Process for producing high-purity polyphenylene sulfide resin

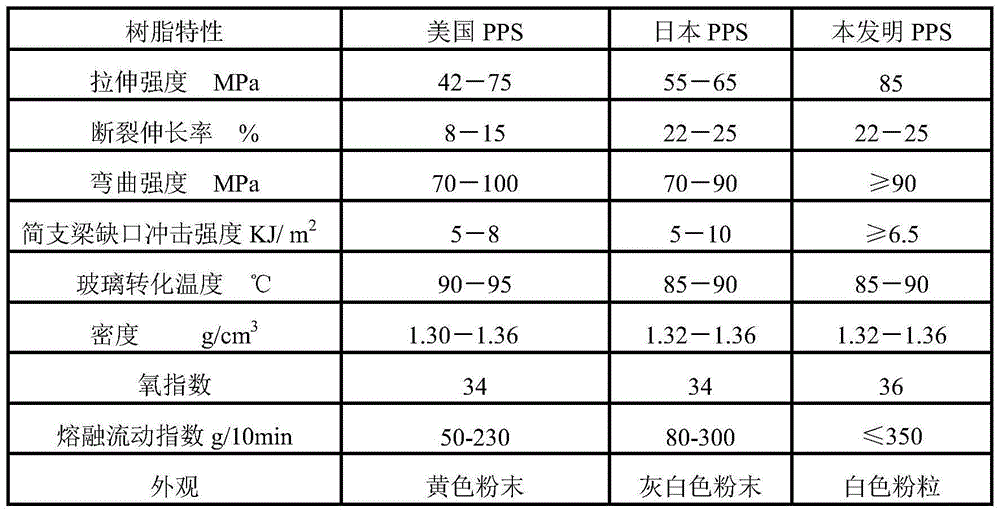

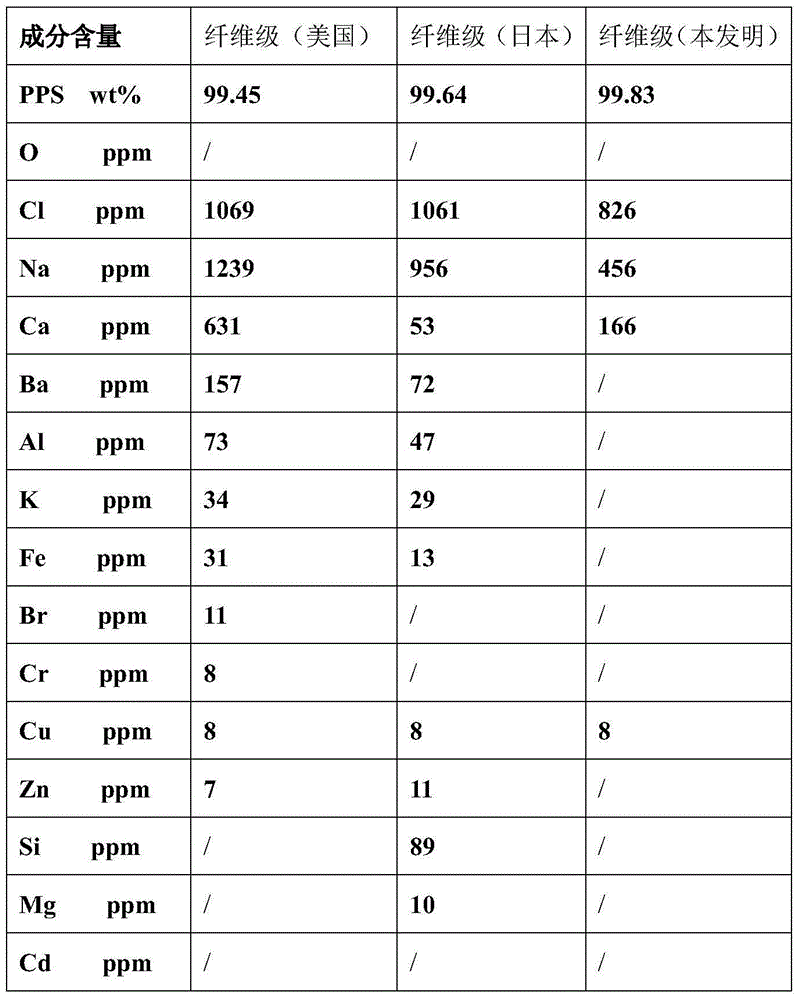

A polyphenylene sulfide resin, high-purity technology, applied in the field of polyphenylene sulfide high-tech material synthesis, can solve problems such as exhaust pressure relief, reaction failure, material ratio imbalance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the reactor, add sodium sulfide containing 1 water of crystallization, oxygen-free deionized water, lithium chloride, N-methylpyrrolidone, wherein Na 2 S:H 2 The molar ratio of O:LiCl:NMP is 1.0:13.0:0.88:1.8. Under the condition of feeding nitrogen, the temperature in the reactor is raised to 204°C at a rate of 1°C / min, and the dehydration time is 180min. When the dehydration rate is above 160°C, the dehydration rate is controlled within the range of 6000ml / min; when the dehydration is completed, the Na in the dehydration system 2 S:H 2 O:LiCl:NMP molar ratio becomes 1.0:.8:0.88:1.8; 2 S:p-DCB:H 2 The molar ratio of O:LiCl:NMP is 1.0:0.96:1.8:0.88:1.8; Nitrogen gas is passed into the synthesis system, and the air in the polymerization system is replaced to seal the polymerization reaction system, and then the polymerization system is heated to raise the temperature. When rising to the low temperature stage, the temperature in this stage is controlled at 180°C an...

Embodiment 2

[0024] In the reactor, add sodium sulfide containing 3 crystal waters, anaerobic deionized water, lithium chloride, N-methylpyrrolidone, wherein Na 2 S:H 2 The molar ratio of O:LiCl:NMP is 1.0:9.0:0.28:6.8. Under the condition of feeding nitrogen, the temperature in the reactor is raised to 210°C at a speed of 