Method for chemically extracting purified water-soluble natural organic substances by solid film

A technology of organic substances and solid membranes, applied in the direction of solvent extraction of liquid solutions, etc., can solve the problems of reducing transmembrane pressure difference, extremely high pressure stability control requirements, and polluting industrial wastewater from extracts, so as to achieve separation efficiency and effect The effect of improving and reducing industrial wastewater discharge and solving potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

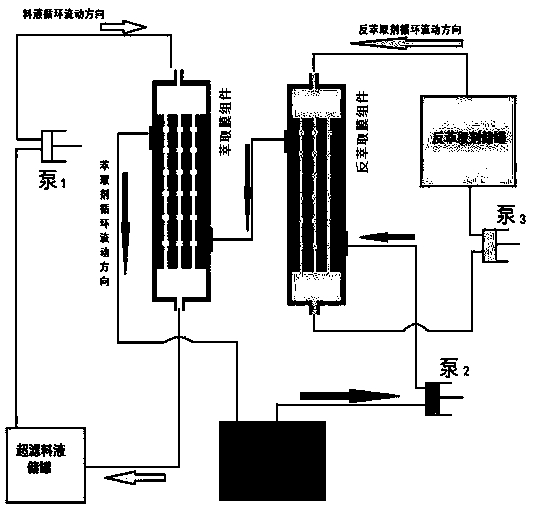

Image

Examples

Embodiment 1

[0045] Get 50kg of kudzu root, add 12 times of water to reflux extraction, extract 1.5 hours each time, extract 2 times, and combine to obtain 1100kg of extract; the extract is ultrafiltered with a ceramic membrane with a pore size of 10nm, and about 1000kg of ultrafiltration permeate is collected; % Trialkylphosphine oxide-sulfonated kerosene is the extraction agent, 0.05% NaOH solution is the stripping agent, and the ultrafiltration permeate is extracted and stripped according to the specific implementation steps of the present invention. The membrane extraction temperature is 20 ° C, and the stripping temperature is 35 ℃; the flow velocity of the ultrafiltration permeate, extractant, and back-extraction solution are 1.0m / min, 0.25m / min, and 0.65m / min, respectively, and the membrane extraction time is 12 hours; collect about 1000kg of back-extraction solution; The pH value of the liquid was adjusted to 4 with HCl, passed through a polyamide resin column, and eluted with 70% e...

Embodiment 2

[0047] Take 50 kg of rhubarb, add 20 times the amount of water to reflux extraction, extract 30 minutes each time, extract 2 times, and combine to obtain 900 kg of extract; the water extract is ultrafiltered with a ceramic composite membrane with a pore size of 20 nm to obtain an ultrafiltrate; Use 20% hydrochloric acid solution to adjust the pH to 3.0, use 5% trialkylphosphine oxide-sulfonated kerosene as the extraction agent, and 0.5% ammonia water as the stripping agent, and extract the ultrafiltration permeate according to the specific implementation steps of the present invention Back extraction, membrane extraction temperature is 25°C, back extraction temperature is 30°C; flow velocity of ultrafiltrate, extraction agent, and back extraction liquid are 2.0m / min, 0.3m / min, 1.0m / min respectively, and membrane extraction time is 8 hours ; Collect about 800kg of back extract; Concentrate the back extract under reduced pressure to 50kg, adjust the pH value to 2 with hydrochlori...

Embodiment 3

[0049] Take 50kg of licorice, add 24 times the amount of 0.75% ammonia water to reflux extraction, extract 1 hour each time, extract 3 times, and combine to obtain 1100kg of extract; ultrafilter the extract with a ceramic membrane with a pore size of 10nm, and collect about 1050kg of ultrafiltration permeate , adjust the pH value to 6 with hydrochloric acid, use 20% trialkylphosphine oxide-sulfonated kerosene as the extraction agent, and 0.07% NaOH solution as the stripping agent, and carry out the extraction and stripping of the ultrafiltration permeate according to the specific implementation steps of the present invention , the membrane extraction temperature is 25°C, the back extraction temperature is 40°C, the flow speeds of the ultrafiltrate, extraction agent, and back extraction liquid are 1.0m / min, 0.3m / min, and 0.65m / min respectively, and the total membrane extraction and back extraction liquid After 12 hours, about 1000 kg of back extract was obtained; the back extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com