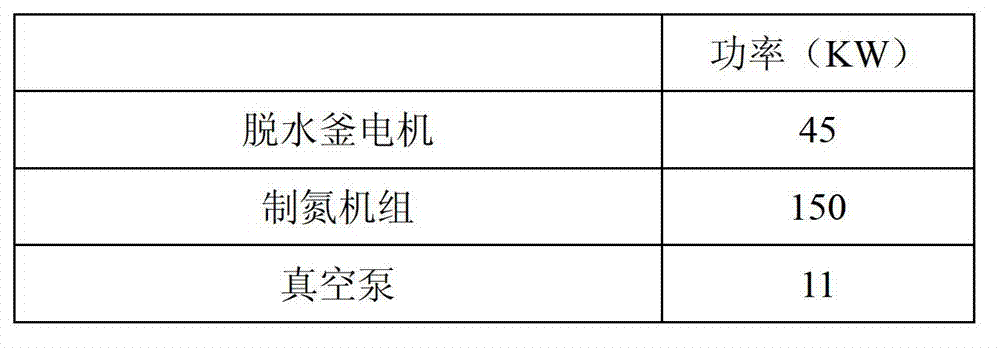

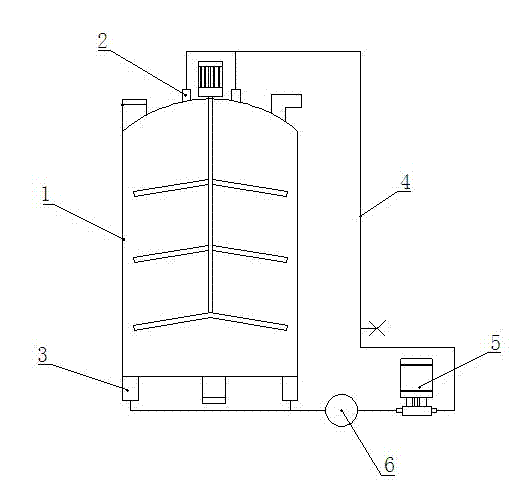

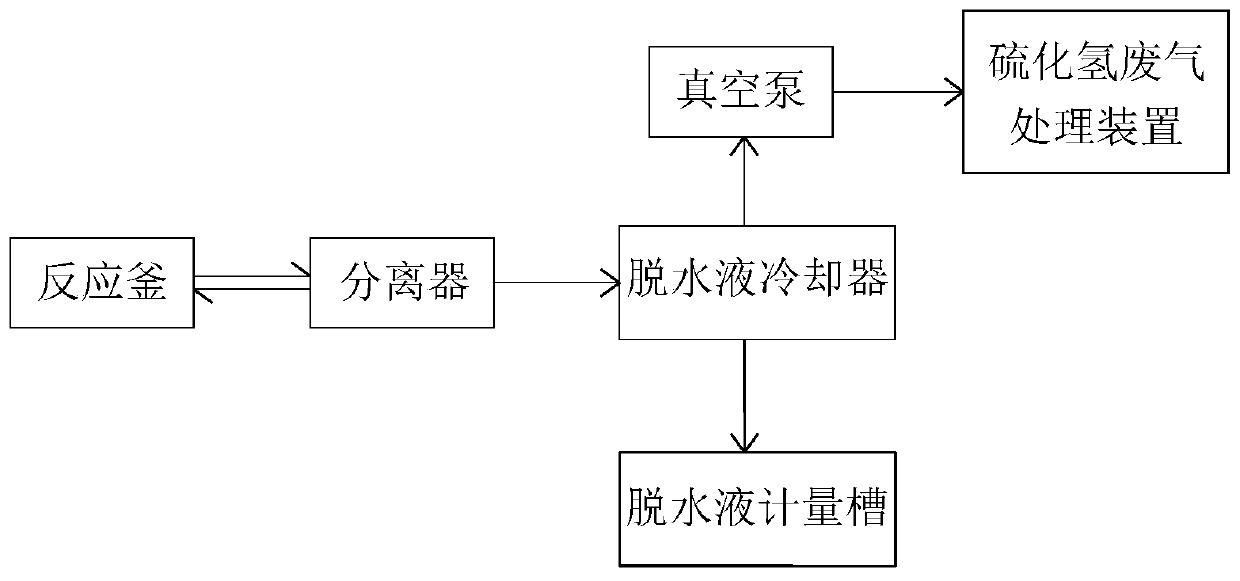

Dehydration process for polyphenyl thioether resin synthesis solvent system

The invention discloses a dehydration process for a polyphenyl thioether resin synthesis solvent system. According to the dehydration process, in a process flow that sodium sulfide and p-dichlorobenzene are taken as raw materials, N-methyl-2-pyrrolidone is taken as a solvent, and polyphenyl thioether resin is produced through condensation polymerization, the purity, whiteness and particle shape of the polyphenyl thioether resin are improved by controlling the content of moisture in a synthetic system so as to meet the requirements on the application and development of polyphenyl thioether resin subsequent products; raw materials, i.e. Na2S, NMP, NaOH and H2O, are enabled to exist in the polyphenyl thioether resin synthesis solvent system in a certain molar ratio; the raw materials, such as Na2S, NMP and NaOH, in a formulation are added into an ordinary reaction kettle in a certain excessive proportion at a dehydration treatment stage; vacuum dehydration treatment is carried out on the polyphenyl thioether resin synthesis solvent system during stirring at certain temperature and pressure under the condition that air in the polyphenyl thioether resin synthesis solvent system is replaced with nitrogen; a dehydration treatment process for the polyphenyl thioether resin synthesis solvent system is completed after the moisture content of the polyphenyl thioether resin synthesis solvent system is determined by adopting a rapid moisture determinator; and meanwhile, NaOH aqueous liquid of certain temperature and concentration is required for absorbing hydrogen sulfide produced due to the fact that the sodium sulfide is unstable and pyrolyzed during dehydration, so as to protect environments from being polluted.

Owner:SICHUAN DEYANG CHEM +1

Preparation method of polyphenylene sulfide

The invention relates to the field of high molecular material synthesis, in particular to a preparation method of polyphenylene sulfide. The preparation method comprises the following steps of: adding Na2S.9H2O, N-methyl pyrrolidone and a reaction assistant into a polymerization kettle, supplying nitrogen to replace air, then heating to 180 DEG C for dehydration at a dehydration rate of 80-95%, adding an N-methylpyrrolidine solution containing p-dichlorobenzene into a dehydrated system in Step (1) for reaction for 3-8h at 190-230 DEG C, after the reaction finishes, obtaining a size mixture, filtering the size mixture, adding a filter cake into boiled pure water, stirring, washing, and performing 90Hz ultrasonic treatment for 15-30min, repeatedly washing for 2-3 times, and obtaining PPS (polyphenylene sulfide) resin after drying. The method has the advantageous effects that the product hue can be obviously improved since sodium thiosulfate is added, even a water content of the system is higher (the dehydration rate is 80%) and the reaction temperature is higher, and the ultrasonic washing can effectively remove inorganic salt impurities included due to macromolecular chain bending and winding in a reaction process.

