Patents

Literature

36results about "Electrolytic organic coupling reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions, devices, systems, for using a Nanopore

ActiveUS20100035260A1Low costRapidityBioreactor/fermenter combinationsElectrolysis componentsStructural biologyMolecular switch

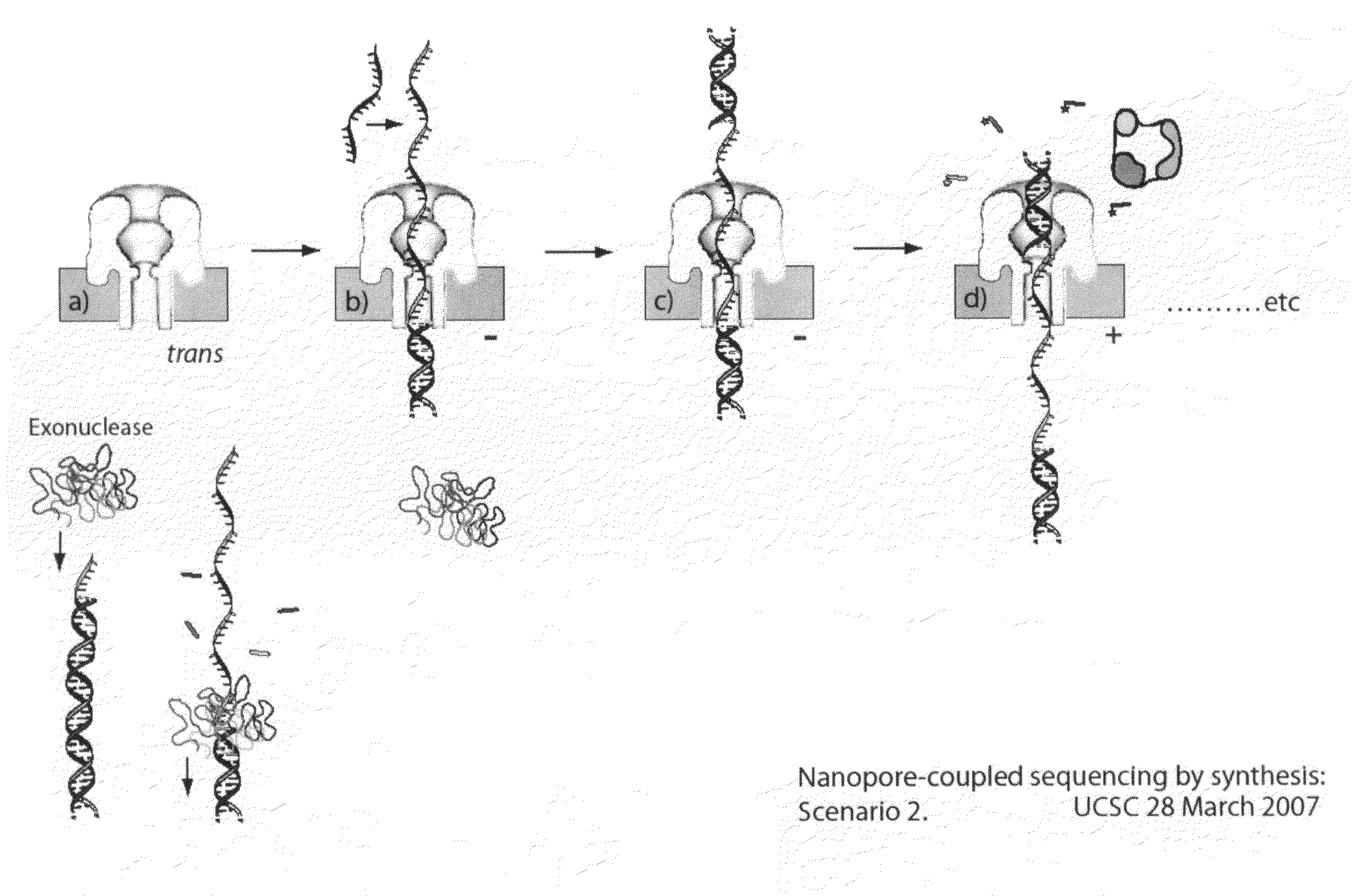

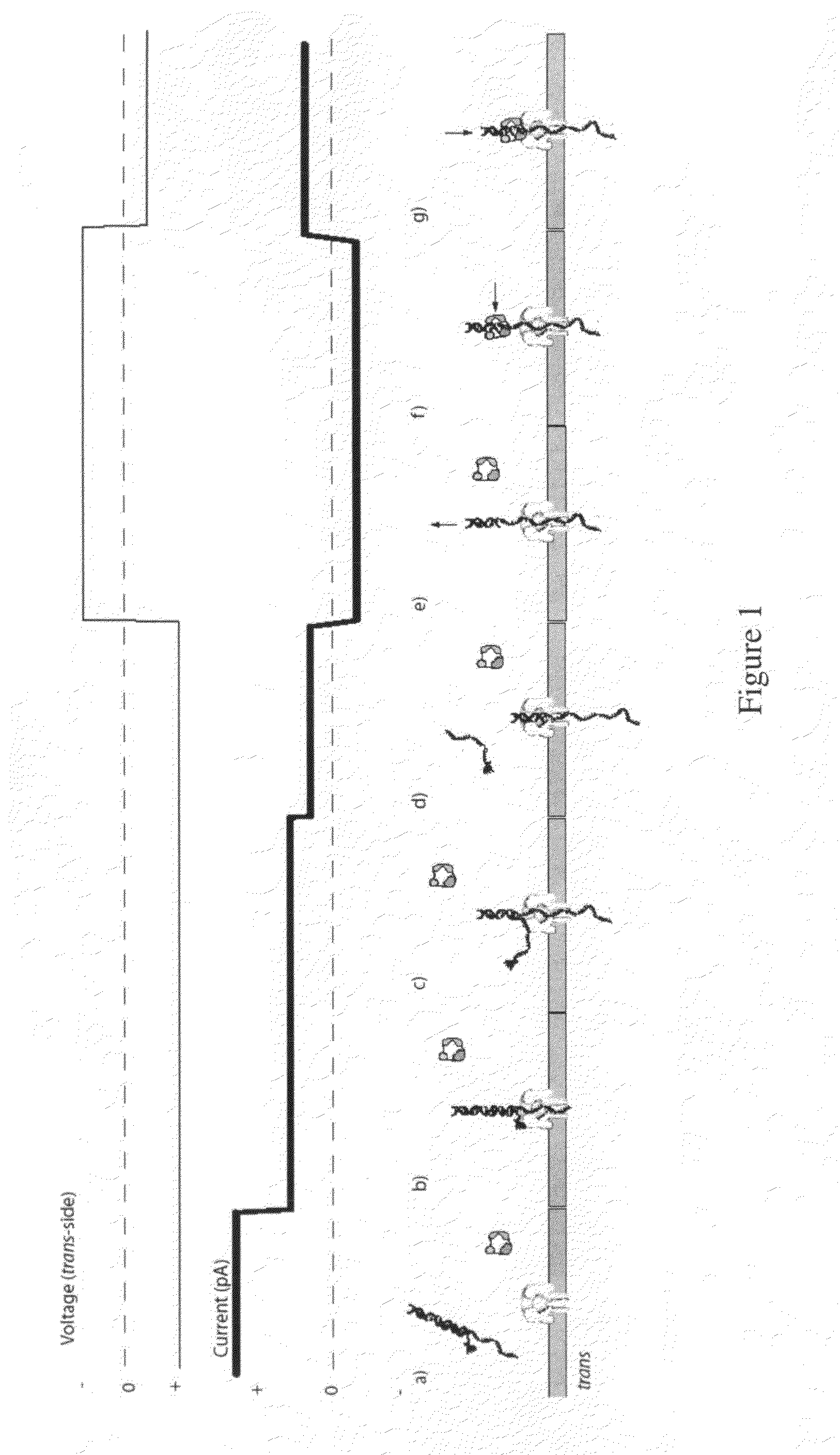

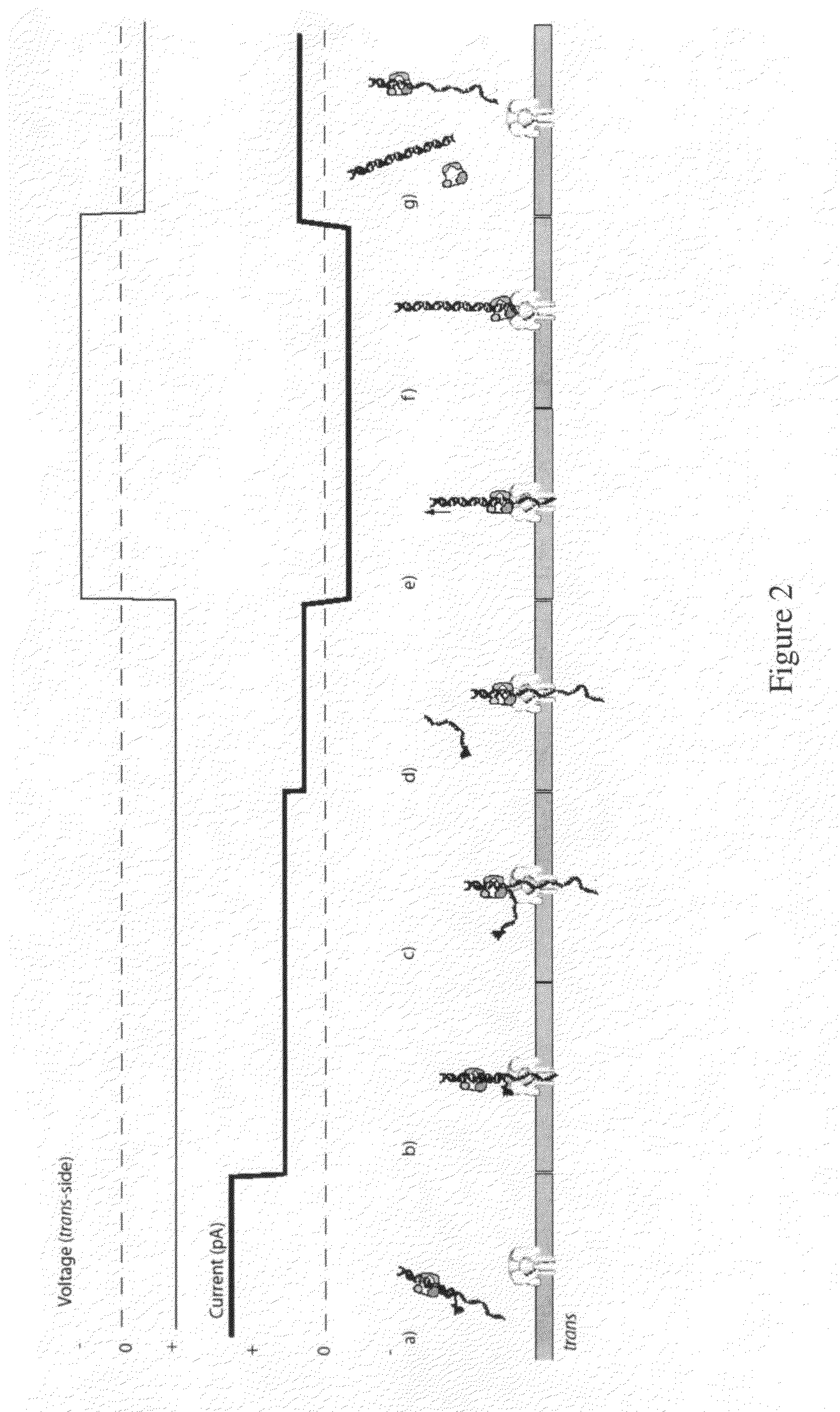

