Patents

Literature

82results about How to "Increase chain length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

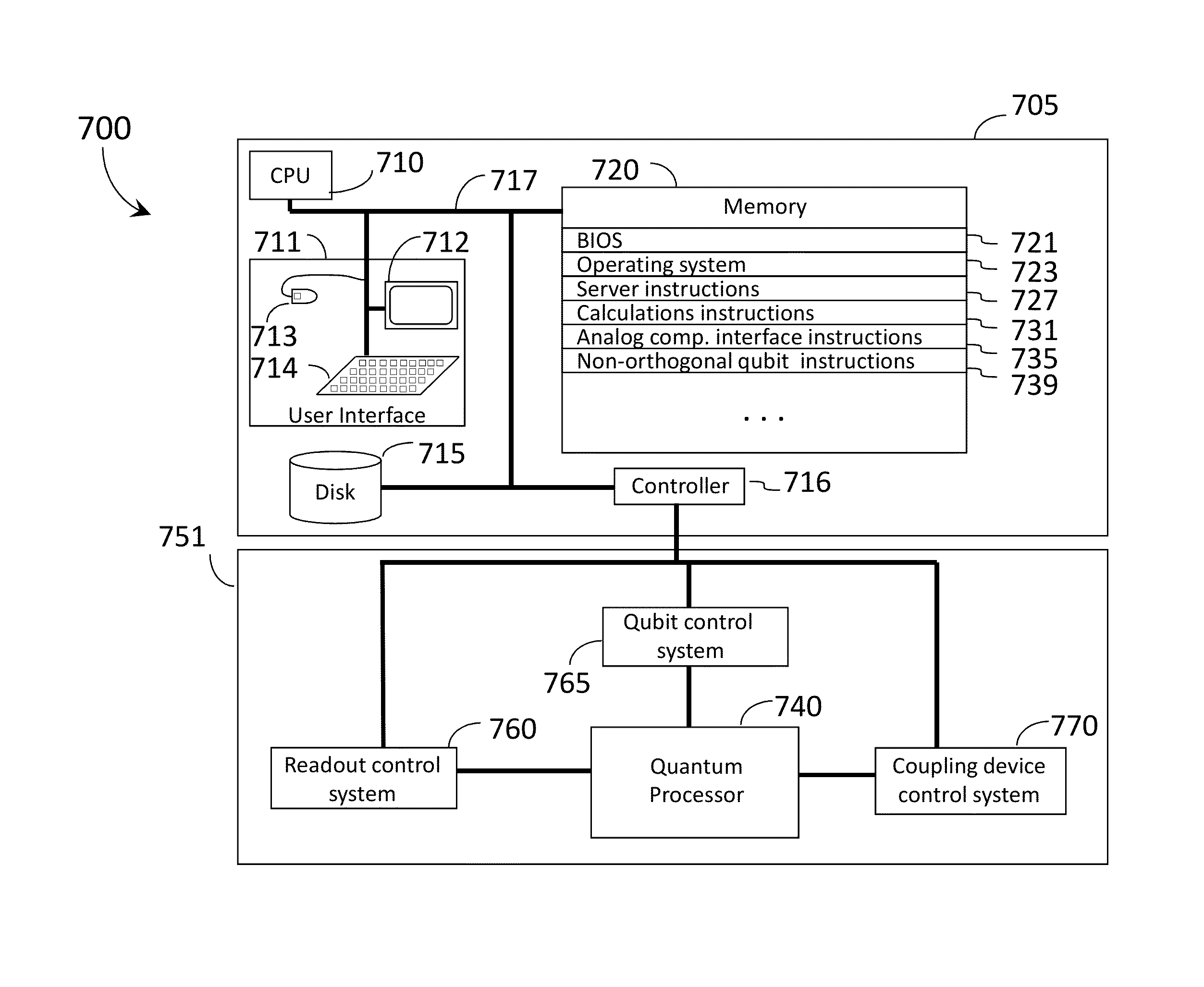

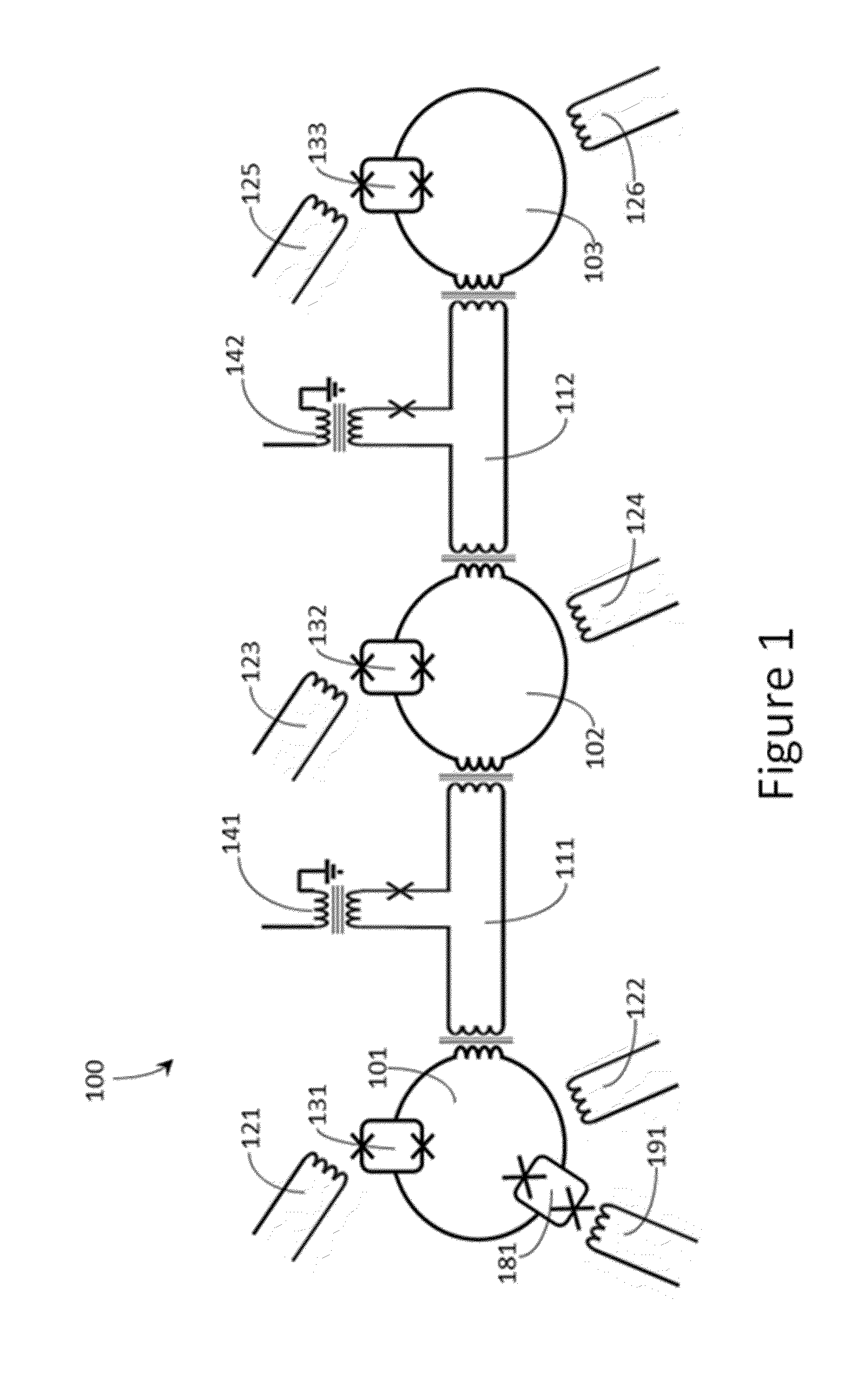

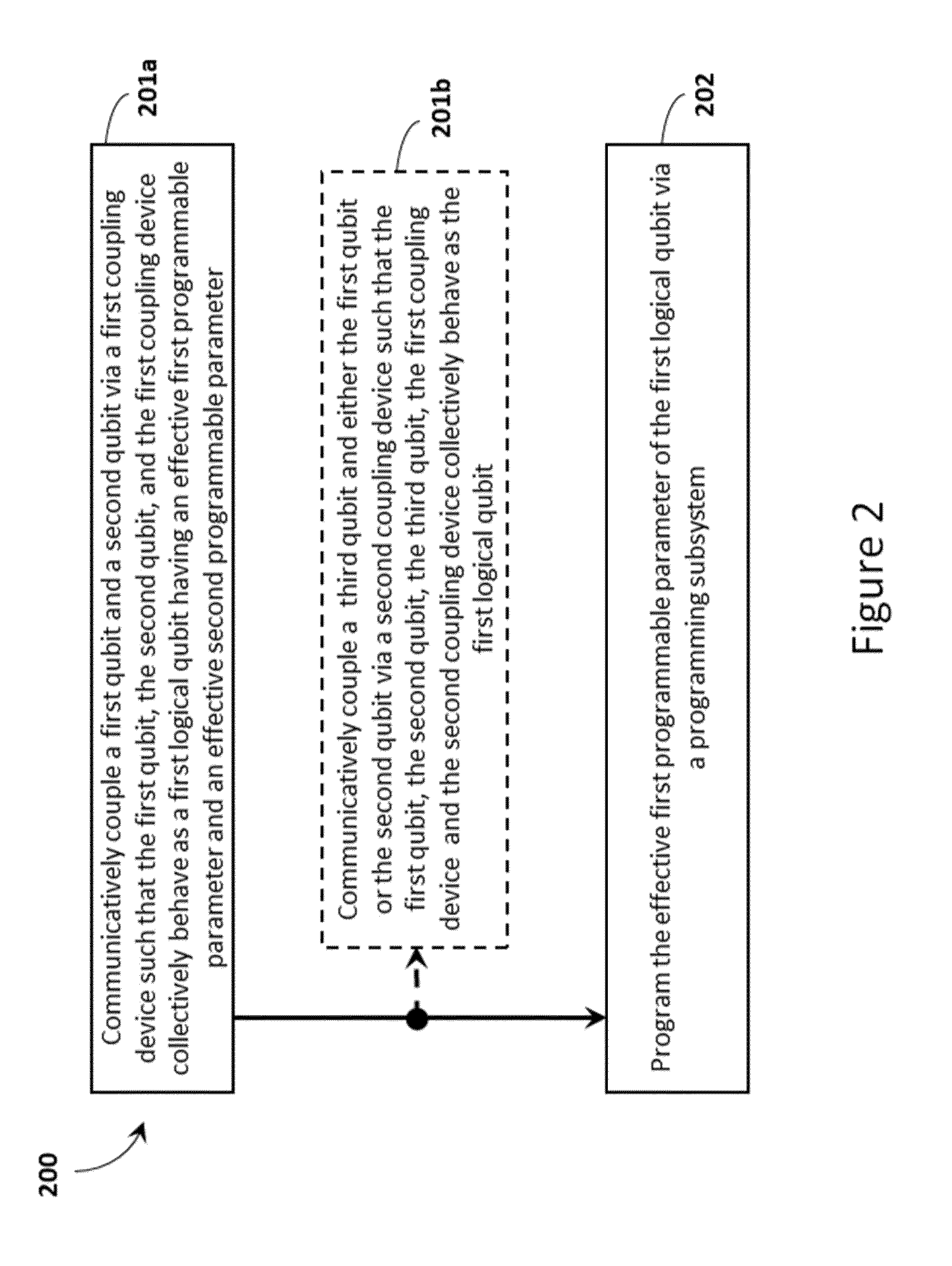

Systems and methods for achieving orthogonal control of non-orthogonal qubit parameters

ActiveUS20150032993A1Improve effective connectionIncrease chain lengthQuantum computersGeneral purpose stored program computerNon orthogonalQuantum electrodynamics

Achieving orthogonal control of non-orthogonal qubit parameters of a logical qubit allows for increasing the length of a qubit chain thereby increasing the effective connectivity of the qubit chain. A hybrid qubit is formed by communicatively coupling a dedicated second qubit to a first qubit. By tuning a programmable parameter of the second qubit of a hybrid qubit, an effective programmable parameter of the hybrid qubit is adjusted without affecting another effective programmable parameter of the hybrid qubit thereby achieving orthogonal control of otherwise non-orthogonal qubit parameters. The length of the logical qubit may thus be increased by communicatively coupling a plurality of such hybrid qubits together.

