Demulsifying dehydration method of oilfield produced fluid

A production fluid and oilfield technology, applied in chemical dehydration/demulsification, etc., can solve problems such as hysteresis, achieve good effect, less equipment investment, and strong surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

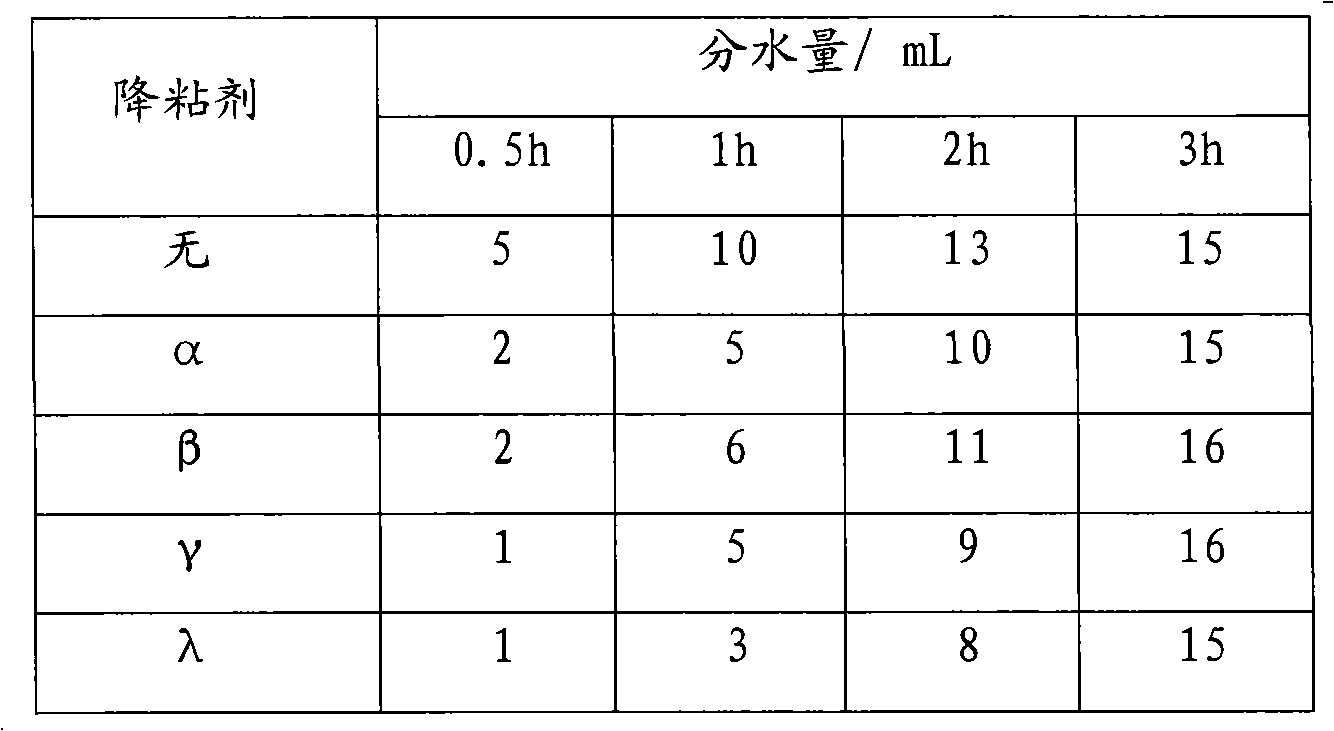

[0028] The water content of the produced fluid is 20%, the added amount of the emulsification viscosity reducer is 200 ppm, and the demulsification aid is dodecyl tributyl phosphorus chloride, and the added amount is 20 ppm. The results are shown in Table 1.

[0029] Table 1

[0030]