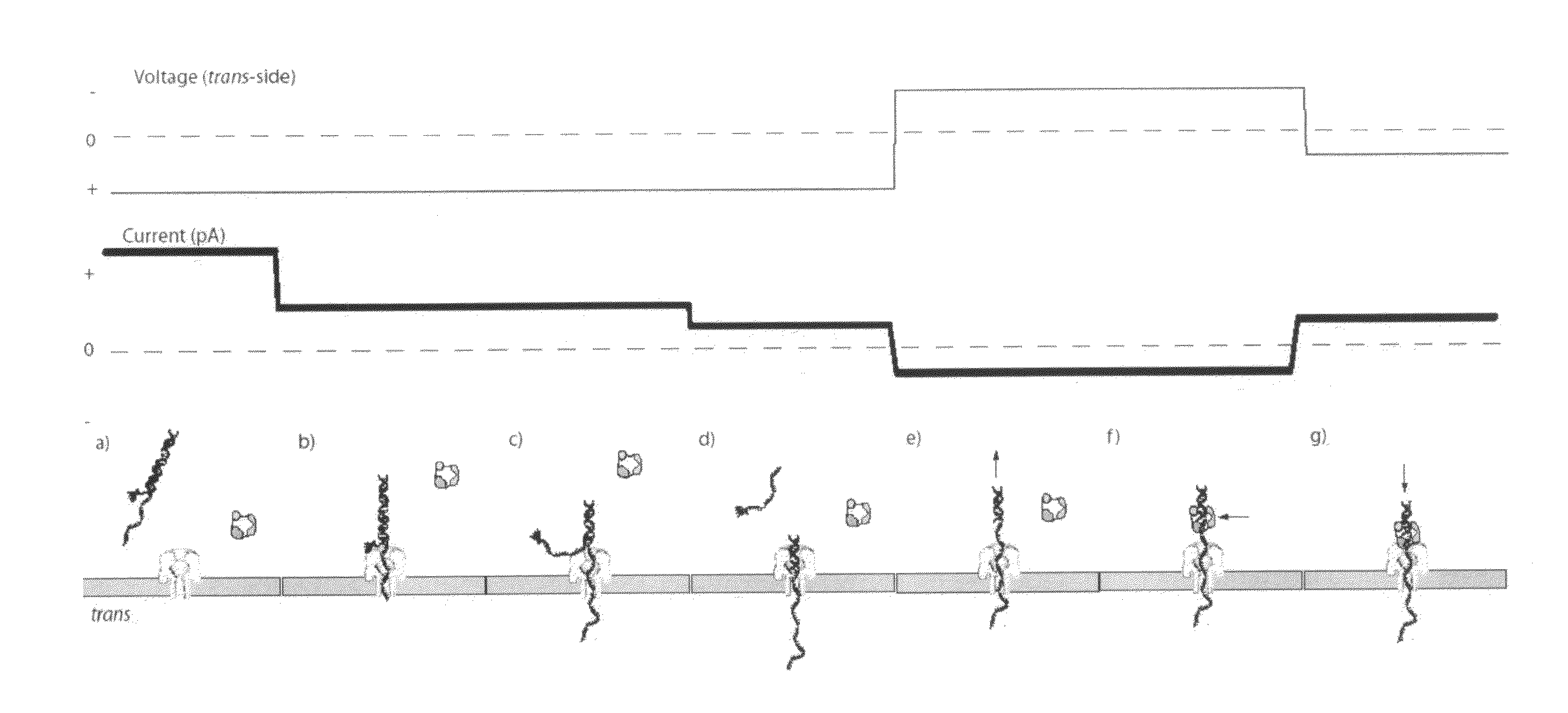

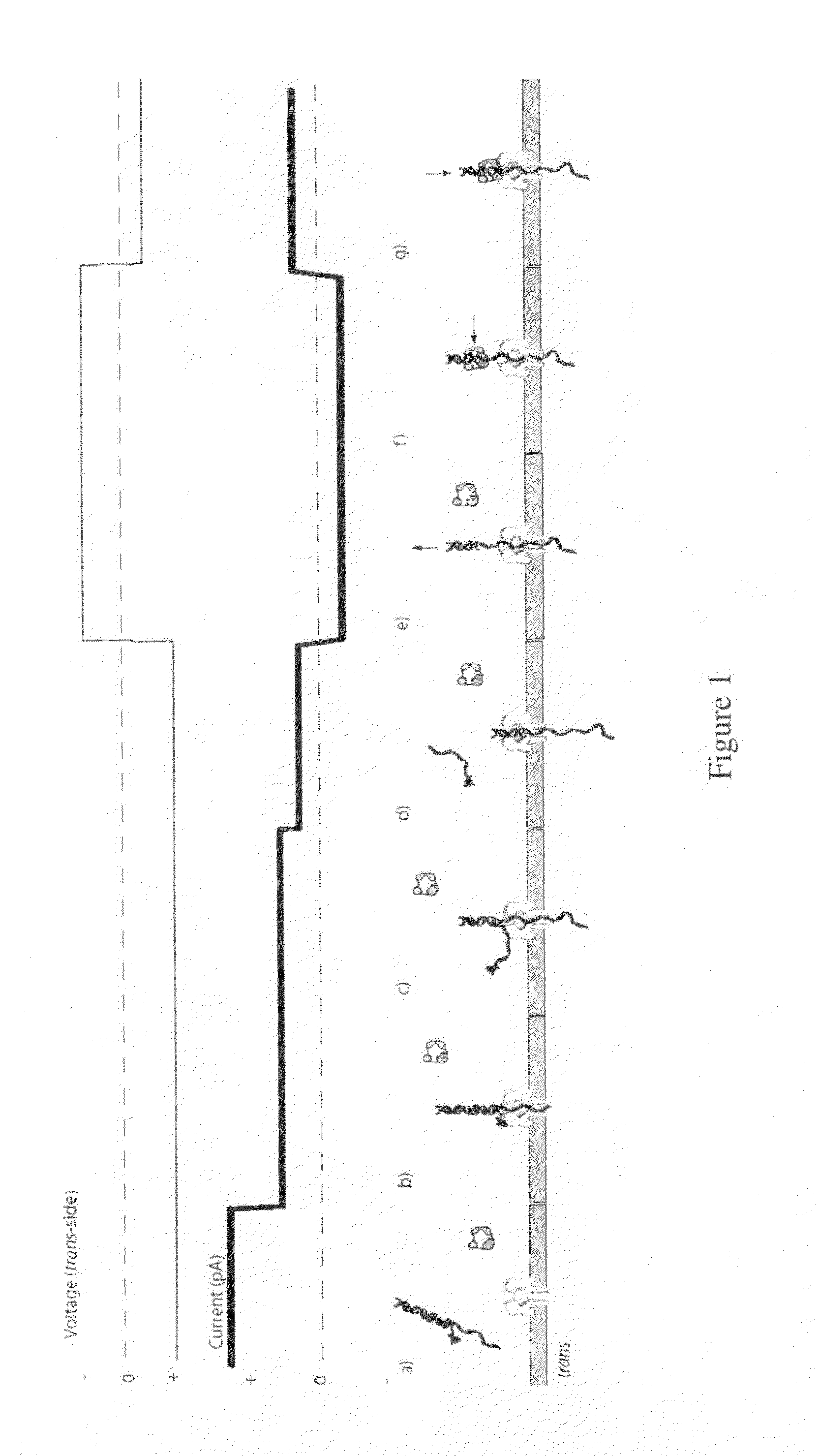

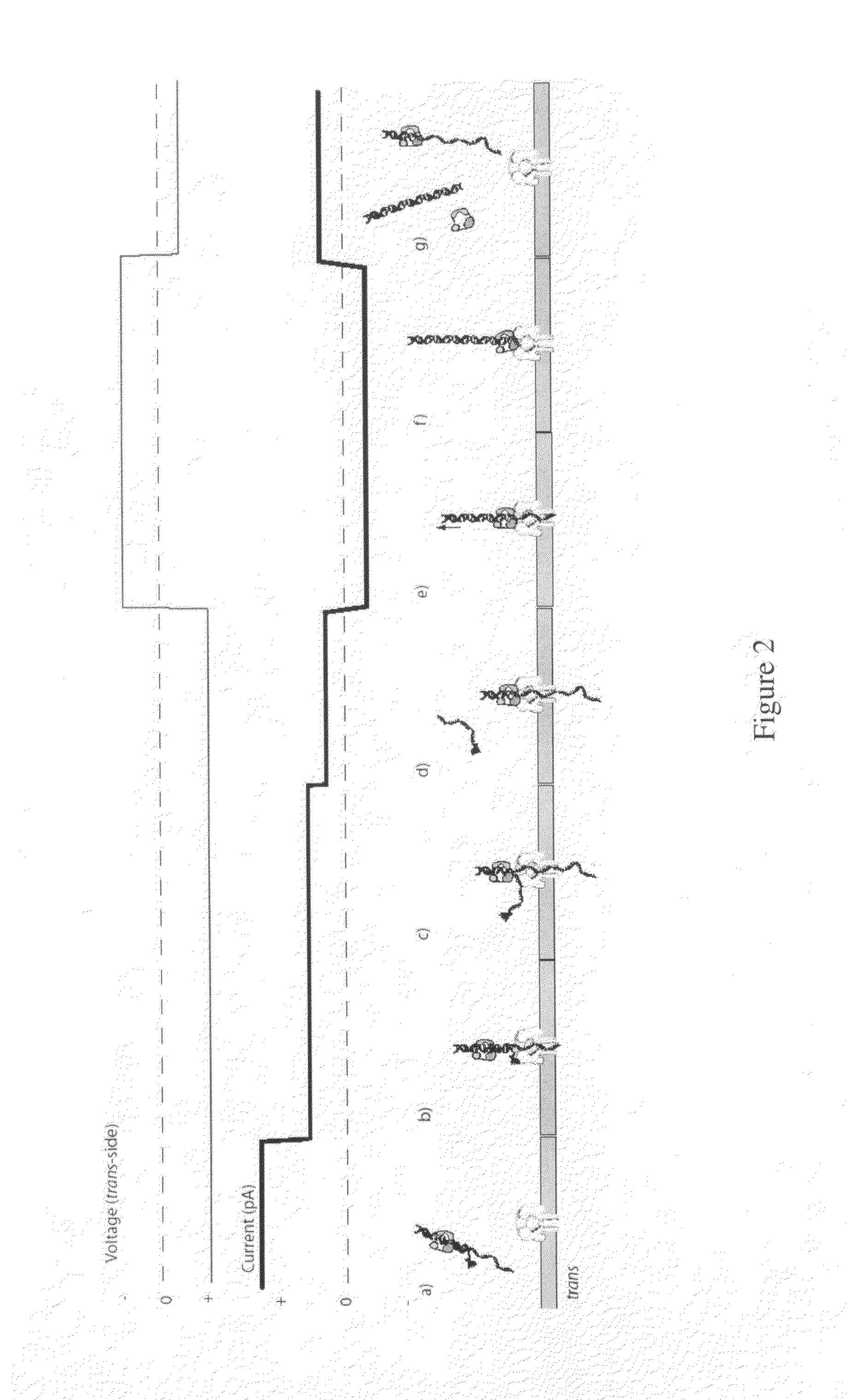

The invention herein disclosed provides for devices and methods that can detect and control an individual polymer in a mixture is acted upon by another compound, for example, an enzyme, in a nanopore in the absence of requiring a terminating nucleotide. The devices and methods are also used to determine rapidly (˜>50 Hz) the nucleotide base sequence of a polynucleotide under feedback control or using signals generated by the interactions between the polynucleotide and the nanopore. The invention is of particular use in the fields of drug discovery, molecular biology, structural biology, cell biology, molecular switches, molecular circuits, and molecular computational devices, and the manufacture thereof.

Owner:RGT UNIV OF CALIFORNIA

Compositions, devices, systems, and methods for using a nanopore

InactiveUS20110005918A1Low costRapidityImmobilised enzymesBioreactor/fermenter combinationsStructural biologyMolecular switch

The invention herein disclosed provides for devices and methods that can detect and control an individual polymer in a mixture is acted upon by another compound, for example, an enzyme, in a nanopore. The devices and methods are also used to determine rapidly (˜>50 Hz) the nucleotide base sequence of a polynucleotide under feedback control or using signals generated by the interactions between the polynucleotide and the nanopore. The invention is of particular use in the fields of molecular biology, structural biology, cell biology, molecular switches, molecular circuits, and molecular computational devices, and the manufacture thereof.