Owner:CHONGQING JUSHI NEW MATERIAL TECH CO LTD

Catalyst used in p-dichlorobenzene hydroxylate for preparing 2,5-dichlorophenol, and preparation method thereof

ActiveCN105921161AEasy to prepareHigh selectivityOrganic chemistryOrganic compound preparationP-dichlorobenzeneActive component

The invention belongs to the field of fine chemical engineering, relates to a catalyst technology, and concretely relates to a preparation method of a catalyst with vanadium phosphorus oxide supported on an oxide used as a carrier, and an application of the catalyst in synthesis of 2,5-dichlorophenol. The catalyst is prepared through adopting SiO2, Al2O3 or TiO2 as a carrier and introducing an active component VPOx (vanadium phosphorus oxide) by an immersion technology. The catalyst prepared through the method has high activity and selectivity in p-dichlorobenzene hydroxylate for preparing 2,5-dichlorophenol.

Owner:CHANGZHOU UNIV

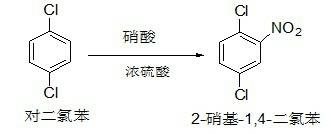

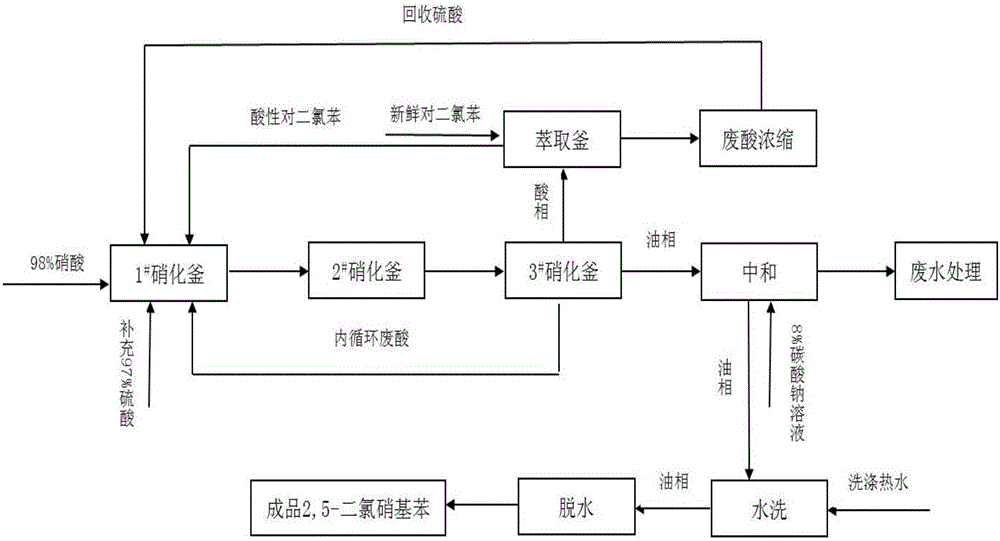

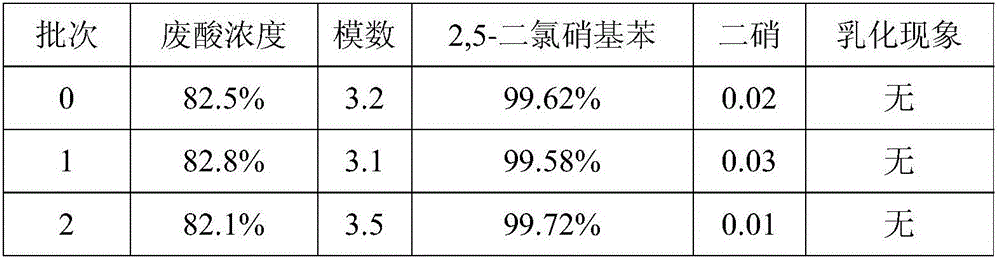

Method for preparation of 2, 5-dichloronitrobenzene by continuous nitration

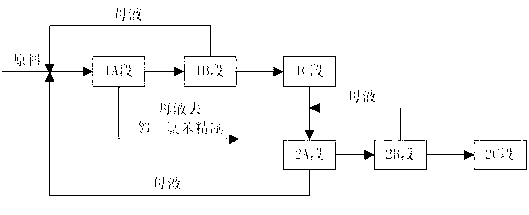

ActiveCN106083596AOptimize process flowWith automatic separation functionNitro compound preparationNitrationOil phase

The invention discloses a method for preparation of 2, 5-dichloronitrobenzene by continuous nitration. The method comprises the steps of: adopting three-stage kettle type continuous reaction, adding sulfuric acid, nitric acid and p-dichlorobenzene in an extraction kettle into a first stage nitrification kettle simultaneously to carry out nitrification reaction, letting nitrification liquid enter a next stage nitrification kettle through self-carried raisers of all nitrification kettles in order to react, at the end of reaction in a third stage nitrification kettle, separating an oil phase and an acid phase, carrying out neutralization, washing and dehydration on the oil phase so as to obtain 2, 5-dichloronitrobenzene, internally recycling part of waste acid in the acid phase back to the first stage nitrification kettle, letting the residual waste acid enter an extraction kettle, and performing p-dichlorobenzene extraction, and then conducting separation to obtain acidic p-dichlorobenzene and extracted waste acid, concentrating the extracted waste acid into concentrated sulfuric acid, and making the concentrated sulfuric acid and acidic p-dichlorobenzene enter the first stage nitrification kettle for recycling. The method provided by the invention adopts automation control, cancels a mixed acid preparation procedure, simplifies the technological process, can realize continuous nitrification reaction, continuous nitrification liquid separation and continuous waste acid extraction.

Owner:江苏拓孚工程设计研究有限公司

Method for preparing ultraviolet-resistant polyphenylene sulfide resin by in situ Polymerization

The present invention is in-situ polymerization process for preparing ultraviolet resisting polyphenyl thioether resin. The process includes the following steps: 1. reaction of titanate coupling treated nanometer TiO2 and benzotriazole in 0.1-10 wt%, and monomers p-dichlorobenzene and sodium sulfide in 90-99.9 wt% inside solvent, in nitrogen atmosphere and in the presence of catalyst; and collecting ultraviolet resisting polyphenyl thioether resin powder from the reaction product; 2. pelletizing and slicing; and 3. spinning, winding and stretching to obtain fiber. The ultraviolet resisting polyphenyl thioether fiber has less color deepening caused by ultraviolet and high mechanical performance before and after ultraviolet irradiation.