Owner:D WAVE SYSTEMS INC

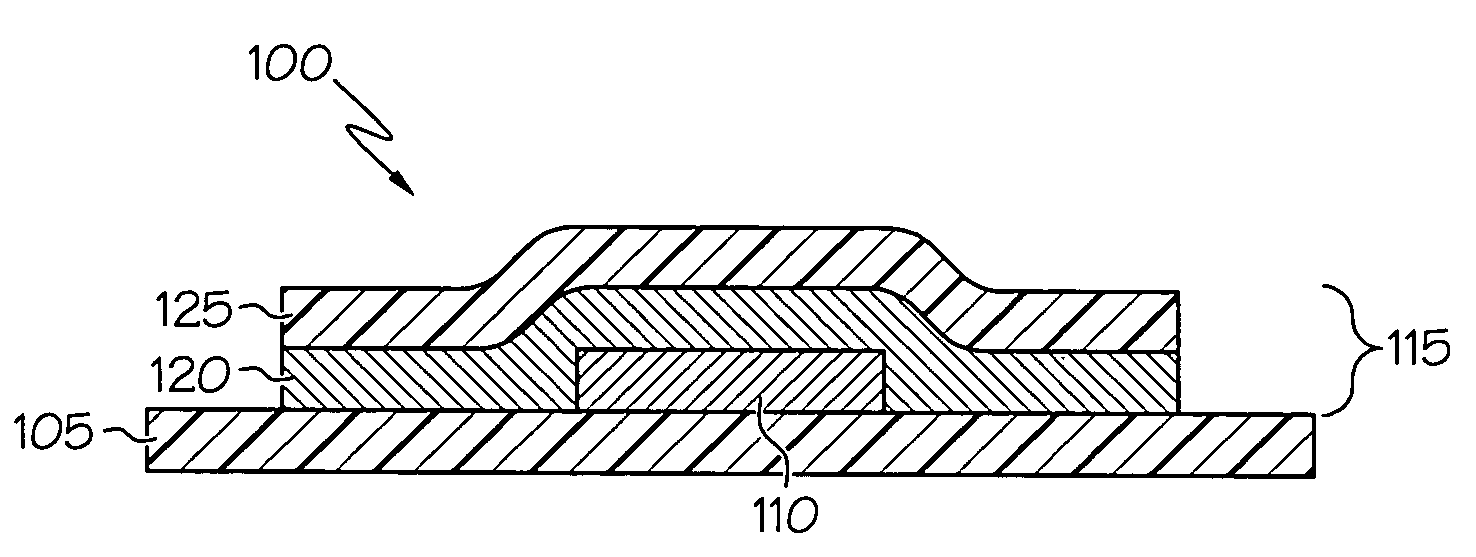

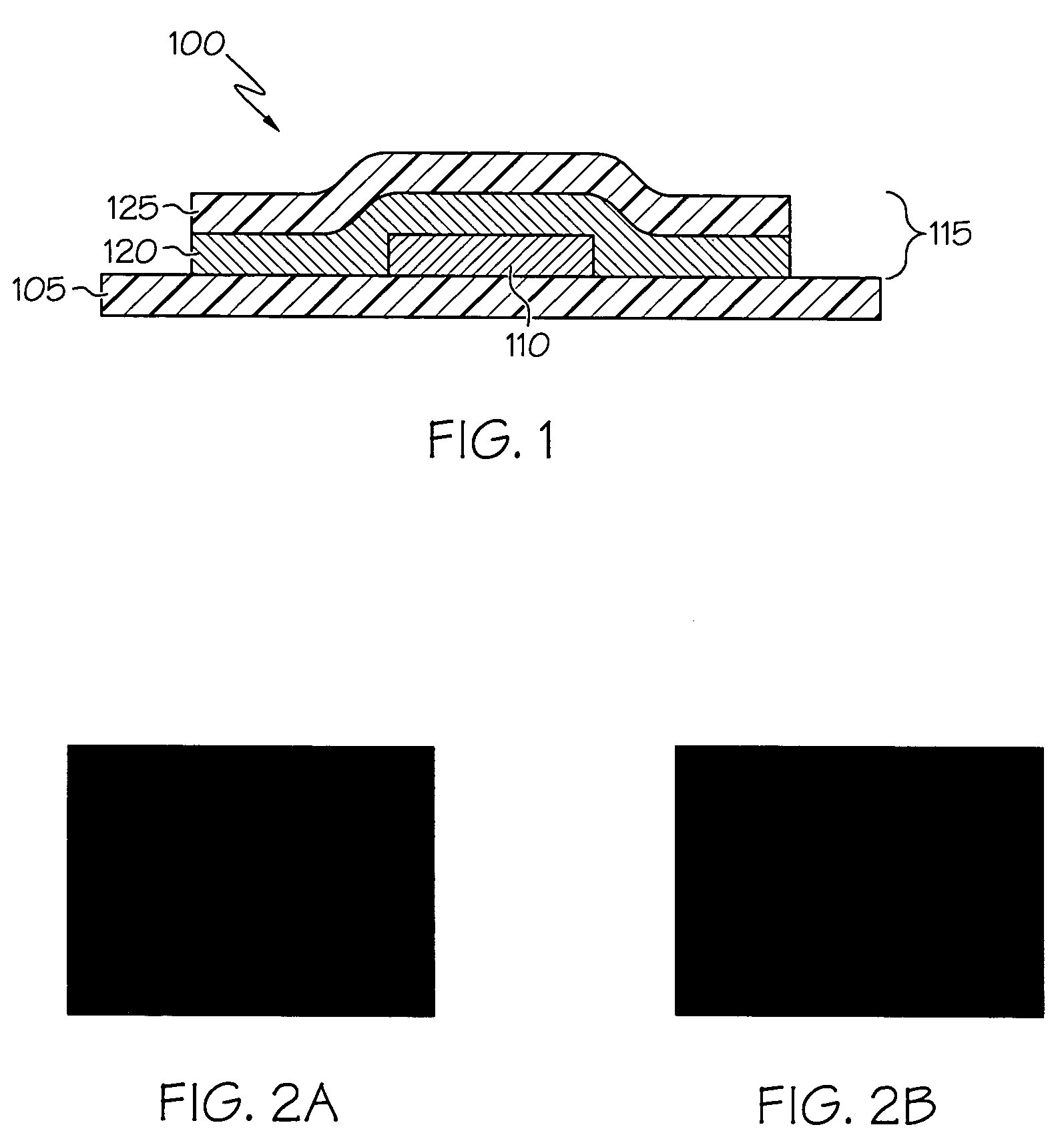

Encapsulated devices and method of making

ActiveUS7767498B2High bulk densityReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingBond energyPolymer science

A method of encapsulating an environmentally sensitive device. The method includes providing a substrate; placing at least one environmentally sensitive device adjacent to the substrate; and depositing at least one barrier stack adjacent to the environmentally sensitive device, the at least one barrier stack comprising at least one barrier layer and at least one polymeric decoupling layer, wherein the at least one polymeric decoupling layer is made from at least one polymer precursor, and wherein the polymeric decoupling layer has at least one of: a reduced number of polar regions; a high packing density; a reduced number of regions that have bond energies weaker than a C—C covalent bond; a reduced number of ester moieties; increased Mw of the at least one polymer precursor; increased chain length of the at least one polymer precursor; or reduced conversion of C═C bonds. An encapsulated environmentally sensitive device is also described.

Owner:SAMSUNG DISPLAY CO LTD

Epoxy polyurethane resin wet-strengthening agent and method for preparing same

ActiveCN1966855AIncrease chain lengthHigh wet strength effectReinforcing agents additionWater resistanceEpoxy polyamide

The epoxy polycyclamide resin wet strength agent featuring in the reaction of polyamine and polyunsaturated acid to make polyamide, which is cationised and then reacts with epichlorohydrin. The final product has a molecular weight range of 100, 000 -150, 000, viscosity range of 10-150 centipoise under normal temperature, with solid content 10-30%. It is applicable for paper making wet strength agent, retention filtration adjuvant, anion catching agent, making the paper having higher glue applicability and water resistance.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Uncured polyurethane waterproofing coating and preparation method thereof

ActiveCN103923565AGood adhesionGrowth Intermediate ConnectivityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention discloses an uncured polyurethane waterproofing coating and a preparation method thereof, belonging to the technical field of polyurethane waterproofing coatings. The uncured polyurethane waterproofing coating is prepared from the following raw materials in percentage by weight: 13-20% of prepolymer, 30-65% of asphalt, 1.0-1.5% of latent curing agent, 3-15% of compatilizer, 2-9% of thermoplastic elastomer and 0-3% of powder stuffing, wherein prepolymer is a substance synthesized by reaction between polyether and isocyanate. The uncured polyurethane waterproofing coating mainly aims to improve the material proportion and polymerization process of polyurethane, and the problem that a hot-melted asphalt material is needed to be heated by using a machine is solved; the uncured polyurethane waterproofing coating is convenient in construction and good in flowability; the viscosity of the constructed material can be automatically enhanced, so that the constructed material can become an elastic plastic body and a favorable waterproofing layer without internal stresses; in addition, the uncured polyurethane waterproofing coating can be well bonded with a coiled material and can be compounded to be waterproof so as to form a waterproofing layer capable of overcoming tension fracture caused by basement layer cracking and preventing puncturing; the uncured polyurethane waterproofing coating is simple and convenient in process, rapid in construction, free of maintenance, high in working efficiency and capable of becoming the development direction of building waterproofing in the further.

Owner:浙江鲁班建材科技股份有限公司

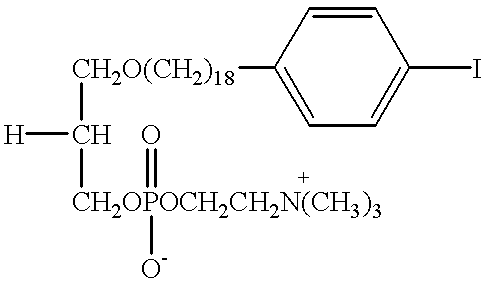

Radioiodinated phospholipid ether analogs and methods of using the same

InactiveUS6255519B1Reduce accumulationReduce the amount requiredRadioactive preparation carriersIsotope introduction to organic compoundsHalf-lifePhospholipid Ethers

Improved radioiodinated phospholipid ether analogs are described which exhibit significant tumor avidity and longer plasma half-life relative to shorter chain analogs. Use of these compounds results in superior imaging and visualization of neoplastic lesions and tumor-specific cytotoxic cancer therapy.

Owner:MICHIGAN RGT UNIV

Sulfide solid electrolyte, preparation method thereof and all-solid-state lithium secondary battery

ActiveCN108258303AAvoid generatingIncrease contentSolid electrolytesFinal product manufactureAll solid stateInorganic sulfide

The invention provides a sulfide solid electrolyte which has a chemical formula shown in formula I or formula II: Li3+3xP1-xZnxS4-xOx (formula I) and Li3P1-xSbxS4-2.5xO2.5x (formula II), wherein x isgrater than or equal to 0.01 and less than or equal to 0.05. According to the invention, a certain amount of ZnO or Sb2O5 is used for double-doping modification of a sulfide solid electrolyte materialLi3PS4 to not only improve air stability of the modified sulfide solid electrolyte, but also benefit to improvement of electrical conductivity of lithium ions. The invention also provides a preparation method of the sulfide solid electrolyte and an all-solid-state lithium secondary battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Leather comprehensive fat liquor and preparation method of the same

ActiveCN103088169AIncrease chain lengthGood flexibilityLeather impregnationOil and greaseEngineering

The invention discloses a leather comprehensive fat liquor and a preparation method of the same. Currently, the defects, such as high price, poor stability, layering propensity, high solvent dosage and pungent smell, are common issues for the leather comprehensive fat liquor. In the method, esterification and sulfitation products of high alcohol, modified soybean phospholipid, sulfonated plant oil, animal fat, mineral oil emulsifier and water are mixed evenly at 45-65 DEG C, the pH value is regulated to be 6-8, and the solid content is regulated to be 45-55%, thus, the leather comprehensive fat liquor is obtained. The product of the method is excellent in appearance liquidity, the leather fatted by the fat liquor is excellent in softness and fullness, and the surface of the fatted leather is smooth and moist.

Owner:传化智联股份有限公司 +2

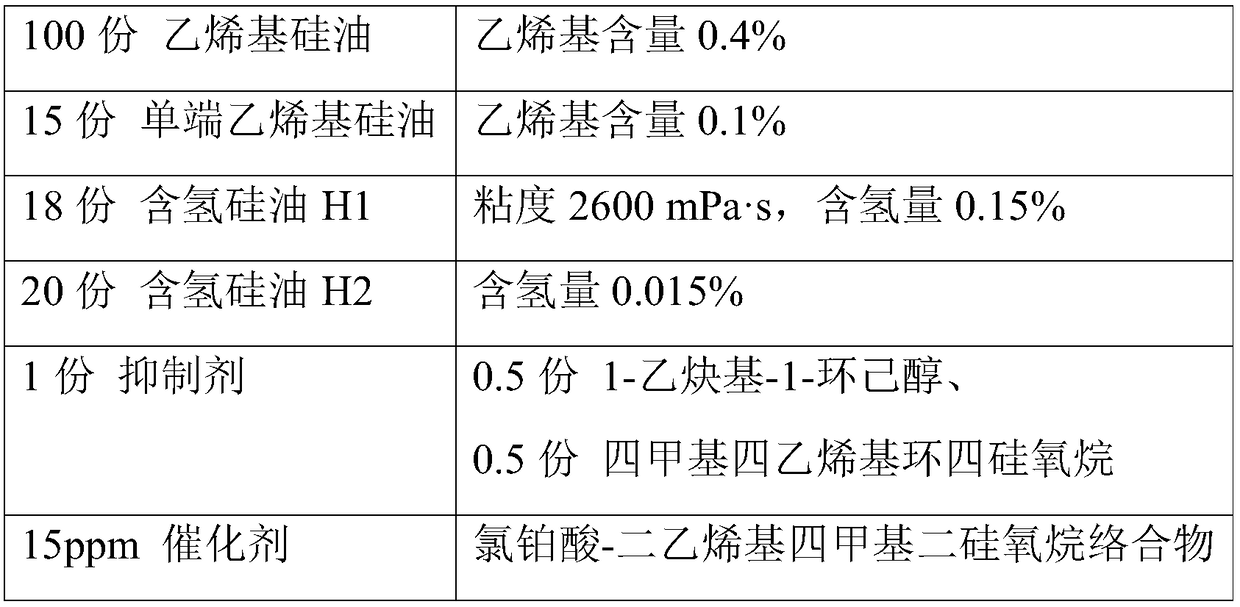

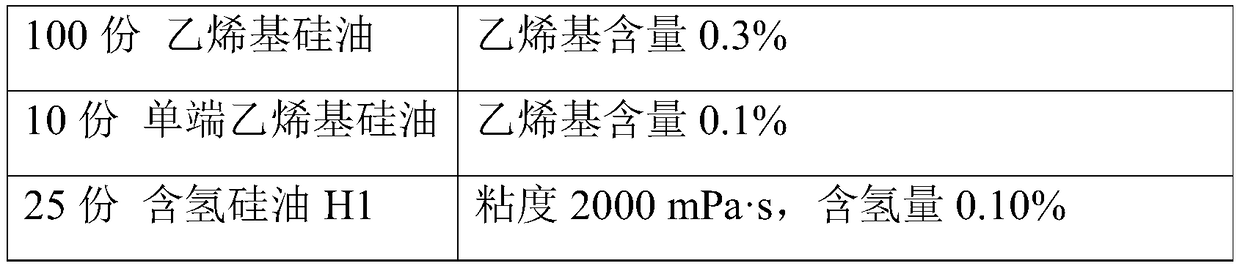

Low-oil-permeability high-strength addition-type silica gel and preparation method thereof

The invention relates to low-oil-permeability high-strength addition-type silica gel and a preparation method thereof. The addition-type silica gel is prepared from the following raw material components in parts by weight: 100 parts of alpha,omega-vinyl polydimethylsiloxane, 5 to 15 parts of single-ended vinyl polydimethylsiloxane, 15 to 30 parts of polymethylhydrosiloxane H1, 10 to 25 parts of polymethylhydrosiloxane H2, 0.01 to 2 parts of inhibitor, and platinum catalyst containing 0.5 to 50 ppm of platinum by mass, wherein nSi-H / nSi-Vi is greater than 1 in the addition-type silica gel. Theaddition-type silica gel has not only higher tensile strength and elongation at break, but superior oil permeability resistance, and stable adhesive performance and dielectric property, and can meet the encapsulating protection requirements of high-end precise electronic parts and components.

