Method for extracting indium from lead copper matte

A technology of lead matte and ferrous sulfate, which is applied in the field of extracting indium from lead matte, can solve the problems of low yield, high cost, and large consumption of reagents, so as to improve the recovery rate of indium, facilitate industrialization, and improve the production efficiency of indium. The effect of leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

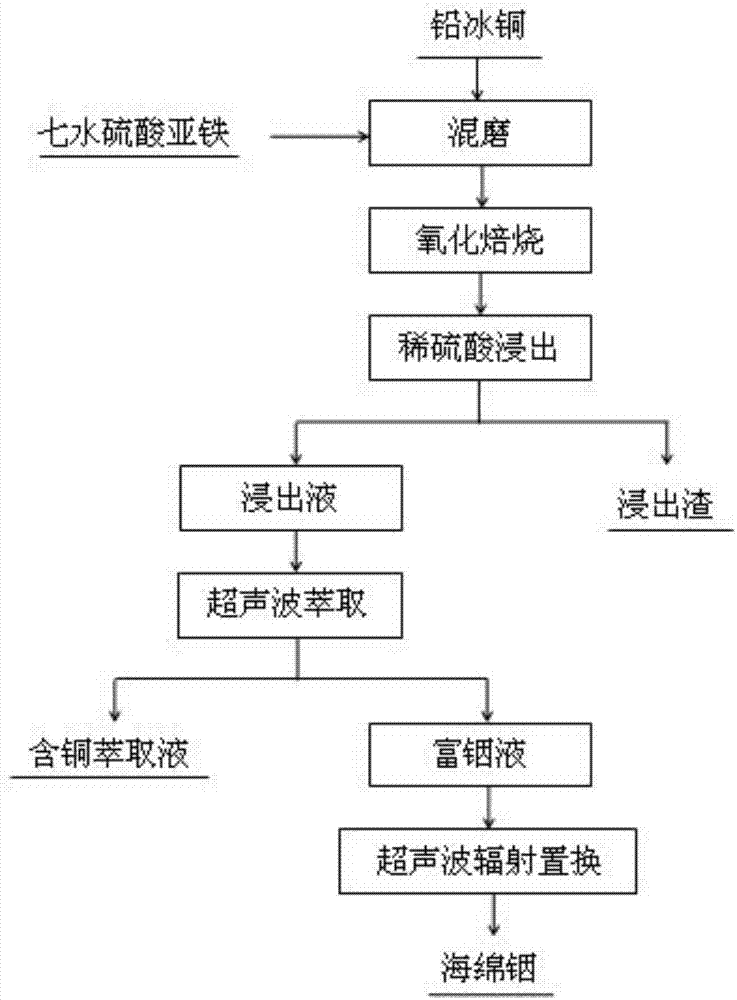

[0048] like figure 1As shown, weigh 1000g of lead matte, and the amount of ferrous sulfate heptahydrate added is 100% of the mass ratio of lead matte, that is, ferrous sulfate heptahydrate is also 1000g, mixed with a roller mill for 60min, and placed in a tube furnace Low-temperature heating and roasting with oxygen flow, the thickness of the material layer is controlled to 10mm, the roasting temperature is 600°C, and the roasting time is 2h; the obtained roasted product is leached with 20% (mass percentage, the same below) dilute sulfuric acid, the leaching time is 4h, and the leaching temperature is 95°C , to obtain the leaching solution and leaching residue; for the leaching solution, extract indium under ultrasonic radiation, the extraction agent is P204, the ratio (OA) is 1:1, the irradiation time is 5min, the extraction stage is 2, and then the organic phase and the aqueous phase are extracted. Separation, the loaded organic phase was back-extracted with 6mol / L hydrochlo...

Embodiment 2

[0050] like figure 1 As shown, take 1000g of lead matte, and the amount of ferrous sulfate heptahydrate added is 80% of the mass ratio of lead matte, that is, 800g of ferrous sulfate heptahydrate, mixed with a roller mill for 60min, and placed in a tube furnace. Oxygen-enriched low-temperature heating and roasting, the thickness of the material layer is controlled to 10mm, the roasting temperature is 550°C, and the roasting time is 1h; the obtained roasted product is leached with 30% dilute sulfuric acid, the leaching time is 3h, the leaching temperature is 70°C, and the leachate and leaching residue are obtained; For the leaching solution, extract indium under ultrasonic radiation, the extraction agent is P204, the ratio (OA) is 1:1, the radiation time is 6min, the extraction stage is 2, and then the organic phase and the aqueous phase are separated, and the organic phase is loaded with 6mol / L hydrochloric acid back extraction, the phase ratio (OA) is 10:1, and the number of...

Embodiment 3

[0052] like figure 1 As shown, take lead matte 1000g, the addition of ferrous sulfate heptahydrate is 60% of the mass ratio of lead matte, that is, ferrous sulfate heptahydrate is 600g, use a roller ball mill to mix and grind for 60min, and place it in a tube furnace Low-temperature heating and roasting with pure oxygen, the thickness of the material layer is controlled to 10mm, the roasting temperature is 650°C, and the roasting time is 1.5h; the obtained roasted product is leached with 50% dilute sulfuric acid, the leaching time is 3h, the leaching temperature is 85°C, and the leachate and leaching residue are obtained ; For the leachate, extract indium under ultrasonic radiation, the extraction agent is P507, the ratio (OA) is 1:1, the radiation time is 4min, the extraction stage is 2, and then the organic phase and the aqueous phase are separated, and the organic phase is loaded using Back extraction with 6mol / L hydrochloric acid, the phase ratio (OA) is 10:1, and the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com