Method for preparation of 2, 5-dichloronitrobenzene by continuous nitration

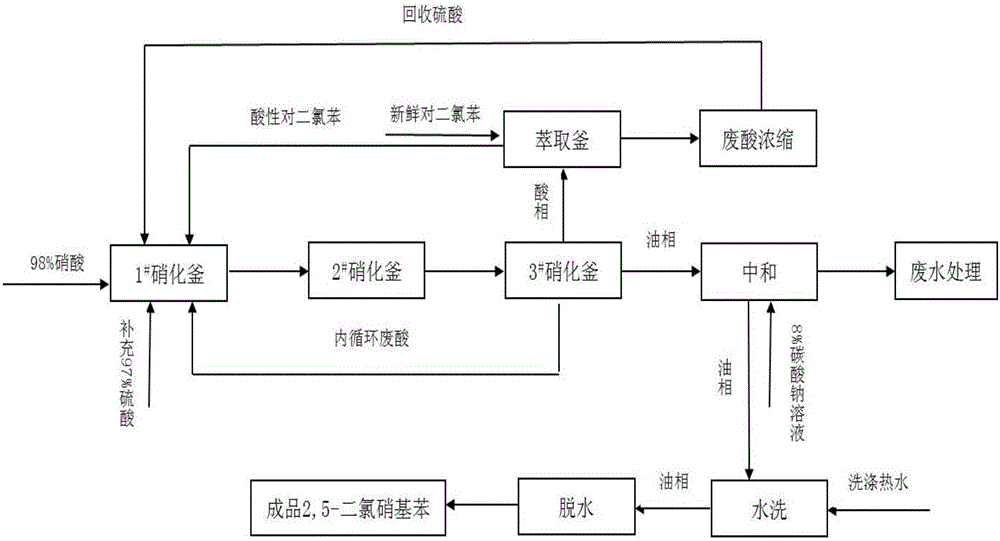

A technology of dichloronitrobenzene and p-dichlorobenzene, which is applied in 2 fields, can solve the problems of large amount of waste acid circulating and the existence of an emulsified layer at the interface of oil phase and acid phase, and achieves improved reaction modulus, stable product quality, and improved equipment. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

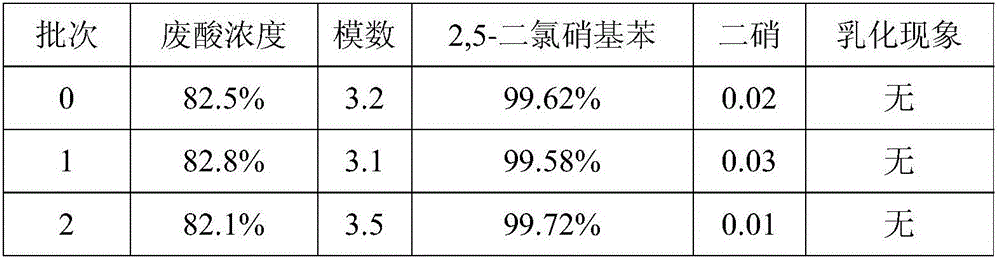

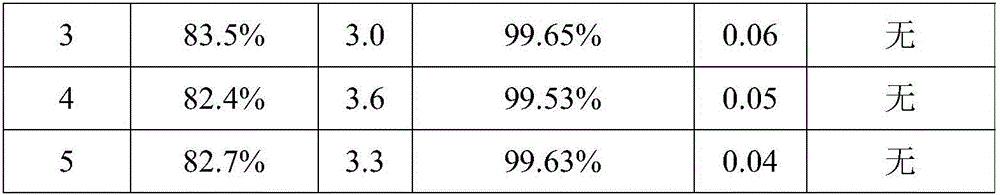

[0024] 1. The production device is composed of 3 nitration kettles and 1 extraction kettle. The total volume of the 3 nitration kettles is 2.5m3 and 1.5m3 respectively. 3 、1.5m 3 , the effective volume is: 1.2m 3 、1.1m 3 、1.1m 3 ;The total volume of the extraction kettle is 1.5m 3 , the effective volume is 1.1m 3 , process control 1 # Nitrification tank temperature 58 ~ 62 ℃, 2 # Nitrification tank temperature 65 ~ 68 ℃; 3 # The temperature of the nitration tank is 65-68°C; the temperature of the extraction tank is 68-70°C; the reaction modulus is 3-4, and the concentration of sulfuric acid is 82-83%. Enter 320L / h p-dichlorobenzene to the extraction kettle, and the acidic p-dichlorobenzene flows into the extraction kettle for 1 # Nitrification kettle, to 1 # 175L / h of 97% sulfuric acid and 120L / h of 98% nitric acid are fed into the nitrification kettle, and the nitrification liquid is successively lifted to the next level of nitrification kettle through the lifters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com