Owner:RGT UNIV OF CALIFORNIA

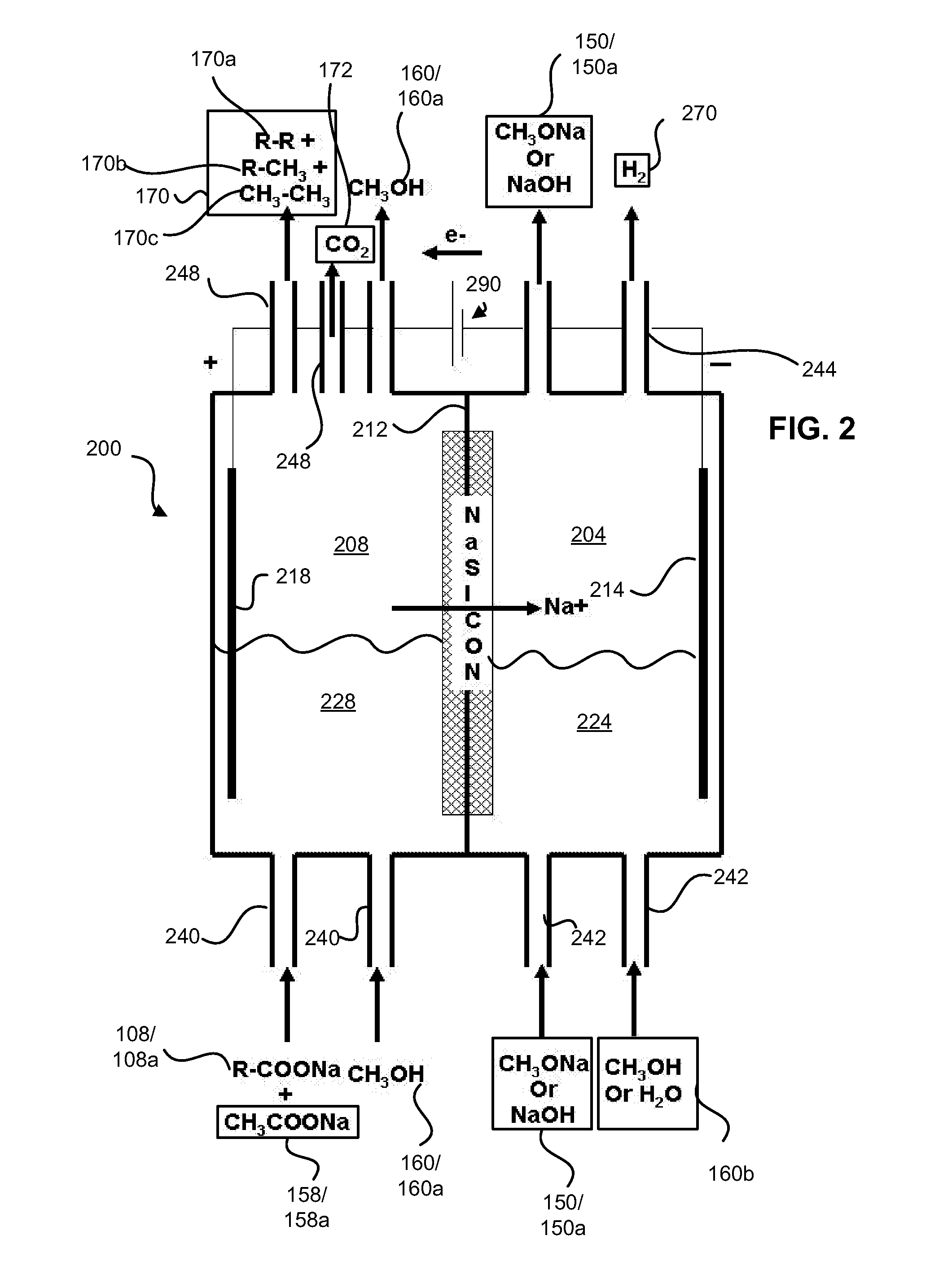

