Method for preparing linear high molecular weight polyphenylene sulfide by utilizing pre-desalting method

A high-molecular-weight, polyphenylene sulfide technology, which is applied in the field of preparing linear high-molecular-weight polyphenylene sulfide by pre-desalination method, can solve the problems of poor product quality, wide molecular weight distribution, and insufficient environmental protection of the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

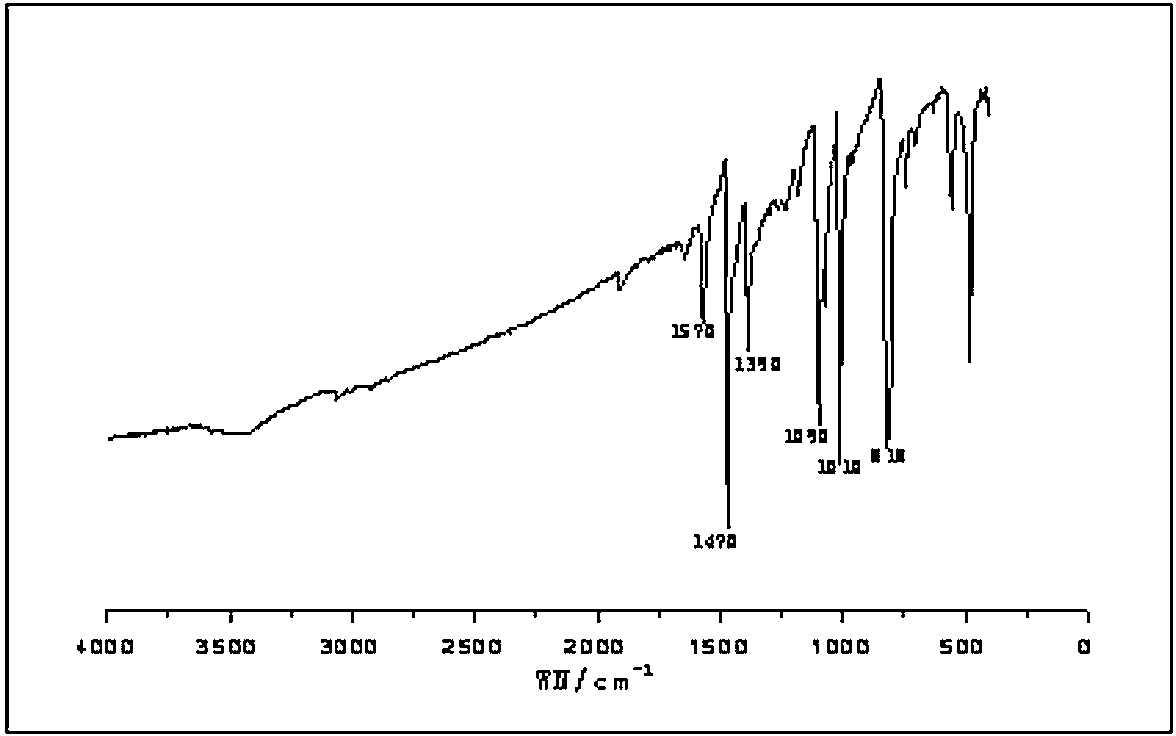

Image

Examples

Embodiment 1

[0022] 424g of lithium chloride was fully stirred and dissolved in 3000g of N-methylpyrrolidone, and then 560g of sodium hydrosulfide was added to fully stir and suspend. 2 Under atmospheric conditions, slowly heat to 80° C., react for 3 hours, and filter to obtain a solution of lithium hydrosulfide in N-methylpyrrolidone. The filter cake of sodium chloride was washed three times with 1000 g of hot N-methylpyrrolidone at 45° C. to obtain 570 g of high-purity white sodium chloride crystals.

[0023] in N 2 Under atmospheric conditions, heat the N-methylpyrrolidone solution of lithium hydrosulfide obtained above to 150° C., react until no hydrogen sulfide gas escapes in the system, and obtain a N-methylpyrrolidone suspension of lithium sulfide. Tail gas is absorbed with lye.

[0024] Add 735g of p-dichlorobenzene and 36g of lithium hydroxide to the N-methylpyrrolidone suspension of lithium sulfide obtained above, raise the temperature to 220°C, and generate by self-vaporizatio...

Embodiment 2

[0028] 445g of lithium chloride was fully stirred and dissolved in 4000g of N-methylpyrrolidone, and then 560g of sodium hydrosulfide was added to fully stir and suspend. 2 Under atmospheric conditions, slowly heat to 80° C., react for 3 hours, and filter to obtain a solution of lithium hydrosulfide in N-methylpyrrolidone. The filter cake of sodium chloride was washed twice with 1500 g of 30° C. hot N-methylpyrrolidone to obtain 560 g of high-purity white sodium chloride crystals.

[0029] in N 2 Under atmospheric conditions, heat the N-methylpyrrolidone solution of lithium hydrosulfide obtained above to 190° C., react until no hydrogen sulfide gas escapes in the system, and obtain a N-methylpyrrolidone suspension of lithium sulfide. Tail gas is absorbed with lye.

[0030]735g of p-dichlorobenzene and 30g of lithium hydroxide were added to the above-mentioned suspension of lithium sulfide in N-methylpyrrolidone, and the temperature was raised to 190°C for pre-polymerization ...

Embodiment 3

[0032] 430g of lithium chloride was fully stirred and dissolved in 5000g of N-methylpyrrolidone, and then 560g of sodium hydrosulfide was added to fully stir and suspend. 2 Slowly heated to 80° C. under atmospheric conditions, reacted for 3 hours, and filtered to obtain a solution of lithium hydrosulfide in N-methylpyrrolidone. The filter cake of sodium chloride was washed three times with 1000 g of hot N-methylpyrrolidone at 50° C. to obtain 565 g of high-purity white sodium chloride crystals.

[0033] in N 2 Under atmospheric conditions, heat the above-mentioned N-methylpyrrolidone solution of lithium hydrosulfide to 170° C., react until no hydrogen sulfide gas escapes in the system, and prepare a suspension of lithium sulfide in N-methylpyrrolidone. Tail gas is absorbed with lye.

[0034] 735g of p-dichlorobenzene and 40g of lithium hydroxide were added to the above-mentioned suspension of lithium sulfide in N-methylpyrrolidone, the temperature was raised to 220°C, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com