Owner:DONGHUA UNIV

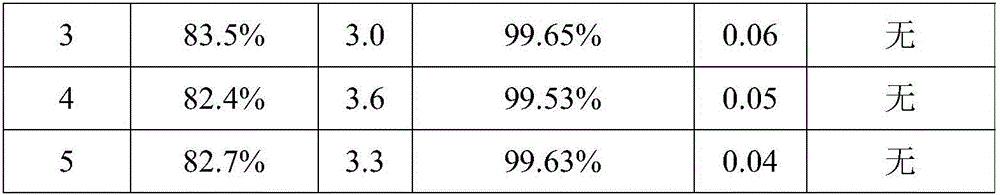

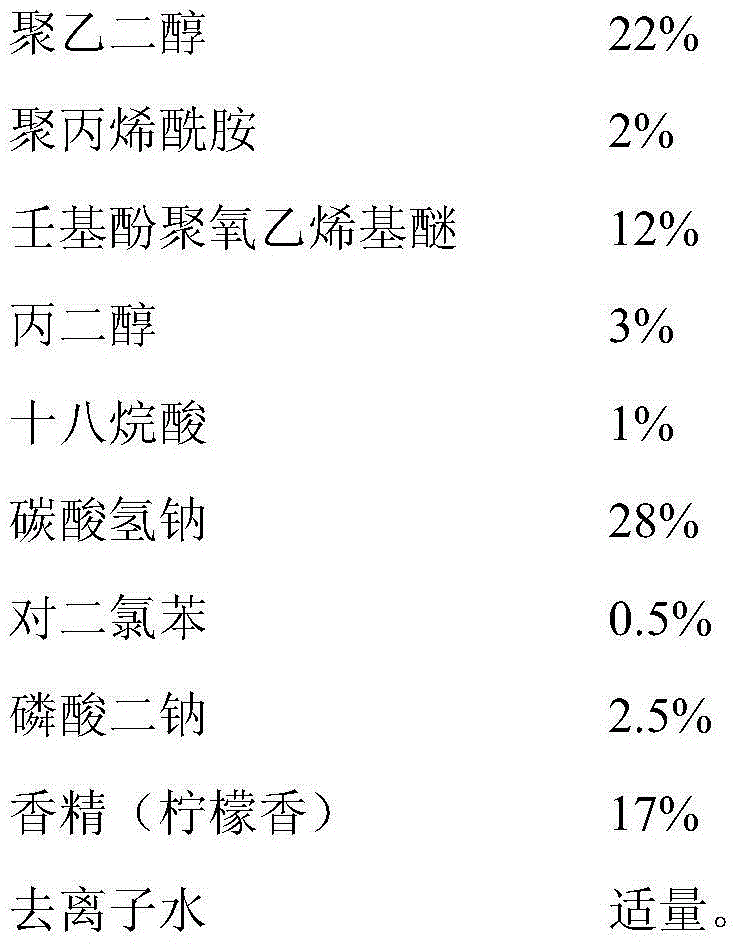

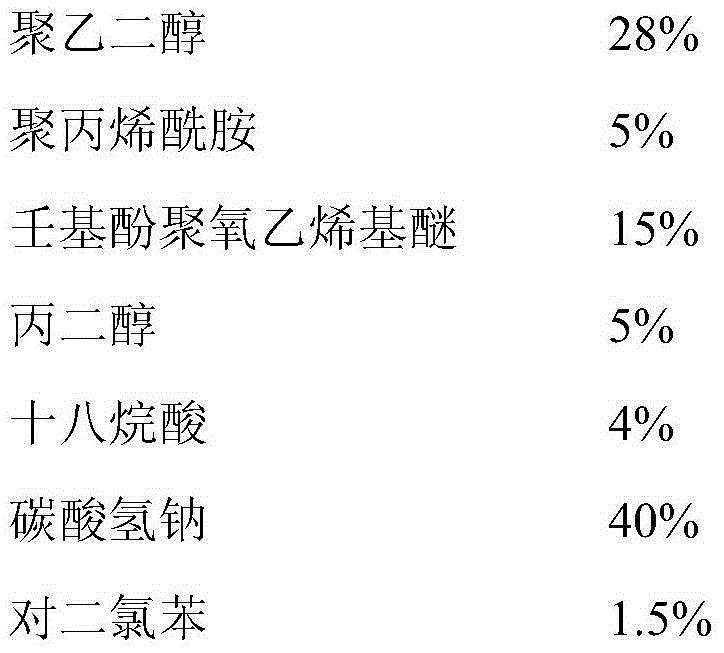

Toilet deodorizing scale inhibitor

InactiveCN104629961AGood scale inhibitionFunction increaseSurface-active non-soap compounds and soap mixture detergentsSodium bicarbonateSorbent

The invention provides a toilet deodorizing scale inhibitor. The toilet deodorizing scale inhibitor comprises polyethylene glycol, polyacrylamide, polyoxyethylene nonylphenyl ether, propanediol, octadecanoic acid, sodium bicarbonate, p-dichlorobenzene, disodium phosphate, an essence (lemon essence) and deionized water. Sodium bicarbonate easily reacts with ammonia to produce an odorless carbonate substance which has the function of deodorizing; the anti-static surfactant can avoid the occurrence of new dirt; polyethylene glycol can form a film on the surface of water to seal and cover residual stink; and propanediol is a good adsorbent to harmful gases such as hydrogen sulfide.

