Patents

Literature

60results about How to "Eliminate emulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vitreoretinal silicone tamponades made by supercritical fluid extraction

InactiveUS7276619B2EconomicalHighly effectiveSilicon organic compoundsSilicon compound active ingredientsSupercritical fluid extractionOligomer

A process for the purification of a silicone oil or fluid using neat supercritical carbon dioxide or a supercritical carbon dioxide mixture extraction to produce vitreoretinal silicone tamponades. The subject process is an economical, highly effective, reproducible, contaminant-free method by which unreacted relatively low molecular weight cyclic siloxanes and oligomers are removed from relatively high molecular weight silicone oil or fluid.

Owner:BARCLAYS BANK PLC AS SUCCESSOR AGENT

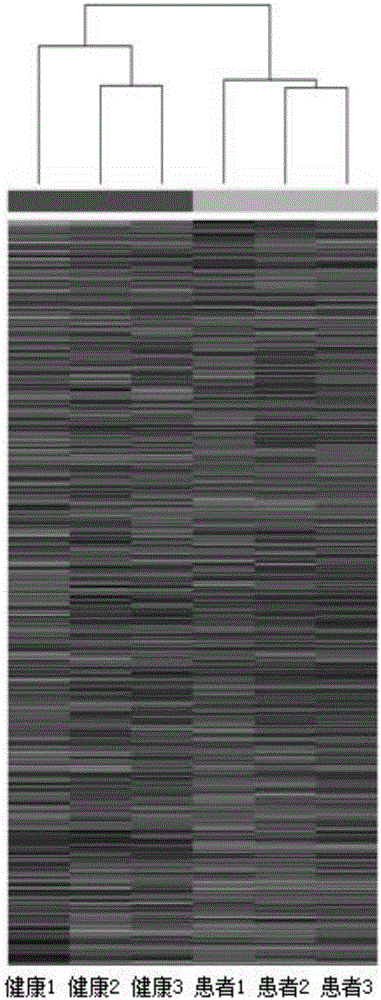

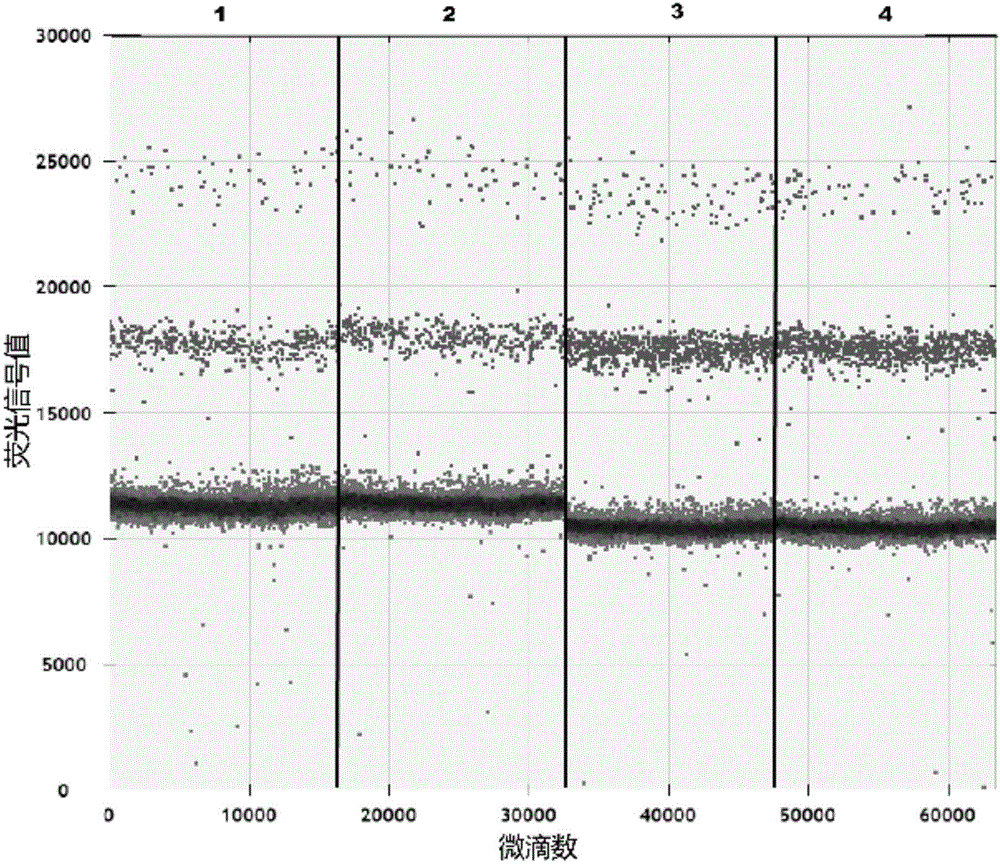

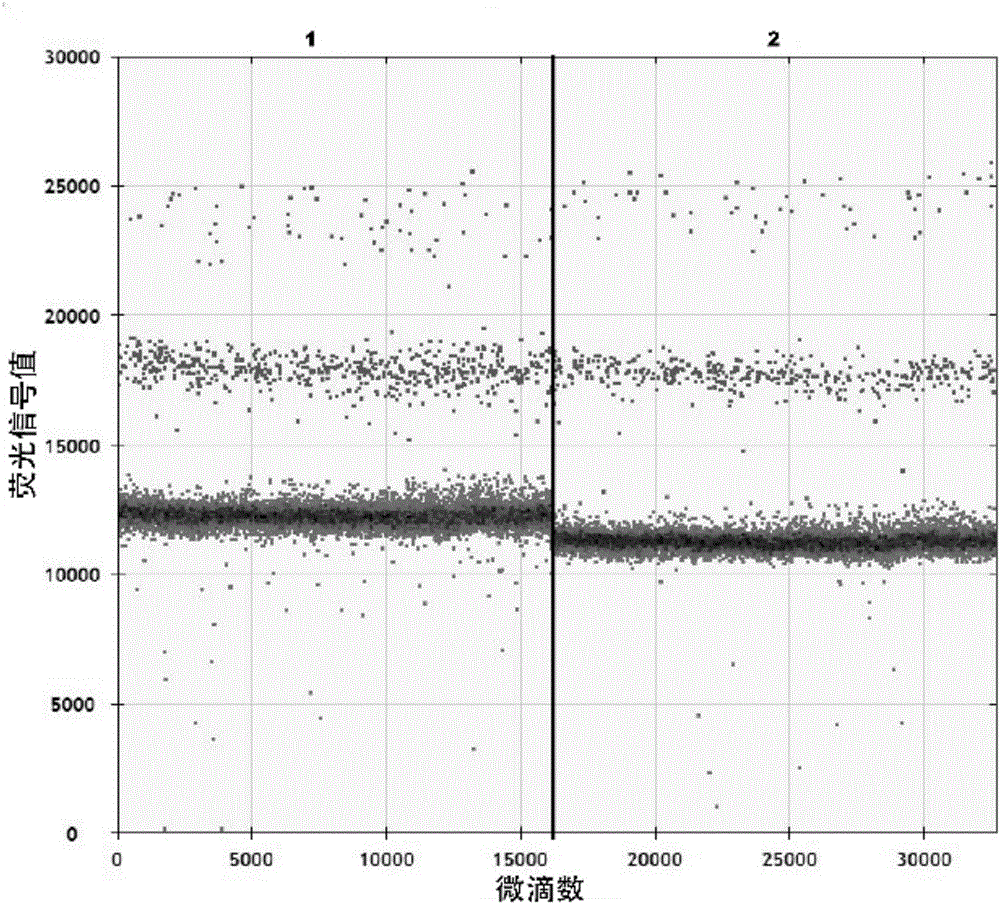

Detection and application of new molecular marker hsa-circ-0001017 of gastric cancer

ActiveCN106591428AReduce yieldHigh yieldMicrobiological testing/measurementDNA/RNA fragmentationHousekeeping geneFluorescence

The invention relates to a cyclic RNA molecular marker for diagnosis of gastric cancer, the cyclic RNA molecular marker is characterized in that the cyclic RNA is hsa-circ-0001017, the invention also provides a method for detection of the cyclic RNA molecular marker in plasma, and the method comprises the following steps: (1) collecting blood, and extracting total RNA in the plasma; (2) performing reverse transcription of the total RNA into cDNA; (3) performing droplet digital PCR detection of a cDNA solution of the step (2) by use of specific amplification back-to-back primers and amplification upstream and downstream primers of housekeeping gene GAPDH, after the completion of the reaction, detecting fluorescence signal values of all droplets, setting a threshold, and determining whether the droplets include the cyclic RNA or the housekeeping gene GAPDH, wherein the droplets higher than the threshold are positive droplets, and the droplets below the threshold are negative droplets; and (4) counting the number of the positive droplets, and calculating the copy number of the hsa-circ-0001017 and the housekeeping gene GAPDH in the plasma for quantitative detection of the hsa-circ-0001017 and the housekeeping gene GAPDH in the plasma. Compared with the prior art, the advantages are that the hsa-circ-0001017 can be specifically expressed in plasma in patients with gastric cancer, and can be used as a new molecular marker for diagnosis of the gastric cancer.

Owner:NINGBO UNIV

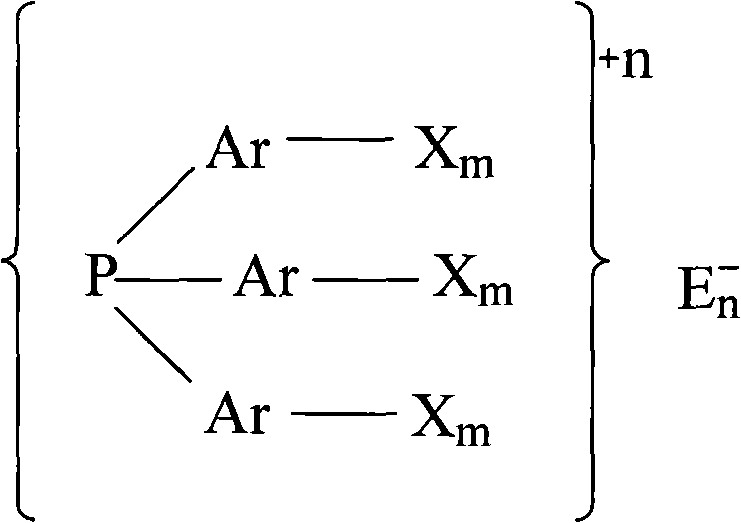

Catalyst for preparing aldehyde by two-phase catalytic hydrogen formylation reaction and application thereof

ActiveCN101722048AEliminate emulsificationReduce rhodium loss in organic phaseOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionSolventSurface-active agents

The invention relates to a catalyst which uses alcohol and water as a solvent and contains water soluble phosphine ligands and rhodium compounds and a method for preparing high-carbon aldehyde by a two-phase catalytic hydrogen formylation reaction by using alpha-olefin above C5 as a raw material. The invention overcomes the defects that the reaction rate of a hydrogen formylation reaction of high-carbon alpha-olefin above C5 is low, and the addition of a surface active agent for improving the reaction rate can generate two-phase emulsification and dissolution and cause phase separation difficulty and the increase of rhodium catalyst loss in a traditional two-phase water soluble rhodium-phosphine catalytic process. The invention can improve the reaction rate or avoid the emulsification, thereby reducing the rhodium catalyst loss. The innocuous and environment-friendly mixed solvent of the alcohol and the water is adopted and can be recycled, and the production cost is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

