Method of preparing polyphenylene sulfide with synthesis mother solution

A technology for synthesizing mother liquor and polyphenylene sulfide, applied in the field of polymer materials, can solve the problems of high manufacturing energy consumption and high cost of synthesizing PPS, and achieve the effects of solving high manufacturing energy consumption, solving high cost and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Taking the dosage of 100Kg 1,4-p-dichlorobenzene as an example, the specific operations are as follows:

[0041] (1) Feeding: first add 630kg of synthetic mother liquor into the dehydration kettle, start stirring, and then put 114.4kg of sodium sulfide pentahydrate, 2.1kg of sodium hydroxide, 7kg of lithium chloride and sodium acetate into the dehydration kettle , seal the feeding port, and pass in nitrogen protection;

[0042] (2) Dehydration: Start to heat up the reactor. When the temperature in the reactor rises to about 130°C, dehydration begins. When the dehydration amount reaches the specified requirements, the dehydration ends; during dehydration, the total amount of dehydration condensate is checked every 10 minutes Measure, and sample and analyze the dehydration condensate from the dehydration condenser until the dehydration is completed when the dehydration amount meets the specified requirements;

[0043] (3) Dissolution of 1,4-p-dichlorobenzene: 100kg of 1,4-...

Embodiment 2

[0049] According to the operation steps described in Example 1, repeat 3 times, the average molecular weights of the polyphenylene sulfide obtained 3 times are respectively: 26800, 26870, 26850, the molecular weight is high and relatively stable, indicating that the method has good stability and reproducibility The quality of the finally obtained polyphenylene sulfide is: 63.3Kg, 62.2Kg, 62.4Kg respectively, the theoretical yield is 73.578Kg, the yield of 3 repeated operations is the lowest 87.03%, and the conversion rate is high.

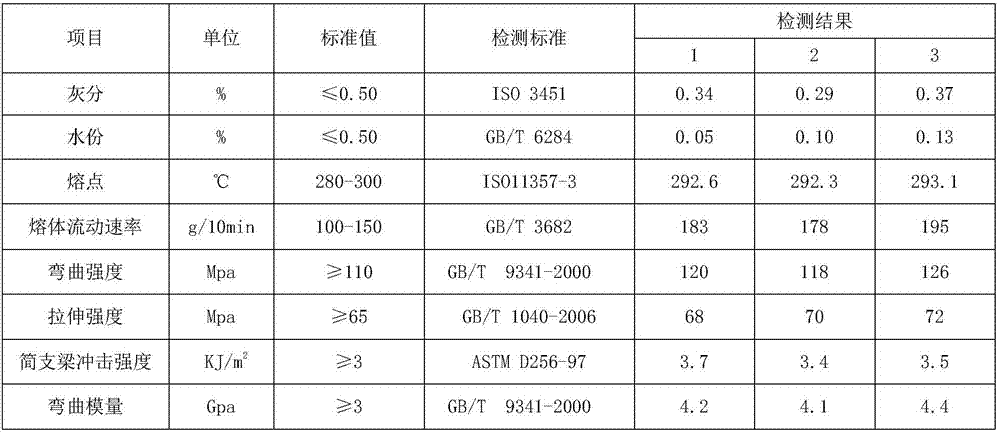

[0050] The physical properties of the polyphenylene sulfide obtained by repeating the operation three times are shown in Table 1:

[0051] Table 1 Physical properties of polyphenylene sulfide

[0052]

[0053] It can be seen from Table 1 that the polyphenylene sulfide prepared by the method of the present invention has excellent mechanical properties and high repeatability.

Embodiment 3

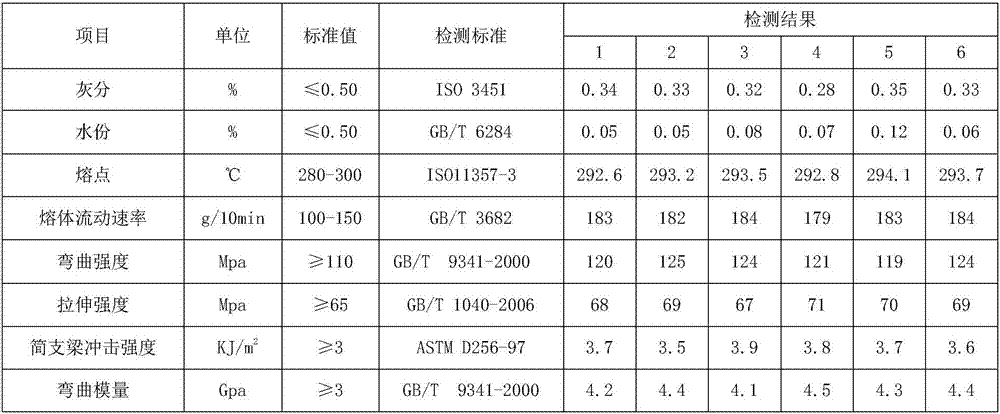

[0055] Carry out 6 groups of control experiments, be respectively compiled into 1,2,3,4,5,6, 6 groups of control experiments change lithium chloride, sodium acetate mixture as catalyzer into lithium chloride, sodium acetate respectively in embodiment 1 , sodium phosphate, sodium carbonate, caprolactone and sodium benzoate, all the other steps and conditions are the same, and the molecular weights of the obtained polyphenylene sulfide products are respectively 26830, 26840, 26820, 26860, 26830, 26850, and the polyphenylene sulfide obtained in Example 1 The molecular weight of sulfide product is consistent, and the kind of catalyzer among the present invention has little influence on the molecular weight of polyphenylene sulfide product, records remaining physical property as table 2:

[0056] Table 2 Effects of catalyst types on the physical properties of polyphenylene sulfide

[0057]

[0058] Based on the data in Table 1 and Table 2, the type of catalyst in the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com