Owner:GUANGZHOU BAIYUN CHEM IND

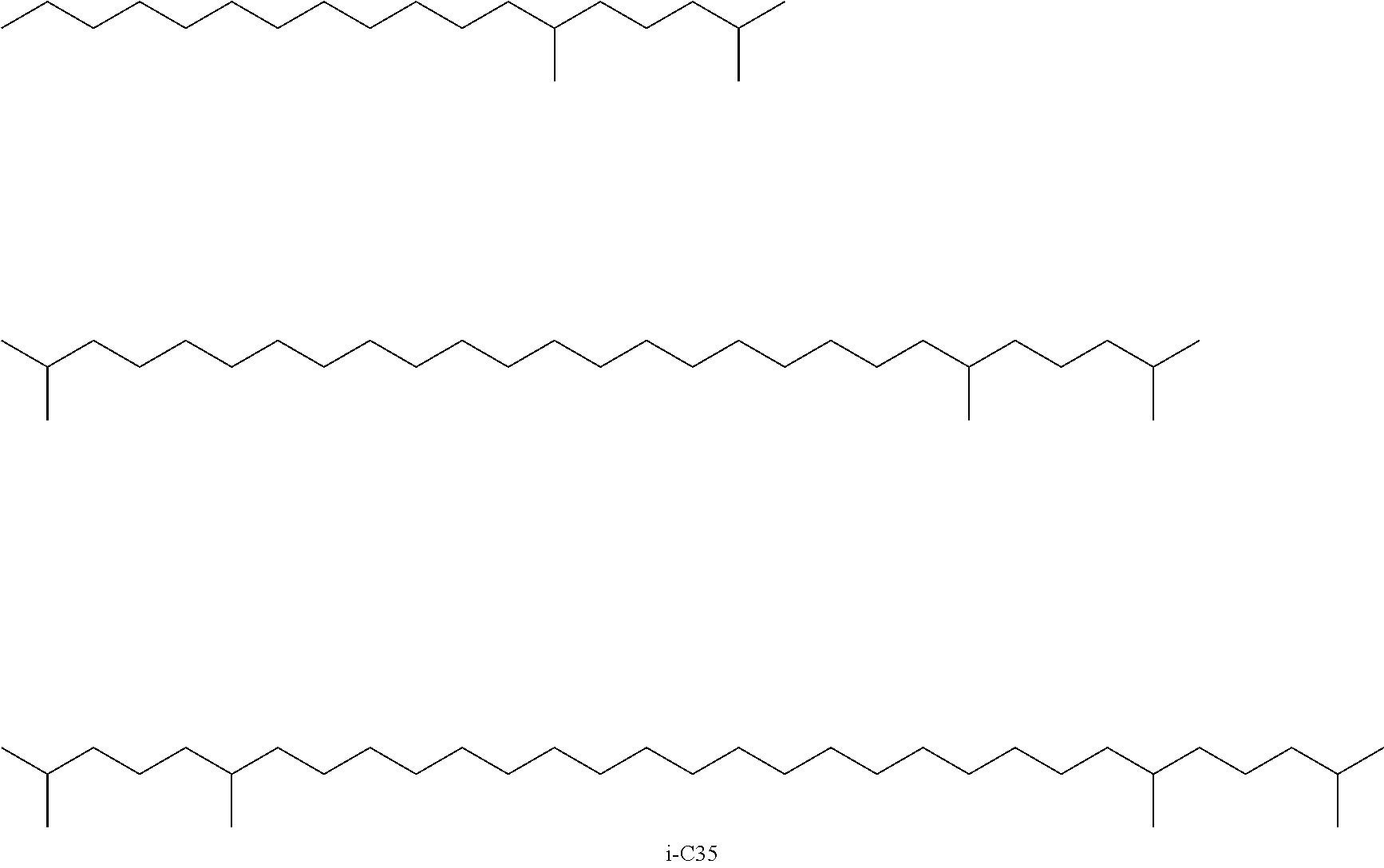

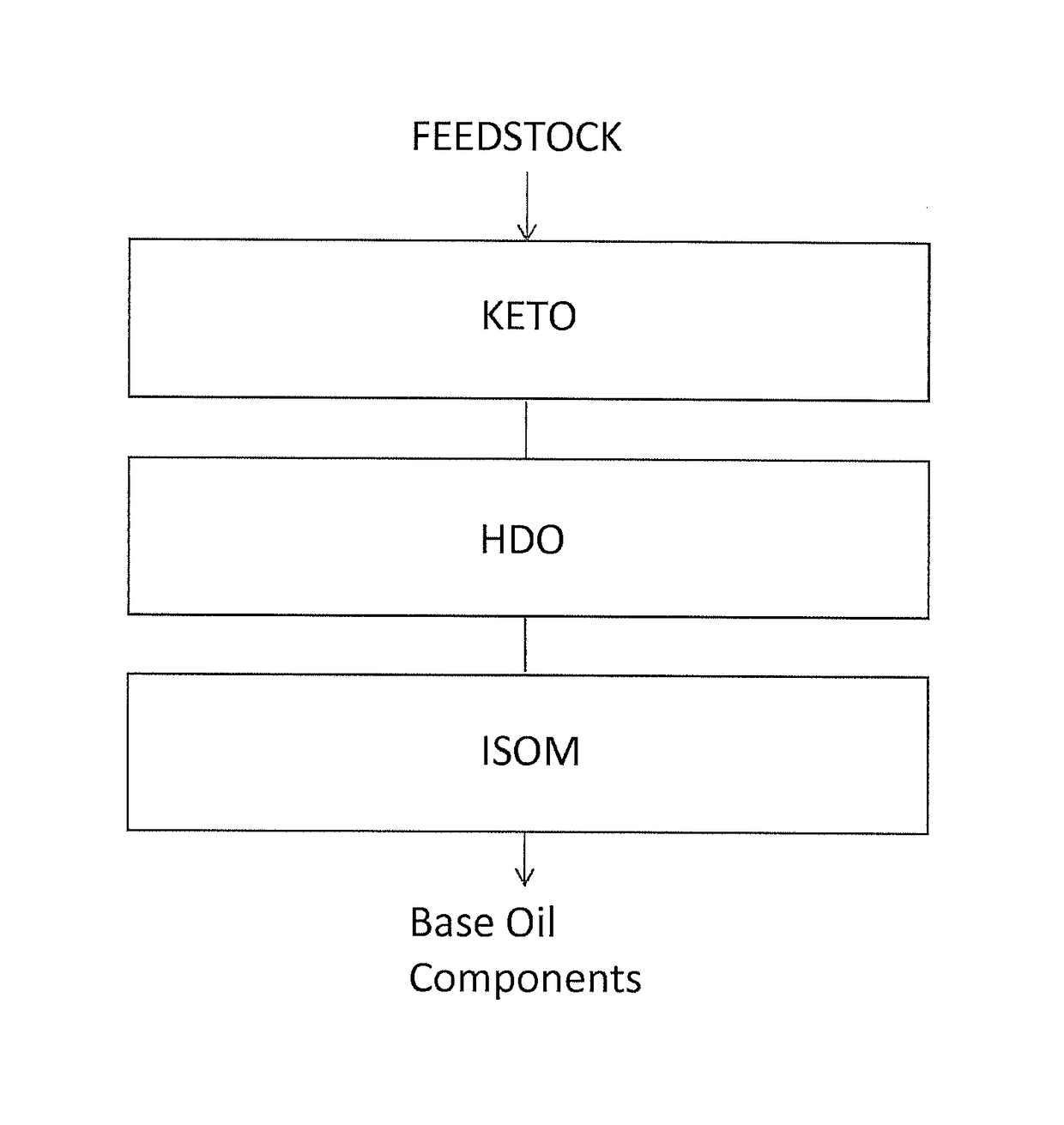

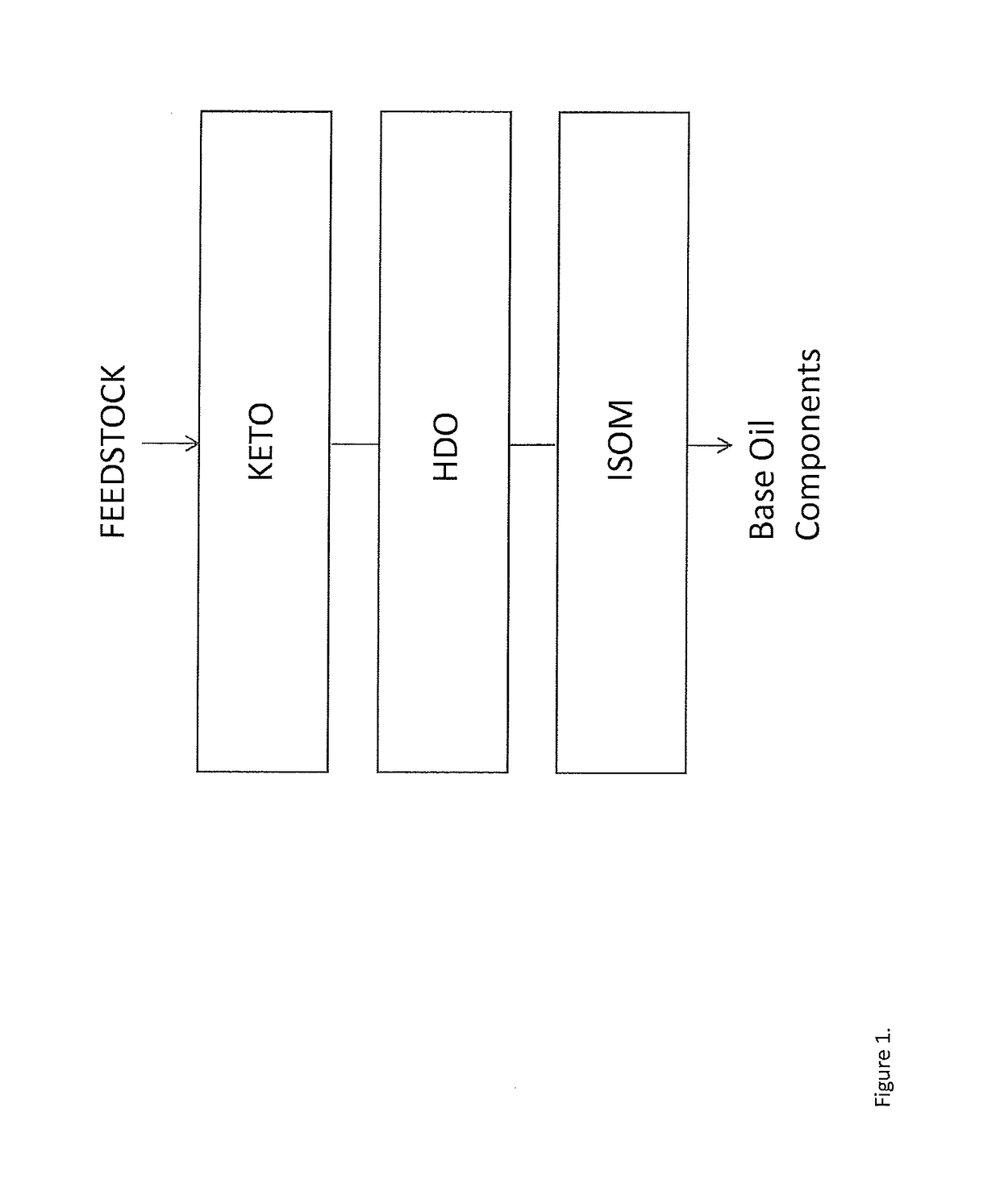

Method for Production of Hydrocarbons by Increasing Hydrocarbon Chain Length

ActiveUS20150018588A1Increase chain lengthQuality improvementFatty acid chemical modificationFatty acids production/refiningHydrogen pressureChain length

The present invention provides a method for increasing hydrocarbon chain length. The method comprises providing a feedstock comprising fatty acids and / or fatty acid esters with hydrocarbon chain length below C23 into a reaction zone in which ketonisation is conducted in the presence of a hydrotreatment catalyst under hydrogen pressure. The obtained ketones have a hydrocarbon chain length of from C24 to C43. The present invention further provides a method for simultaneous production of base oil components and fuel components.