Owner:QINGDAO WATER WORLD ENVIRONMENTAL PROTECTION TECH

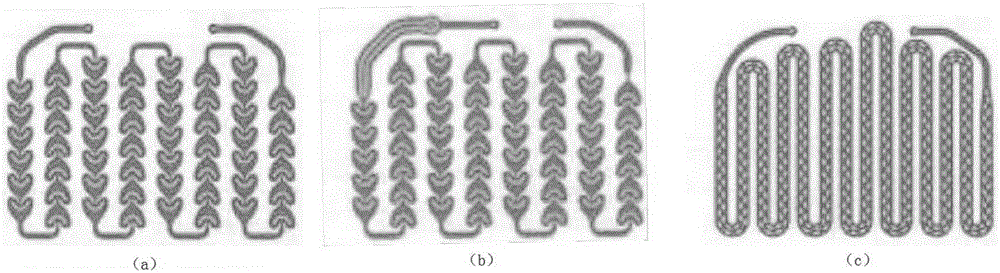

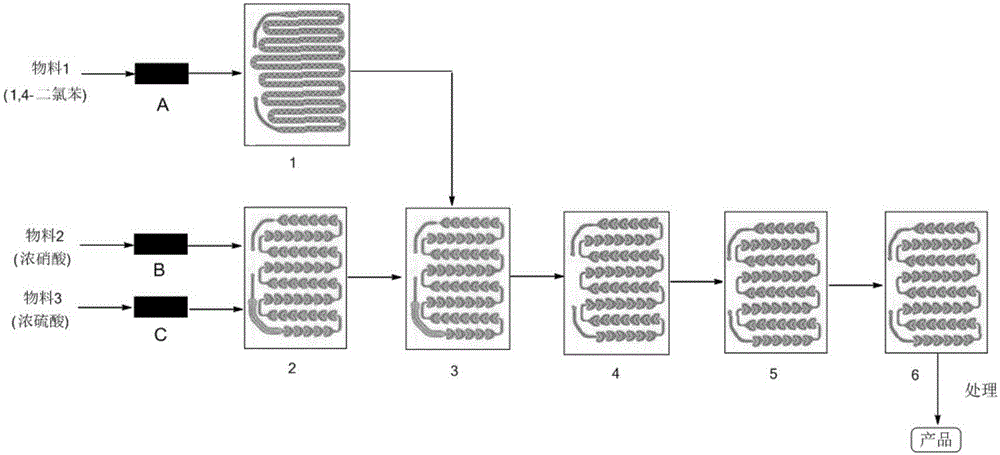

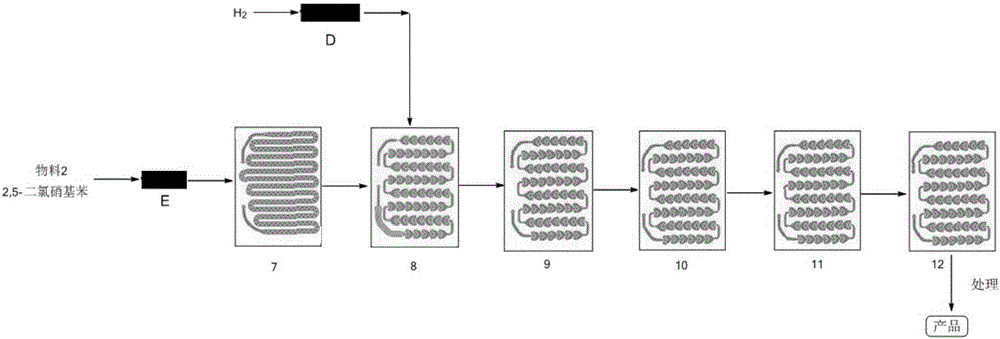

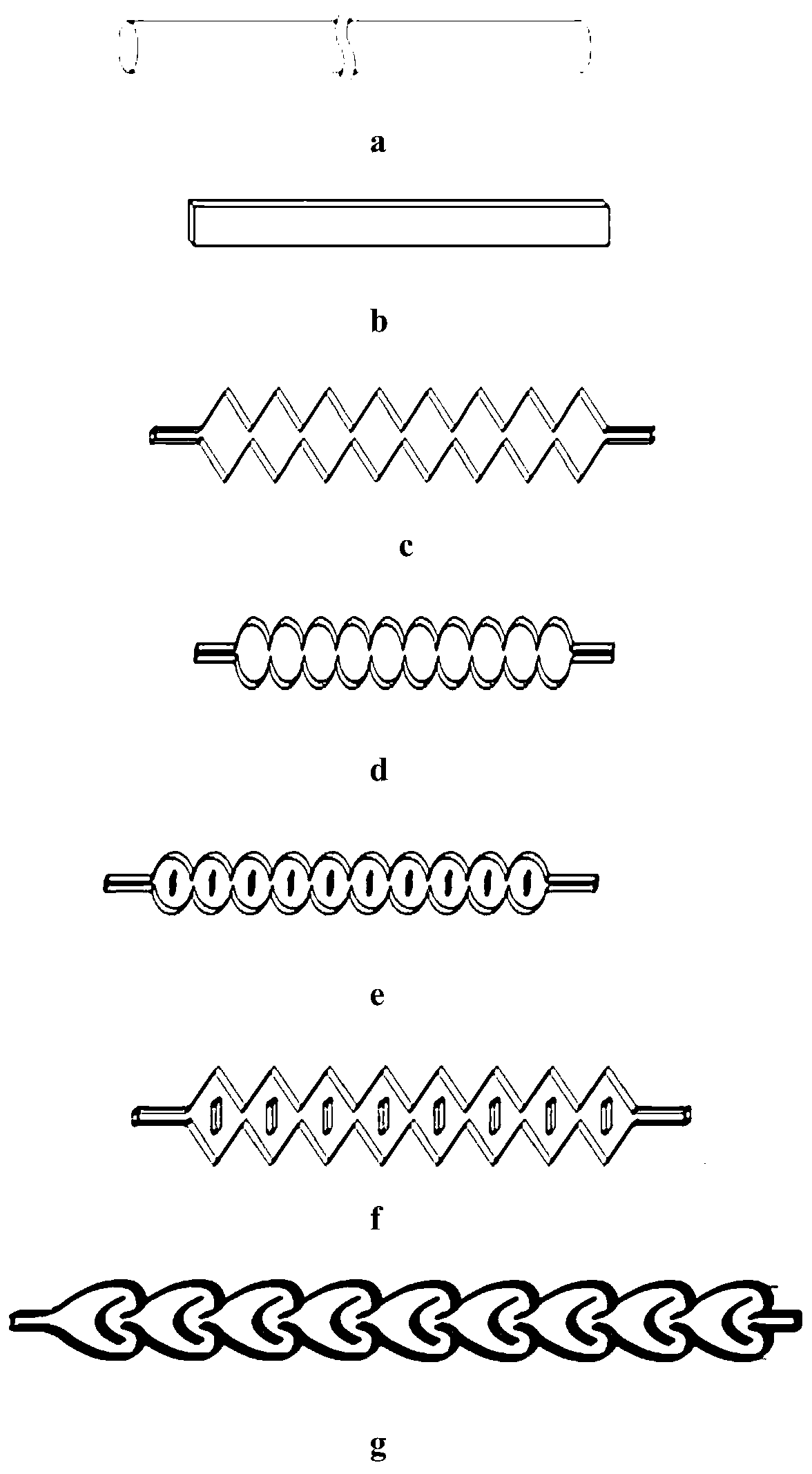

Method for synthesizing 2,5-dichloroaniline by micro-channel reactor

InactiveCN106565500AHigh energy consumptionInhibitory reactivityOrganic compound preparationChemical/physical/physico-chemical microreactorsNitrationSolvent

The invention provides a method for synthesizing 2,5-dichloroaniline by a micro-channel reactor. A nitratlon reaction and a catalytic hydrogenation reaction are performed by using the micro-channel reactor. The method comprises the following steps of nitratlon reaction: raw materials of nitro-p-dichlorobenzene are dissolved into an organic solvent, and are preheated; concentrated nitric acid and concentrated sulfuric acid are mixed and are preheated; the materials enter a reaction module group to take a reaction after the preheating; and an intermediate product of 2,5-Dichloronitrobenzene is obtained after the refining; and catalytic hydrogenation reaction: the 2,5-Dichloronitrobenzene is dissolved into a solvent; Pd-loaded active carbon catalysts are added; dechlorination inhibitors are added, and then, preheating is performed; after the materials are preheated, hydrogen gas enters the reaction module group to take a reaction; and post-treatment is performed to obtain the 2,5-dichloroaniline. The method provided by the invention has the advantages that the mixing effect is good; the temperature and material proportion control is precise; the reaction yield and the product purity are improved; the reaction is safe and stable; the time is short; no amplification effect exists; and wide application prospects are realized in industrial production.

