Method for preparing nano-SiO2 and PVA fiber reinforced polymer mortar

A fiber-reinforced, geopolymer technology is applied in the field of preparation of nano-SiO2 and PVA fiber-reinforced geopolymer mortar to achieve the effects of saving resources and energy, low price and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Nanometer SiO 2 and PVA fiber reinforced polymer mortar preparation raw materials

[0026] Prepare nano-SiO in this embodiment 2 And the materials used in PVA fiber reinforced geopolymer mortar mainly include water, metakaolin, fly ash, water glass, sodium hydroxide, quartz sand, PVA fiber, nano-SiO 2 , water reducing agent, etc., the performance indicators of the raw materials used meet the test requirements, as follows:

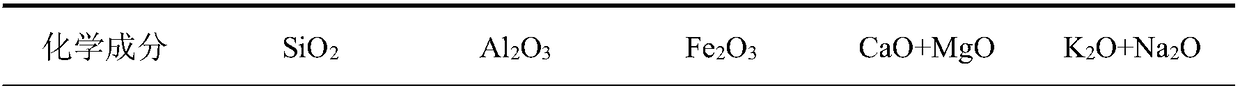

[0027] Metakaolin: The metakaolin produced by Shijiazhuang Chenxing Industrial Co., Ltd. was used in the test, and its chemical composition and physical properties are shown in Table 1 and Table 2.

[0028] Table 1 Main chemical components of metakaolin

[0029]

[0030]

[0031] Table 2 Main physical properties of metakaolin

[0032]

[0033] Fly ash: Class I fly ash produced by Datang Luoyang Thermal Power Co., Ltd. was used in the test of the present invention. The main physical properties are shown in Table 3.

[0034] Tab...

Embodiment 2

[0053] Example 2 Nano SiO 2 Mixing ratio design with PVA fiber reinforced geopolymer mortar

[0054] The embodiment of the present invention investigates PVA fiber dosage, nano-SiO 2 The effect of doping factor on nano-SiO 2 and PVA fiber-reinforced geopolymer mortar mechanical properties, so the control variable method is used in the design of the mix ratio, that is, the fixed water-cement ratio, mortar ratio, water glass modulus and gel ratio (alkali activator and gelling agent) Material ratio) and only change the PVA fiber content or nano-SiO 2 dosage.

[0055] The optimum proportioning and consumption of NaOH and water glass required for polymer synthesis of the embodiment of the present invention compound ratio design, the water-to-cement ratio (the ratio of the water contained in the added water and the alkali activator to the gelled material mass) is determined to be 0.65, The mortar ratio is 1:1. Fly ash replaces 30% by mass of metakaolin in an equal amount, and t...

Embodiment 3

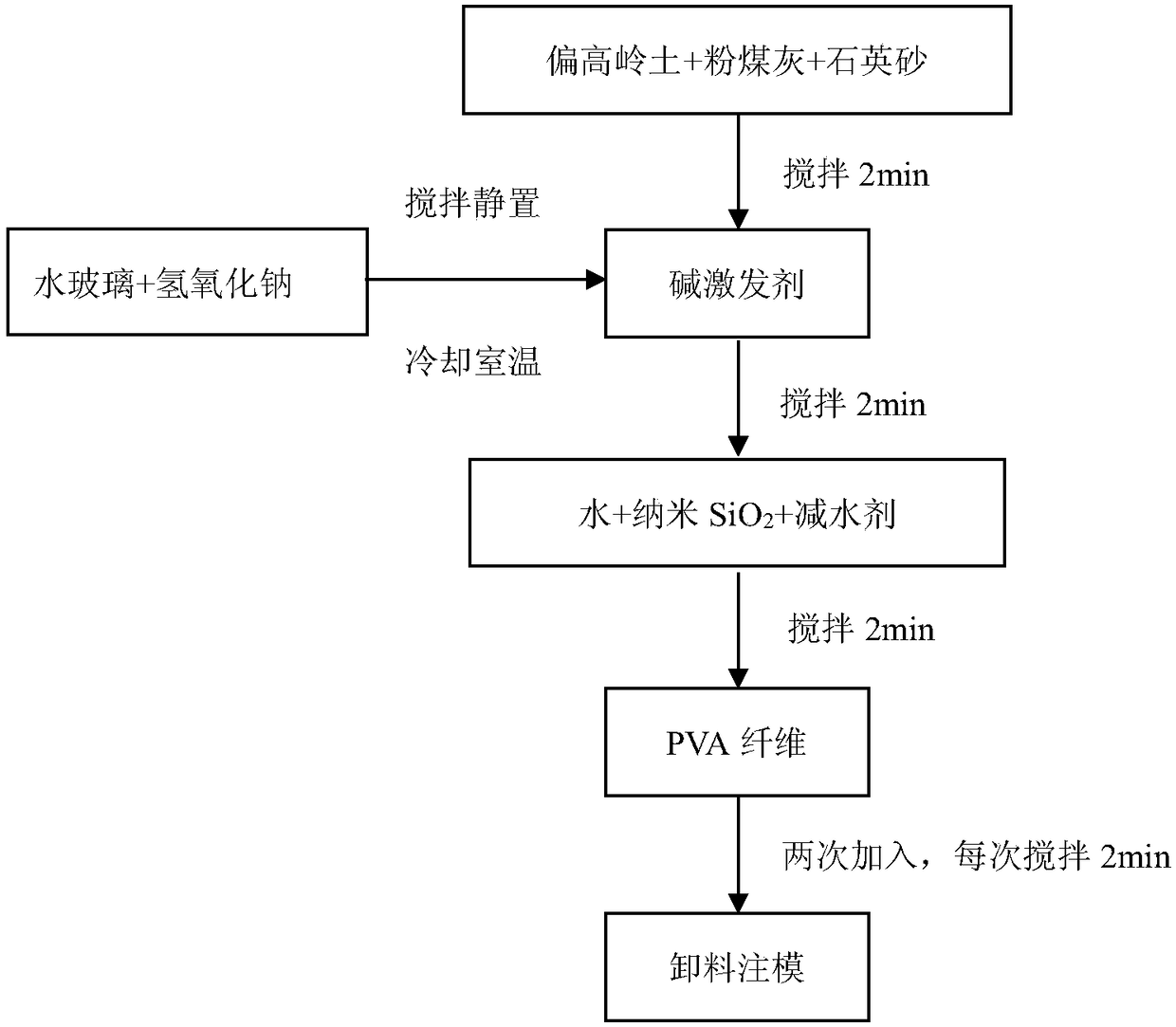

[0064] Example 3 Nano SiO 2 and PVA fiber reinforced geopolymer mortar preparation process

[0065] In the preparation of nano-SiO 2 and PVA fiber-reinforced polymer mortar, to ensure that nano-SiO 2 1. PVA fibers can be evenly distributed and freely dispersed in the matrix, in order to obtain repair mortar materials with good mechanical properties. In order to meet the test requirements, it is necessary to choose a suitable preparation method and process. Nano-SiO 2 And PVA fiber reinforced geopolymer mortar composite molding process such as figure 1 shown, the specific steps are as follows:

[0066] (1) Material pretreatment: Weigh raw material water, metakaolin, fly ash, quartz sand, alkali activator, PVA fiber, nano-SiO 2 , water reducing agent;

[0067] (2) Nano SiO 2 and PVA fiber-reinforced polymer mortar: the metakaolin, fly ash and quartz sand in step (1) were stirred in a mixer for 2 minutes, and under the condition of constant stirring, an alkali activator was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com