Preparation process of high-performance solvent-based copolyacrylate pressure-sensitive adhesive

A technology of copolymerized acrylate and preparation process, applied in the direction of adhesive type, ester copolymer adhesive, etc., can solve the problems of low sticking force, low average molecular weight, and difficulty in reaching a sufficiently large molecular weight, and achieve high temperature resistance. The effect of improved performance, good initial viscosity and strong holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

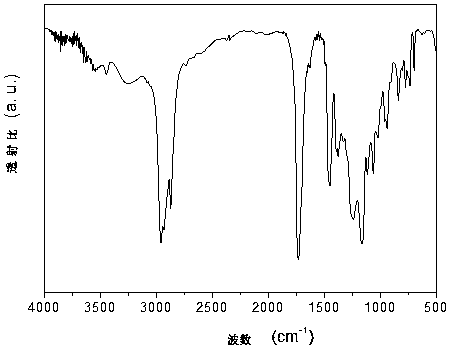

Image

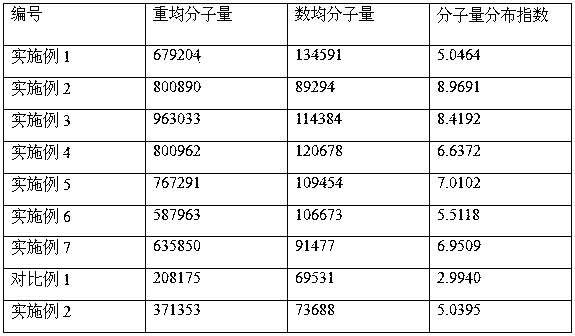

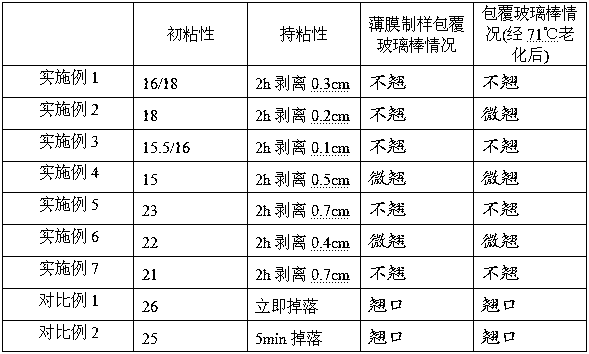

Examples

Embodiment 1

[0025] 1,200 grams of butyl acrylate, 400 g of isooctyl acrylate, 140 g of styrene, 200 g of vinyl acetate, 60 g of acrylic acid, 400 g of toluene, and 1 g of azobisisobutyronitrile were fed into a 50 L mechanically stirred reactor, and after replacing nitrogen three times, set The stirring speed is 100r / min, the temperature is raised to 82°C, the heating speed is 5°C / min, and it stabilizes to the set temperature in about 20 minutes.

[0026] After reacting at 82°C for 2.5 hours, feed 1.5 g of azobisisobutyronitrile from the solid feeding port, add 400 g of toluene from the liquid feeding port, set the stirring speed at 50 r / min, and continue the reaction for 1 hour.

[0027] Then raise the temperature to 88°C, add 1000g of ethyl acetate from the liquid feeding port, feed 1.5g of azobisisobutyronitrile from the solid feeding port, continue to react for 1 hour, then cool down, add 1200g of ethyl acetate, stir evenly from The feeding port discharges the material into the contain...

Embodiment 2

[0032] 1,000 grams of butyl acrylate, 600 g of isooctyl acrylate, 100 g of styrene, 240 g of vinyl acetate, 60 g of hydroxyethyl acrylate, 400 g of toluene, and 0.75 g of azobisisoheptanonitrile were fed into a 50L mechanically stirred reactor, and nitrogen was replaced three times After that, set the stirring speed at 100 r / min, raise the temperature to 82° C., and the heating rate is 5° C. / min. About 20 minutes to stabilize to the set temperature.

[0033] After 2.5 hours of reaction time at 76°C, feed 1 g of azobisisoheptanonitrile from the solid feeding port, add 400 g of toluene from the liquid feeding port, set the stirring speed at 50 r / min, and continue the reaction for 2 hours.

[0034] Then raise the temperature to 84°C, add 1000g of ethyl acetate from the liquid feeding port, feed 1.5g of azobisisoheptanonitrile from the solid feeding port, continue to react for 2 hours, then cool down, add 1200g of ethyl acetate, stir evenly from The feeding port discharges the ma...

Embodiment 3

[0039]1,600 grams of butyl acrylate, 340 g of methyl methacrylate, 60 g of methacrylic acid, 400 g of chlorobenzene, and 0.75 g of azobisisoheptanonitrile were fed into a 50L mechanically stirred reactor, and after replacing the nitrogen three times, the stirring speed was set at 100r / min, the temperature was raised to 82°C, and the heating rate was 5°C / min. About 20 minutes to stabilize to the set temperature.

[0040] After 4.5 hours of reaction time at 76°C, feed 0.25 g of azobisisoheptanonitrile from the solid feeding port, add 400 g of toluene from the liquid feeding port, set the stirring speed at 50 r / min, and continue the reaction for 2 hours.

[0041] Then raise the temperature to 84°C, add 1000g of propyl acetate from the liquid feeding port, feed 1.5g of azobisisoheptanonitrile from the solid feeding port, continue to react for 2 hours, then cool down, add 1200g of propyl acetate, stir evenly from The feeding port discharges the material into the container, and it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com