Owner:NESTE OIL OY

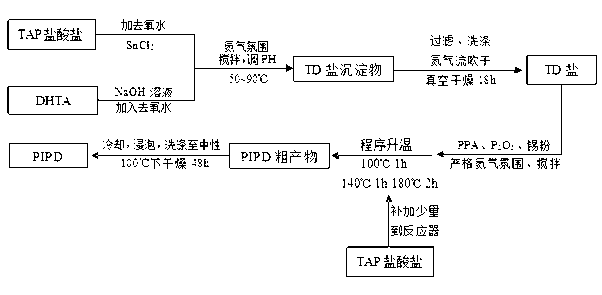

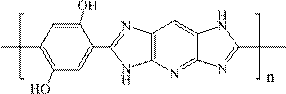

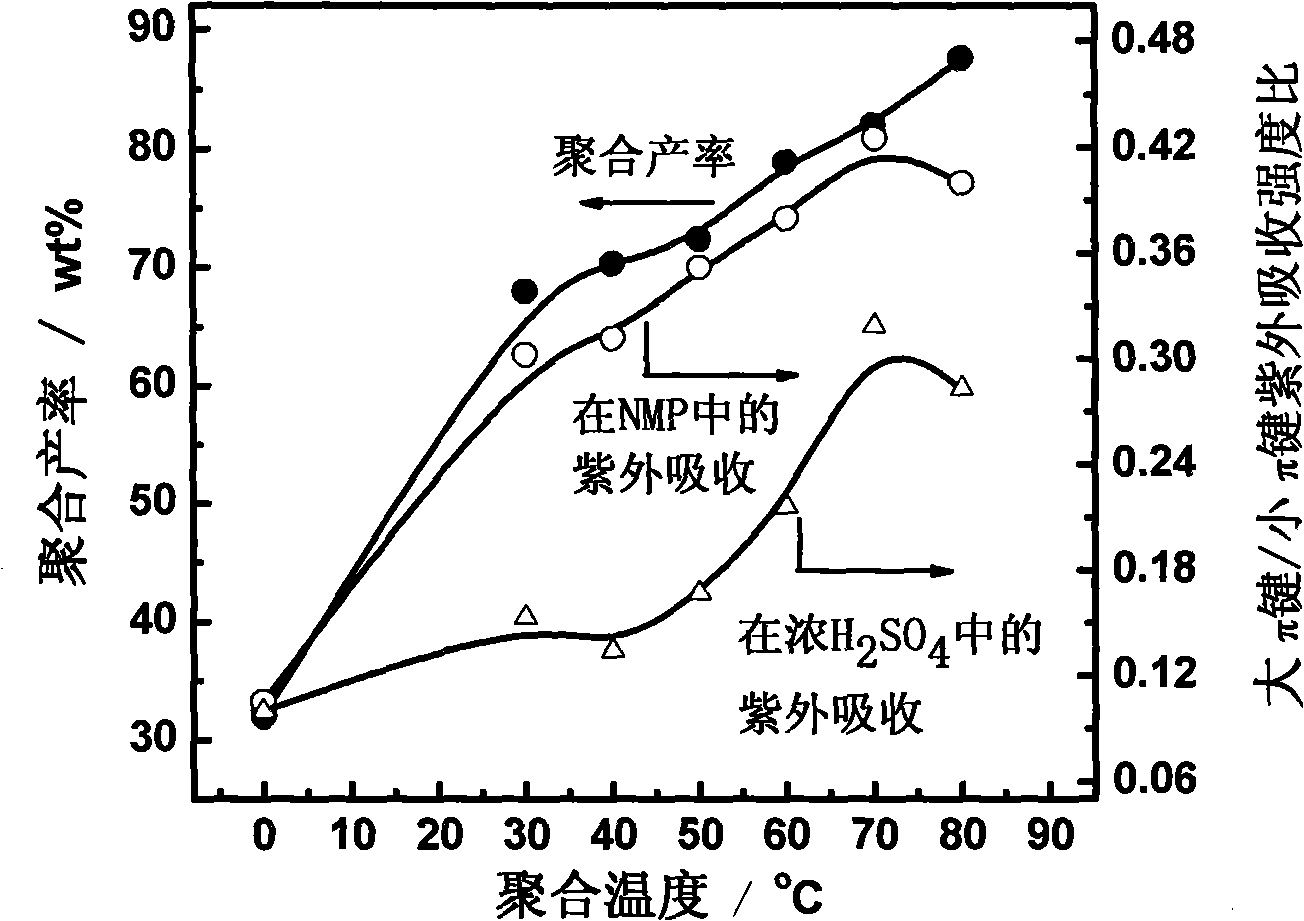

Preparation method for poly(2,5-dihydroxyl-1,4-phenylene pyridobisimidazole)

ActiveCN103224625AIncrease chain lengthHigh molecular weightMonocomponent synthetic polymer artificial filamentFiberPhosphoric acid

The invention relates to a preparation method for poly(2,5-dihydroxyl-1,4-phenylene pyridobisimidazole). The preparation method is realized by the following synthetic method: 2,3,5,6-tetraminopyridine (TAP) hydrochloride and 2,5-dihydroxyl-terephthalic acid (DHTA) are used as raw materials to carry out salificaton by an acid-base neutralization reaction so as to obtain 2,3,5,6-tetraminopyridine-2,5-dihydroxyl-terephthalate composite salt (TD salt); then high molecular weight PIPD fibers are prepared by temperature programmed solution polymerization in a polyphosphoric acid (PPA) system. The method solves the problems of low molecular weight and harsh polymerization conditions of a conventional method, aiming at the difficulties that amino groups are easily oxidized and equimolar ratio reaction can be kept in a whole process. The TD salt obtained by the process for synthesizing the 2,5-dihydroxyl-terephthalc acid-2,3,5,6-tetraminopyridine (TD) composite salt is stable in quality and easy to store; the polymerization reaction combines the advantages of a direct method and a TD salt method, so that the PIPD polymer with higher molecular weight is obtained without changing polymerization environment and polymerization equipment.

Owner:NANJING UNIV OF SCI & TECH

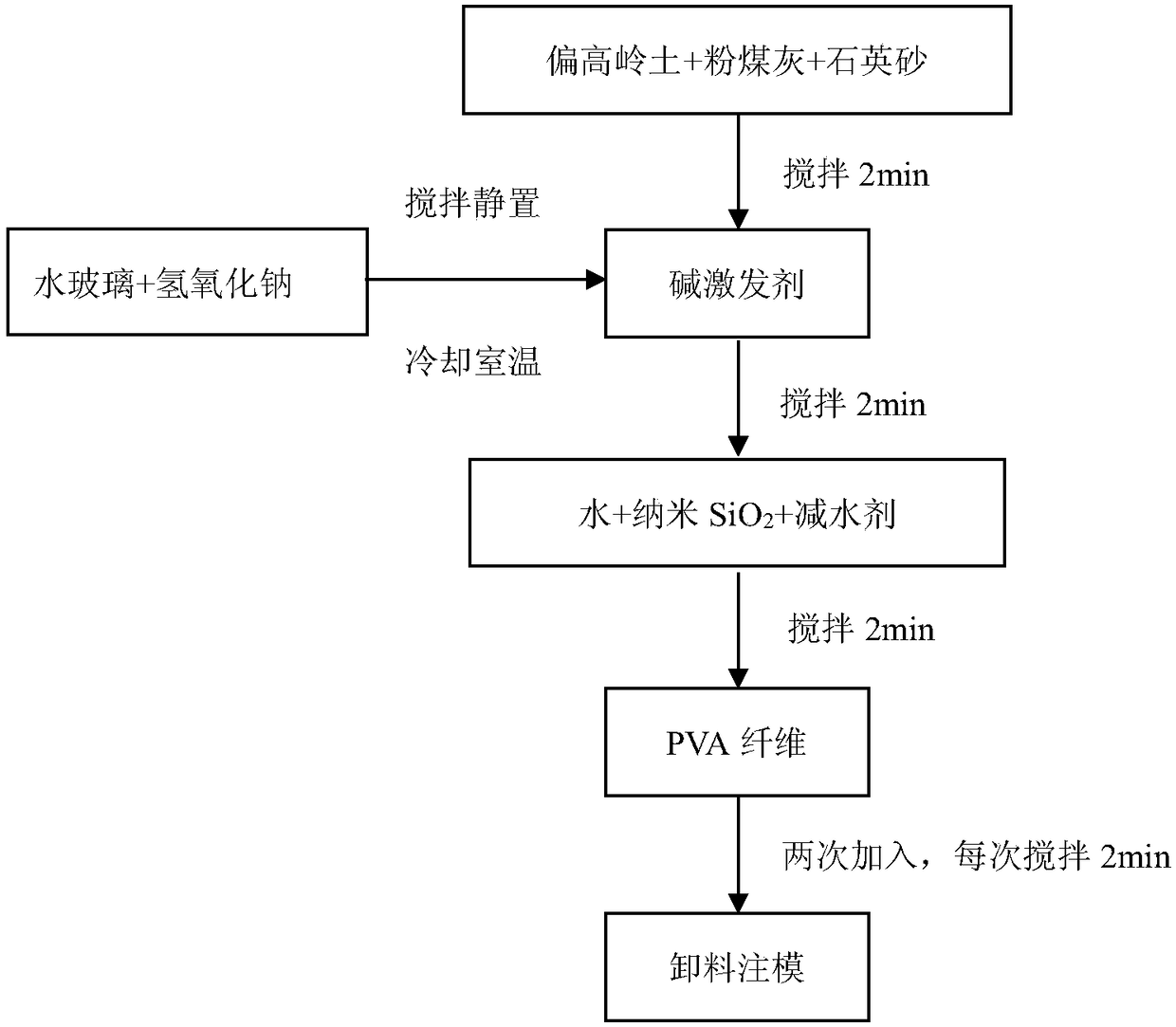

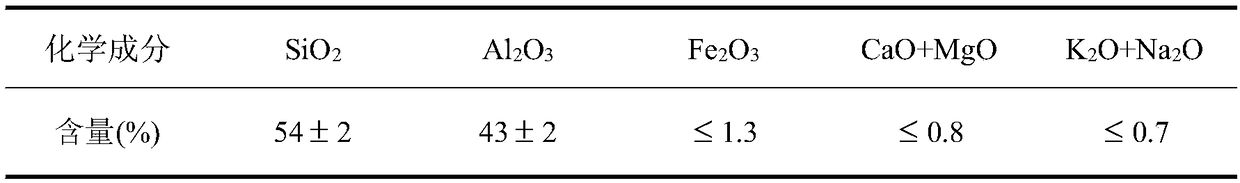

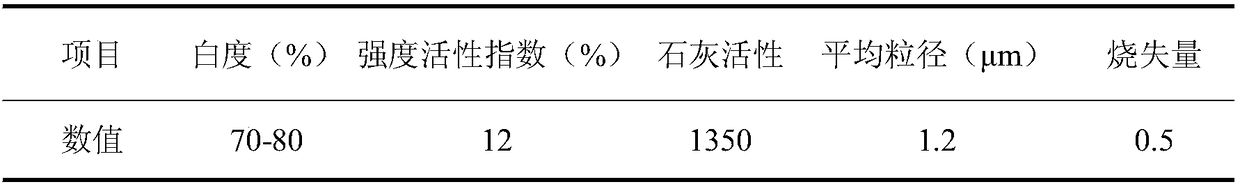

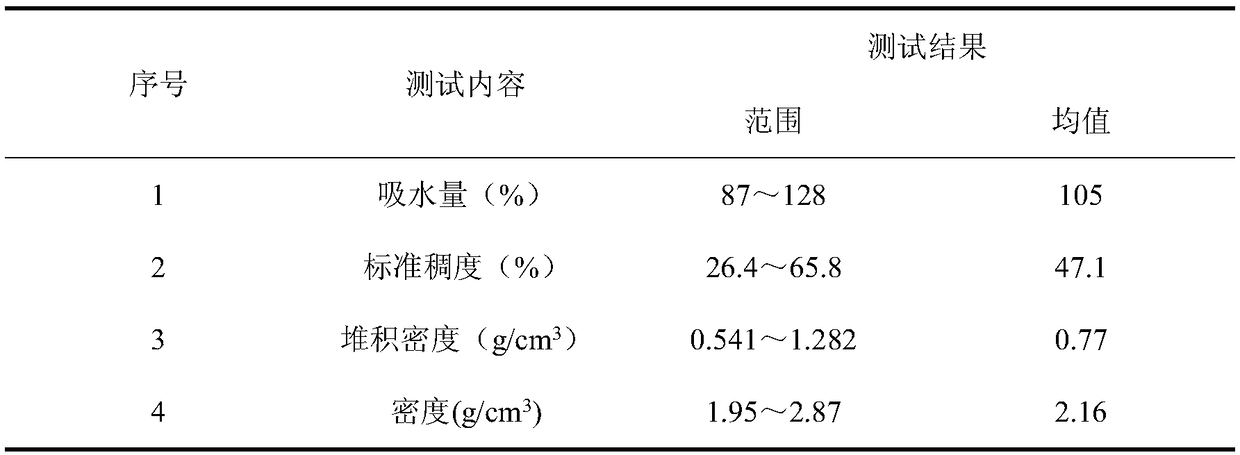

Method for preparing nano-SiO2 and PVA fiber reinforced polymer mortar

The invention discloses a method for preparing nano-SiO2 and PVA fiber reinforced polymer mortar, belonging to the field of inorganic polymer materials. The method comprises the following steps: stirring pre-treated metakaolin, pulverized fuel ash and quartz sands in a stirrer for 2 minutes; adding alkali-activator under a constant stirring state; continuously stirring for 2 minutes; adding a nano-SiO2 mixed solution, continuously stirring for 2 minutes; and adding PVA fibers twice under a constant stirring situation, stirring for 2 minutes each time to obtain the nano-SiO2 and PVA fiber reinforced polymer mortar. The nano-SiO2 and PVA fiber reinforced polymer mortar has excellent mechanical performance and excellent adhesion characteristic, and has a broad application prospect in the fields of construction, road and bridges, hydraulic engineering, military science and the like.