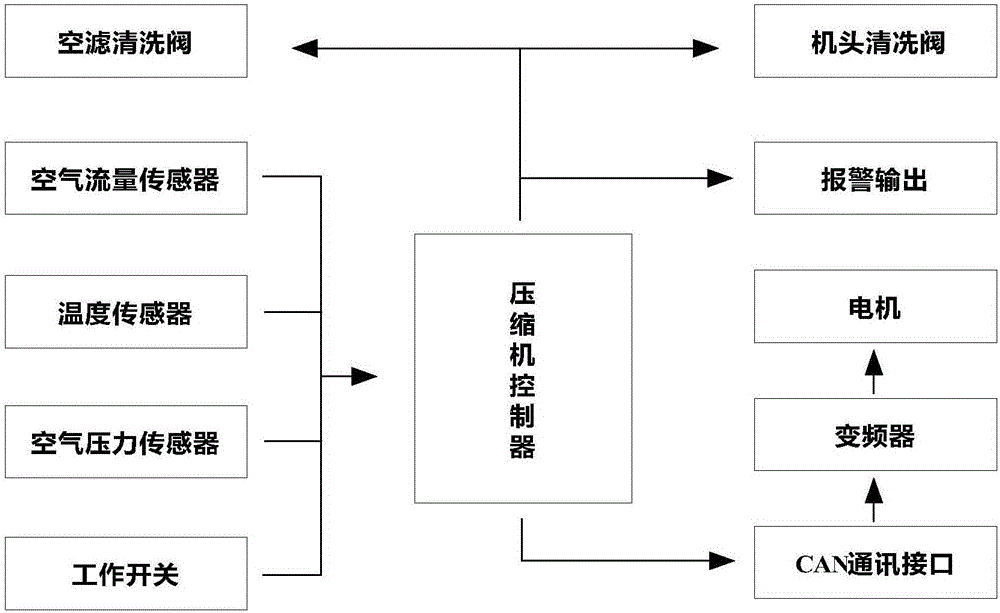

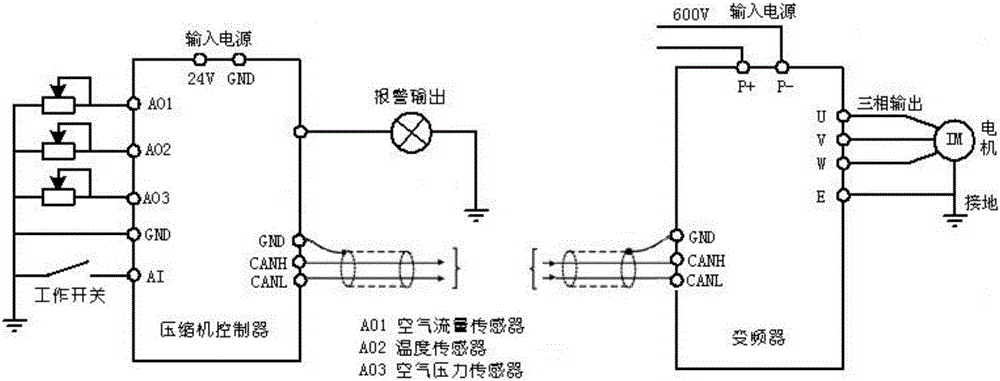

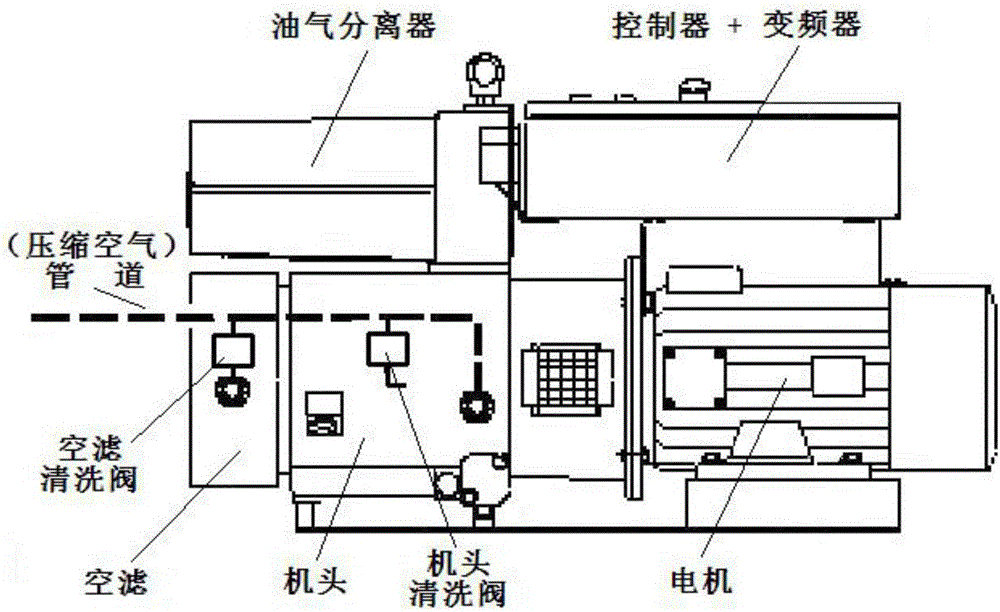

Controller of air compression system of electric passenger car

ActiveCN106194740APrevent and detect abnormal phenomena in timeAvoid start-stop jitterPower-operated mechanismPump controlCommunication interfaceAir compression

The invention provides a controller of an air compression system of an electric passenger car. An air flow sensor, a temperature sensor, an air pressure sensor and an operating switch are all connected with the compressor controller. The compressor controller, a CAN communication interface, a frequency converter and a motor are sequentially connected. An alarm output indicator light is connected with the compressor controller. A compressor head cleaning valve and an air filter cleaning valve are connected to the same compressed air pipeline. The compressed air pipeline is connected with an air filter chamber through the air filter cleaning valve. The compressed air pipeline is connected with a compressor head through the compressor head cleaning valve. The air flow and the air pressure of the air compression system and the temperature of the compressor head are collected through the compressor controller, the operating air pressure and the operating state of a compressor are adjusted in real time, and thus the air compressor is made to operate in the optimal state all the time; and the failure rate of the compressor is decreased, and the service life of the compressor is prolonged.

Owner:ANHUI ANKAI AUTOMOBILE

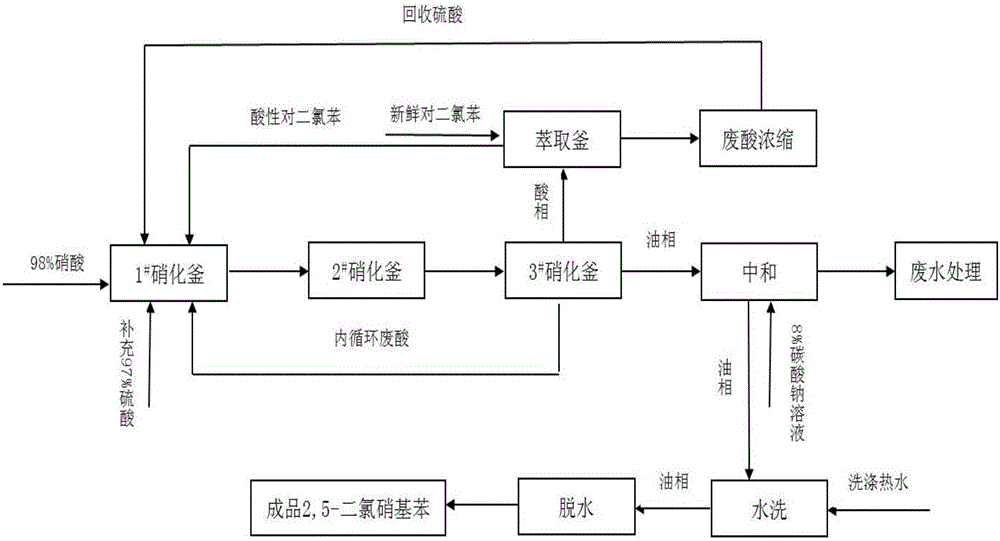

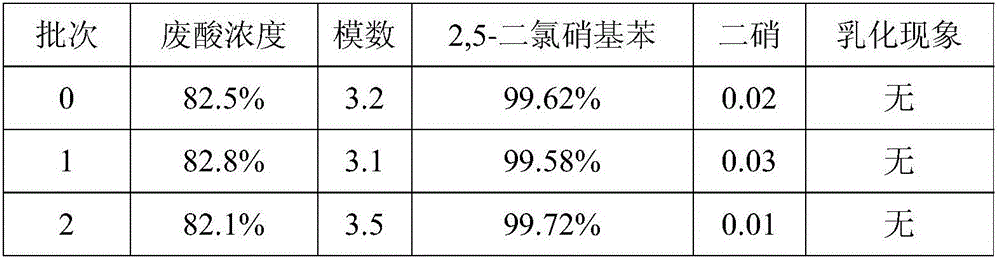

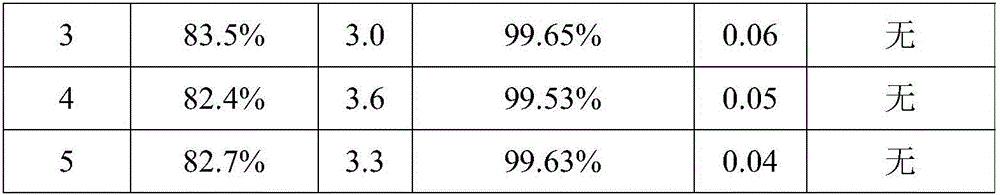

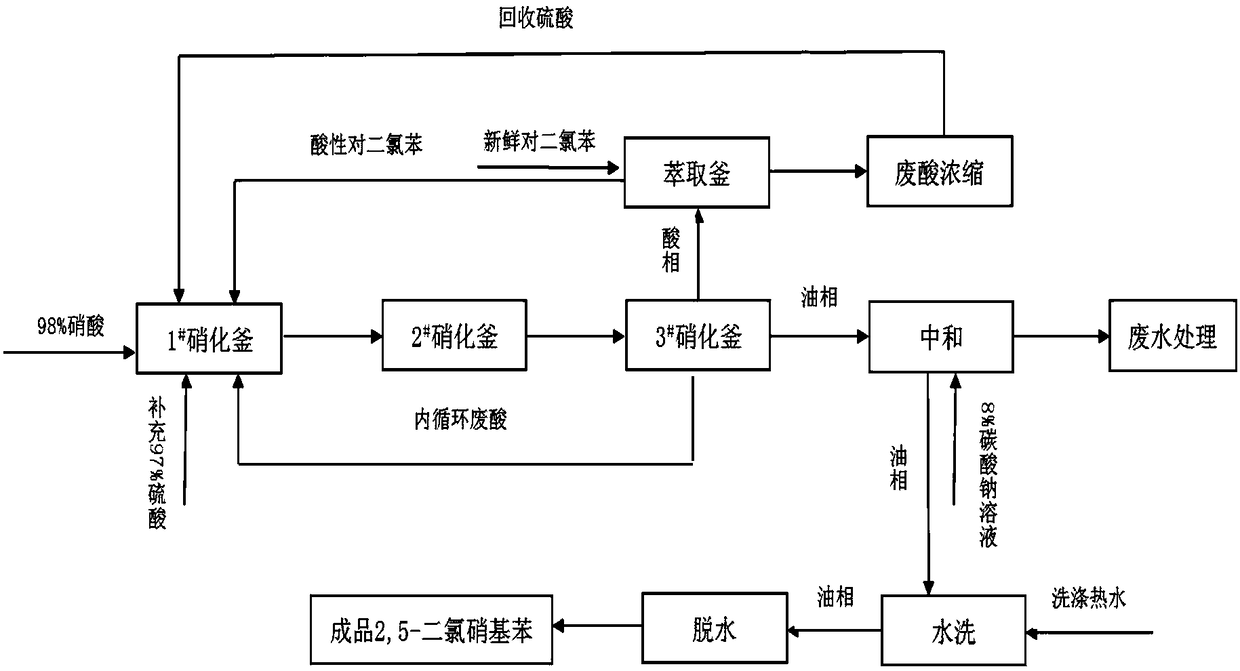

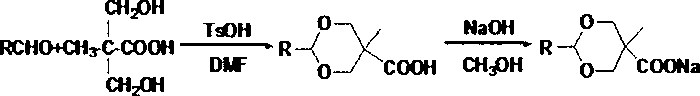

Method for preparation of 2, 5-dichloronitrobenzene by continuous nitration

ActiveCN106083596AOptimize process flowWith automatic separation functionNitro compound preparationNitrationOil phase

The invention discloses a method for preparation of 2, 5-dichloronitrobenzene by continuous nitration. The method comprises the steps of: adopting three-stage kettle type continuous reaction, adding sulfuric acid, nitric acid and p-dichlorobenzene in an extraction kettle into a first stage nitrification kettle simultaneously to carry out nitrification reaction, letting nitrification liquid enter a next stage nitrification kettle through self-carried raisers of all nitrification kettles in order to react, at the end of reaction in a third stage nitrification kettle, separating an oil phase and an acid phase, carrying out neutralization, washing and dehydration on the oil phase so as to obtain 2, 5-dichloronitrobenzene, internally recycling part of waste acid in the acid phase back to the first stage nitrification kettle, letting the residual waste acid enter an extraction kettle, and performing p-dichlorobenzene extraction, and then conducting separation to obtain acidic p-dichlorobenzene and extracted waste acid, concentrating the extracted waste acid into concentrated sulfuric acid, and making the concentrated sulfuric acid and acidic p-dichlorobenzene enter the first stage nitrification kettle for recycling. The method provided by the invention adopts automation control, cancels a mixed acid preparation procedure, simplifies the technological process, can realize continuous nitrification reaction, continuous nitrification liquid separation and continuous waste acid extraction.

Owner:江苏拓孚工程设计研究有限公司

Method for removing aluminum in rare-earth solution

ActiveCN103146921AHigh implementabilityHigh recovery rateProcess efficiency improvementWastewaterRare earth

The invention relates to a method for removing aluminum in rare-earth solution. The method comprises the following steps of: carrying out saponification for an organic phase, separating aluminum from rare-earth liquid via a method of distilling and extracting, and a distilling and extracting flow rate is as following: a volume ratio of the organic phase: rare-earth solution : washing liquid: reverse liquid is (40-60): (100-200): (3-20): (1-3) L / min; the concentration of REO (rare-earth oxide) in rare-earth solution is (1.6-1.77) mol / L, the concentration of Al2O3 is (0.003-0.03) mol / L, the acidity of washing liquid is (0.1-3.0) mol / L, and the acidity of reverse liquid is (1.0-4.5) mol / L; a distilling and extracting class is that an extracting section: a washing section: a reverse-extracting section equals to 8:10:7; and a recovery rate of rare earth reaches above 99.98 percent. According to the method, a process for removing aluminum is shortened, the phenomenon of emulsification in the extraction is eliminated, the separation efficiency is good, linkage extraction is realized, the recovery rate of rare earth is high, and produced waste water is easier to treat.