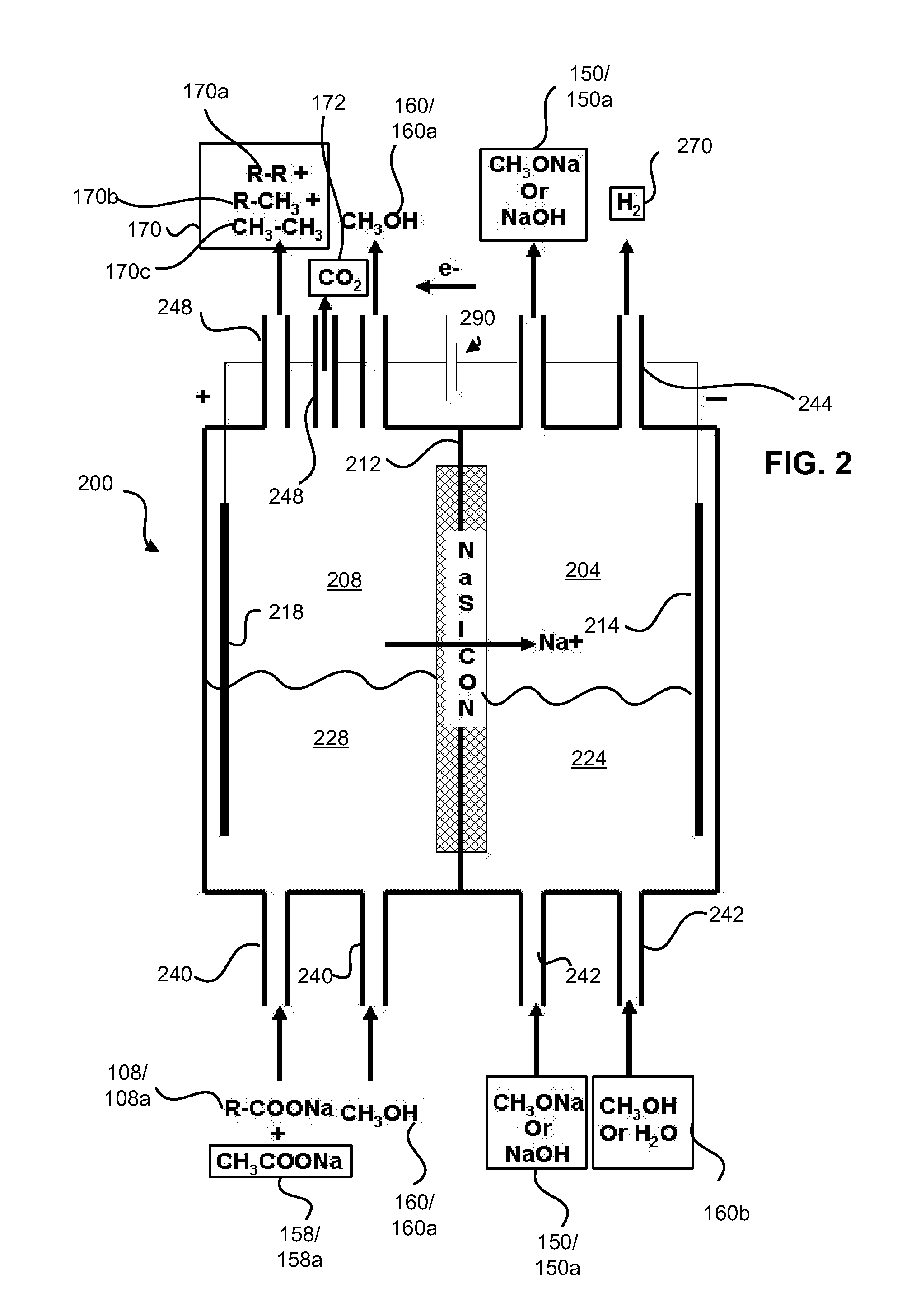

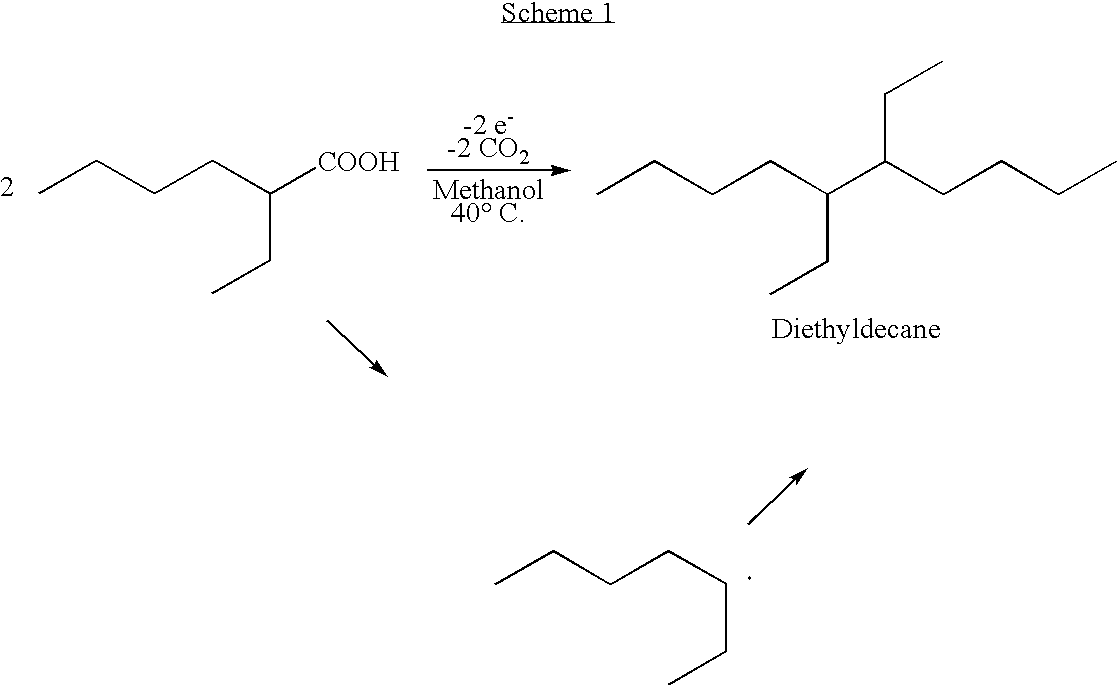