Embodiment 2

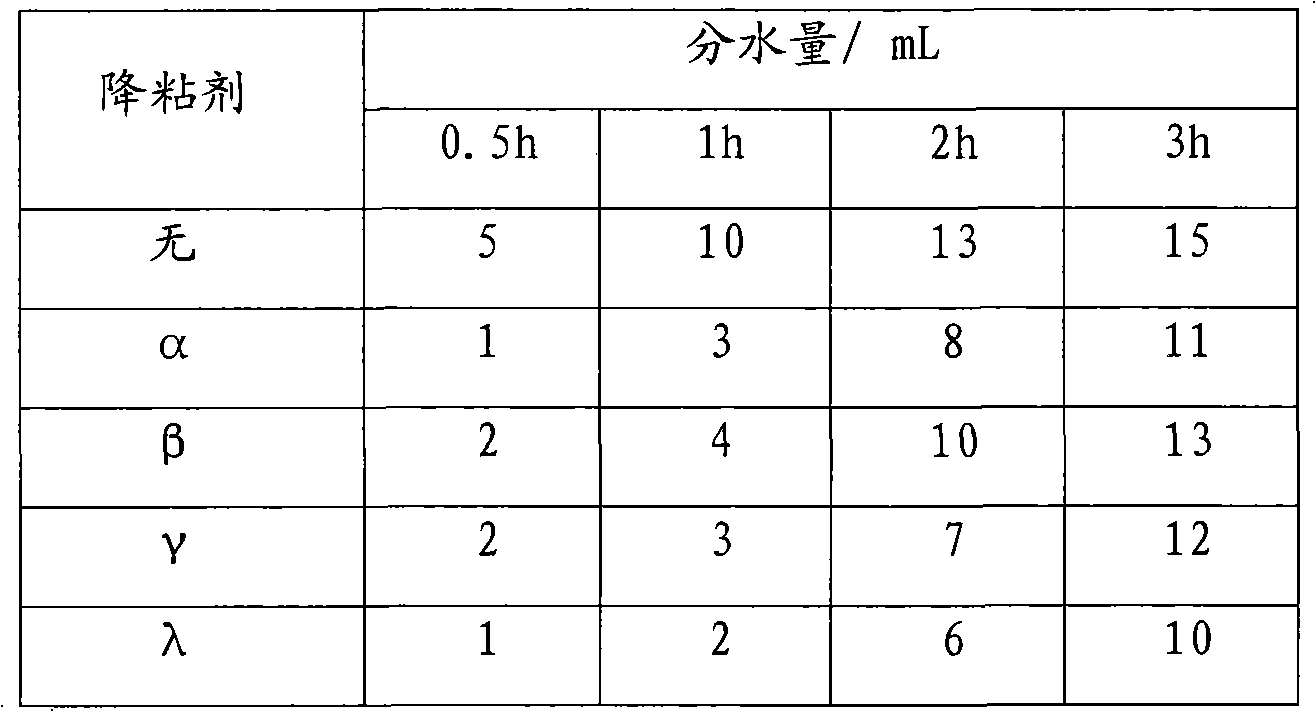

[0036] The water content of the produced fluid is 20%, the addition amount of the emulsification viscosity reducer is 300ppm, and the demulsification aid is tetradecyltriphenylphosphonium bromide, and the addition amount is 30ppm. The results are shown in Table 3.

[0037] table 3

[0038]

Embodiment 3

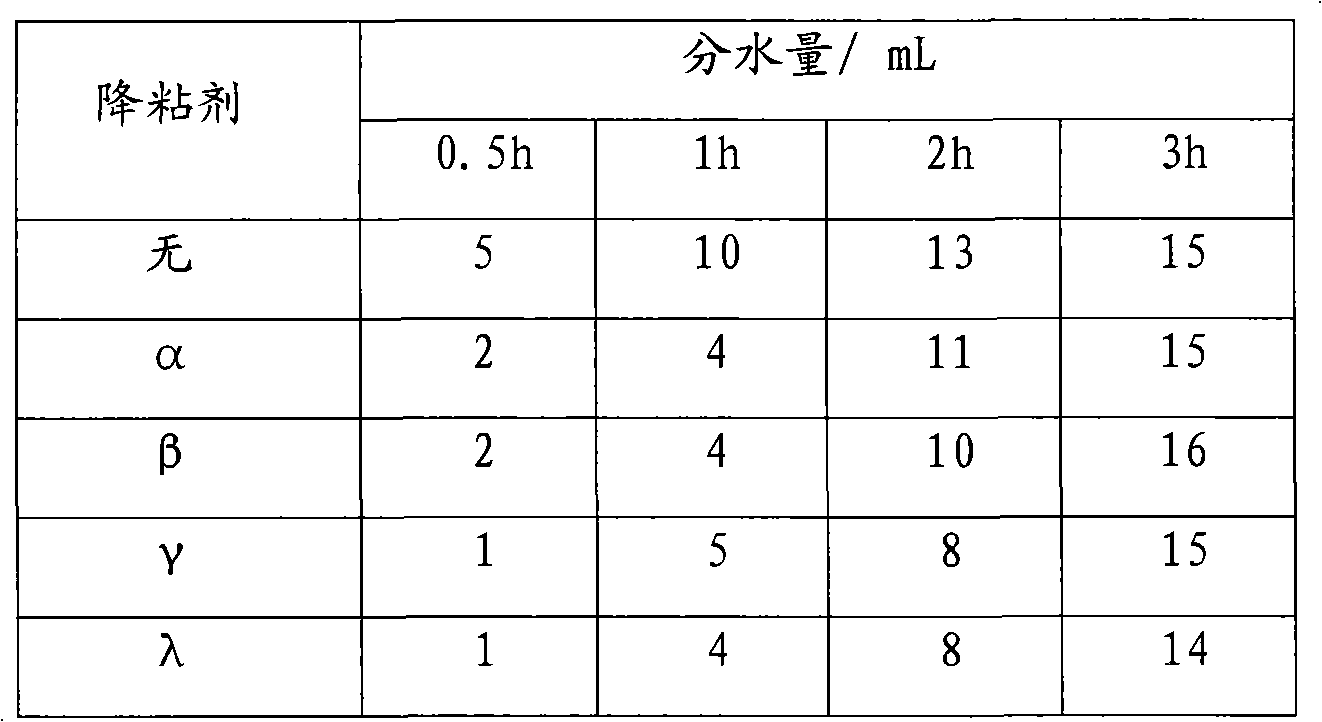

[0045] The water content of the produced fluid is 30%, the added amount of the emulsification viscosity reducer is 500 ppm, and the demulsification aid is dodecyloxymethyltributylphosphorus chloride, and the added amount is 50 ppm. The results are shown in Table 5.

[0046] table 5

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com