Owner:CHINA NORTHERN RARE EARTH (GROUP) HIGH TECH CO LTD

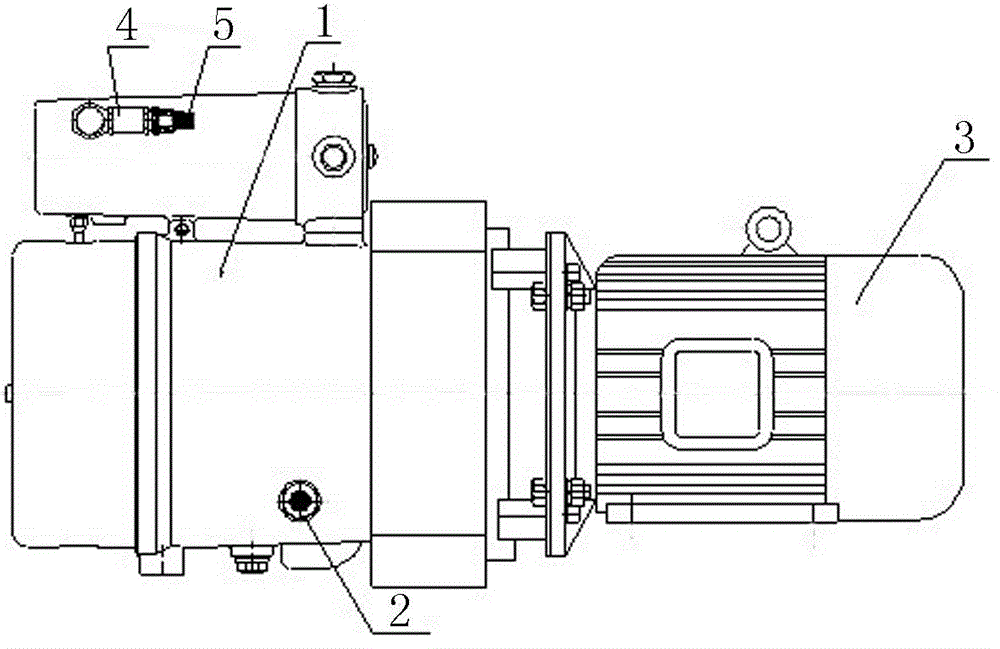

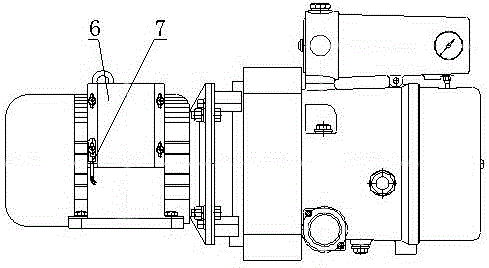

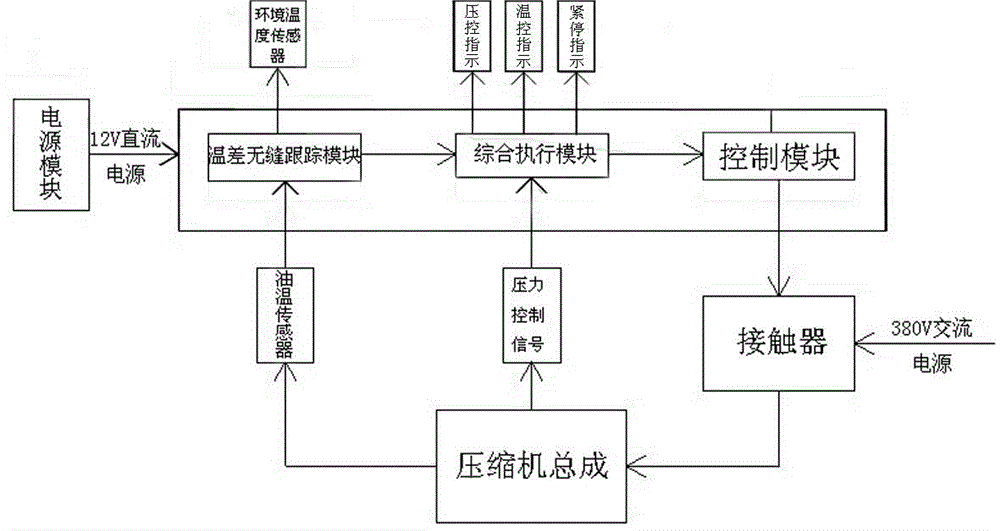

Electronic intelligent controller, control method and air compressor applying controller

InactiveCN102943753AReduce continuous idlingExtended service lifePositive displacement pump componentsPump controlAutomatic controlAir compressor

The invention relates to an electronic intelligent controller, a control method and an air compressor applying the controller, and the electronic intelligent controller, comprise a seamless tracking operational amplifier, a control module and a comprehensive executive module which sequentially carry out signal transmission. The invention has the beneficial effects that: as an oil temperature sensor and an environment temperature sensor are additionally arranged on the air compressor, according to the real-time lubricating oil temperature and the environment temperature which are probed by the temperature sensors, the starting and stopping can be automatically controlled, the lubricating oil temperature can be guaranteed to be always higher to dew point temperature, the lubricating oil emulsification phenomenon which can be generated in the prior art can be eliminated, and simultaneously, the phenomenon that in order to improve the operating temperature of the air compressor, the air compressor continuously idles can be reduced; the service life of the air compressor can be prolonged, the unnecessary energy consumption and the maintenance cost of a user on the air compressor can be reduced, and the installation is convenient and reliable; and an overflowing valve is arranged on an exhaust port, and the overflowing valve is connected with a muffler, so that the noise of the air compressor can be reduced.

Owner:WEILONG PUMP CO LTD

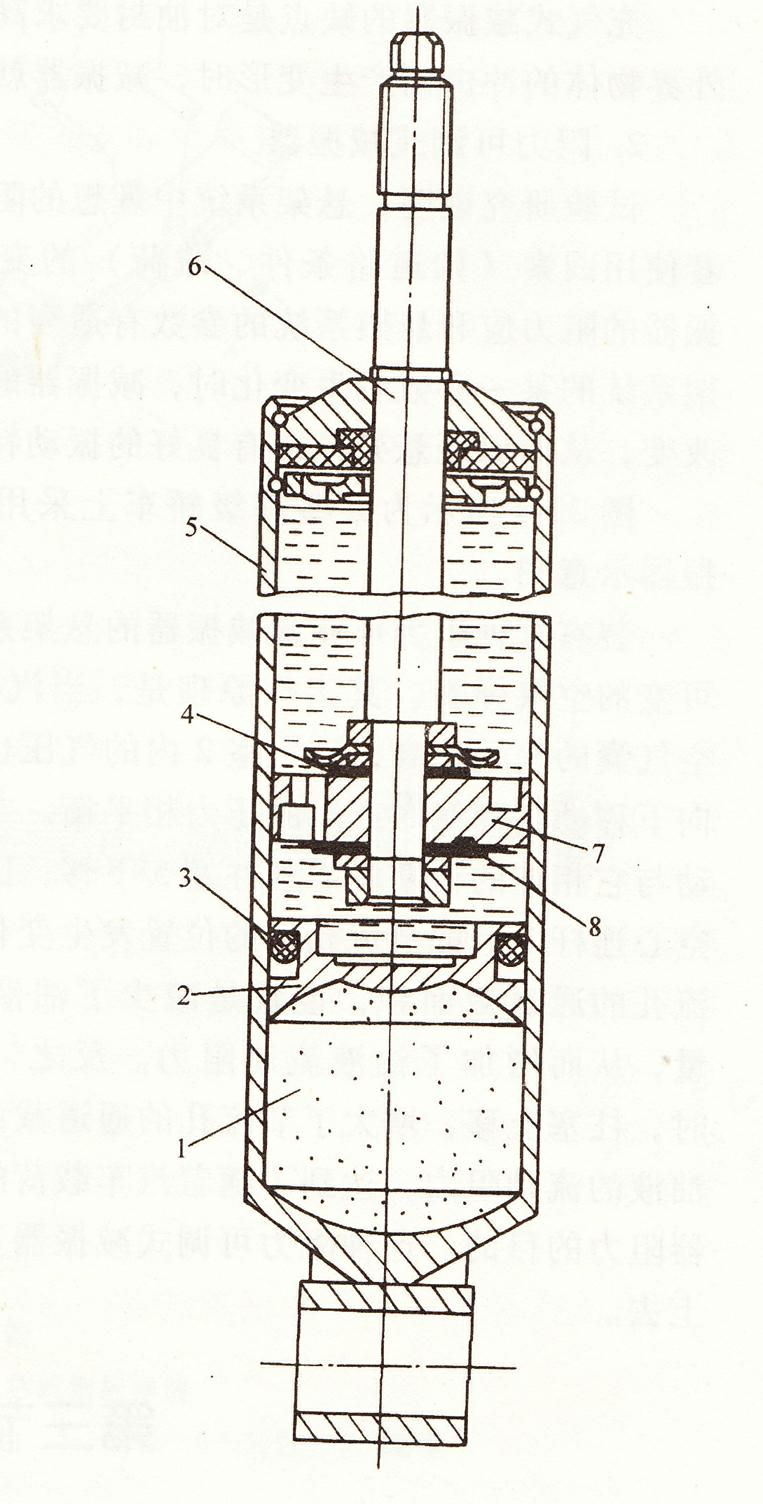

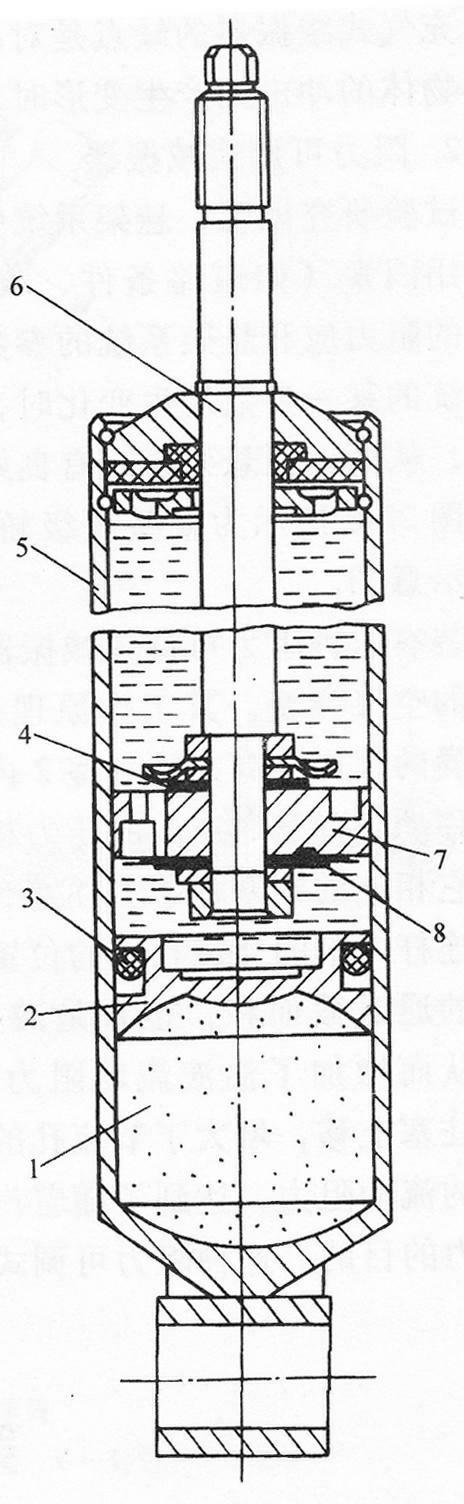

Inflatable vibration damper

InactiveCN102518730ASimple structureImprove shock absorptionGas and liquid based dampersEngineeringHigh pressure

The invention discloses an inflatable vibration damper, which is characterized by including a sealed air chamber, a floating piston, an O-shaped seal ring, a compression valve, a working cylinder, a piston rod, a working piston and a rebound valve, wherein the floating piston is mounted at the lower part of the working cylinder and connected with one end of the working cylinder into the sealed air chamber; the piston rod is vertical to the floating piston; the O-shaped seal ring is mounted on the floating piston; the working piston is arranged above the O-shaped seal ring; and the compression valve and the rebound valve are mounted on the working piston. The structure of the inflatable vibration damper is simplified by adopting the floating piston, and meanwhile the O-shaped seal ring with a big cross section on the floating piston separates the high-pressure gas from the oil gas, thereby avoiding the oil emulsification.

Owner:张洪领

Tributyl phosphate extraction resin for zirconium-hafnium separation and preparation method thereof

ActiveCN101643847AEfficient separationEliminate emulsificationProcess efficiency improvementAlcoholSeparation coefficient

The invention relates to tributyl phosphate extraction resin for zirconium-hafnium separation and a preparation method thereof. The preparation method is characterized by comprising the following steps: adding a solvent into a reaction kettle, wherein the solvent is a mixture of water and alcohols and the mixed weight ratio of the water and the alcohols is 100:2-100; after the solvent is stirred evenly, adding resin into the solvent, wherein the weight ratio of the solvent to the resin is 100:5-100; after the mixture is stirred evenly, adding tributyl phosphate into the mixture, wherein the weight ratio of the tributyl phosphate to the resin is 15-400:100; and stirring the mixture for 0.5 to 20 hours at the temperature of between 10 and 100 DEG C, and filtering the mixture to obtain the TBP extraction resin. The TBP-resin prepared by the method serving as the extraction resin for filling an extraction chromatographic column can effectively separate zirconium and hafnium, fully exerts the advantages of a liquid-liquid extraction process such as large TBP extracted zirconium capacity and large zirconium-hafnium separation coefficient, and eliminates the problem of emulsification produced by liquid-liquid extraction so as to successfully implement a zirconium-hafnium TBP extraction separation process.

Owner:有研资源环境技术研究院(北京)有限公司

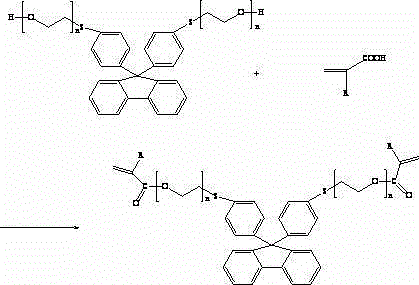

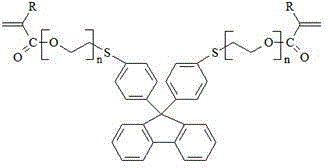

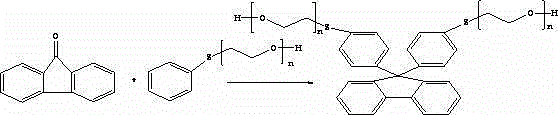

Photocuring resin containing polyethoxy bisthiophenyl fluorene structure and preparation method thereof

The invention relates to the technical field of a resin and a preparation method thereof, particularly a photocuring resin containing polyethoxy bisthiophenyl fluorene structure and a preparation method thereof. The preparation method comprises the following steps: adding 9.9-(4-thiophenyl-hydroxypolyethoxy)bis fluorene and (methyl)acrylic acid into an organic solvent, and carrying out esterification reaction by using an organic acid as a catalyst in the presence of a polymerization inhibitor and a reducer; and after the reaction finishes, carrying out salt washing, neutralization, water washing, drying and reduced pressure distillation to remove the solvent, thereby obtaining the 9.9-(4-thiophenyl-(methyl)acryloyloxypolyethoxy)bis fluorene. The polyethoxy acrylate resin containing bisthiophenyl fluorene structure is a colorless or light yellow transparent photocuring resin, has favorable heat resistance and transparency, and has different refractive index gradients.