Owner:HEILONGJIANG XINCHUANG BIOLOGICAL TECH DEV CO LTD

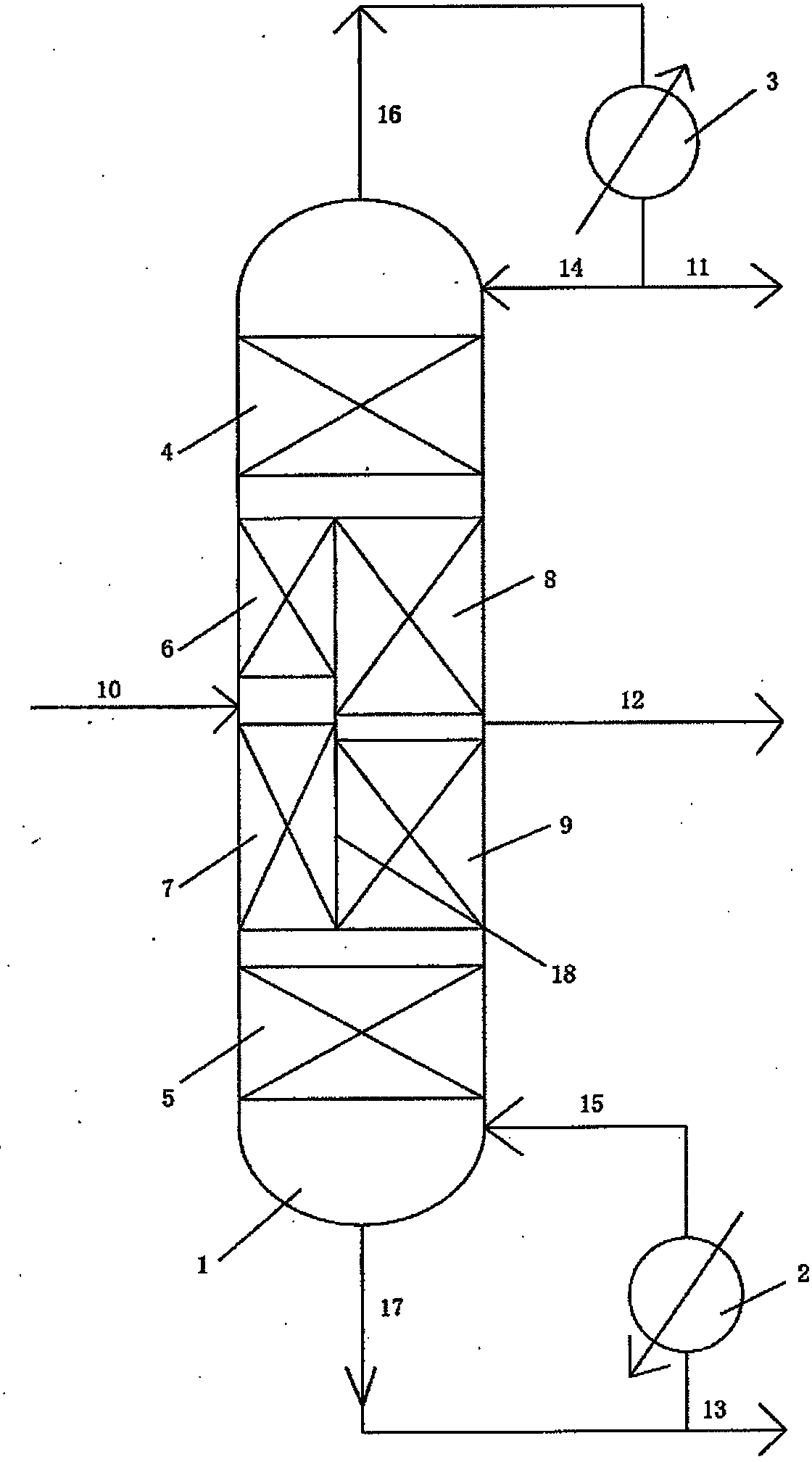

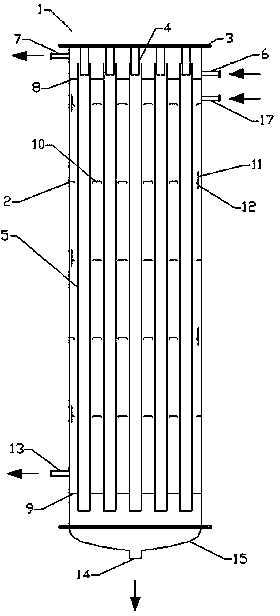

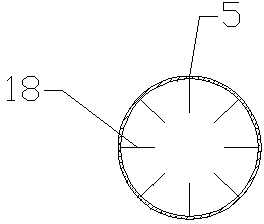

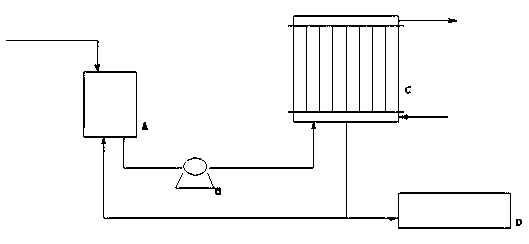

Distillation equipment and method for separating dichlorobenzene isomers

The invention discloses distillation equipment and method for separating dichlorobenzene isomers. The distillation equipment comprises a dividing wall tower, a tower kettle reboiler and a tower top condenser, wherein the dividing wall tower comprises a middle tower region, a tower top distillation section arranged above the middle tower region and used for performing distillation and separation on m-dichlorobenzene and p-dichlorobenzene, and a tower kettle stripping section arranged below the middle tower region and used for stripping and separating m-dichlorobenzene and o-dichlorobenzene; the middle tower region is divided into a pre-separation tower region and a finished product separation tower region by a baffle plate arranged in a longitudinal direction; the pre-separation tower region is parallel to the finished product separation tower region; the pre-separation tower region comprises an upper feeding distillation section and a lower feeding stripping section; the finished product separation tower comprises an upper m-dichlorobenzene / p-dichlorobenzene stripping section and a lower p-dichlorobenzene / o-dichlorobenzene distillation section. According to the distillation equipment, the dichlorobenzene isomers, namely the m-dichlorobenzene, the p-dichlorobenzene and o-dichlorobenzene can be separated in a distillation tower through the dividing wall tower, so that the energy consumption, the equipment investment and the occupied area are reduced.

Owner:李群

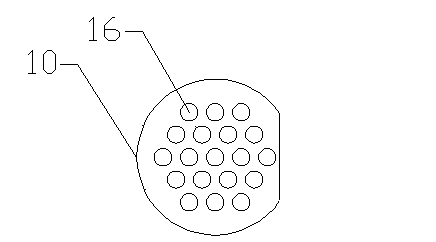

Purification method of p-dichlorobenzene

InactiveCN103772137AGood for melting outPrevent collapseSolution crystallizationHalogenated hydrocarbon preparationPurification methodsEngineering

The invention discloses a purification method of p-dichlorobenzene, which mainly solves the problems of unstable product purity and difficult industrial amplification of a p-dichlorobenzene purification technology in the prior art. The purification method of p-dichlorobenzene adopts the technical scheme that mixed dichlorobenzene enters the top of a crystallizer through a material inlet, a part of mixed dichlorobenzene enters a crystallization pipe through a distributor at the top of the crystallizer, the other part of mixed dichlorobenzene flows out from a material overflow port, a cooling medium enters the crystallizer and forms a cooling medium liquid film on an external wall of a falling film crystallization pipe through cooling medium guide holes in a cooling medium distribution tray, an overflow weir and a downcomer are arranged on the cooling medium distribution tray, the redundant cooling medium flows down to a tray of a next stage through the downcomer and is finally discharged from a cooling medium outlet, the mixed dichlorobenzene liquid film precipitates p-dichlorobenzene crystals on the wall of the crystallization pipe with the fall of temperature, and uncrystallized residual liquid is discharged from a material outlet at the bottom of a tower, so that the problems are better solved, and the method can be used for industrial production of p-dichlorobenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recovery method of N-methylpyrrolidone solvent in polyphenylene sulfide synthesis slurry

The invention relates to a recovery method of an N-methylpyrrolidone (NMP) solvent in polyphenylene sulfide (PPS) synthesis slurry. The process includes: subjecting the produced PPS synthesis slurry centrifugal separation, carrying out water precipitation, centrifugation and other steps on the obtained centrifugate to remove PPS particles and PPS oligomers, then using diluted hydrochloric acid to perform treatment, adjusting the pH to 6.5-7.5, under the protection of nitrogen, maintaining a vacuum degree of 0.090-0.10MPa and a temperature of 70-90DEG C, performing pressure reduced rectification, at the same time using a thermal insulation material to conduct thermal insulation on a rectification device, when water and p-dichlorobenzene are completely distilled off, conducting heating to 150-170DEG C, and performing rectification to obtain NMP. According to the method, the NMP recovery rate reaches 95%, and the purity reaches more than 99%.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

Method for manufacturing high-performance polyphenylene sulfide fibre paper

InactiveCN101148841AImprove insulation performanceImprove conductivitySynthetic cellulose/non-cellulose material pulp/paperFireproofingChemical corrosion

The present invention discloses process of making high performance composite polyphenyl thioether paper and high performance composite polyphenyl thioether fiber paper. Through synthesizing polyphenyl thioether resin with sodium sulfide and p-dichlorobenzene as main materials; melt spinning the polyphenyl thioether resin into fibril; hot drafting the fibril, curling and cutting to obtain 2-10 mm long short fiber; and a wet paper making process with the short fiber, inorganic stuffing and other reinforcing fiber, high performance composite polyphenyl thioether fiber paper and composite paper are made. The high performance composite polyphenyl thioether paper and the high performance composite polyphenyl thioether fiber paper have high insulating performance or conducting performance, high strength, high fireproofing performance, high chemical corrosion resistance and other advantages, and may be applied widely.

