Method for removing aluminum in rare-earth solution

A rare earth material liquid and solution technology, which is applied in the direction of improving process efficiency, can solve the problems of increasing production costs, difficulty in wastewater treatment, and many steps, and achieve the effects of eliminating emulsification, continuous production process, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

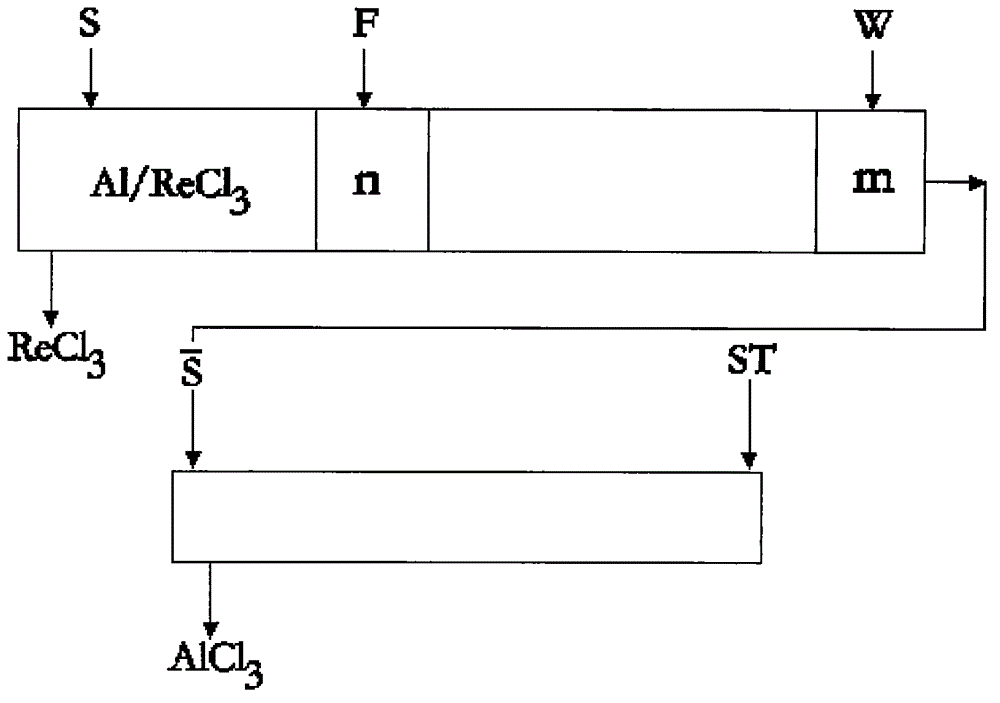

Image

Examples

Embodiment 1

[0017] The REO in the praseodymium neodymium rare earth feed liquid is 1.68mol / L, and the Al 2 o 3 It is 0.003~0.03mol / L. Using the method of fractional distillation extraction, the organic phase is saponified first, and then the above-mentioned feed liquid is extracted. The fractional distillation extraction process conditions are:

[0018] The organic phase is prepared as follows: naphthenic acid: isooctyl alcohol: the volume ratio of kerosene is 25%: 20%: 55%;

[0019] The degree of saponification of the organic phase is controlled at 0.1-0.5mol / L;

[0020] Fractional extraction flow ratio is: organic phase: rare earth feed liquid: lotion: reverse liquid volume ratio is 40-60:50-80:3-20:1-3L / min, wherein the acidity of the lotion is 0.1-3.0mol / min L, the acidity of the reverse liquid is 1.0-4.5mol / L;

[0021] Fractional extraction stage distribution is as follows: extraction section: washing section: stripping section stage ratio is 8:10:7;

[0022] The extraction mixi...

Embodiment 2

[0026] The REO in the praseodymium neodymium rare earth feed liquid is 1.68mol / L, and the Al 2 o 3 It is 0.003~0.03mol / L. Using the method of fractional distillation extraction, the organic phase is saponified first, and then the above-mentioned feed liquid is extracted. The fractional distillation extraction process conditions are:

[0027] The organic phase is prepared as follows: naphthenic acid: isooctyl alcohol: the volume ratio of kerosene is 25%: 20%: 55%;

[0028] The degree of saponification of the organic phase is controlled at 0.1-0.5mol / L;

[0029] Fractional extraction flow ratio is: organic phase: rare earth feed liquid: washing liquid: reverse liquid volume ratio is 40-60: 80-120: 3-20: 1-3L / min; acidity of washing liquid is 0.1-3.0mol / L , the acidity of the reverse liquid is 1.0-4.5mol / L;

[0030] Fractional extraction stage distribution is as follows: extraction section: washing section: stripping section stage ratio is 8:10:7;

[0031] The extraction mix...

Embodiment 3

[0035] The REO in the praseodymium neodymium rare earth feed liquid is 1.68mol / L, and the Al 2 o 3 It is 0.003~0.03mol / L. Using the method of fractional distillation extraction, the organic phase is saponified first, and then the above-mentioned feed liquid is extracted. The fractional distillation extraction process conditions are:

[0036] The organic phase is prepared as follows: naphthenic acid: isooctyl alcohol: the volume ratio of kerosene is 25%: 20%: 55%;

[0037] The degree of saponification of the organic phase is controlled at 0.1-0.5mol / L;

[0038] Fractional extraction flow ratio is: organic phase: rare earth feed liquid: lotion: reverse liquid volume ratio is 40-60: 120-200: 3-20: 1-3L / min; acidity of lotion is 0.1-3.0mol / L , the acidity of the reverse liquid is 1.0-4.5mol / L;

[0039] The distribution of fractional extraction stages is as follows: extraction section: washing section: stripping section is 8:10:7;

[0040] The extraction mixing time is 5min; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com