3°C / min, and the dehydration time is 150min. When the dehydration rate is above 160°C, the dehydration rate is controlled within the range of 8000ml / min; when the dehydration is completed, the Na in the dehydration system 2 S:H 2 O:LiCl:NMP molar ratio becomes 1.0:1.0:0.28:5.8; 2 S:p-DCB:H 2 The molar ratio of O:LiCl:NMP is 1.0:1.28:1.0:0.28:5.8; Nitrogen is passed into the synthesis system, and the air in the polymerization system is replaced to seal the polymerization reaction system, and then the polymerization system is heated to raise the temperature. When rising to the low temperature stage, the temperature in this stage is controlled at 200°C and the pressure ...

Embodiment 3

[0027] In the reactor, add sodium sulfide containing 1.5 crystal waters, anaerobic deionized water, lithium chloride, N-methylpyrrolidone, wherein Na 2 S:H 2 The molar ratio of O:LiCl:NMP is 1.0:11.0:0.43:2.8. Under the condition of feeding nitrogen, the temperature in the reactor is raised to 206°C at a rate of 1-3°C / min, and the dehydration time is 155min. When the temperature rises above 160°C, the dehydration rate is controlled within the range of 6369ml / min; when the dehydration is completed, the Na in the dehydration system 2 S:H 2 O:LiCl:NMP molar ratio becomes 1.0:1.3:0.43:2.8; 2 S:p-DCB:H 2 The molar ratio of O:LiCl:NMP is 1.0:1.08:1.3:0.43:2.8; Nitrogen is passed into the synthesis system, and the air in the polymerization system is replaced to seal the polymerization reaction system, and then the polymerization system is heated to raise the temperature. When rising to the low temperature stage, the temperature in this stage is controlled at 186°C and the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com