Novel feeding equipment for oil pipe cleaning production line

The technology of feeding equipment and production line is applied in the field of feeding equipment for new oil pipe cleaning production line, which can solve the problems of low cleaning efficiency and high labor intensity, and achieve the effects of high cleaning efficiency, solving labor intensity and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

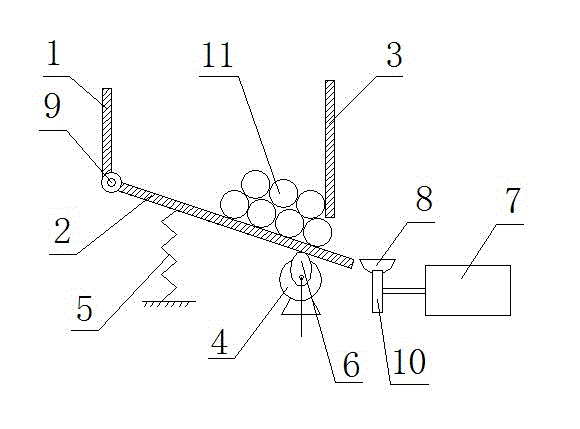

[0010] The following is a further description of the feeding equipment of the new oil pipe cleaning production line in conjunction with the accompanying drawings:

[0011] The feeding equipment of the new oil pipe cleaning production line is composed of a vibration box and a transportation device. The cam 6 is formed; the left end of the feed plate 2 is movably installed on the rotating shaft 9 and can rotate around the rotating shaft 9, the left side of the feed plate 2 is equipped with a rear baffle plate 1, and the right side of the feed plate 2 is equipped with a The front material baffle 3, the feed plate 2 and the material baffle 3 can be closed or separated. Damping spring 5 is installed on the left end of feed plate 2 bottoms, and feed motor 4 is installed on the right end of feed plate 2 bottoms, and travel cam 6 is installed on the output shaft of feed motor 4. Described transportation device comprises transportation groove 8, driving device 10 and transportation mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com