Owner:SICHUAN DEYANG CHEM

Polyphenylene sulfide/polyphenylene sulfide sulphone copolymer and preparation method thereof

The invention belongs to the field of synthesizing a high-polymer material, and particularly relates to a polyphenylene sulfide / polyphenylene sulfide sulphone copolymer and a preparation method thereof. The polyphenylene sulfide / polyphenylene sulfide sulphone copolymer is prepared from 10mol of p-dichlorobenzene, 2-4mol of an oxidizing agent, 8-15mol of sodium sulfide, 0.05-0.5 mol of a polymerization catalyst, 0.03-0.2mol of an oxidation catalyst, 0.2-0.8mol of a copolymerization catalyst, 1-5mol of a branching agent, and 500-1000mol of a solvent. The high-quality polyphenylene sulfide / polyphenylene sulfide sulphone copolymer is prepared by oxidizing a polyphenylene sulfide prepolymer and then performing copolymerization reaction between a polyphenylene sulfide sulphone prepolymer prepared through oxidization and the branched polyphenylene sulfide.

Owner:黄孟良 +2

Application of solid acid catalyst to preparation of 2,5-dichloronitrobenzene

The invention discloses application of a solid acid catalyst to preparation of 2,5-dichloronitrobenzene. The preparation method comprises the following steps of: fully mixing p-toluenesulfonic acid serving as a catalyst and a p-dichlorobenzene solution in a kettle, dripping 98 mass percent concentrated nitric acid, performing nitration reaction at certain temperature, keeping the temperature after the reaction is finished, and standing; performing solid-liquid separation to obtain a crude product of 2,5-dichloronitrobenzene; and neutralizing the obtained crude product to reach a certain pH value range by using caustic soda, washing with water, and separating to obtain pure 2,5-dichloronitrobenzene. The p-toluenesulfonic acid is used as the catalyst, reaction steps are effectively simplified, and the emission of wastewater and waste liquor is reduced; materials are reacted completely and the utilization rate is high when the 2,5-dichloronitrobenzene is prepared by external circulation nitration reaction; and the finished product prepared by the method has the yield of 125 percent, and the content is more than or equal to 99.8 percent.

Owner:JIANGSU LONGCHANG CHEM

Method of preparing polyphenylene sulfide with synthesis mother solution

The invention discloses a method of preparing polyphenylene sulfide with a synthesis mother solution and relates to the field of high polymer materials. Sodium sulfide and p-dichlorobenzene are taken as raw materials; the synthesis mother solution is taken as a solvent; sodium hydroxide is taken as an assistant. Particularly, the method sequentially comprises the steps of feeding, dehydration, 1,4-p-dichlorobenzene dissolution, dropwise adding, pre-polymerization, filtering, washing, drying and package to form a polyphenylene sulfide product at last. The method takes the synthesis mother solution as the solvent; the dosage of pure N-methyl pyrrolidone in a polyphenylene sulfide resin synthesis process can be reduced; the recovery cost is greatly lowered; low molecular weight polyphenylene sulfide resin in the synthesis mother solution, sodium sulfide and 1,4-p-dichlorobenzene carry out polymerization reaction again by the action of a catalyst; the waste of the low molecular weight polyphenylene sulfide resin is reduced in a recovery process of the synthesis mother solution; the synthesis mother solution also contains a certain amount of catalyst; the dosage of the catalyst is reduced in the synthesis process, so that the production cost is further lowered.

Owner:四川中科兴业高新材料有限公司

Film-grade polyphenylene sulfide resin and preparation method thereof

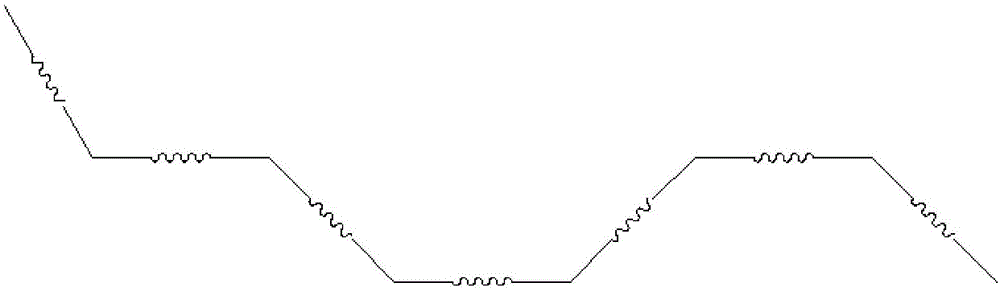

The invention discloses film-grade polyphenylene sulfide resin. The film-grade polyphenlene sulfide resin is mainly prepared from sodium sulfide, alkali metal hydroxides, a catalyst, p-dichlorobenzene and meta dichlorobenzene which are reacted in the environment of 220-260 DEG C for 3-6 hours. The invention further provides a preparation method of the resin, and the method comprises the steps that 1, the sodium sulfide and the alkali metal hydroxides are stirred and dispersed in solvent NMP, and after dehydration is conducted, a mixture is obtained; 2 the solvent NMP, the catalyst, the p-dichlorobenzene and the meta dichlorobenzene are added to the mixture, heating is conducted to make the temperature range from 220 DEG C to 260 DEG C to conduct polymerization for 3-6 hours, and the film-grade polyphenylene sulfide resin is obtained. According to the film-grade polyphenylene sulfide resin, an adequate amount of the meta dichlorobenzene is added when the PPS resin is compounded by taking the p-dichlorobenzene as the raw material, a linear type polyphenylene sulfide molecular chain is changed into an elastic polyphenylene sulfide molecular chain with a bend structure, and the transverse tensile capacity of a polyphenylene sulfide film prepared from the resin is enhanced. In addition, the weight-average molecular weight of a polymer is controlled by controlling the reaction temperature and the reaction time, and the thickness of the formed film is more even.

Owner:GUANGZHOU GAOBAER PLASTIC

Polyphenylene sulfide resin synthesis process

ActiveCN109535426AReduce the content of metal ionsImproved performance characteristicsSynthesis methodsSodium hydrosulfide

The invention discloses a polyphenylene sulfide resin synthesis process, which aims to obtain a resin synthesis method with good particle formation, high product yield, high solvent recovery rate, andreduced corrosion degree of a polymerization reaction device. The method adopts sodium sulfhydrate containing sodium crystallization, sodium hydroxide, and p-dichlorobenzene as raw materials, and takes N-methylpyrrolidone as a solvent, and a condensation polymerization reaction is carried out in a synthesis system, after the low temperature and high temperature polycondensation is completed, acetate, NMP and an aqueous solution are added by a high-pressure pump, then the materials are insulated at a high temperature, cooled, and filtered, and a filter cake is purified by a NMP solvent, repeatedly washed with deionized water and filtered, and the filter cake is dried to obtain the polyphenylene sulfide resin. The polyphenylene sulfide resin synthesized by the invention is widely used in the fields of aerospace, electronic machinery, petrochemical, food, light industry, thermal power generation, cement industry, steel manufacturing, environmental protection, textile industry and the like.

