Purification method of p-dichlorobenzene

A technology of p-dichlorobenzene and purification method, applied in chemical instruments and methods, halogenated hydrocarbon preparation, solution crystallization, etc., can solve the problems of difficult industrial amplification, unstable product quality, low product purity, etc. Conducive to the effect of large-scale and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

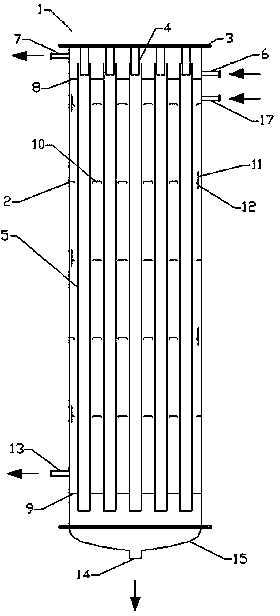

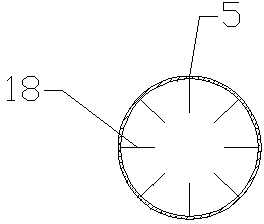

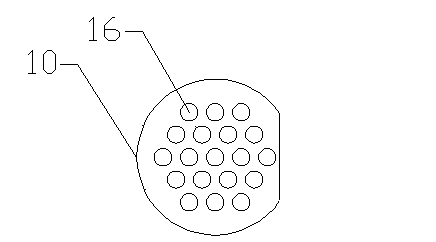

[0033] The crystallizer 1 for the purification of p-dichlorobenzene, the crystallizer shell 2 is closed at the opposite end by the top plate 3 and the lower head 15, the falling film crystallizing tube 5 is provided in the crystallizer shell 2 and the upper part of the crystallizer 1 Material inlet 6 and material overflow port 7; the lower head 15 of the crystallizer is provided with a material outlet 14; the falling film crystallization tube is provided with a distributor 4; the upper part of the crystallizer shell is provided with a cooling medium inlet 17, and the lower part is provided with a cooling medium outlet 13. A cooling medium distribution tray 10 is provided in the crystallizer. The cooling medium distribution tray 10 is provided with a cooling medium guide hole 16, an overflow weir 11, and a downcomer 12; the falling film crystallization tube 5 passes through the guide hole 16. Fix by the upper tube plate 8 and the lower tube plate 9.

[0034] The mold shell 2 is cy...

Embodiment 2

[0042] The crystallizer of Example 1 is used for mixing dichlorobenzene to purify high-purity p-dichlorobenzene 99.7%.

[0043] The mass concentration of p-dichlorobenzene in the mixed dichlorobenzene feed is 65%, and the rest is m-dichlorobenzene, o-dichlorobenzene, trichlorobenzene, etc.

[0044] The purification operation of p-dichlorobenzene includes three steps of crystallization, evaporation and crystal melting:

[0045] Crystallization: Mix dichlorobenzene at 60°C, feed rate of 500L / h, cooling medium temperature of 30°C, and other operations are the same as in Example 1.

[0046] Evaporation After 2 hours of feeding, stop feeding, and make the cooling medium rise to 53°C at a heating rate of 5°C / h

[0047] Melting the crystals After the evaporation operation is completed, the temperature of the cooling medium is increased to 60°C to melt the crystals to obtain high-purity products, which are discharged from the material outlet 14 for collection. The final product with a mass con...

Embodiment 3

[0050] The crystallizer of Example 1 is used for mixing dichlorobenzene to purify high-purity p-dichlorobenzene 99.5%.

[0051] The mass concentration of p-dichlorobenzene in the mixed dichlorobenzene feed is 40%, and the rest is m-dichlorobenzene, o-dichlorobenzene, trichlorobenzene, etc.

[0052] The purification operation of p-dichlorobenzene includes three steps of crystallization, evaporation and crystal melting:

[0053] Crystallization: Mix dichlorobenzene at 60°C, feed rate 500L / h, cooling medium temperature 5°C, and other operations are the same as in Example 1.

[0054] Evaporation After feeding for 2 hours, stop feeding and make the cooling medium rise to 52.5°C at a temperature rise rate of 10°C / h

[0055] Melting the crystals After the evaporation operation is completed, the temperature of the cooling medium is increased to 60°C to melt the crystals to obtain high-purity products, which are discharged from the material outlet 14 for collection. The final product with a mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com