Film-grade polyphenylene sulfide resin and preparation method thereof

A technology of polyphenylene sulfide resin and film grade, which is applied in the field of production and synthesis of polymer materials. The effect of enhanced stretching capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

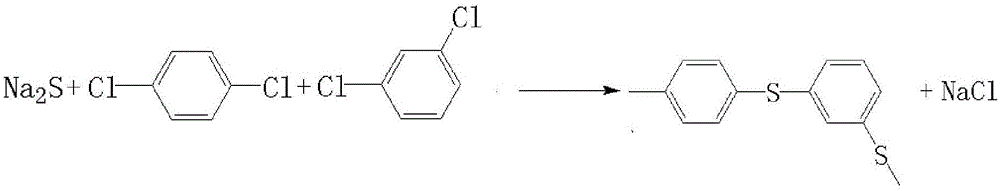

Method used

Image

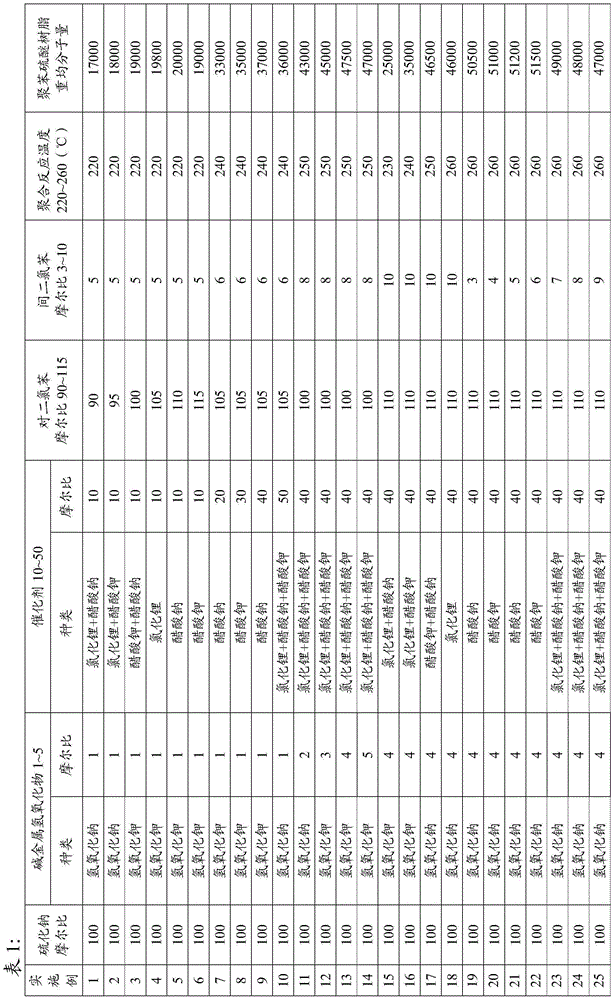

Examples

Embodiment 1

[0016] Add sodium sulfide, sodium hydroxide and NMP solvent into the reaction kettle, heat up to 150-200° C. after mixing, and dehydrate for 1-3 hours to obtain the mixture. Then, add NMP solvent, a mixture of lithium chloride and sodium acetate (catalyst), p-dichlorobenzene and m-dichlorobenzene into the reactor, heat the reactor to 220° C., and keep it warm for 3 hours to carry out the polymerization reaction. Finally, the polymerized substance undergoes processes such as precipitation and separation to remove the NMP solvent to obtain a film-grade polyphenylene sulfide resin.

[0017] In this embodiment, in terms of molar ratio, 100 sodium sulfide, 1 sodium hydroxide, 10 catalysts, 90 p-dichlorobenzene, and 5 m-dichlorobenzene.

[0018] At present, the common polyphenylene sulfide resin is polycondensed by nucleophilic substitution reaction of p-dichlorobenzene and sodium sulfide in a polar solvent. Its polymer chain is linear and regular in structure, and has good longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com