Owner:ZHENGZHOU UNIV

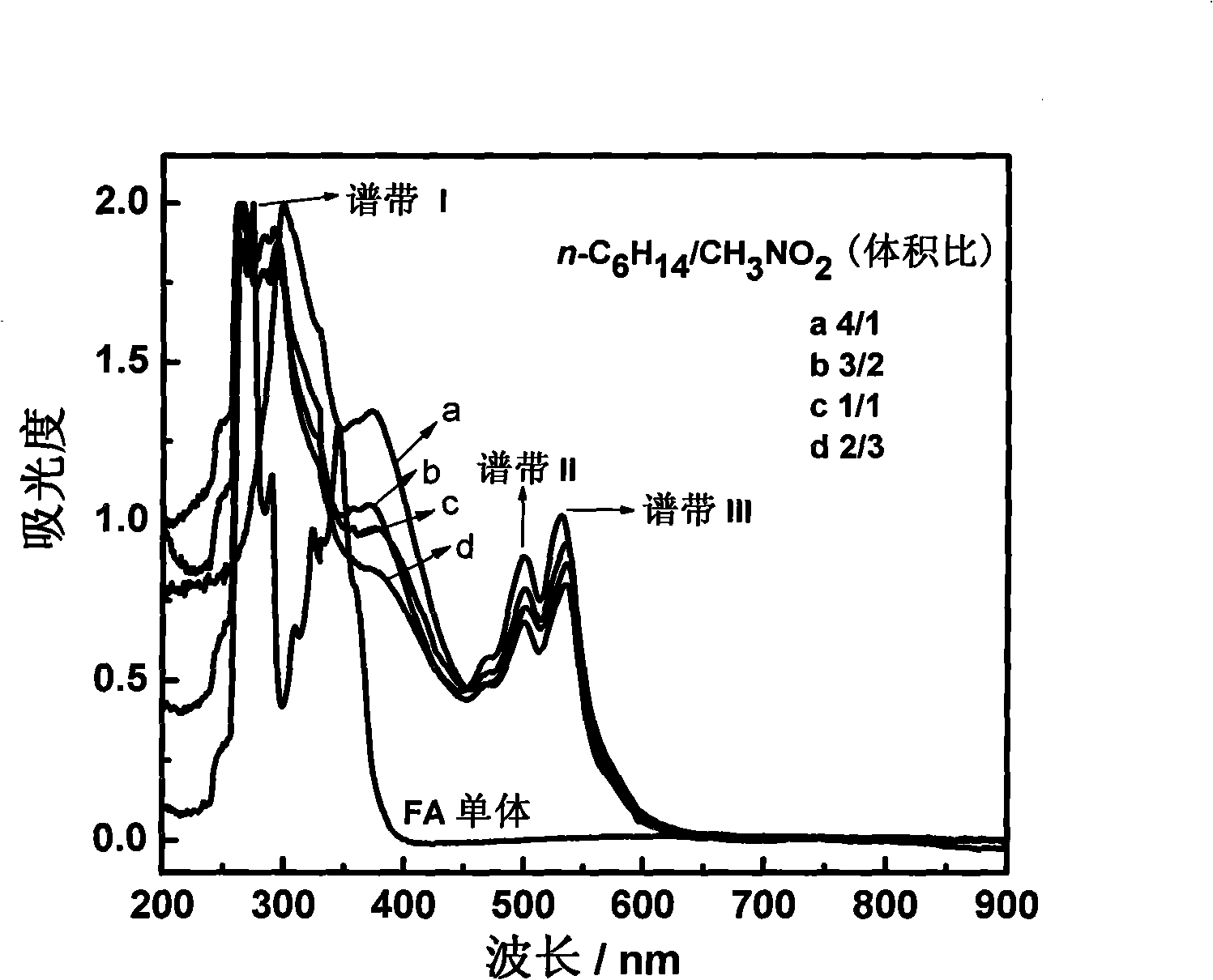

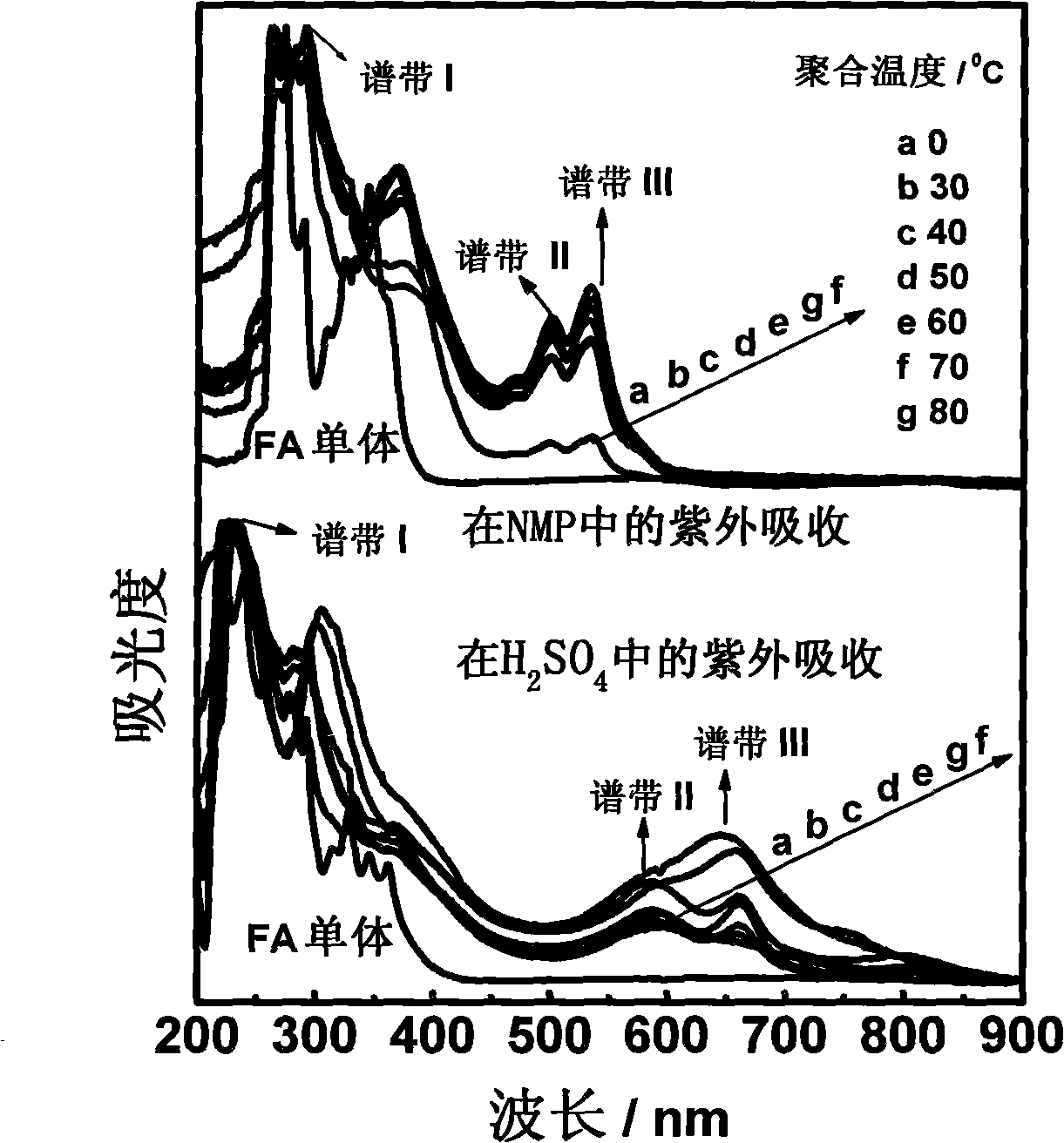

Method for preparing polyfluoranthene in two-phase system

The invention discloses a method for preparing polyfluoranthene in a biphasic system, which is characterized in that: fluoranthene is dissolved into a first solvent to prepare a fluoranthene solution, oxidant is dissolved into a second solvent to prepare an oxidant solution, and the first solvent and the second solvent are not mixed; and the fluoranthene solution is dripped into the oxidant solution to completely react to produce the polyfluoranthene. The method has simple, convenient and easy operation, needs simple equipment, and has adjustable and high-efficient reaction conditions.

Owner:TONGJI UNIV

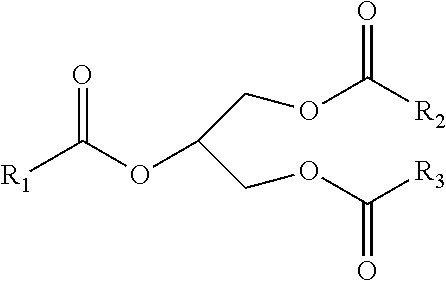

Golf ball comprising renewable resource component

The invention is directed to a golf ball comprising a core and a cover, wherein at least one of the core and the cover comprises about 10 wt % or greater of a renewable polymer composition comprising an ultra high molecular weight polyhydroxyalkanoate compound having the formula:—OCR1R2(CR3R4)nCO—wherein n is an integer, and wherein R1, R2, R3 and R4 are selected from the group comprising saturated and unsaturated hydrocarbon radicals, halo- and hydroxy-substituted radicals, hydroxy radicals, halogen radicals; nitrogen-substituted radicals, oxygen-substituted radicals, or hydrogen atoms. In one embodiment, the golf ball also comprises about 90 wt % or less of a non renewable polymer composition. The golf ball may also comprise an intermediate layer disposed about the core and adjacent the cover, wherein at least one of the core, the cover and the intermediate layer comprises the renewable polymer composition. The renewable polymer composition comprises at least one of a flexural modulus of about 50,000 psi or greater and a tensile strength of about 2,000 psi or greater. The at least one of the core and the cover or the intermediate layer may comprise a hardness of from about 50 Shore C to about 90 Shore C.

Owner:ACUSHNET CO

Nanometer SiO2 and PVA (polyvinyl alcohol) fiber reinforced geopolymer mortar

The invention discloses nanometer SiO2 and PVA (polyvinyl alcohol) fiber reinforced geopolymer mortar, and belongs to the field of inorganic polymeric materials. The nanometer SiO2 and PVA fiber reinforced geopolymer mortar comprises water, metakaolin, fly ash, quartz sand, alkali activators, PVA fibers, nanometer SiO2 and water reducing agents. The nanometer SiO2 and PVA fiber reinforced geopolymer mortar has the advantages of good mechanical property, excellent bonding characteristics and broad application prospect in the fields of buildings, roads and bridges, water conservation, military science and the like.

Owner:ZHENGZHOU UNIV

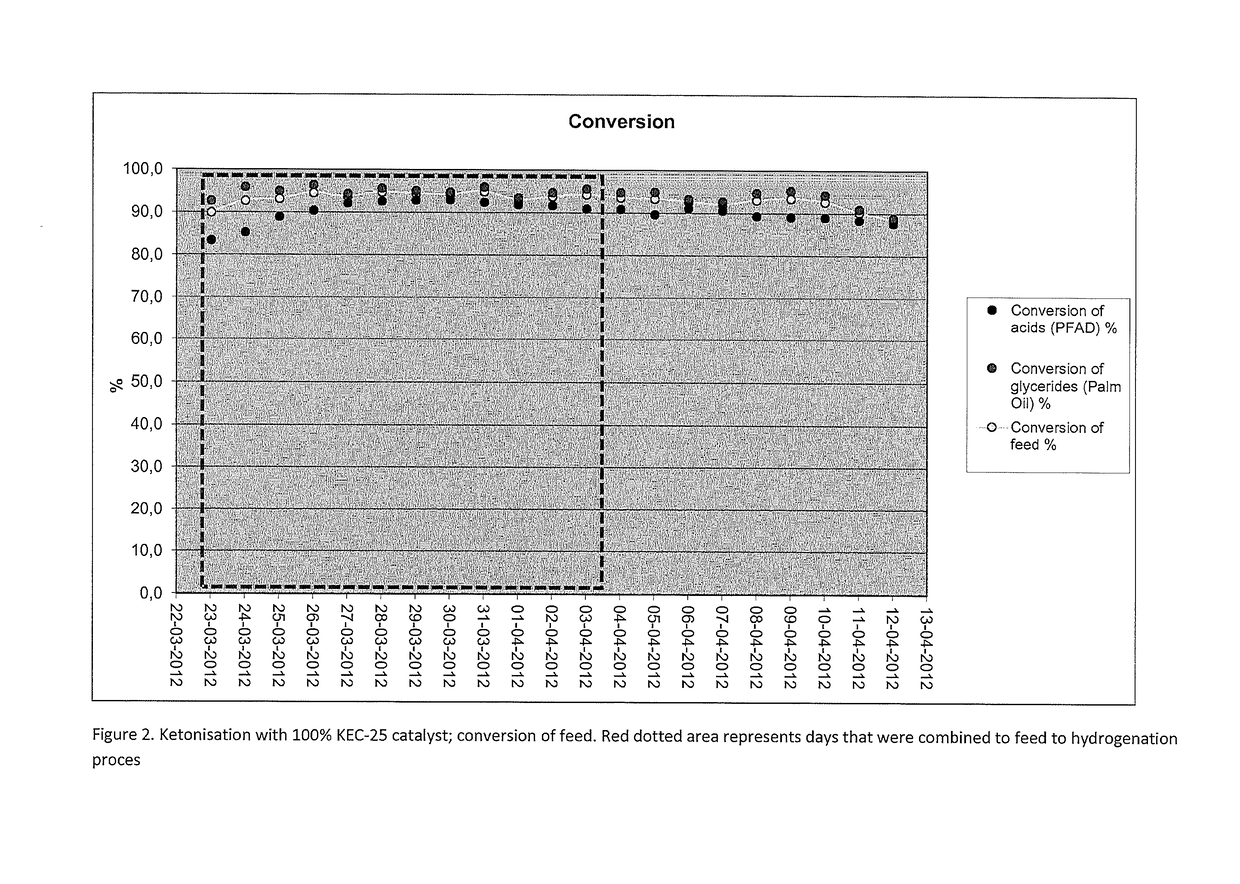

Method for ketonisation of biological material

ActiveUS20170362154A1Simple and cost-effectiveIncrease chain lengthMolecular sieve catalystsRefining to change hydrocarbon structural skeletonKetoneChain length

A method for producing ketones includes a) providing a feedstock of biological origin having fatty acids and / or fatty acid derivatives having an average chain length of 24 C-atoms or less; b) subjecting the feedstock to a catalytic ketonization reaction in the presence of aK2O / TiO2-catalyst; and c) obtaining from the ketonization reaction a product stream having ketones, which ketones have a longer average hydrocarbon chain length than the average hydrocarbon chain length in the feedstock, wherein step b) is carried out directly on the feedstock and in the presence of the K2O / TiO2-catalyst as the sole catalyst applied in the ketonization reaction.

