Distillation equipment and method for separating dichlorobenzene isomers

A technology for isomers and dichlorobenzene, which is applied in the field of rectification and separation of dichlorobenzene isomers, and can solve the problems of huge investment, high number of theoretical plates, and complicated technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

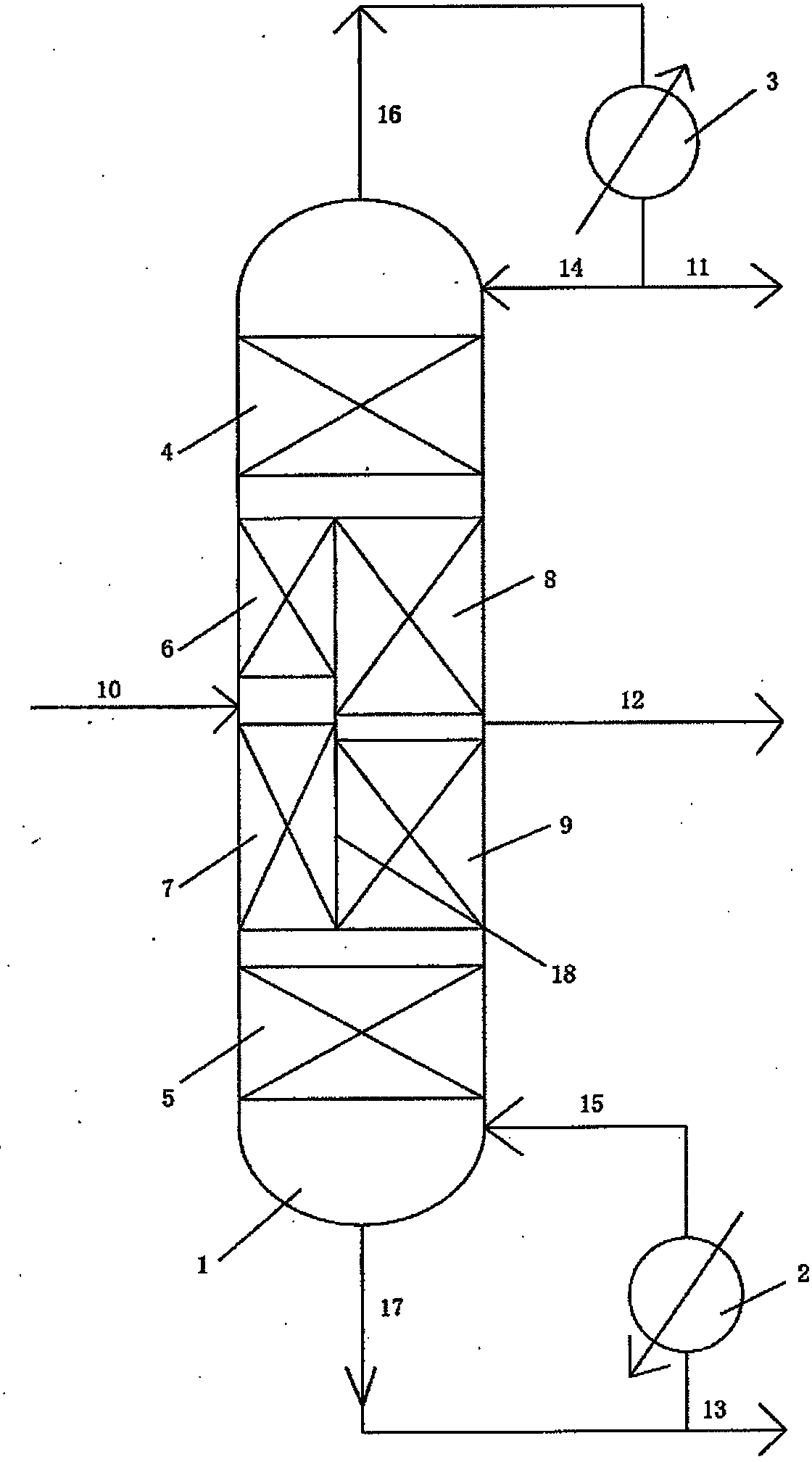

[0035] According to the first embodiment of the present invention, a dividing wall column 1 is used to separate the dichlorobenzene raw material containing m-, p-, ortho-isomers, and the mixture is composed of 8% m-dichlorobenzene, 46% p-dichlorobenzene and 46% o-dichlorobenzene composition. The mixture of m-, p-, ortho-dichlorobenzene enters the dividing wall column 1 with a bubble point of 1000kg / hr flow rate. The number of theoretical plates in the pre-separation tower is 130, and the feed plate is the 82nd theoretical plate in the pre-separation tower area. The number of theoretical plates in the m-p-dichlorobenzene separation tower area is 280, of which 206 are in the rectifying section 4 at the top of the tower, and 74 are in the upper m-p-dichlorobenzene stripping section 8. The number of theoretical plates in the p- and o-dichlorobenzene separation tower area is 130, of which 50 are in the lower p- and o-dichlorobenzene rectification section 9, and 80 are in the botto...

no. 2 example

[0037] According to the second embodiment of the present invention, a dividing wall column 1 is used to separate the dichlorobenzene raw material containing m-, p-, ortho-isomers, and the mixture is composed of 54% m-dichlorobenzene, 24% p-dichlorobenzene and 22% o-dichlorobenzene composition. The mixture of m-, p-, ortho-dichlorobenzene enters the dividing wall column 1 with a bubble point of 1000kg / hr flow rate. The number of theoretical plates in the pre-separation tower is 180, and the feed plate is the 69th theoretical plate in the pre-separation tower area. The number of theoretical plates in the m-p-dichlorobenzene separation tower area is 240, of which 85 are in the overhead rectifying section 4, and 155 are in the upper m-p-dichlorobenzene stripping section 8. The number of theoretical plates in the p- and o-dichlorobenzene separation tower area is 160, of which 96 are in the lower p- and o-dichlorobenzene rectification section 9, and 64 are in the bottom stripping s...

no. 3 example

[0039] According to the third embodiment of the present invention, a dividing wall column 1 is used to separate the dichlorobenzene raw material containing m-, p-, ortho-isomers, and the mixture is composed of 5% m-dichlorobenzene, 60% p-dichlorobenzene and 35% o-dichlorobenzene composition. The mixture of m-, p-, ortho-dichlorobenzene enters the dividing wall column 1 with a bubble point of 1000kg / hr flow rate. The number of theoretical plates in the pre-separation tower is 83, and the feed plate is the 58th theoretical plate in the pre-separation tower area. The number of theoretical plates in the m-p-dichlorobenzene separation tower area is 278, of which 173 are in the top rectifying section 4, and 105 are in the upper m-p-dichlorobenzene stripping section 8. The number of theoretical plates in the p- and o-dichlorobenzene separation tower area is 155, of which 78 are in the lower p- and o-dichlorobenzene rectification section 9, and 77 are in the tower bottom stripping se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com