Owner:德阳科吉高新材料有限责任公司

Process for producing high-purity polyphenylene sulfide resin

The invention discloses a process for synthesizing high-purity polyphenylene sulfide resin. The high-purity polyphenylene sulfide resin is made of p-dichlorobenzene and sodium sulfide with certain crystal water, lithium chloride is used as a solubilizing assistant, and N-methyl-2-pyrrolidone is used as a solvent, so that the high-purity polyphenylene sulfide resin can be synthesized. The process includes that chemical raw materials such as oxygen-free deionized water, the sodium sulfide, the lithium chloride and the NMP (N-methyl-2-pyrrolidone) need to be added in a dehydration system before dehydration technological procedures are carried out, and then the p-dichlorobenzene is added into a synthesis system after heating dehydration is completely carried out on the synthesis system, so that condensation polymerization can be carried out. The process has the advantage that the high-purity polyphenylene sulfide resin synthesized and produced by the aid of the process can be widely applied to the fields of aerospace, electronic machinery, petrochemical engineering, foods, light industry, thermal power generation, cement industry, iron and steel manufacture, environmental protection, textile industry and the like.

Owner:何展潮

Method for preparing linear high molecular weight polyphenylene sulfide by utilizing pre-desalting method

The invention relates to a method for preparing linear high molecular weight polyphenylene sulfide by utilizing a pre-desalting method. The method comprises the steps of adding sodium sulfhydrate into NMP (N-methyl-2-pyrrolidone) dissolved with lithium chloride under the inert gas shielding, separating solid sodium chloride after reacting under the heating condition of 70-110 DEG C, obtaining an NMP solution of lithium hydrogen sulfide, continuing to heat to 150-190 DEG C till no hydrogen sulphide escapes, obtaining an NMP suspension of lithium sulfide, adding p-dichlorobenzene and a catalyzing amount of lithium hydroxide at a molar ratio of (0.95-1.1):1, performing and accomplishing polymerization reaction for generating a target product at 190-280 DEG C and 0.1-0.5 MPa, and collecting a precipitation product after cooling. The product is 284-289 DEG C in melting point, 50000-52000 in weight-average molecular weight, 2-3 in molecular weight distribution index, and less than 300ppm in chloride ion content. Since a great deal of sodium chloride is removed before the polymerization reaction, the method solves the problems that a product produced by the traditional method is high in sodium chloride content, and sodium chloride is difficult to remove to result in low quality of the product.

Owner:SHANDONG MINGHUA NEW MATERIAL CO LTD

Process for fractional crystallization of p-dichlorobenzene

InactiveCN102838448AReduce contentHigh yieldHalogenated hydrocarbon preparationPolymer scienceP-dichlorobenzene

The invention discloses a process for fractional crystallization of p-dichlorobenzene, and is characterized by taking 80 wt% of p-dichlorobenzene as a raw material, wherein raw materials are refined in a fractional crystallizer by adopting a secondary six-section melt crystallization technology, so that a product with the mass percentage of the p-dichlorobenzene of more than 99.8% is obtained. The process, provided by the invention, has the advantages of simple operation, high product yield, low energy consumption, and easiness in popularization and application.

Owner:JIANGSU LONGCHANG CHEM

Method for dehydrating sodium sulfide polyhydrate in polyphenylene sulfide production

The invention relates to the technical field of sodium sulfide dehydration, particularly to a method for dehydrating sodium sulfide polyhydrate in polyphenylene sulfide production. The specific schemeis that the method comprises: adding sodium sulfide polyhydrate, NMP, an auxiliary agent and sodium hydroxide into a reaction kettle, and heating and dehydrating the materials in the reaction kettle;making the mixed steam generated by the dehydrating enter a separator, separating, returning the separated liquid returns to the reaction kettle, and carrying out condensation recovery and waste gastreatment on the separated gas; and adding molten p-dichlorobenzene into the reaction kettle, and carrying out a step-by-step heating reaction on the mixed solution in the reaction kettle to finally obtain the polyphenylene sulfide product. In the prior art, the existing PPS production is high in dehydration temperature, performs two-section evaporation dehydration by requiring steam and other energy sources, is instable, and does not have the fixed dehydration time, and the process control is instable during dehydration to cause a large amount of liquid carrying so as to cause the high NMP content in the dehydrated water. According to the invention, the problem in the prior art is solved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Method for producing m-dichlorobenzene with aromatic hydrocarbon chlorination waste as raw material

InactiveCN103896727AEfficient use ofImprove protectionHalogenated hydrocarbon separation/purificationMolecular sieveIsomerization

The invention discloses a method for producing m-dichlorobenzene with aromatic hydrocarbon chlorination waste as a raw material. The method comprises the following steps: separating mixed dichlorobenzene stoste from the aromatic hydrocarbon chlorination waste, performing directional isomerization on the mixed dichlorobenzene stoste under catalysis of an HZSM 5 molecular sieve to translocate mixed dichlorobenzene into m-dichlorobenzene to obtain mixed dichlorobenzene of m-dichlorobenzene, p-dichlorobenzene and o-dichlorobenzene, selectively adsorbing p-dichlorobenzene by using an MFI hydrophobic amorphous silica zeolite molecular sieve as an adsorbent to obtain a mixed solution of m-dichlorobenzene and o-dichlorobenzene, and performing rectification separation to obtain m-dichlorobenzene with mass fraction higher than 99.5%. In the method disclosed by the invention, resource utilization is performed on the aromatic hydrocarbon chlorination waste to separate and extract the mixed dichlorobenzene stoste, p-dichlorobenzene whit higher content is separated by using two high-performance molecular sieves, and high-concentration m-dichlorobenzene is prepared by rectification technology; by adopting the production method disclosed by the invention, m-dichlorobenzene with mass fraction higher than 99.5% can be obtained, resources are saved and the environment is protected.

Owner:JIANGSU LONGCHANG CHEM

A fiber-grade polyphenylene sulfide resin synthesis method

The present invention discloses a fiber-grade polyphenylene sulfide resin synthesis method, taking sodium bisulfide and p-dichlorobenzene as raw materials, N-methyl pyrrolidone as the solvent and C5-C6 fatty acid salt formed through dehydration to C5-C6 fatty acid and sodium hydroxide as the polymerization additive for synthesis through polymerization. White polyphenylene sulfide resin is obtained through acidification and washing of reaction slurry. In view of the fact that MFR is below 125 g / 10 min, weight-average molecular weight as measured by GPC is over 4.2×104, and whiteness is over 90, it can satisfy requirements for fiber polyphenylene sulfide resin. C5-C6 fatty acid salt according to the method of the present invention has a higher solubility in NMP, which can better promote polymerization. It is to be fully diverted into the filtrate after filter prior to conversion into free fatty acid again through acidification with hydrochloric acid. C5-C6 fatty acid is available for azeotropy with water, which has a limited solubility in water. Therefore, it is applicable to recycle C5-C6 fatty acid from the filtrate through azeotropy with water, and thereby solve the problem with separation of additive and sodium chloride that are soluble in water.

Owner:ZHEJIANG NHU SPECIAL MATERIALS +3

Preparation method of fenbendazole which is benzimidazole anti-helminthic drug

InactiveCN106397334AOperational securitySuitable for industrial productionOrganic chemistryFenbendazoleNitration

The invention discloses a preparation method of fenbendazole which is a benzimidazole anti-helminthic drug. Fenbendazole is obtained by taking p-dichlorobenzene as a raw material through nitration, amination, condensation, reduction and ring-closure, and the final product content is 98-101%. The preparation method is simple and efficient, is safe to operate, and is suitable for industrial production.