Owner:东莞市贝特利新材料有限公司

Method for measuring concentration of C60 nanocrystal particles in water medium

InactiveCN102944528AEliminate emulsificationEliminate foamColor/spectral properties measurementsAcetic acidSurface-active agents

The invention discloses a method for measuring the concentration of C60 nanocrystal particles in water medium. The method comprises the following steps: pure glacial acetic acid is added into nC60 water suspension which contains a surface active agent to destabilize; toluene is used to extract C60 in the destabilized water suspension; the water suspension is stirred; the water suspension is frozen and stirred; then, an ultraviolet-visible spectrophotometer is used to measure the absorbance of the upper layer of toluene solution of the frozen water suspension; the concentration of C60 in a sample is calculated according to a standard curve through the absorbance; and the rate of the C60 concentration which is obtained through calculating to the standard C60 concentration is used as the recovery rate of the C60 concentration measurement. According to the method, the glacial acetic acid is used as a destabilizing agent to eliminate the phenomenon that emulsification and foams are generated during the C60 concentration measurement process under the condition of containing the surface active agent, so that the C60 concentration measurement can be enabled to be normally carried out, and moreover, the higher C60 recovery rate can be obtained.

Owner:SHANGHAI JIAO TONG UNIV

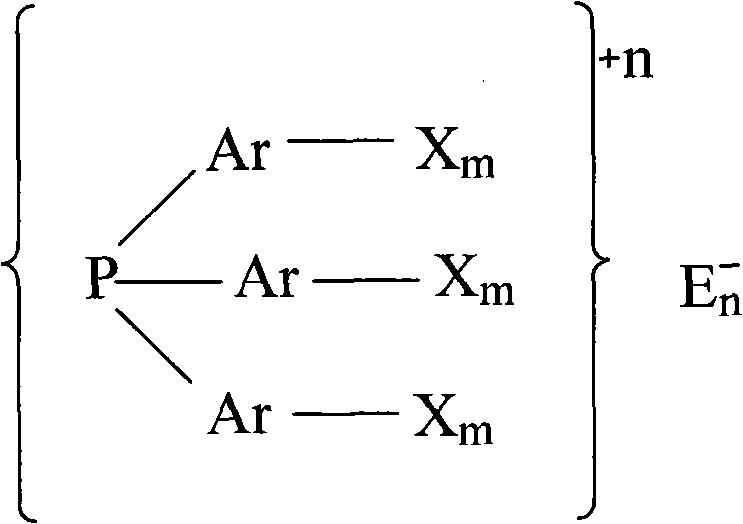

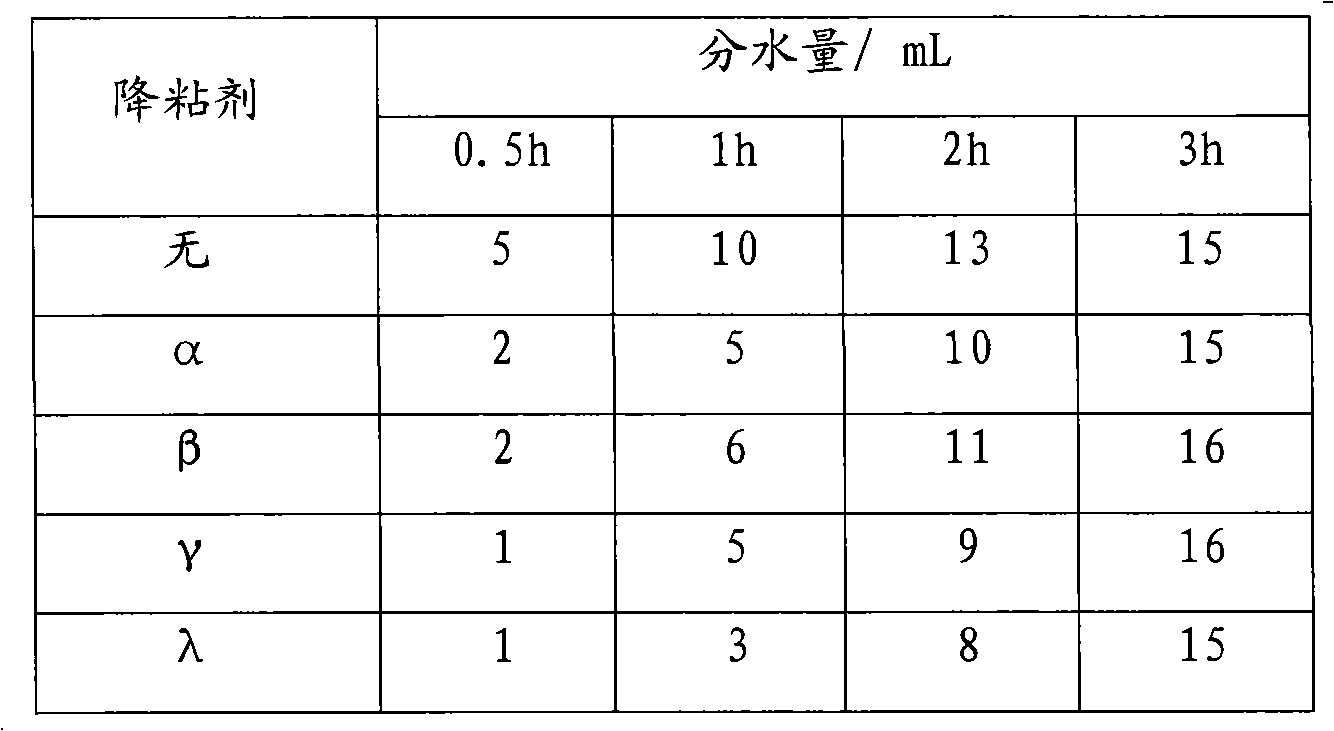

Demulsifying dehydration method of oilfield produced fluid

ActiveCN102876357ALow costLow toxicityDewatering/demulsification with chemical meansReducerBenzyl group

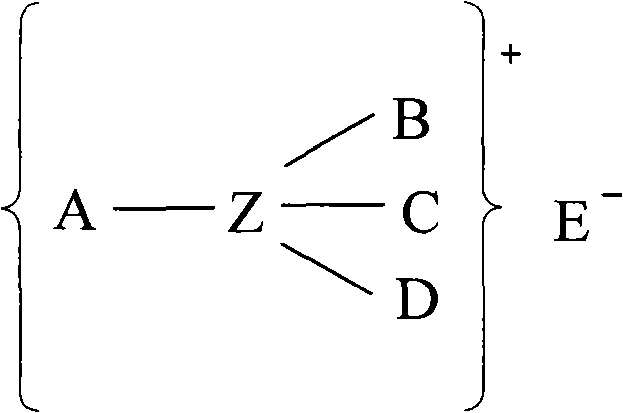

A demulsifying dehydration method of an oilfield produced fluid comprises a step that the demulsifying dehydration is carried out through mixing the oilfield produced fluid, a demulsifying assistant and a demulsifying agent. The oilfield produced fluid contains an emulsified viscosity reducer; the application amount of the demulsifying assistant is 10-200ppm on the basis of the quality of the oilfield produced fluid; and the demulsifying assistant has a structure represented by a general formula of [R1P<+>(R2)3]nX<n->, R1 is a C6-22 alkyl or alkoxy group, R2 is a C1-4 alkyl, hydroxyalkyl, phenyl, benzyl or tolyl group, n is an integer between 1 and 3, X is Cl<->, Br<-> or HCOO<-> when n is 1, X is SO4<2-> when n is 2, and X is PO4<3-> when n is 3.

Owner:CHINA PETROLEUM & CHEM CORP +1

Demulsifying and detoxifying method of gallium extracting system

InactiveCN101892386AEliminate emulsificationEliminate poisonProcess efficiency improvementSuspended particlesPhosphoric acid

The invention discloses a demulsifying and detoxifying method of a gallium extracting system, which is characterized by comprising the following steps of: A. processing of materials and liquids: the elimination of suspended particles, the preprocessing of a high-iron liquid and the preprocessing of a high-arsenic liquid; B. addition of a thinner and an improver in an extracting agent: adding 20-40 percent by volume of sulfonated kerosene as the thinner to reduce the viscosity of a load extracting agent, reducing emulsification and accelerating layering; adding 0.5-1 percent by volume of tributyl phosphate as the improver which can effectively inhabit the emulsification of a gallium extracting agent; and C. demulsification and detoxification in the extracting process: extracting by using a container or a pool, and inhabiting emulsification and accelerating detoxification by flexibly controlling and adopting the proper balance time and intensity of extraction, washing and reverse extraction. According to the operation of the method, the emulsifying and poisoning phenomena of the extracting agent in the gallium extracting process can be completely eliminated.

Owner:南京中锗科技有限责任公司

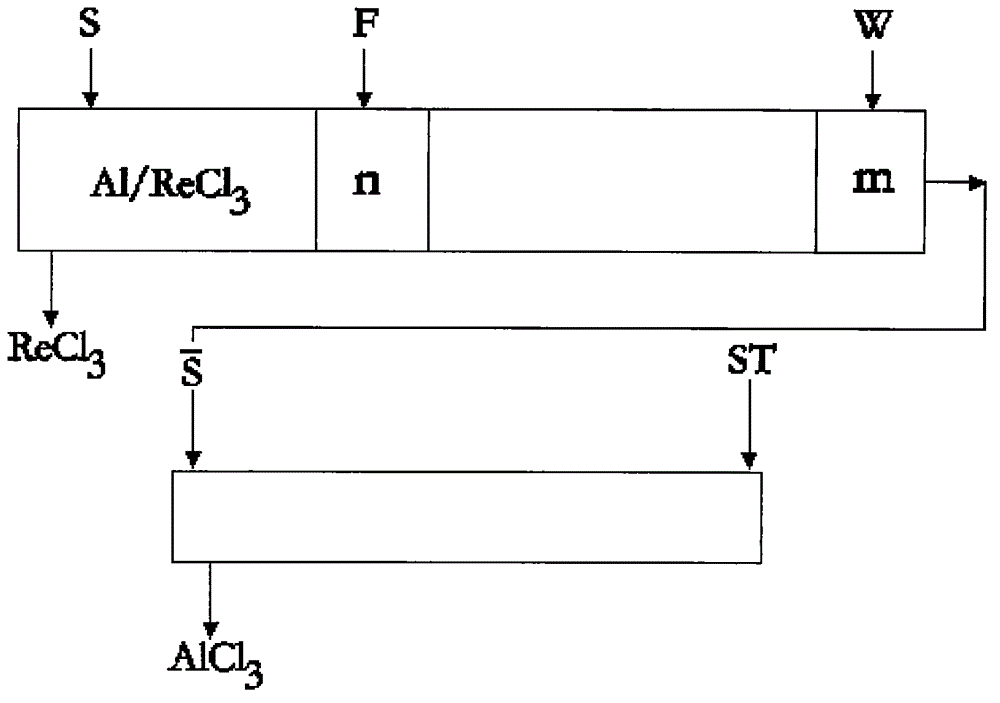

Molybdenum-rhenium separation trialkylamine leaching resin and preparation method thereof

InactiveCN102268547AFast solvent extractionLarge capacityProcess efficiency improvementOrganosolvIndustrial effluent

The invention relates to a trialkylamine extraction resin for molybdenum-rhenium separation and a preparation method thereof. The technical scheme adopted is: the trialkylamine extraction resin for molybdenum-rhenium separation uses epoxy resin as the skeleton, silica as the carrier, the extraction agent is N235, its content is 40%-50%, and the particle size is 100-200 mesh. The invention also discloses a preparation method of the extraction resin. The extraction resin provided by the invention not only has the characteristics of fast solvent extraction speed and large capacity, but also has the advantages of solid-liquid separation and no organic solvent loss pollution. The extraction resin prepared by the invention can effectively separate molybdenum and rhenium, and the molybdenum-rhenium separation coefficient is large, which not only brings into play the advantages of the solvent extraction process, but also eliminates the emulsification problem caused by extraction, and can be widely used in industrial eluents, industrial Separation and recovery of rhenium in wastewater and polluted rivers.

Owner:LIAONING UNIVERSITY

Method for refining and purifying N-acylamino acid or salt thereof

ActiveCN103408448AEliminate emulsificationImprove desalination performanceOrganic compound preparationCarboxylic acid amide separation/purificationEmulsionN acylaminoacid

The invention relates to a method for refining and purifying N-acylamino acid or salt thereof. The method comprises the following steps of: (1) adding acid to materials, namely the N-acylamino acid or the salt thereof, acidifying till the pH value is less than 2, heating up till the N-acylamino acid is molten, and stirring till the materials are uniformly dispersed or formed into an emulsified state; (2) cooling the materials obtained from the step (1) till the N-acylamino acid is crystallized or solidified, wherein an emulsion system is demulsified because substances which play surface activity roles become solids, and N-acylamino acid crystals are dispersed in water; (3) heating up to melt the N-acylamino acid crystals, forming an organic phase after aggregation, layering with a water phase, and standing to separate out a water layer. The method disclosed by the invention can be used for solving the problem of poor layering by utilizing a crystal demulsification method and can be used for obviously enhancing the desalting effect by thoroughly layering the water phase and the organic phase; according to the method provided by the invention, the refined N-acylamino acid or the salt thereof is low in salt content and less in impurity.

