Heavy inferior crude oil inorganic salt organic acid organic metal compound combined removal process

An organometallic and combined removal technology, applied in the direction of only multi-stage series refining process treatment, etc., can solve the problems of catalyst deactivation, intensified crude oil emulsification, and difficulty in industrialization, so as to improve the demetallization effect and reduce the degree of emulsification , the effect of reducing the amount of alkali injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

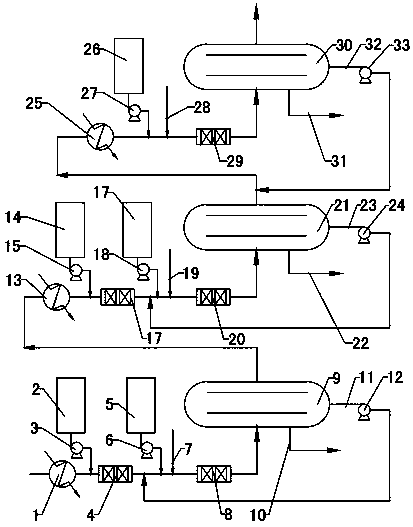

[0032] The demulsifier used in this example is an oil-soluble demulsifier compounded according to heavy and inferior crude oil products; the metal removal agent is obtained by compounding macromolecular chelating agents, coordination compounds and corrosion inhibitors; Composite obtained; the voltage of the high-voltage and high-frequency pulsed electric field used is 4kV, the frequency is 4kHz, and the pulse width ratio is continuously adjustable within the range of 0.1~1.0; the high-voltage and high-frequency pulsed electric field adopts double insulating composite material plates; the detection is pending Inorganic salt concentration, acid value, Ca content and Ni content in heavy and inferior crude oil are: 196.6mg / L, 4mg / g, 400μg / g, 40μg / g.

[0033] 1) The heavy and low-quality crude oil passes through the primary heat exchanger 1 to exchange heat to 285°C, joins the demetallizing agent pumped from the demetallizing agent tank 2 through the metal injection pump 3, and ente...

Embodiment 2

[0037] The process is different from Example 1 in that the voltage of the high-voltage and high-frequency pulsed electric field used is 3000V, the frequency is 7000Hz, and the pulse width ratio is continuously adjustable in the range of 0.1 to 1.0; the concentration of inorganic salts, Acid value, Ca content and Ni content are respectively: 200mg / L, 5mg / g, 500μg / g, 50μg / g;

[0038] After the treatment, the concentration of inorganic salts in the crude oil decreased to 2.9 mg / L, the acid value decreased to 0.51 mg / g, the Ca content decreased to 52 μg / g, and the Ni content decreased to 7 μg / g.

Embodiment 3

[0040] The process is different from Example 1 in that the voltage of the high-voltage and high-frequency pulsed electric field used is 20000V, the frequency is 1000Hz, and the pulse width ratio is continuously adjustable in the range of 0.1 to 1.0; the concentration of inorganic salts, Acid value, Ca content and Ni content are respectively: 198mg / L, 4.8mg / g, 450μg / g, 45μg / g;

[0041] After the treatment, the inorganic salt concentration of the crude oil decreased to 2.8 mg / L, the acid value decreased to 0.5 mg / g, the Ca content decreased to 50 μg / g, and the Ni content decreased to 6.3 μg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com