Owner:JIANGSU BAOZONG & BAODA PHARMACHEM

Polyphenylene sulfide production method

The invention discloses a polyphenylene sulfide production method, which comprises the following active ingredients: water-containing sodium sulfide, p-dichlorobenzene, phase solvent, solvent, and auxiliaries, wherein the phase solvent adopts 2-dimethyl benzoyl isocyanate, and the auxiliaries adopt chlorinated polyethylene. The polyphenylene sulfide production method concretely comprises the following steps: firstly, drying and dewatering the water-containing sodium sulfide, phase solvent, solvent, and auxiliaries, wherein the dewatering time lasts 30-50min, and the temperature is at 150-175DEG C; adding the p-dichlorobenzene after drying and dewatering, filtering after filtering, adding washing liquor while filtering, and filtering and rying to obtain polyphenylene sulfide. Through the mode, the invention can provide a polyphenylene sulfide production method, which is simple in operation steps, and easy to realize, the purity of polyphenylene sulfide can be controlled to the greatest extent during reaction, more refuses cannot be generated during reaction, and thus the environment can be effectively protected.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

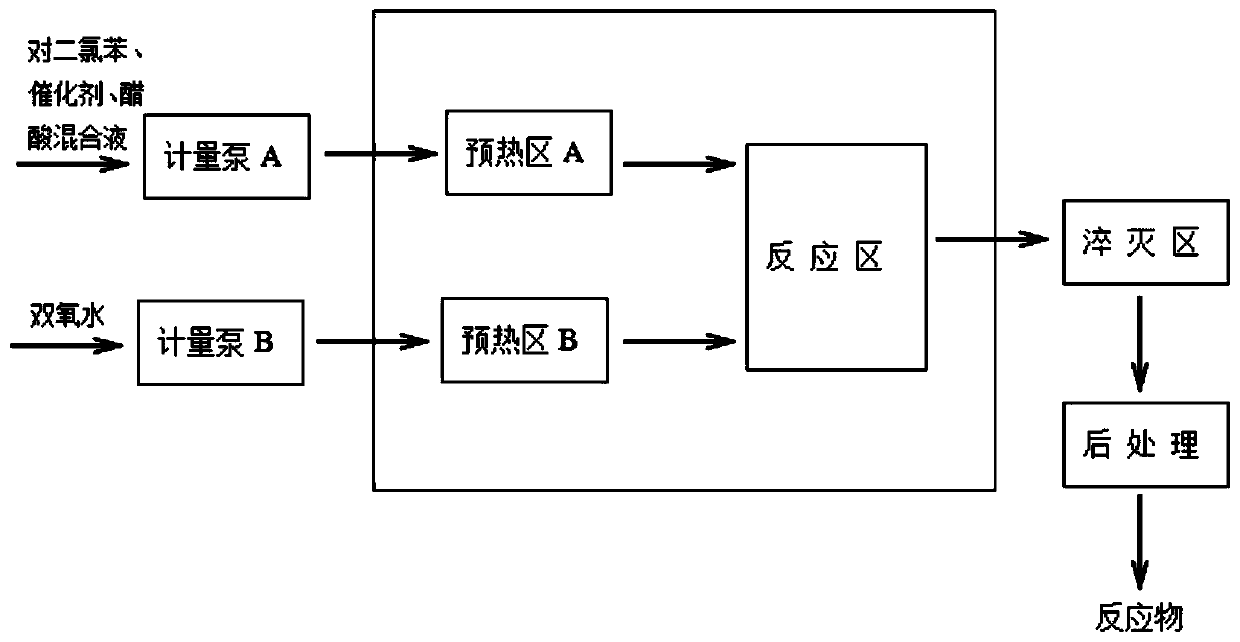

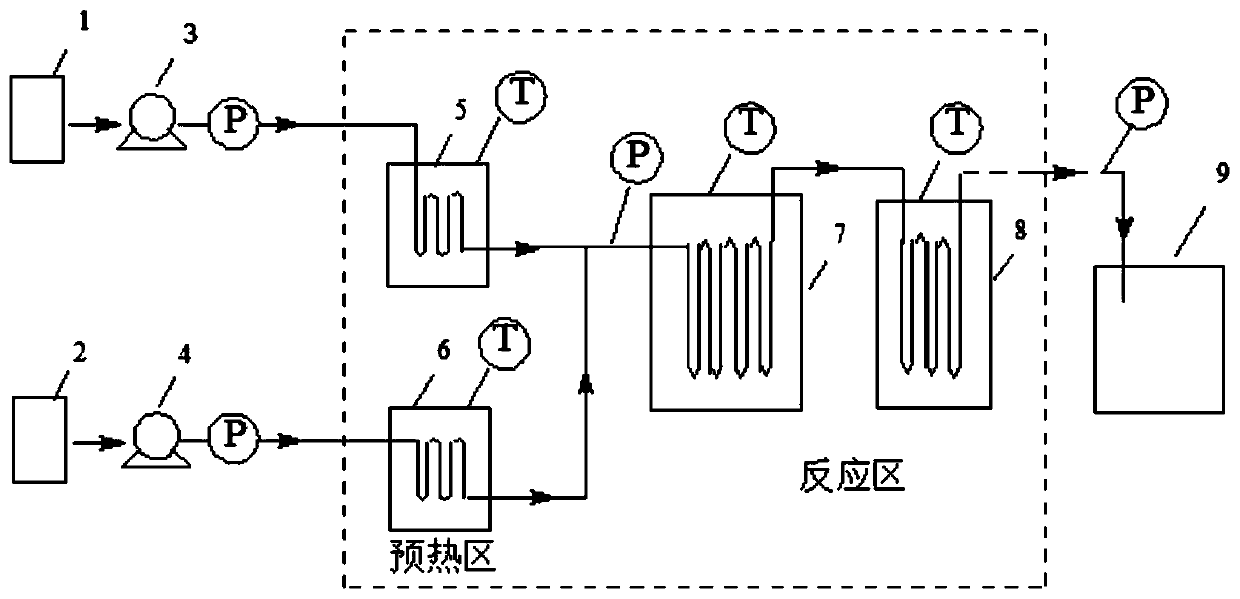

Method for preparing 2, 5-dichlorophenol through continuous oxidation of p-dichlorobenzene

PendingCN110642678AExtended service lifeShort reaction timeOrganic chemistryOrganic compound preparationPtru catalystReaction temperature

The invention discloses a method for preparing 2, 5-dichlorophenol by directly oxidizing p-dichlorobenzene in a micro-channel reactor, and belongs to the field of fine chemical engineering. Accordingto the method, the p-dichlorobenzene is used as a raw material, hydrogen peroxide is used as an oxidant, acetic acid is used as a solvent, and one or more of iron, iron oxide or an iron metal complexis / are used as a catalyst to complete the preparation process of the 2, 5-dichlorophenol in a micro-channel reactor system. According to the method, the temperature and the retention time in the reaction process can be strictly controlled, the accumulation of oxygen is reduced, the reaction temperature is accurately controlled, temperature runaway is prevented, and the safety of a reaction deviceis improved; due to the strong mass transfer effect of the micro-channel reactor, the mass transfer effect among the raw materials in the reaction system is enhanced, and the reaction efficiency is greatly improved.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com