Owner:NESTE OIL OY

Method for producing polyester-imine wire coating enamel

ActiveCN104140757AReduce energy consumptionSolve the problem of clogging and pressure suppression of the reactorCoatingsPolyesterPolymer science

The invention relates to a method for producing polyester-imine wire coating enamel. The method is characterized by comprising the following steps: firstly, performing ester exchange reaction on dimethyl terephthalate, ethylene glycol and THEIC under the catalysis of tetrabutyl titanate; reserving methanol in a reflux tank of methanol in advance; pumping methanol to the top of a rectification column by virtue of a reflux pump for reflux to wash sublimated dimethyl terephthalate; after the ester exchange reaction ends, adding trimellitic anhydride and 4,4'-diaminodiphenylmethane by precisely controlling the feeding temperature of imidization reaction to prepare polyester imide resin; secondly, mixing and blending the polyester imide resin, bisphenol A modified phenolic resin, poly butyl titanate, high methyl-etherified melamine resin, sodium perfluorononoxy benzene sulfonate and an S-100 solvent to obtain paint. The prepared polyester-imine wire coating enamel has good lubricating property and leveling property, and is convenient for downstream users to coat lines under high DV values; an enamelled wire obtained by coating the lines by using the paint has good thermal property and mechanical property.

Owner:JIANGSU BAICHUAN GAOKE NEW MATERIAL CO LTD +1

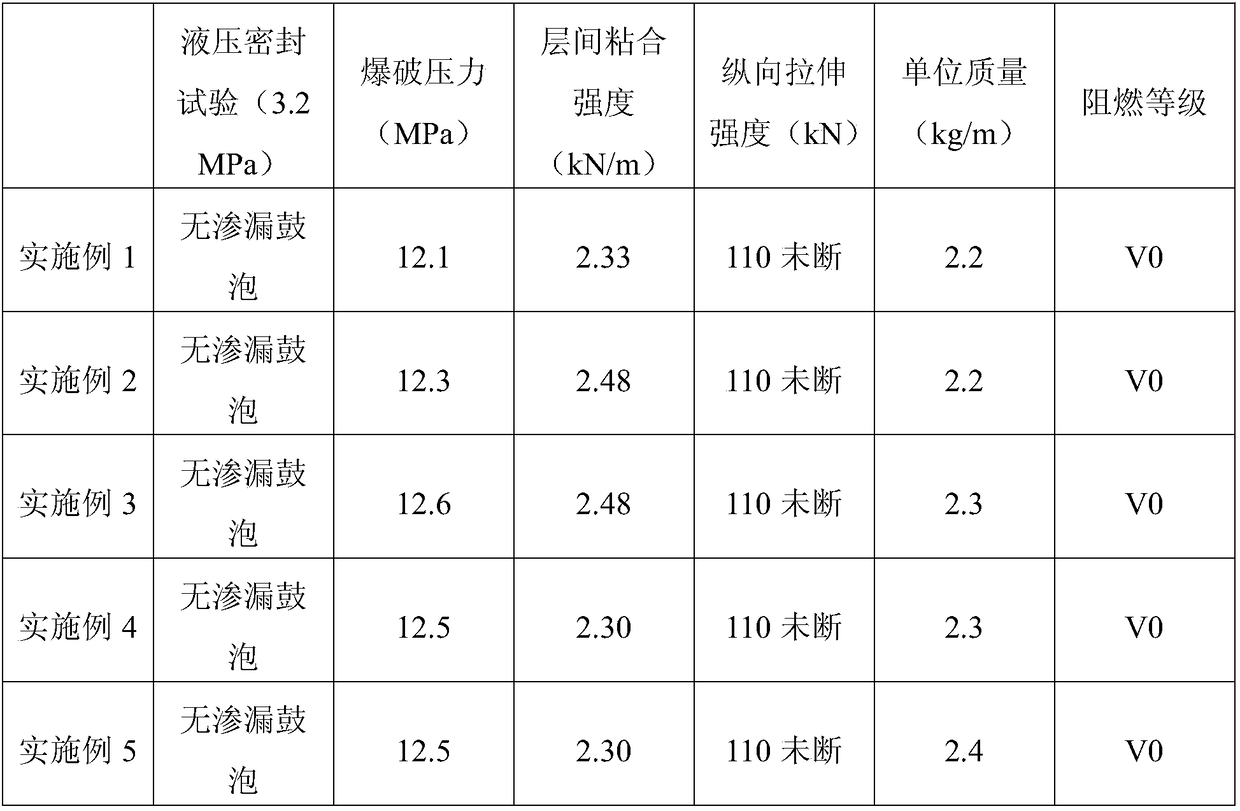

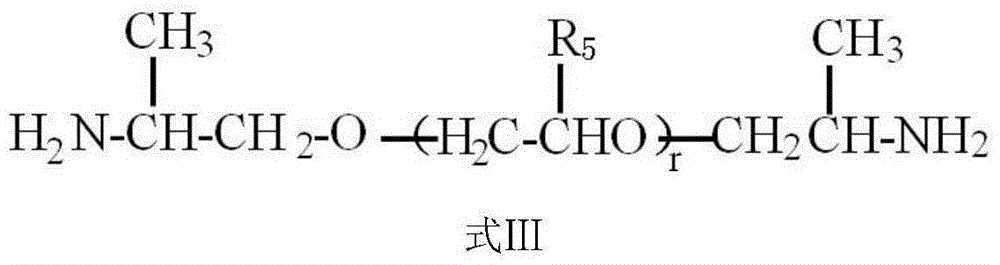

Flame-retardant bio-based polyurethane hose and production method thereof

ActiveCN108253207AIncrease chain lengthHigh molecular weightFlexible pipesPipe protection against damage/wearFiberPolyol

The invention discloses a flame-retardant bio-based polyurethane hose. An inner rubber layer and an outer rubber layer are bio-based polyurethane thermoplastic elastic bodies, and a strip billet reinforcement layer is formed by weaving polyimide fibers. Meanwhile, a production method of the hose is disclosed. According to the bio-based polyurethane thermoplastic elastic bodies, soybean oil is adopted as initial raw materials, the thermal bodying (Diels Alder cyclization reaction) and ozonation / reduction technology relatively simple in process is applied in a cooperation manner, bio-based polyol containing high-reactivity primary hydroxyl is prepared, the polyurethane thermoplastic elastic bodies are prepared on the basis, and therefore existing petroleum-based polyol can be replaced; a flame retardant is added, mechanical performance degradation of the bio-based polyurethane thermoplastic elastic bodies is avoided, and meanwhile the flame-retardant performance of the bio-based polyurethane thermoplastic elastic bodies is improved; and the strip billet reinforcement layer is formed by weaving the self-flame-retardant polyimide fibers, and the hose has the excellent flame retardant performance.

Owner:ZHONG YU HOSES TECH CO LTD

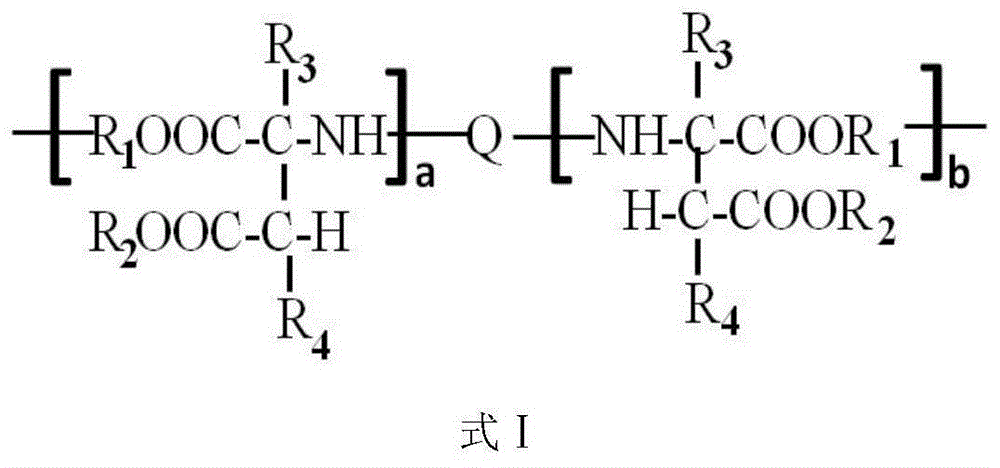

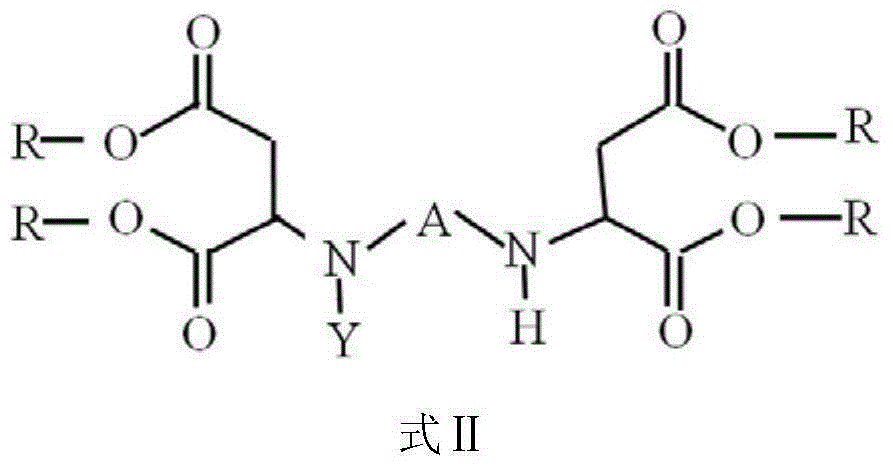

Anti-corrosion paint, application thereof and pipeline coating

ActiveCN105199573AIncrease chain lengthImprove low temperature toughnessAnti-corrosive paintsPolyurea/polyurethane coatingsPrepolymerPolyaspartic acid

The invention provides anti-corrosion paint, an application thereof and a pipeline coating. The anti-corrosion paint comprises a first component and a second component, wherein the first component comprises polyether amine, first modified polyaspartic acid ester and second modified polyaspartic acid ester, and the second component comprises isocyanate and / or a prepolymer thereof. Compared with traditional polyaspartic acid ester urea paint, by means of the added polyether amine component, ether linkage with good flexibility can be introduced in a final cured resin molecular chain, and the chain length and the low-temperature toughness of the cured resin molecular chain are improved; by means of added second modified polyaspartic acid ester, increase of the heat-resistant temperature as well as improvement of weather resistance, smoothness and scratching resistance of the coating is facilitated. When the anti-corrosion paint is matched with a fusion bonded epoxy powder bottom coating, the problems of stripping and joint coating stripping in application of a polyethylene anti-corrosion layer of a conventional pipeline as well as poor high temperature cathodic stripping resistance of a polyuria coating can be solved very well.

Owner:北京碧海云智新材料技术有限公司

Golf ball comprising renewable resource component

The invention is directed to a golf ball comprising a core and a cover, wherein at least one of the core and the cover comprises about 10 wt % or greater of a renewable polymer composition comprising an ultra high molecular weight polyhydroxyalkanoate compound having the formula:—OCR1R2(CR3R4)nCO—wherein n is an integer, and wherein R1, R2, R3 and R4 are selected from the group comprising saturated and unsaturated hydrocarbon radicals, halo- and hydroxy-substituted radicals, hydroxy radicals, halogen radicals; nitrogen-substituted radicals, oxygen-substituted radicals, or hydrogen atoms. In one embodiment, the golf ball also comprises about 90 wt % or less of a non renewable polymer composition. The golf ball may also comprise an intermediate layer disposed about the core and adjacent the cover, wherein at least one of the core, the cover and the intermediate layer comprises the renewable polymer composition. The at least one of the core and the cover or the intermediate layer may comprise a hardness of from about 50 Shore C to about 90 Shore C.