Owner:NANJING HUASHI NEW MATERIAL

Coking demulsifier and preparation method thereof

InactiveCN103951009AReduce oil contentPromote stratificationFatty/oily/floating substances removal devicesNon-miscible liquid separationDemulsifierInorganic ions

The present invention discloses a coking demulsifier, which comprises, by weight, 25-40% of a cationic surfactant, 5-10% of a dispersant, 5-10% of a wetting agent, 10-20% of a corrosion inhibitor, and the balance of water. The present invention further discloses a preparation method for the coking demulsifier. According to the present invention, rapid demulsification of the delayed coking apparatus oil-water separation tank can be achieved, and the oil content in the discharged water can be significantly reduced; the water is clear after demulsification; corrosion of the water body on equipment is reduced; and the coking demulsifier does not contain inorganic ions, and does not affect the existing water system.

Owner:宜兴汉光高新石化有限公司

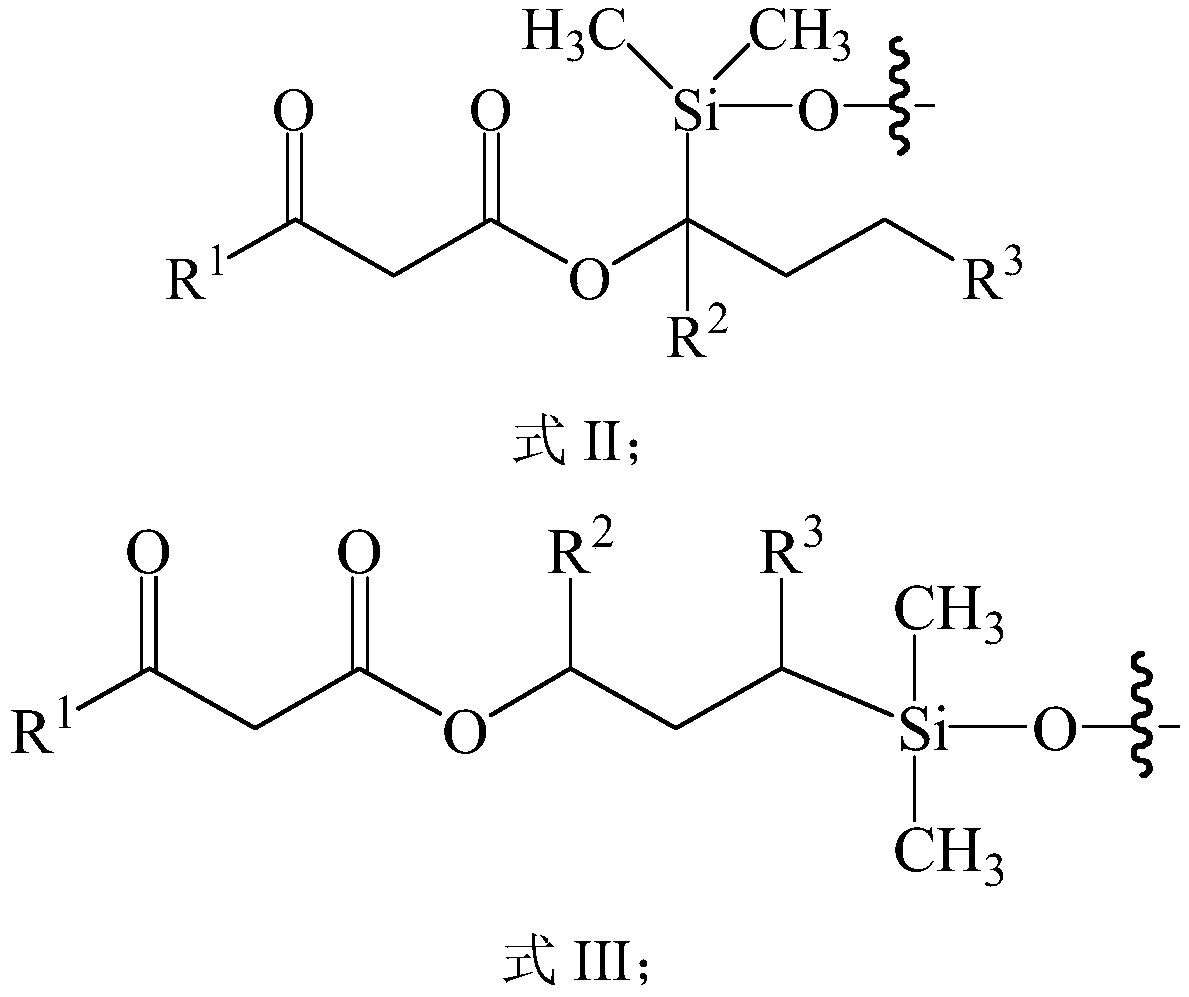

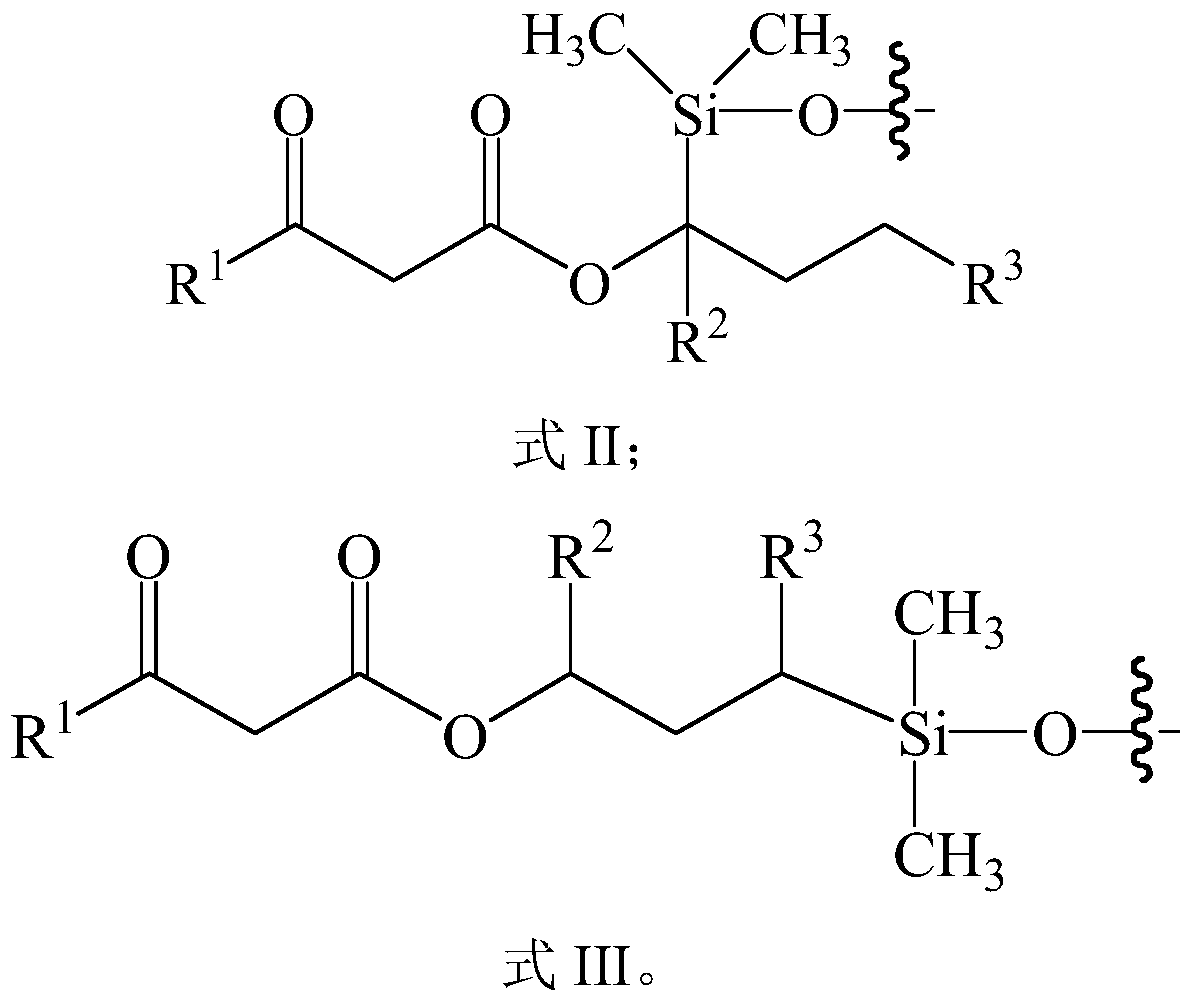

Modified MQ resin, and preparation method and application thereof

The invention provides a modified MQ resin, and a preparation method and an application thereof. The modified MQ resin comprises a compound with a structure represented by formula I; and in the formula I, MA is selected from a functional group containing a beta-dicarbonyl group, MH is selected from dimethyl siloxane, M is selected from trimethyl siloxane, m is selected from 0.02 to 0.3, n is selected from 0.05 to 0.8, a is selected from 0.4 to 1.4, and m + n + a is greater than 0.6 and less than 1.6. The modified MQ resin provided by the invention has very good cohesiveness and good mechanicalstrength, so that the modified MQ resin provided by the invention is a cohesive reinforced modified MQ resin, the manufacturing process of the packaging adhesive can be simplified, and the productioncost of the packaging adhesive is reduced.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Method for extracting lithium from brine

InactiveCN112063857AEliminate emulsificationEase of industrial applicationProcess efficiency improvementPhysical chemistryPhosphoric acid

The invention discloses a method for extracting lithium from brine. According to the method, tributyl phosphate, an amide compound and a diluent are used as extraction agents and ferric salt as a co-extraction agent to extract the brine. The method comprises the following steps of: (1) preparing the co-extraction agent into a solution to obtain a co-extraction agent solution; carrying out mixed extraction on the co-extraction agent solution, the tributyl phosphate and the diluent, and separating to obtain a first organic phase; (2) adding the amide compound, the tributyl phosphate and the diluent into the first organic phase to obtain a second organic phase; and (3) mixing the second organic phase with the brine, extracting, and separating to obtain a lithium-containing extracting solution. According to the method for extracting the lithium from the brine, an emulsification phenomenon easily occurring during extraction of the tributyl phosphate and the amide compound can be eliminated,smooth operation of an extraction process is ensured, application limitation of an amide extraction agent is reduced, corrosion condition of extraction equipment during extraction can be reduced, andthe industrial application of the tributyl phosphate and the amide compound as the extraction agent is facilitated.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

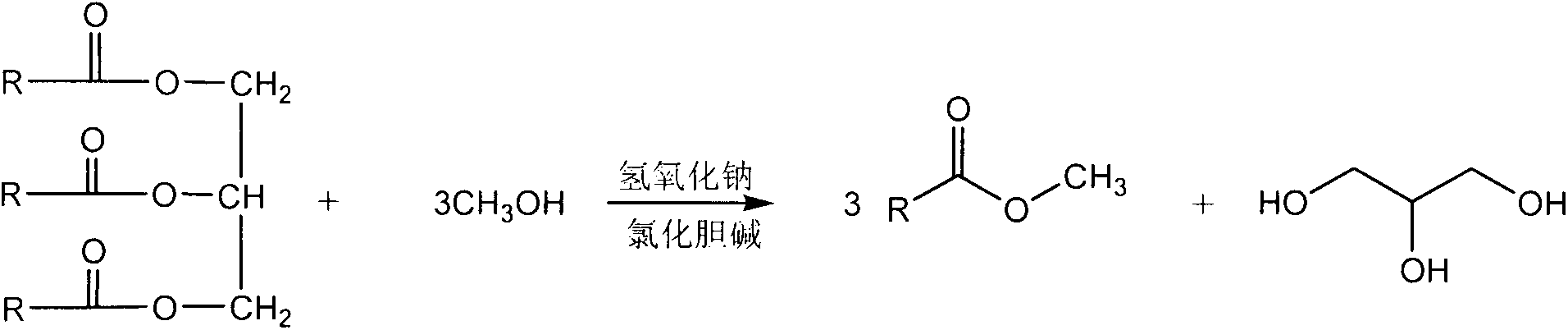

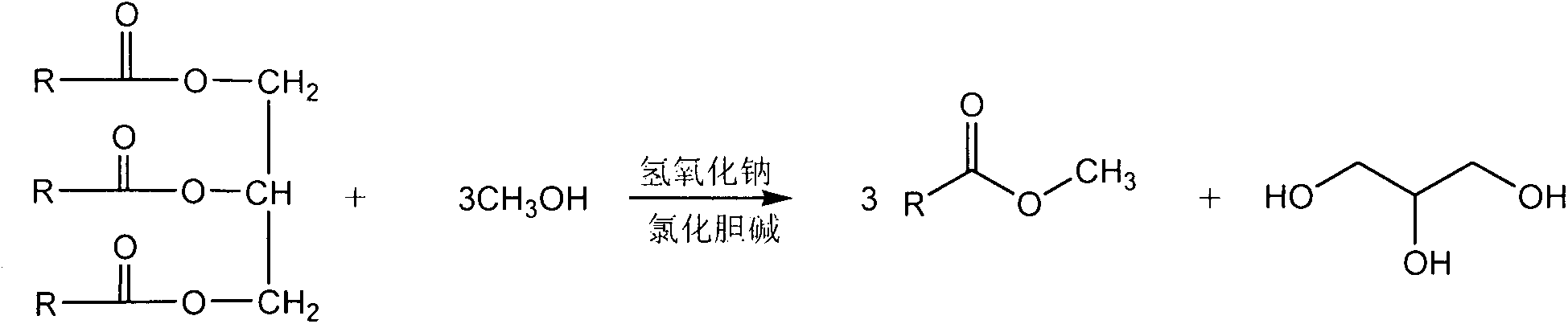

Method for preparing biodiesel through inducing eutectic system on site

InactiveCN103525562AEliminate emulsificationSimple processFatty acid esterificationBiofuelsEmulsionMethanol

The invention discloses a method for preparing biodiesel through inducing a eutectic system on site. The method comprises the steps of stirring and heating vegetable oil and methanol under normal pressure to obtain biodiesel. The method disclosed by the invention has the advantages that firstly, choline chloride serves as an inductive agent of the eutectic system, so that the emulsion phenomenon is eliminated and the process flow is simplified; secondly, the reaction condition is mild and the reaction can be carried out under normal pressure and under the condition of methanol backflow temperature; thirdly, a sodium hydroxide catalyst is adopted and the catalyst is low in cost, high in activity and little in consumption; fourthly, the product is high in purity and little in impurity; fifthly, the eutectic system and the product are easily separated after the reaction is completed, so that the system is easily recycled and the method is friendly to the environment.

