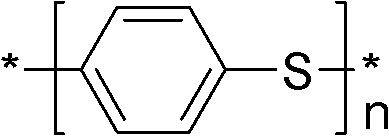

Method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin

A polyphenylene sulfide resin, polyphenylene sulfide technology, applied in the direction of one-component synthetic polymer rayon, fiber chemical characteristics, textiles and papermaking, etc., can solve the problem of poor processing stability and limited polyphenylene sulfide chain growth , polyphenylene sulfide resin color depth and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

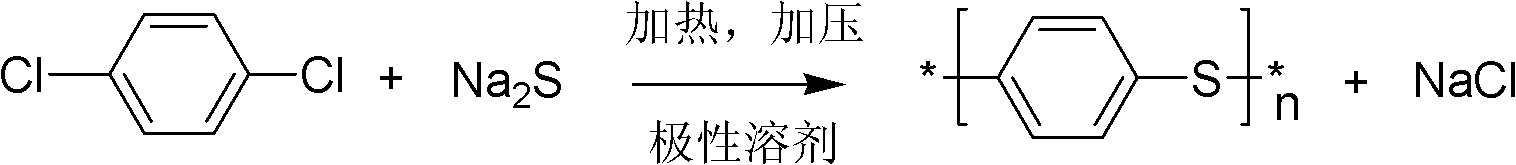

Method used

Image

Examples

Embodiment 1

[0036] The feed is: anhydrous sodium sulfide / p-dichlorobenzene / N-methylpyrrolidone / anhydrous trisodium phosphate=1.52-1.6mol / 1.5mol / 0.5-1.2L / 40g, the air in the autoclave is replaced with nitrogen, and the Inject 0.6-0.1MP nitrogen. Low temperature 160-230°C for 2-4 hours, high temperature 240-280°C for 3-6 hours, 250-300°C feeding for 1-2 hours, 250-300°C for 0.5-2 hours of p-dichlorobenzene capping. Stirring speed 50-150R / Min. After the reaction was completed, it was filtered and washed to obtain a white powder. The white powder is measured by high-temperature gel chromatography to obtain an average molecular weight Mw of 4.4-5.2×10 4 gmol -1 , molecular distribution index 2.4-3.01. The white powder is fused and granulated into milky white granules, and the product yield is 96-98%.

Embodiment 2

[0038] The feeding material is: anhydrous sodium sulfide / p-dichlorobenzene / N-methylpyrrolidone / anhydrous trisodium phosphate=1.5mol / 1.5mol / 0.5-1.2L / 40g, nitrogen replaces the air in the autoclave, and injects into the autoclave 0.6-1MP nitrogen. Low temperature 160-230°C for 2-3 hours, high temperature 240-280°C for 3-6 hours, 250-300°C feeding for 0.5-2 hours, 250-300°C for 0.5-2 hours to end-block dichlorobenzene. Stirring speed 50-150R / Min. After the reaction was completed, it was filtered and washed to obtain a white powder. The white powder is measured by high-temperature gel chromatography to obtain an average molecular weight Mw of 3.0-3.2×10 4 gmol -1 , molecular distribution index 2.3-2.5. The white powder is fused and granulated into milky white granules, and the product yield is 96-97%.

Embodiment 3

[0040] The feed is: anhydrous sodium sulfide / p-dichlorobenzene / N-methylpyrrolidone / anhydrous trisodium phosphate=1.52-1.6mol / 1.5mol / 0.5-1.2L / 40g, the air in the autoclave is replaced with nitrogen, and the Inject 0.5-1MP nitrogen. Low temperature 160-230°C for 2-3 hours, high temperature 240-280°C for 2-6 hours, 250-300°C feeding 1,2,4-trichlorobenzene for 0.5-4 hours, 250-300°C 1,2, 4-Trichlorobenzene capped for 0.5-4 hours. Stirring speed 50-150R / Min. After the reaction was completed, it was filtered and washed to obtain a white powder. The white powder is measured by high-temperature gel chromatography to obtain an average molecular weight Mw of 3.7-4.8×10 4 gmol -1 , molecular distribution index 2.2-2.5. The white powder is fused and granulated into milky white granules, and the product yield is 96-97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com