Owner:ACUSHNET CO

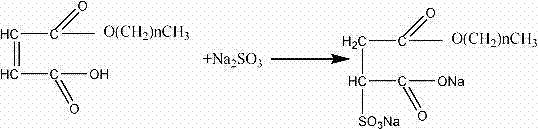

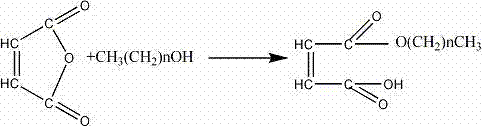

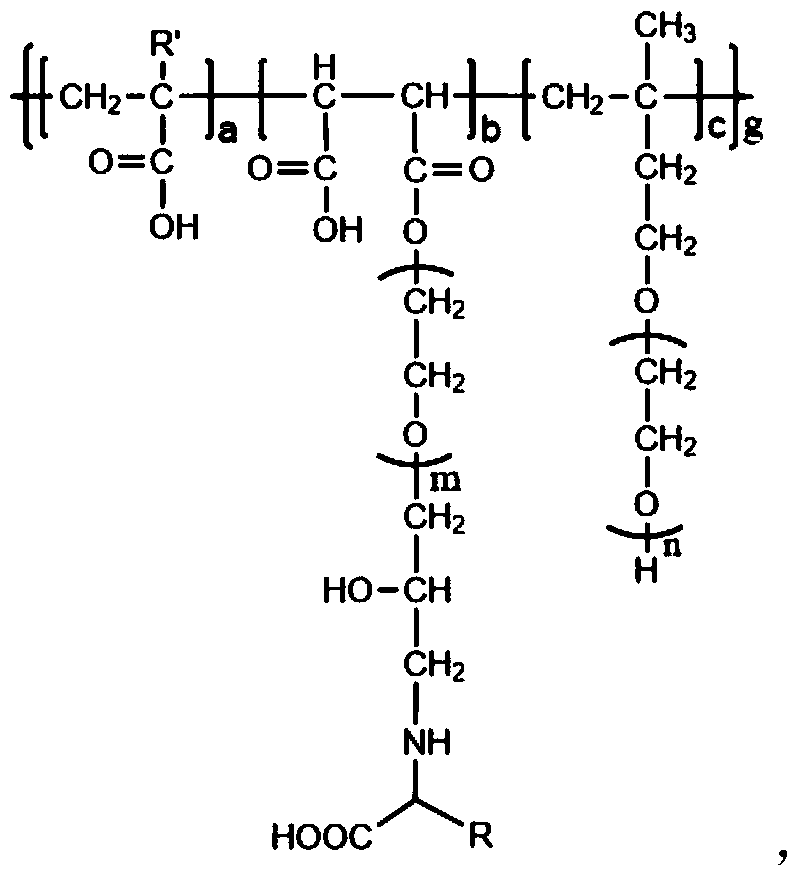

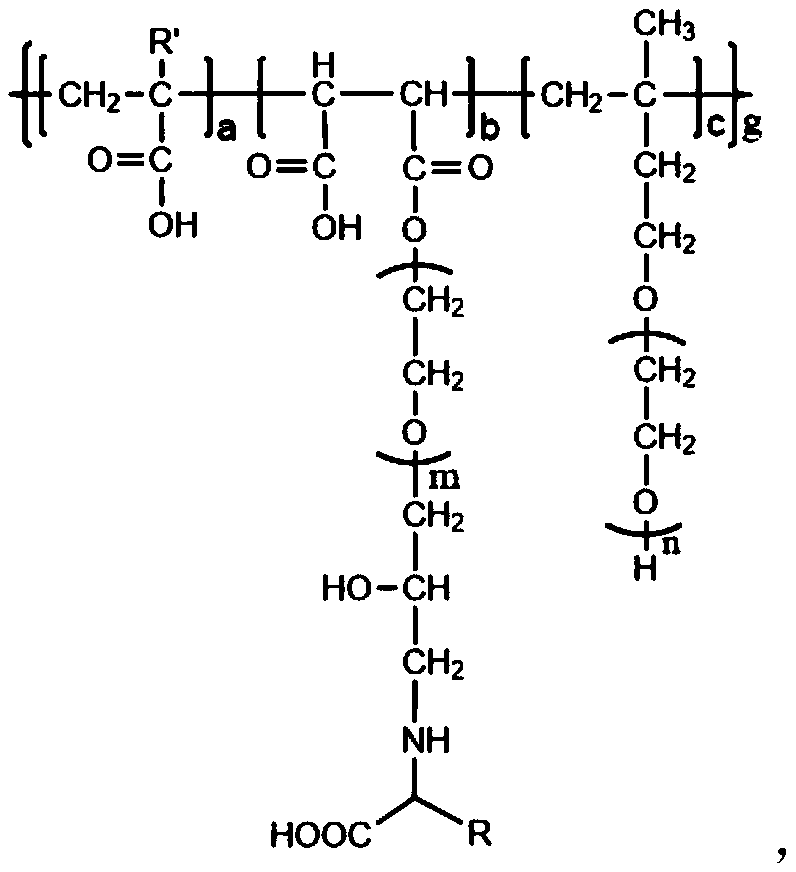

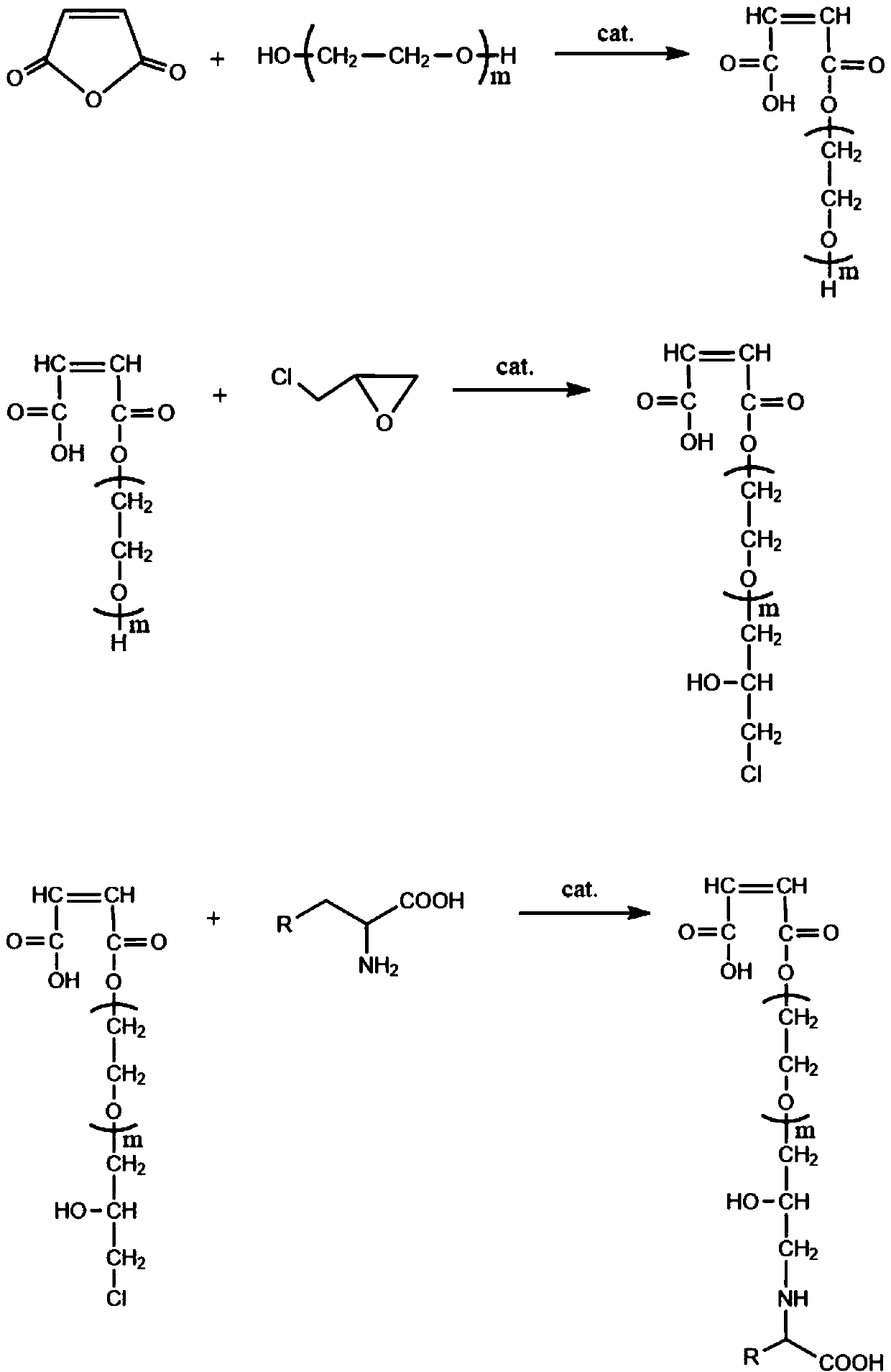

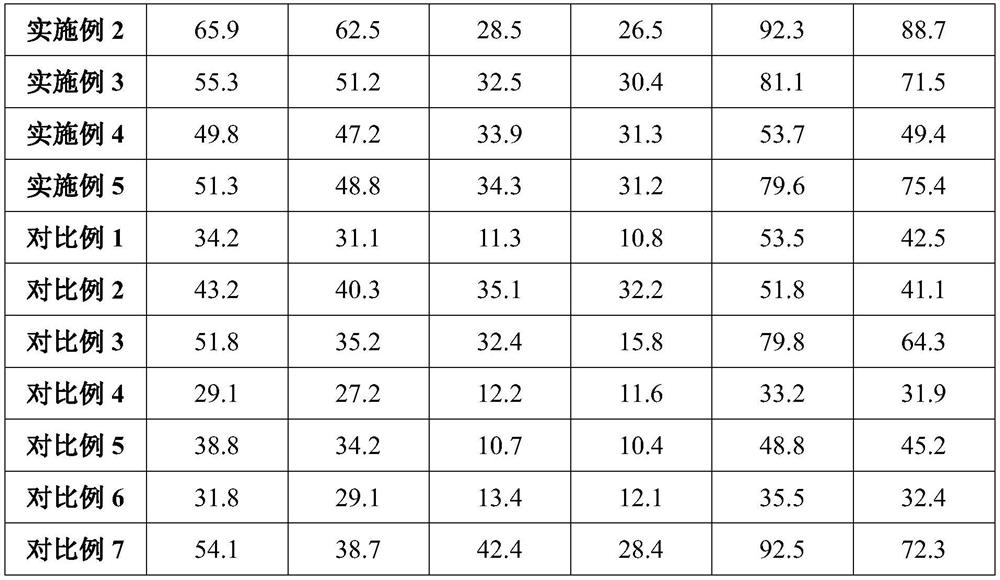

Amino acid-modified mud-resistant polycarboxylic acid water reducing agent and preparation method thereof

ActiveCN110760037AImprove anti-adsorption abilityImprove copolymerization compatibilityOrganic compound preparationPreparation by caroxylic acid/anhydride-hydrocarbon reactionMaleic anhydrideAcid water

The invention discloses an amino acid-modified mud-resistant polycarboxylic acid water reducing agent. An amino acid-modified unsaturated acid ester, an unsaturated carboxylic acid, and isopentenol polyoxyethylene ether are used as raw materials, and the polycarboxylic acid water reducing agent is formed by free radical polymerization under the action of an initiator and a chain transfer agent. The amino acid-modified unsaturated acid ester is prepared by using maleic anhydride, polyethylene glycol, epichlorohydrin and an amino acid as raw materials, and sequentially carrying out an esterification reaction, a ring-opening reaction and a substitution reaction under the condition of no solvent. The mass percentage of each raw material is as follows: 3-15% of the amino acid-modified unsaturated acid ester, 5-13% of the unsaturated carboxylic acid, 70-90% of the isopentenol polyoxyethylene ether, 0.5-1.5% of the initiator, and 0.5-1.0% of the chain transfer agent. The water reducing agenthas the effects of an absorption anchoring group and a steric hindrance structure, and at the same time, the electrostatic repulsion effect, a non-polar structure, and the terminal steric hindrance effect of the water reducing agent are utilized to inhibit the surface adsorption and intercalation adsorption of the water reducing agent by clay, so that adsorption resistance to clay is improved.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD +2

Method for synthesizing grafted starch pulp by utilizing bioenzyme

InactiveCN102212169AImprove performanceEvenly distributedFibre treatmentFermentationGamma irradiationChloride

The invention relates to a preparation method for grafted starch pulp, in particular to a method for synthesizing grafted starch pulp by utilizing bioenzyme, which is characterized by comprising the following steps: 1) irradiating native starch in a <60>Co-gamma irradiation field to obtain irradiated starch; 2) treating the irradiated starch with a debranching enzyme: mixing the irradiated starch with water, carrying out internal mixing in an internal mixer, then cooling to 40-60 DEG C, adding a calcium chloride solution and the debranching enzyme, and continuing internal mixing for 30-60 minutes to obtain amylose; and 3) adding alpha-olefin to the amylose, heating to 110-140 DEG C, and continuing internal mixing for 30-60 minutes to obtain the grafted starch pulp, wherein the addition amount of the alpha-olefin is 6-10% of the irradiated starch by mass. The method has the advantages of simple process, low equipment investment and low cost, and can achieve a good sizing effect and good film sizing property.

Owner:湖北顶新环保新材料有限公司

Non-curing polyurethane waterproof coating and preparation method thereof

ActiveCN103923565BGood adhesionGrowth Intermediate ConnectivityPolyurea/polyurethane coatingsBituminous coatingsElastomerPolymer science

The invention relates to a non-curing polyurethane waterproof coating and a preparation method thereof, belonging to the technical field of polyurethane waterproof coating. It consists of the following raw materials in percentage by weight: prepolymer 13-20%, asphalt 30-65%, latent curing agent 1.0-1.5%, compatibilizer 3-15%, thermoplastic elastomer 2-9%, powder Sexual filler 0-30%, the prepolymer is a reaction composition of polyether and isocyanate. The core of the invention improves the material ratio and polymerization process of polyurethane, which overcomes the problems that hot-melt asphalt materials need to be heated by machines, etc. It is convenient for construction and has good fluidity. The waterproof layer without internal stress can also have good adhesion with the coiled material. It can be composited waterproof to form a waterproof layer that overcomes the cracking of the base layer and prevents puncture. The process is simple and can be quickly constructed. It needs maintenance and has fast work efficiency, which can become the development direction of building waterproofing in the future.

Owner:浙江鲁班建材科技股份有限公司

Golf ball comprising renewable resource component

The invention is directed to a golf ball comprising a core and a cover, wherein at least one of the core and the cover comprises about 10 wt % or greater of a renewable polymer composition comprising an ultra high molecular weight polyhydroxyalkanoate compound having the formula:—OCR1R2(CR3R4)nCO—wherein n is an integer, and wherein R1, R2, R3 and R4 are selected from the group comprising saturated and unsaturated hydrocarbon radicals, halo- and hydroxy-substituted radicals, hydroxy radicals, halogen radicals; nitrogen-substituted radicals, oxygen-substituted radicals, or hydrogen atoms. The ultra high molecular weight polyhydroxyalkanoate compound is coupled with the at least one non renewable polymer composition by at least one of dipole-dipole coupling, ion-dipole coupling, ion-ion coupling and coupling via hydrogen bonding. In one embodiment, the golf ball comprises about 90 wt % or less of the non renewable polymer composition. The golf ball may also comprise an intermediate layer disposed about the core and adjacent the cover, wherein at least one of the core, the cover and the intermediate layer comprises the renewable polymer composition. The at least one of the core, the cover and the intermediate layer may comprise a hardness of from about 50 Shore C to about 90 Shore C.