Owner:CHANGZHOU UNIV

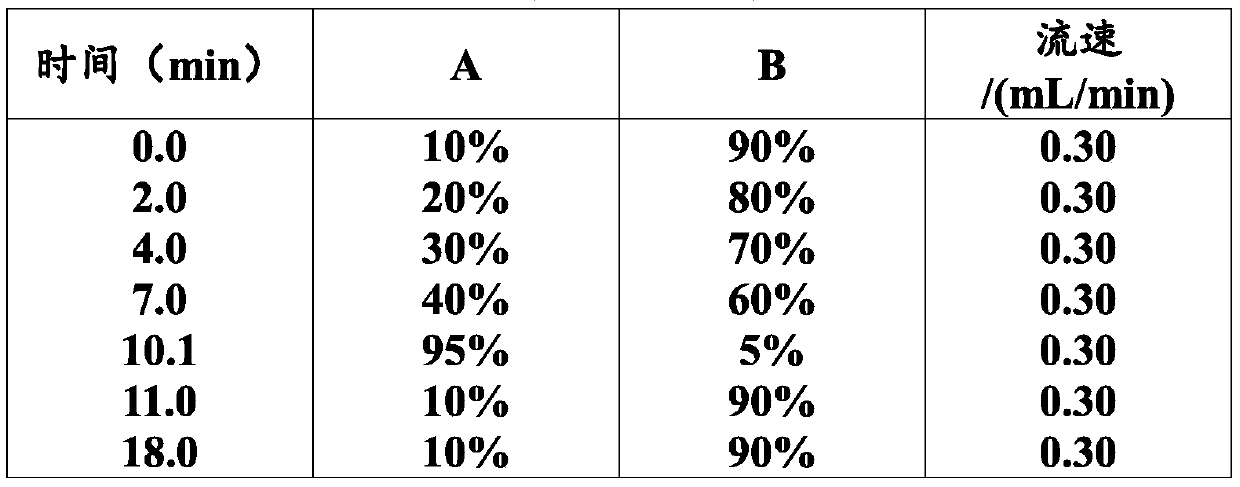

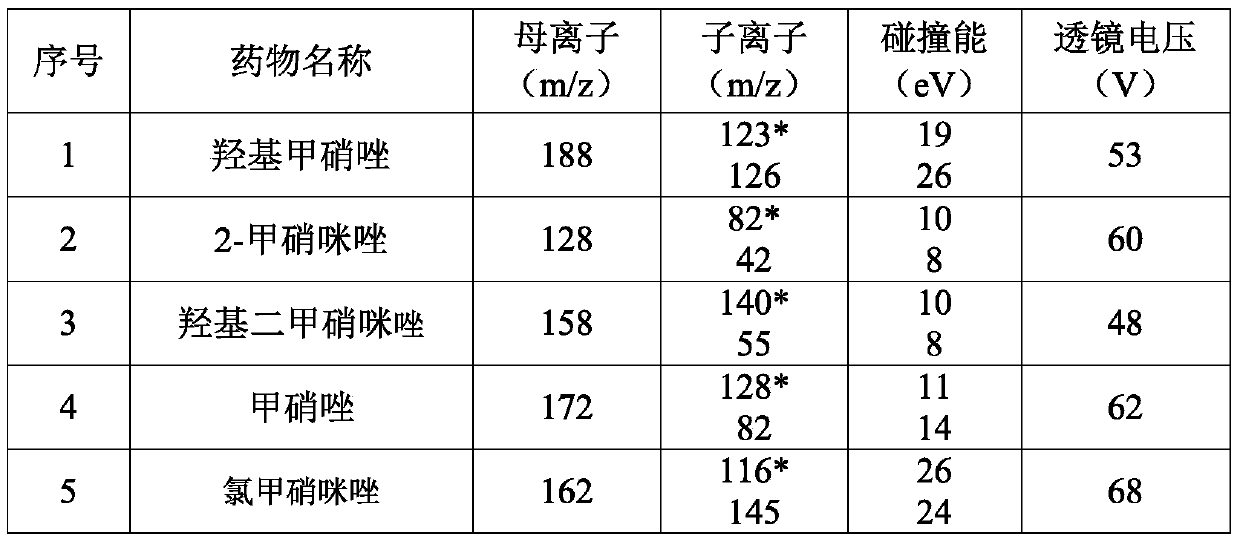

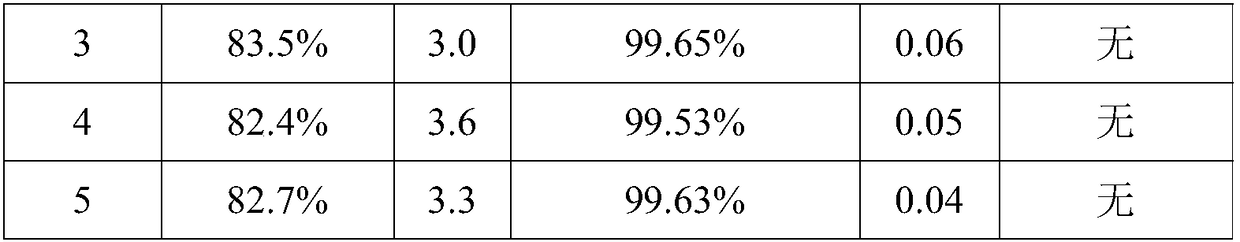

Method for detecting antibiotic residues in milk

A method for detecting antibiotic residues in milk comprises the following steps: (1) the milk is placed in a centrifuge tube, a demulsifier, ethyl acetate and a phosphate buffered solution are added sequentially, a mixture is subjected to ultrasonic extraction, an extract is centrifuged, and a liquid to be purified is obtained; (2) the liquid to be purified is transferred to a solid-phase extraction column for purification, and an eluent is collected; the eluent is blown with nitrogen in a water bath until the eluent is almost dry, an aqueous acetonitrile solution is added, the materials are mixed on a turbine mixer, a mixture passes through a millipore filter, and a filtrate is to be detected; (3) an LC-MS (liquid chromatography-mass spectrometry) method is used for determination and confirmation, and an external standard method is used for quantification. According to the method for detecting the antibiotic residues in the milk, the accuracy of a detection result can be improved effectively, and beneficial guarantee is provided for food safety.

Owner:ZHONGBIAO TESTING HENAN SERVICE +1

A kind of method for preparing 2,5-dichloronitrobenzene by continuous nitration

ActiveCN106083596BOptimize process flowWith automatic separation functionNitro compound preparationThree stageNitration

The invention discloses a method for preparation of 2, 5-dichloronitrobenzene by continuous nitration. The method comprises the steps of: adopting three-stage kettle type continuous reaction, adding sulfuric acid, nitric acid and p-dichlorobenzene in an extraction kettle into a first stage nitrification kettle simultaneously to carry out nitrification reaction, letting nitrification liquid enter a next stage nitrification kettle through self-carried raisers of all nitrification kettles in order to react, at the end of reaction in a third stage nitrification kettle, separating an oil phase and an acid phase, carrying out neutralization, washing and dehydration on the oil phase so as to obtain 2, 5-dichloronitrobenzene, internally recycling part of waste acid in the acid phase back to the first stage nitrification kettle, letting the residual waste acid enter an extraction kettle, and performing p-dichlorobenzene extraction, and then conducting separation to obtain acidic p-dichlorobenzene and extracted waste acid, concentrating the extracted waste acid into concentrated sulfuric acid, and making the concentrated sulfuric acid and acidic p-dichlorobenzene enter the first stage nitrification kettle for recycling. The method provided by the invention adopts automation control, cancels a mixed acid preparation procedure, simplifies the technological process, can realize continuous nitrification reaction, continuous nitrification liquid separation and continuous waste acid extraction.

Owner:江苏拓孚工程设计研究有限公司

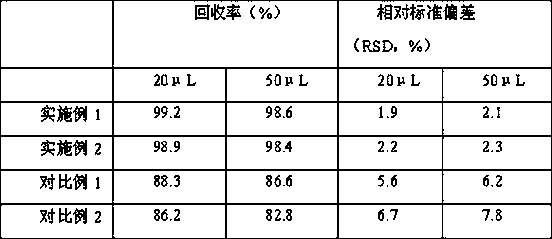

Quick detection method of acrylamide

ActiveCN110208439AAccurate measurementImprove solubilityComponent separationSodium acetateNitrogen gas

The invention discloses a quick detection method of acrylamide. The method comprises the following steps: coarsely grinding and ultrasonically treating the sample; adding a n-hexane solution in the treated sample, performing ungrease treatment, abandoning n-hexane phase to obtain a to-be-extracted sample; taking a sodium chloride solution and a sodium acetate solution to perform extraction; performing purification treatment, adding carrez reagent I and carrez reagent II in the treated sample, standing, centrifuging, taking supernatant to pass through a SPE column, collecting the to-be-detectedsample solution obtained after filtering; concentrating effluent to nearly dry under the nitrogen flow; and analyzing by using liquid chromatography-mass spectrum / mass spectrometer. The quick detection method disclosed by the invention is high in detection accuracy, and can further promote the acrylamide to dissolve in the extraction solvent when the emulsification phenomenon is eliminated; the effect for removing particles, oils and like impurities are good, the blocking in an extraction column is avoided, the detection limit is low, the determination precision is high, and the acrylamide amount in the sample can be more precisely determined.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

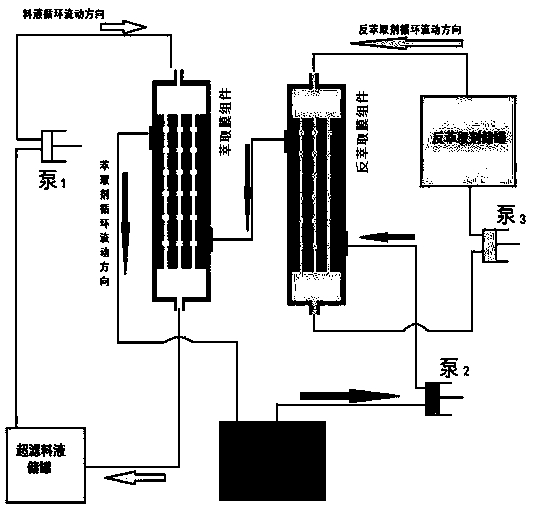

Method for chemically extracting purified water-soluble natural organic substances by solid film

ActiveCN109731368ASolve potential safety hazardsReduce industrial wastewater dischargeLiquid solutions solvent extractionAmount of substanceChemistry

The invention discloses a method for chemically extracting purified water-soluble natural organic substances by a solid film. Based on an ultra-filtration-solid film extraction coupling technique, chemical extraction is combined with the ultra-filtration-solid film extraction coupling technique, so that chemical reaction among chemical extraction agents and functional groups of separated substances is implemented to form an extraction complex which can dissolve in an organic phase and is transferred to the organic phase, high separating selectivity is achieved, existence forms of the separatedsubstances in a water phase and the organic phase are different, the concentrations of the separated substances in an oil phase and the water phase and distribution coefficients of the separated substances in the oil phase and the water phase are unrelated, and the extraction rate of the separated substances is only related to the solubility degree of the extraction complex in the organic phase,so that the method can efficiently extract target material plant extracts with low concentration. The method is used for membrane extraction processes, ultra-filtration liquid, back-extracts and extracts are consistently cycled, more efficient and accurate extraction is achieved, and industrial operation is easily implemented.

Owner:GANSU UNIV OF CHINESE MEDICINE

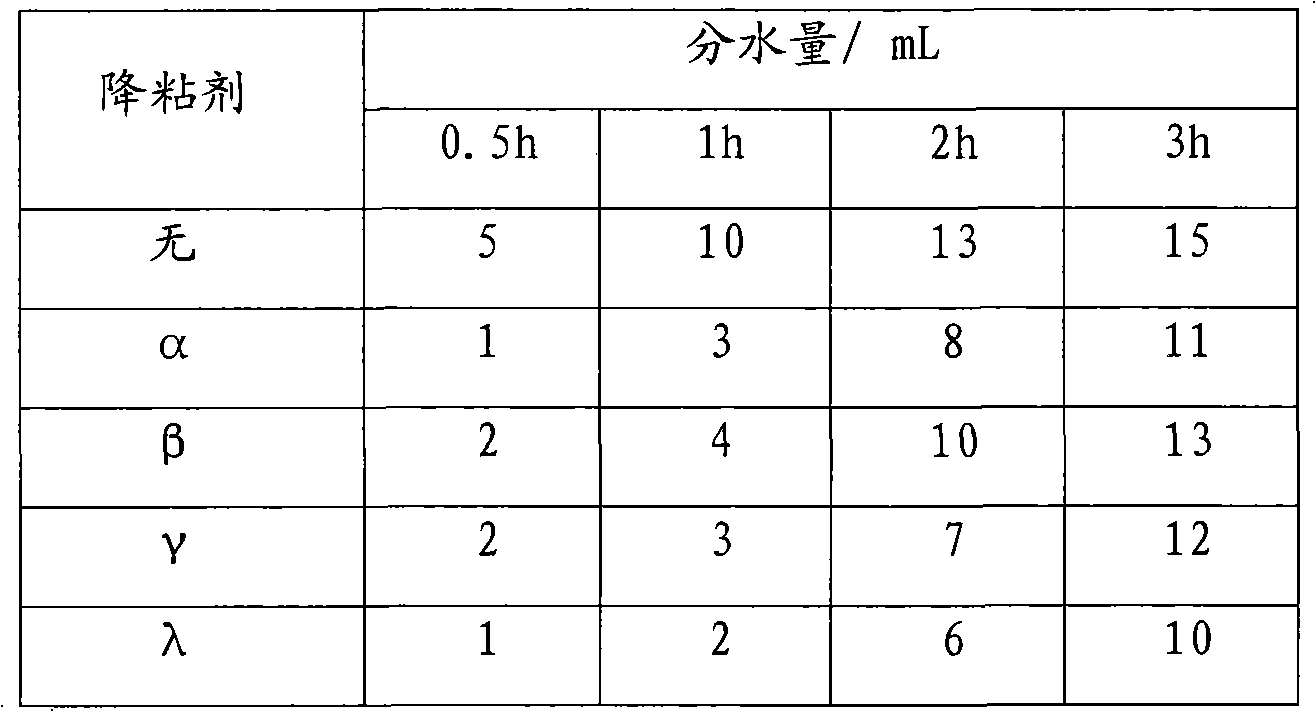

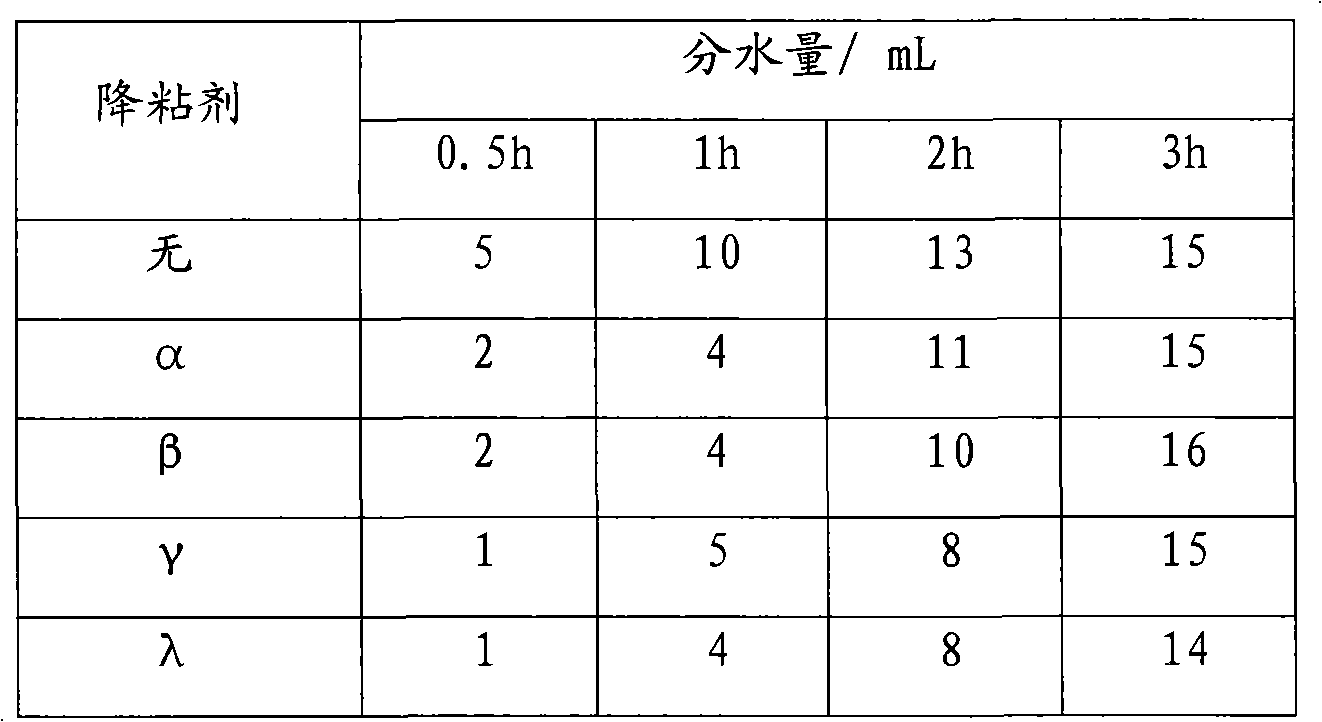

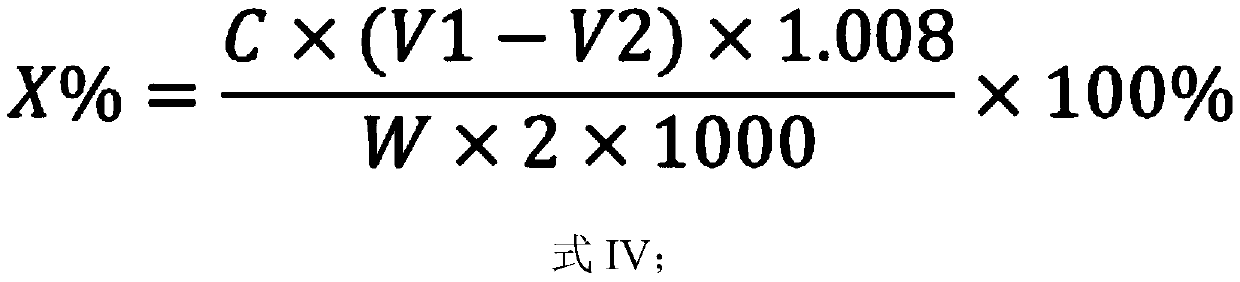

Dehydration method of oilfield produced fluid

ActiveCN102952566AImprove the bactericidal effectEliminate emulsificationDewatering/demulsification with chemical meansReducerCis-Butenedioic Acid

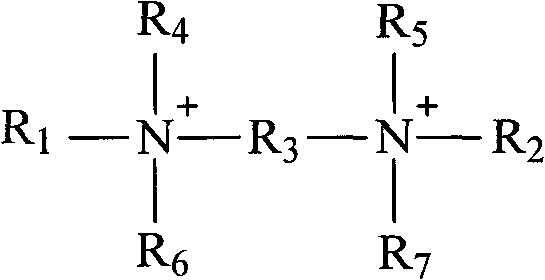

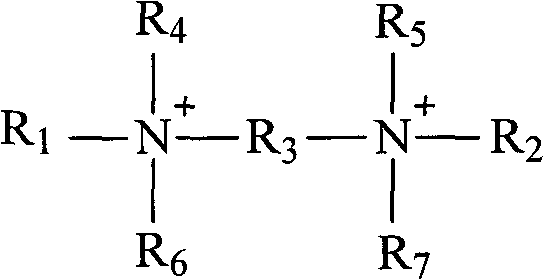

The invention relates to a dehydration method of oilfield produced fluid. According to the invention, oilfield produced fluid, quaternary ammonium salt and a demulsifying agent are mixed, such that demulsification dehydration is carried out. The oilfield produced fluid contains an emulsification viscosity reducer. According to the mass of the oilfield produced fluid as a reference, the dosage of quaternary ammonium salt is 10-300ppm. The cation portion of the quaternary ammonium salt has a structure represented by the formula below. R1 and R2 can be the same or different, and R1 and R2 are C8-C22 alkyl or C8-C22 substituted alkyl; R4, R5, R6, and R7 can be the same or different, and R4, R5, R6, and R7 are C1-C4 alkyl, C1-C4 alkoxy, polyoxyethylene with polymerization degree of 1-20, or polyoxyethylene / polyoxypropylene with polymerization degree of 1-20; and R3 is C2-C8 alkylene or diethylene maleate.

Owner:CHINA PETROLEUM & CHEM CORP +1

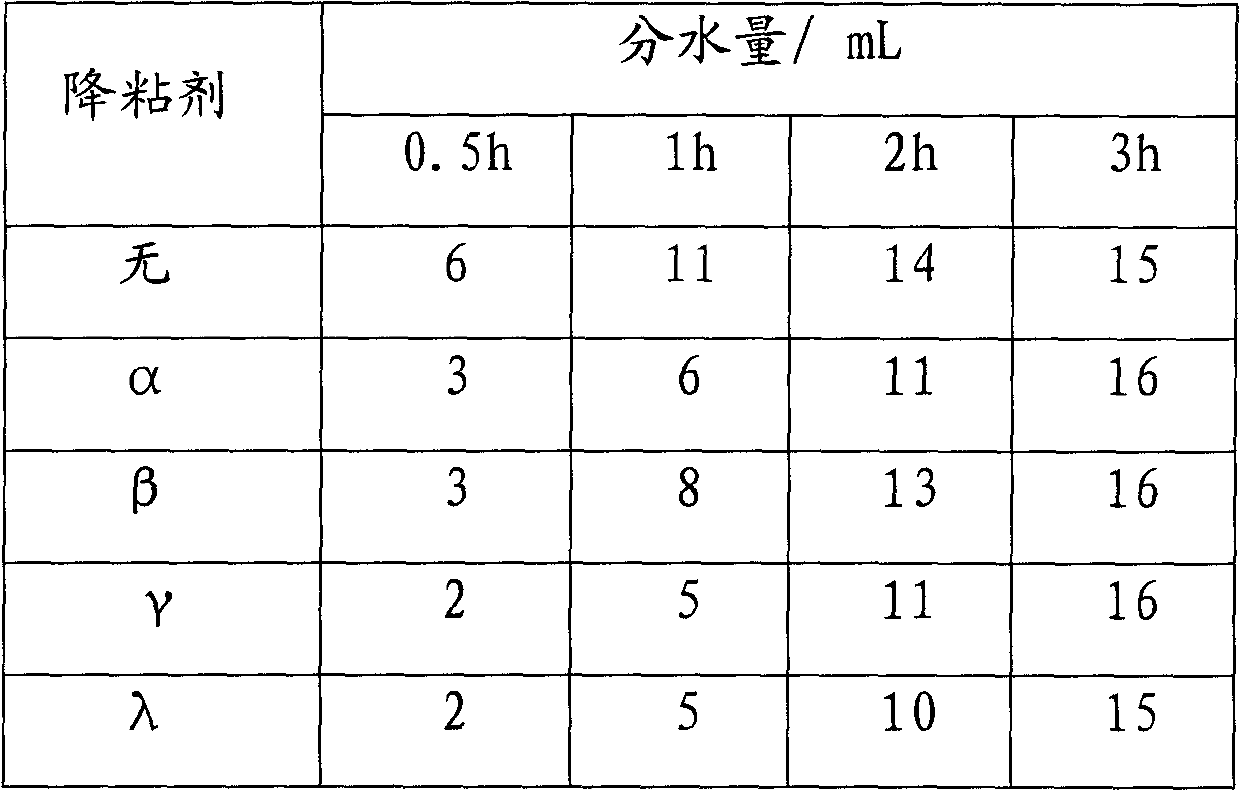

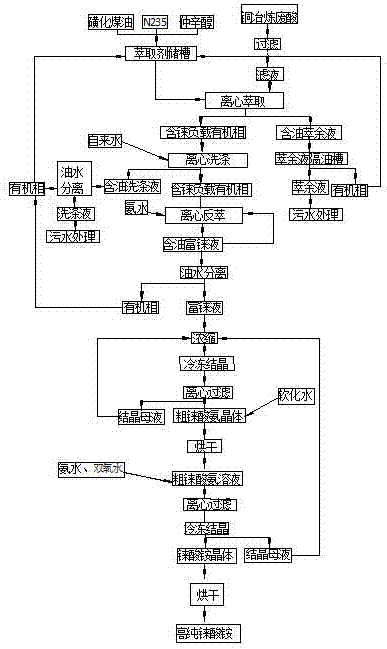

Novel process for recovering metallic rhenium from copper smelting waste acid

InactiveCN107460320AReduce recycling costsRealize online automatic controlProcess efficiency improvementRheniumAutomatic control

The invention relates to a novel process for recovering metallic rhenium from copper smelting waste acid. The novel process comprises the following steps: through pretreatment, centrifugal extraction, centrifugal washing, centrifugal reverse extraction, concentration, freezing crystallization and recrystallization, so that valuable metallic rhenium in the copper smelting waste acid is recovered, and a high purity ammonium rhenate product is obtained; and meanwhile, the on-line and automatic PLC control is realized in the overall technological process design. With the adoption of the novel process for recovering metallic rhenium from the copper smelting waste acid provided by the technical scheme of the invention, the following benefits are achieved: 1, the technological process is short, the operation is simple and convenient; 2, the equipment floor area is small, the investment cost is low, and the cost can be controlled at RMB1450 Yuan / kg of ammonium rhenate; 3, the degree of automation is high, and the on-line monitoring and controlling are realized; 4, compared with the conventional box-type extraction process, the novel process has the advantages as follows: the extraction efficiency is high, the organic phase retention volume is small, the extraction balance in all time periods is achieved, the real-time start / stop is realized, the treatment capacity is high, the emulsification is eliminated, the on-line cleaning is realized, the recovery rate of valuable metallic rhenium is high, and the separation effect of valuable metallic rhenium from metallic impurities is good; and 5, the sewage quantity is small, the secondary pollution is avoided, and the environmental friendliness is achieved.