Owner:ACUSHNET CO

Recycled polyester material and preparation method thereof

ActiveCN111978686AHigh tensile strengthImprove bending strengthPlastic recyclingPolyesterGlass fiber

The invention discloses a recycled polyester material and a preparation method thereof. The recycled polyester material is composed of waste polyester, an inorganic filler, glass fiber, a chain extender, a deodorant, a dispersant, an antioxidant, an ultraviolet absorber and a heat stabilizer. The preparation method of the recycled polyester material includes the following steps: 1) preparing wastepolyester particles; 2) mixing the waste polyester particles, the inorganic filler, the glass fiber, the chain extender, the deodorant and the dispersant uniformly, and carrying out extrusion granulation to obtain the recycled material; and 3) mixing the recycled material, the antioxidant, the ultraviolet absorber and the heat stabilizer uniformly, and then performing extrusion granulation to obtain the recycled polyester material. The recycled polyester material has high tensile strength, high bending strength, high elongation at break, good aging resistance and good workability, the recycling preparation process is simple, and the recycled polyester material can be used as an injection molding raw material of helmets, household appliance shells, building boards and toys without additionof new resin.

Owner:GUANGZHOU UNIVERSITY

Golf ball comprising renewable resource component

The invention is directed to a golf ball comprising a core and a cover, wherein at least one of the core and the cover comprises about 10 wt % or greater of a renewable polymer composition comprising an ultra high molecular weight polyhydroxyalkanoate compound having the formula:—OCR1R2(CR3R4)nCO—wherein n is an integer, and wherein R1, R2, R3 and R4 are selected from the group comprising saturated and unsaturated hydrocarbon radicals, halo- and hydroxy-substituted radicals, hydroxy radicals, halogen radicals; nitrogen-substituted radicals, oxygen-substituted radicals, or hydrogen atoms. In one embodiment, the golf ball also comprises about 90 wt % or less of a non renewable polymer composition. The golf ball may also comprise an intermediate layer disposed about the core and adjacent the cover, wherein at least one of the core, the cover and the intermediate layer comprises the renewable polymer composition. The renewable polymer composition comprises at least one of a notched Izod impact strength of about 0.5 ft-lbs / inch or greater and a polydispersity of from about 1.0 to about 4.0. The at least one of the core and the cover or the intermediate layer may comprise a hardness of from about 50 Shore C to about 90 Shore C.

Owner:ACUSHNET CO

Black or gray biaxially oriented polyester film with a high portion of cyclohexanedimethanol and a primary and secondary dicarboxylic acid portion and a method for its production and its use

InactiveUS20120196968A1Cost-effective to manufactureGood electrical insulation propertyFlow mixersTransportation and packagingDicarboxylic acidDiol

The invention relates to a biaxially oriented film containing at least one black pigment. The film is predominantly formed from a polyester whose diol component includes at least 80 mol-% of 1,4-cyclohexanedimethanol (CHDM), and whose the dicarboxylic acid component includes at least 80 mol-% of one or more benzenedicarboxylic acid(s) and / or one or more naphthalene dicarboxylic acid(s). The dicarboxylic acid component includes a main dicarboxylic acid component forming an at least 55 mol-% portion, chosen from either 2,6-naphthalene dicarboxylic acid or terephthalic acid. The dicarboxylic acid component further includes a secondary dicarboxylic acid component, present in an amount of at least 18 mol-%, with the secondary dicarboxylic acid component differing from the main dicarboxylic acid component. The invention further relates to a method for producing the film and its use.

Owner:MITSUBISHI POLYESTER FILM

Novel positive ion fixative preparing method

The invention discloses a novel positive ion fixative preparing method. The novel positive ion fixative preparing method comprises the following steps that mixing is conducted by using dimethylamine as the main raw material, using hexamethylenediamine and dimethylamino-ethyl methylacrylate as auxiliary materials and using water as solvent, so that a mixed monomer is formed, wherein the molar ratio of the hexamethylendiamine to the dimethylamine is 0.01-0.5:1; epoxy chloropropane is dripped into the mixed monomer in the first step, so that a pre-polymerized monomer is formed, wherein the molar ratio of the epoxy chloropropane to the mixed monomer is 0.5-4:1, and the reaction temperature is controlled between 10 DEG C and 60 DEG C; after dripping is completed, the temperature is kept between 70 DEG C and 95 DEG C, and water is added and the reaction is ended when the viscosity is increased to 300-1000 cps; inorganic acid and water are added into an obtained product, and the pH value is adjusted to be 3-5. According to the novel positive ion fixative preparing method, the reaction condition is mild, the reaction yield is high, and sudden polymerization caused by direct polymerization is avoided; in addition, the electric charge density is higher than that of similar products in China and foreign counties by 10%, the production cost is low, and the method is suitable for large-scale industrial production.

Owner:TIANHE CHEM SUZHOU CO LTD

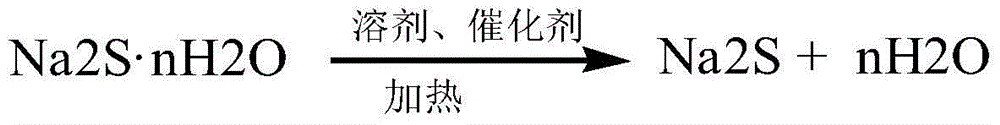

Method for synthesizing fiber-grade polyphenylene sulfide through adding composite accelerant in intermediate stage

The invention discloses a method for synthesizing fiber-grade polyphenylene sulfide through adding a composite accelerant in an intermediate stage. The method comprises the step: with p-dichlorobenzene and waterish sodium sulfide as reaction raw materials, synthesizing polyphenylene sulfide through polycondensation, wherein the composite accelerant is added in the intermediate stage of the reaction and is formed by mixing the four components: lithium chloride, p-dichlorobenzene, trichlorobenzene and / or m-dichlorobenzene and N-methylpyrrolidone. Compared with the prior art, the method disclosed by the invention is simple in process and low in production cost, and the synthesized polyphenylene sulfide is high in molecular weight, good in appearance and favorable in quality.

Owner:ZHUHAI CHANGXIAN CHEM TECH

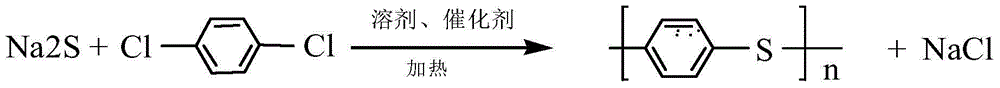

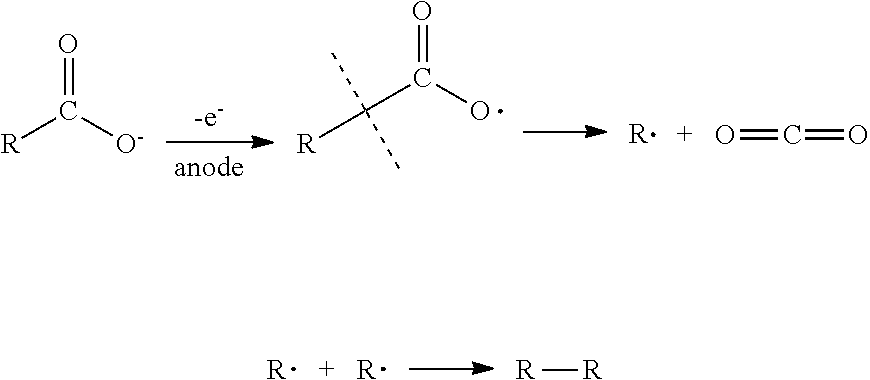

Process for producing alkanes using microorganisms combined with kolbe synthesis

InactiveUS20180208947A1Increased and decreased level of acyl-CoAIncrease chain length specificityElectrolysis componentsElectrolytic organic coupling reactionsCarboxylateChemistry

The present invention relates to a method of producing at least one alkane, the method comprising, —producing at least one carboxylic acid from a carbon source using a genetically modified microorganism, and —performing Kolbe electrolysis on the carboxylic acid to produce the alkane, wherein the alkane comprises at least 6 carbon atoms and the carboxylic acid comprises at least 4 carbon atoms and wherein the carbon source is selected from the group consisting of ethanol, acetate, propionate, butyrate, isobutyrate, valerate, hexanoate and combinations thereof and the microorganism is capable of producing the carboxylic acid using ethanol-carboxylate fermentation.

Owner:EVONIK DEGUSSA GMBH

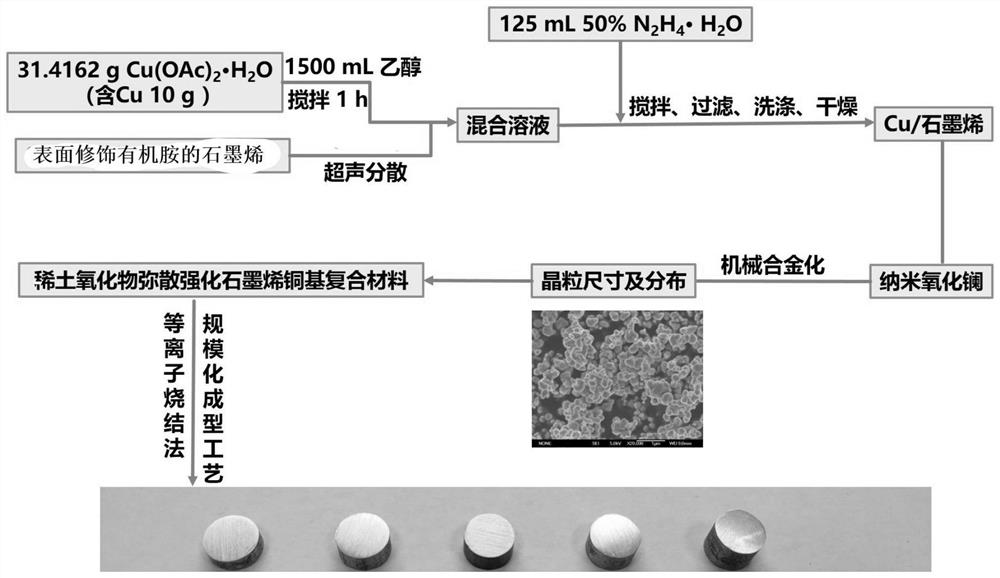

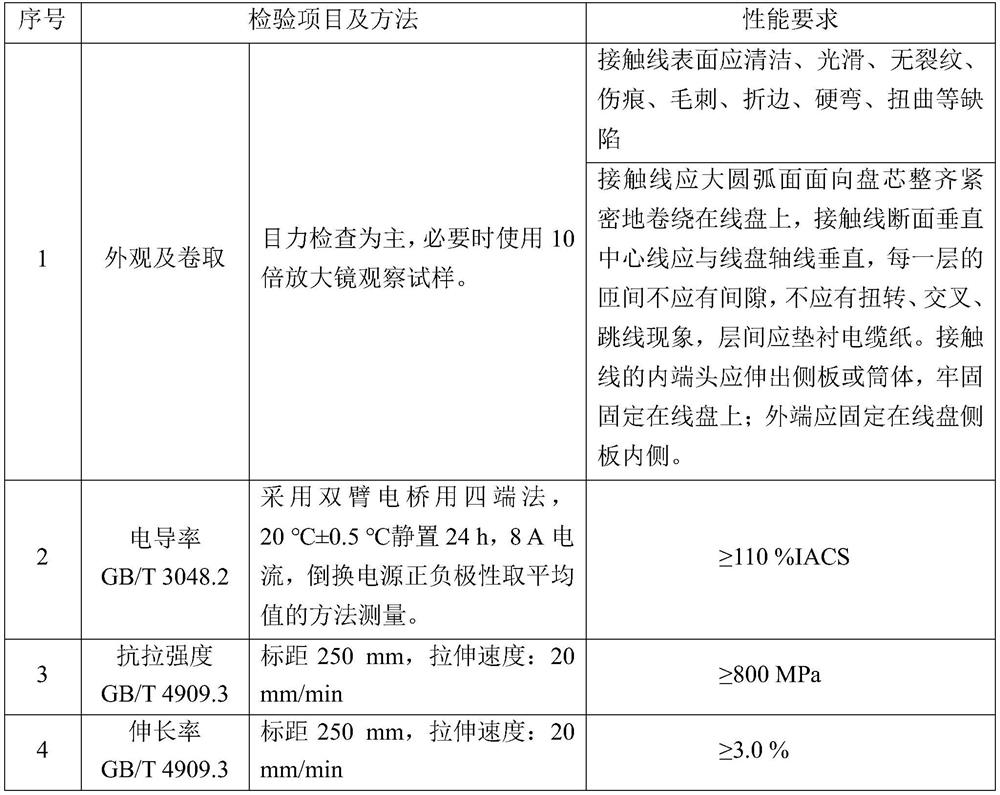

Rare earth modified graphene copper-based composite material and preparation method and application thereof

ActiveCN114480899AReduce conductivityHigh mechanical strengthCarbon compoundsConductive materialCopper saltGraphene

The invention belongs to the field of modification of graphene copper-based composite materials in the field of materials, and particularly relates to a rare earth modified graphene copper-based composite material and a preparation method and application thereof. The preparation method comprises the specific steps that graphite, organic amine and an alcohol substance are subjected to ball milling and then separated in different centrifugal intervals, the obtained product is dispersed into the alcohol substance to obtain dispersion liquid, then the dispersion liquid and copper salt are subjected to a copper mirror reaction and reduced to prepare the graphene copper-based composite material, the graphene copper-based composite material and rare earth oxide are mixed and subjected to ball milling to obtain mixed powder, and the graphene copper-based composite material is prepared. And finally, spark plasma sintering is conducted, and the rare earth modified graphene copper-based composite material is obtained. The graphene copper-based composite material is prepared by constructing a uniform and stable graphene-amine salt-copper ion system, and the problem that the interface bonding property between graphene and copper is poor is solved; the design and preparation of the rare earth oxide dispersion strengthened copper-based composite material are provided, and the mechanical strength of the copper-based composite material can be greatly improved while the conductivity is not obviously reduced.

Owner:SHENZHEN INST OF ADVANCED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com