Owner:铜陵有色金属集团股份有限公司

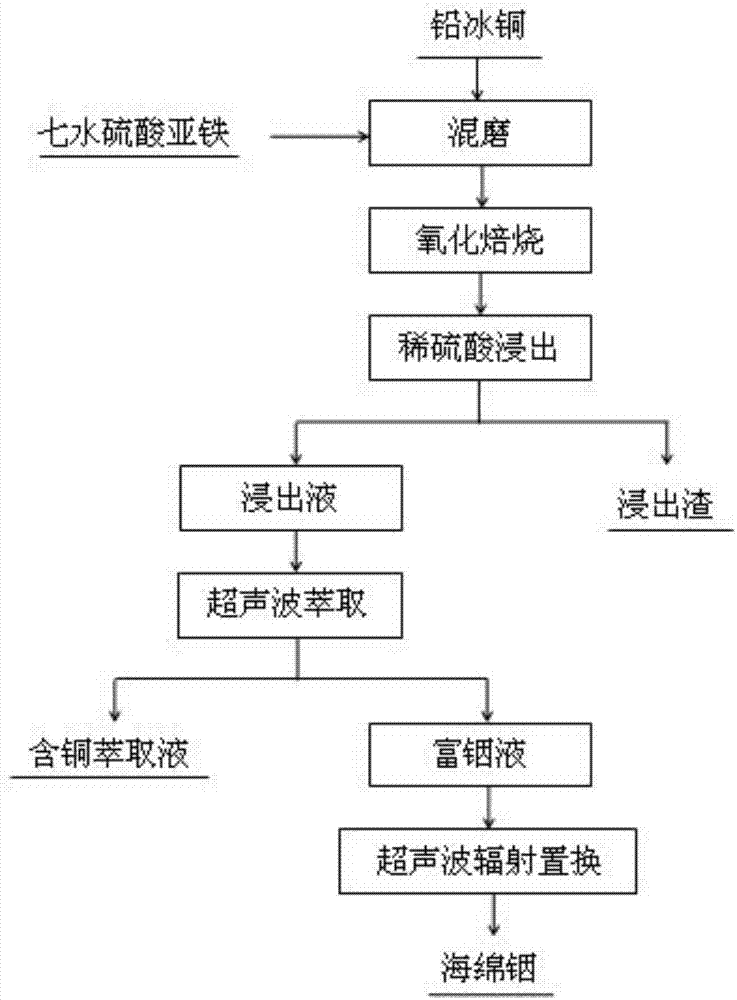

Method for extracting indium from lead copper matte

ActiveCN107034368AHigh recovery rateEliminate emulsificationProcess efficiency improvementIndium metalPregnant leach solution

The invention discloses a method for extracting indium from lead copper matte. The method comprises the following steps that A, the lead copper matte and ferrous sulfate are mixed and ground, and the mass ratio of the lead copper matte to the ferrous sulfate is (0.1-1.5):1 according to the mass ratio; B, the mixed and ground materials are put into a tube furnace to be subjected to oxidizing roasting through oxygen containing gas, and roasting matter is obtained; C, the roasting matter is leached through dilute sulphuric acid, then filtering and washing are carried out, and leaching residues and lixivium are obtained; D, the lixivium is subjected to indium extraction under ultrasonic radiation, and copper containing extraction liquid and indium-enriched liquid are obtained; and E, metal replacement is adopted by the indium-enriched liquid under ultrasonic radiation to obtain sponge indium. According to the method, the leaching rate and the recovery rate of the indium are increased; meanwhile, ultrasonic waves are introduced in the extraction process, and the emulsification problem of the indium in the extraction process is eliminated; the ultrasonic waves are introduced in the indium metal replacement process, the replacement effect is improved, and the replacement time is shortened; and the whole-process technology is simple, industrialization can be achieved easily, and good industrial application prospects are achieved.

Owner:昆明寰世科技开发有限公司

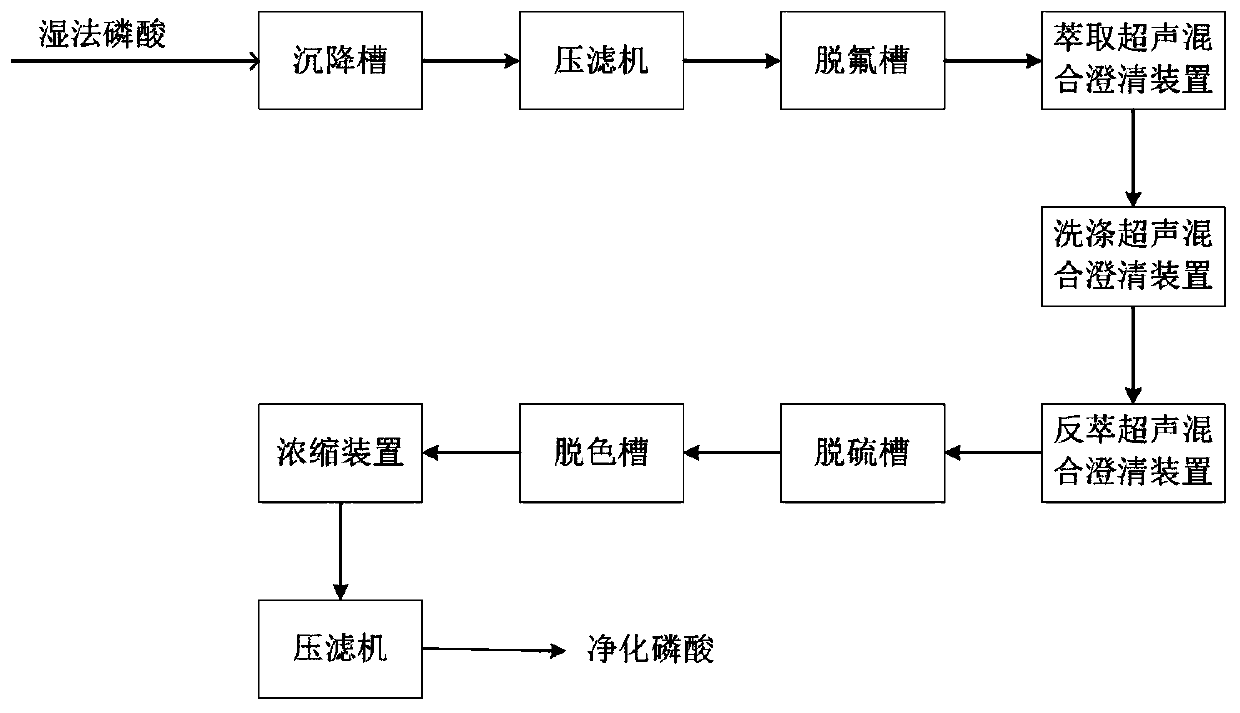

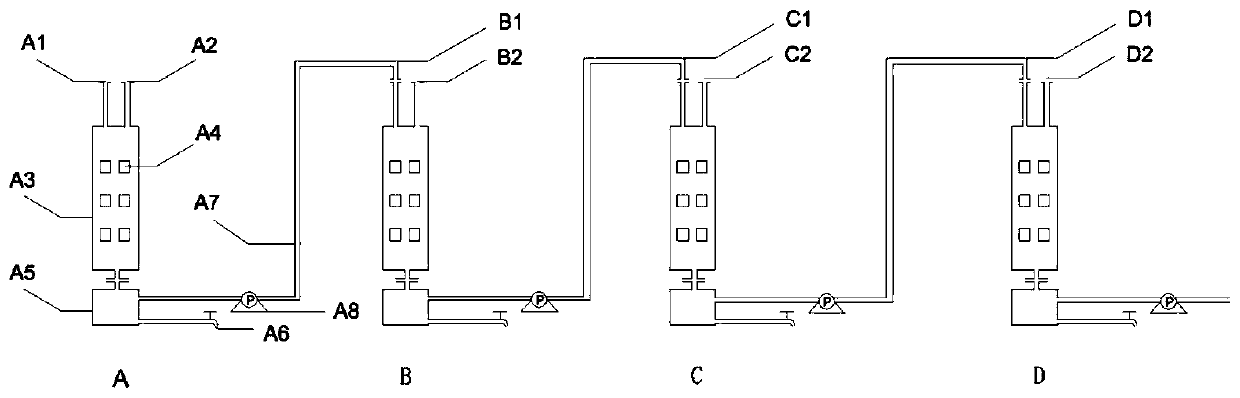

Production method for purifying low-concentration wet-process phosphoric acid, and purification apparatus thereof

ActiveCN110357060AAchieve purificationImprove removal effectPhosphorus compoundsOrganic solventThree stage

The invention relates to a production method for purifying low-concentration wet-process phosphoric acid, and a purification apparatus thereof, wherein food-grade phosphoric acid is prepared from low-concentration wet-process phosphoric acid by using a solvent extraction method. According to the method, the process comprises: pretreatment, extraction, washing, back extraction, defluorination, andposttreatment; the organic solvent for extraction is one or a plurality of materials selected from dibutyl butanephosphonate, dimethyl heptyl methyl phosphonate, diisooctyl isopropyl phosphonate and butyl dibutyl phosphonate; a ratio of extractants is adjusted; the extraction section, the washing section and the back extraction section are completed by at least three stages of ultrasonic mixer clarification devices; and during the washing, quaternary ammonium salt cations [N(C2H5)4]<+> (or [N(C3H7)4]<+>) are added to the washing liquid to improve the SO4<2-> removing efficiency. According to the present invention, the method and the apparatus are used in the industrial production of food grade phosphoric acid from wet-process phosphoric acid so as to significantly shorten the purificationprocess, reduce the consumption, and ultimately reduce the production cost of the entire process.

Owner:广西川金诺化工有限公司

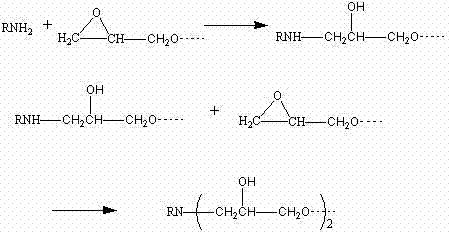

High-efficiency oil slurry settling agent

PendingCN110384957AImprove function and effectMicrospheres are stableSedimentation separationIonEmulsion

The invention relates to a high-efficiency oil slurry settling agent, belonging to the technical field of settling agents. According to the invention, brewer's grains are subjected to pulverization, nitrification, mixing with triethyl citrate and other treatment to obtain a component with a high film-forming property and a unique chelate structure, and the component is adsorbed onto the surfaces of particles through formation of hydrogen bonds by a part of ionic groups and the particles and plays a bridging role among the particles so as to allow settled flocs to be generated and settling effect to be improved; active resin is produced from tert-butylphenol and tetraethylenepentamine, and is used as an initiator for anionic ring-opening polymerization with epoxypropane so as to produce polyether substances, so an interfacial film is allowed to become loose, the strength of a droplet interface film is weakened or destroyed, and the stability of an emulsion is destroyed, thereby achieving the effects of coalescence, flocculation and sedimentation. The high-efficiency oil slurry settling agent of the invention solves the problem of poor sedimentation effect of commonly-used oil slurrysettling agent at present.

Owner:李嘉诚

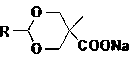

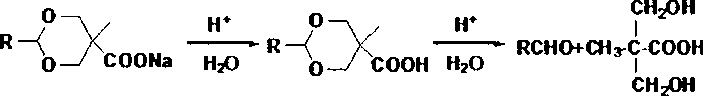

Easily separated degradable sodium carboxylate surfactant and preparation and performance thereof

InactiveCN103240033AEasy to synthesizeHigh yieldOrganic chemistryTransportation and packagingCarboxylateActive agent

The invention discloses an easily separated degradable sodium carboxylate surfactant and preparation and performance thereof. The invention discloses an easily separated degradable sodium carboxylate surfactant containing 1,3-dioxane. The surfactant is specifically 5-methyl-2-alkyl-1,3-dioxane-5-carboxylate and has the structural formula shown in the description, wherein a, R=C4H9; b, R=C5H11; c, R=C6H13; d, R=C7H15; e, R=C9H19; f, R=C10H21; and g, R=C11H23. The surfactant is convenient in synthesis, high in yield, small in surface tension and critical micelle concentration and wide in application temperature, serves as an emulsifying agent in an emulsion polymerization solution and is better than the traditional surfactant; and the surfactant is stable under neutral and alkaline conditions, can become sold to be separated out under the alkaline conditions, the separated solid is treated to become the original material which can be recycled, the unexpected foam and emulsification phenomena can be eliminated after the product action is exerted, and the surfactant is a novel environment-friendly product.

Owner:HUNAN UNIV OF SCI & ENG

Heavy inferior crude oil inorganic salt organic acid organic metal compound combined removal process

ActiveCN108117885AReduce energy consumptionGood demulsification effectTreatment with plural serial refining stagesHigh pressureOrganic compound

The invention relates to a heavy inferior crude oil inorganic salt organic acid organic metal compound combined removal process and belongs to the technical field of heavy inferior crude oil treatment. The heavy inferior crude oil inorganic salt organic acid organic metal compound combined removal process is characterized in that transformation is conducted on the basis of three-stage electric desalination, the first stage realizes removal of organic metal compounds and part of inorganic salt, the second stage realizes removal of organic acid and part of inorganic salt, the third stage realizes deep removal of inorganic salt, sewage after first-stage organic metal compound and inorganic salt removal and sewage after three-stage desalination treatment are introduced into a sewage treatmentsystem, sewage after secondary-stage organic acid and inorganic salt removal is introduced into a naphthenic acid recovering system, a naphthenic acid resource is recovered, and the high emulsion phenomenon which may occur in the electric removal process is treated by a high-voltage and high-frequency pulse electric field and by an emulsion layer liquid reinjection mode.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com