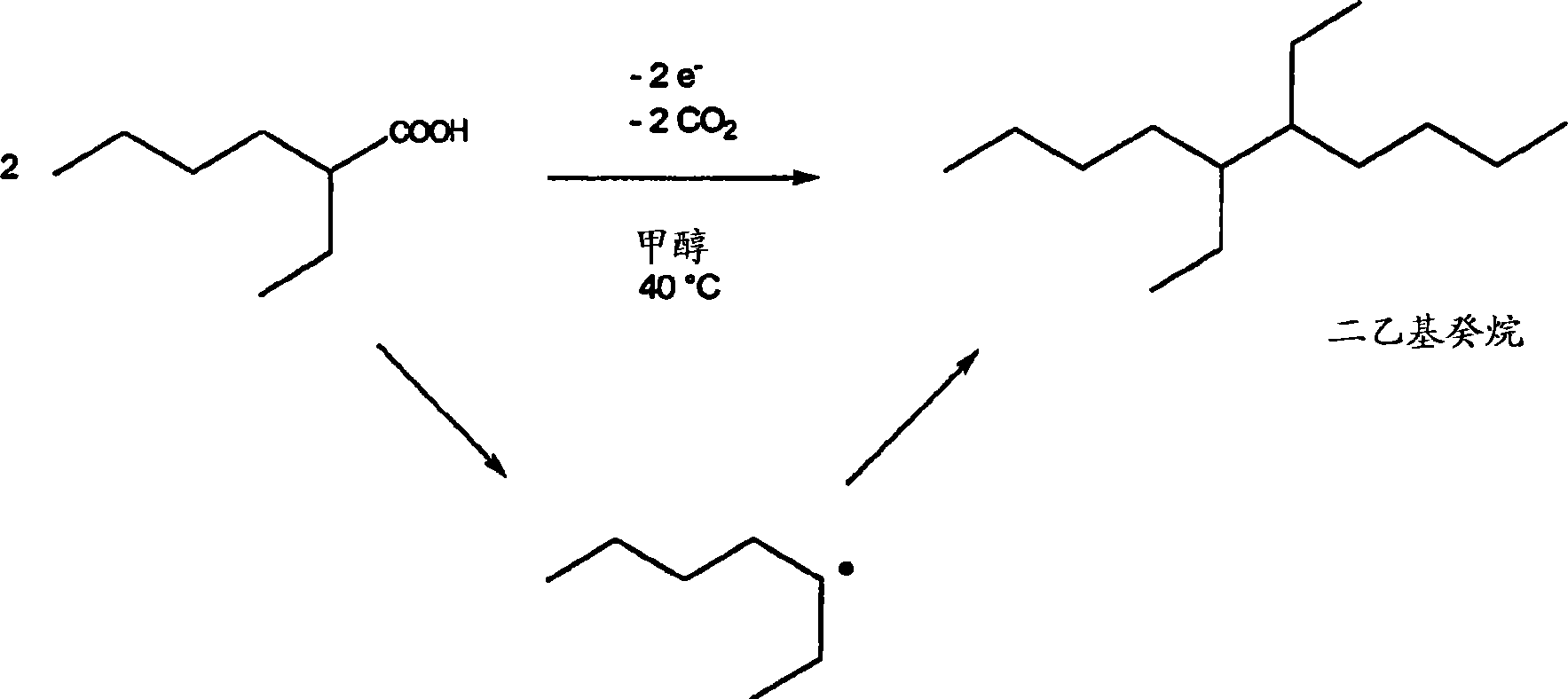

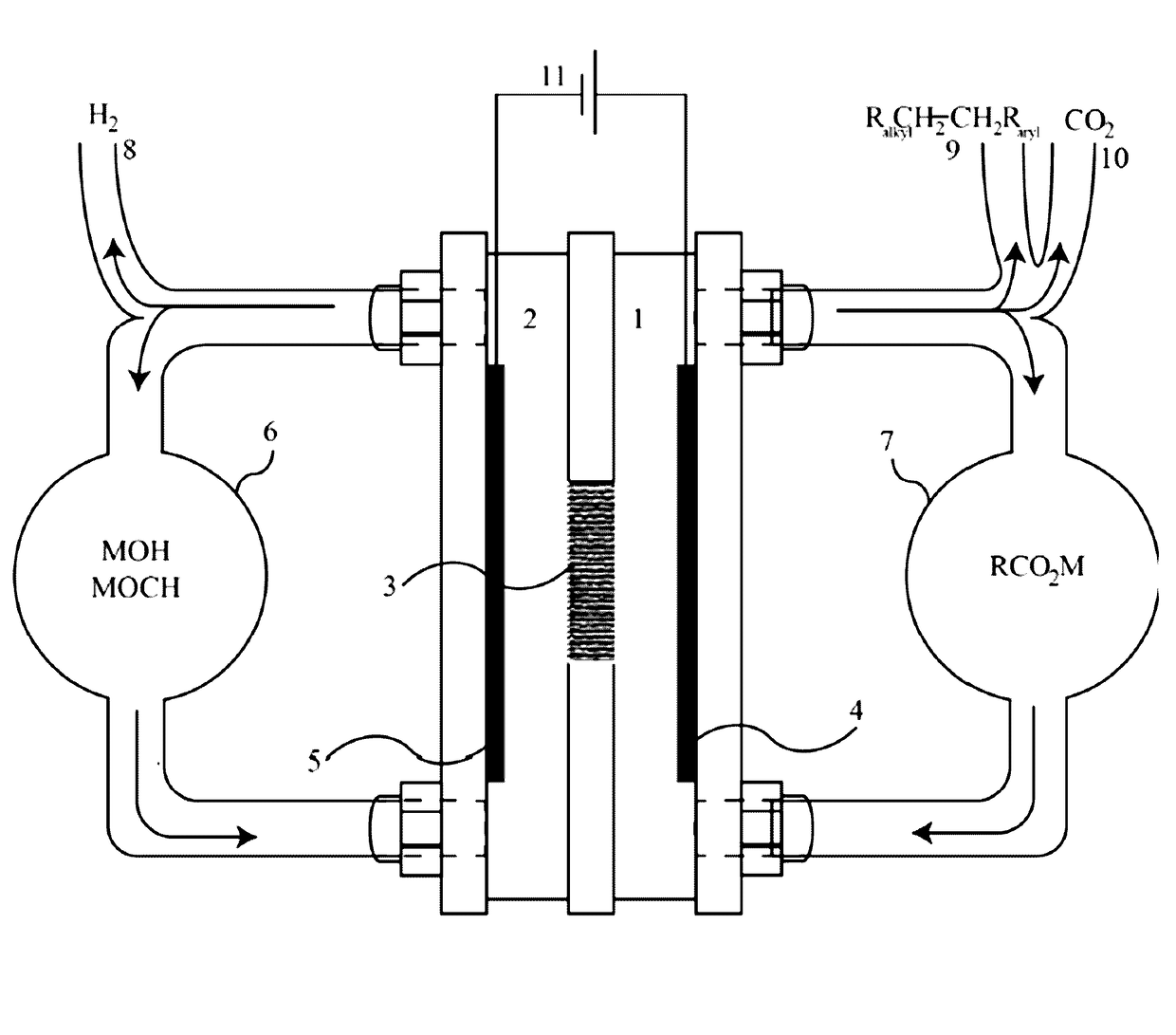

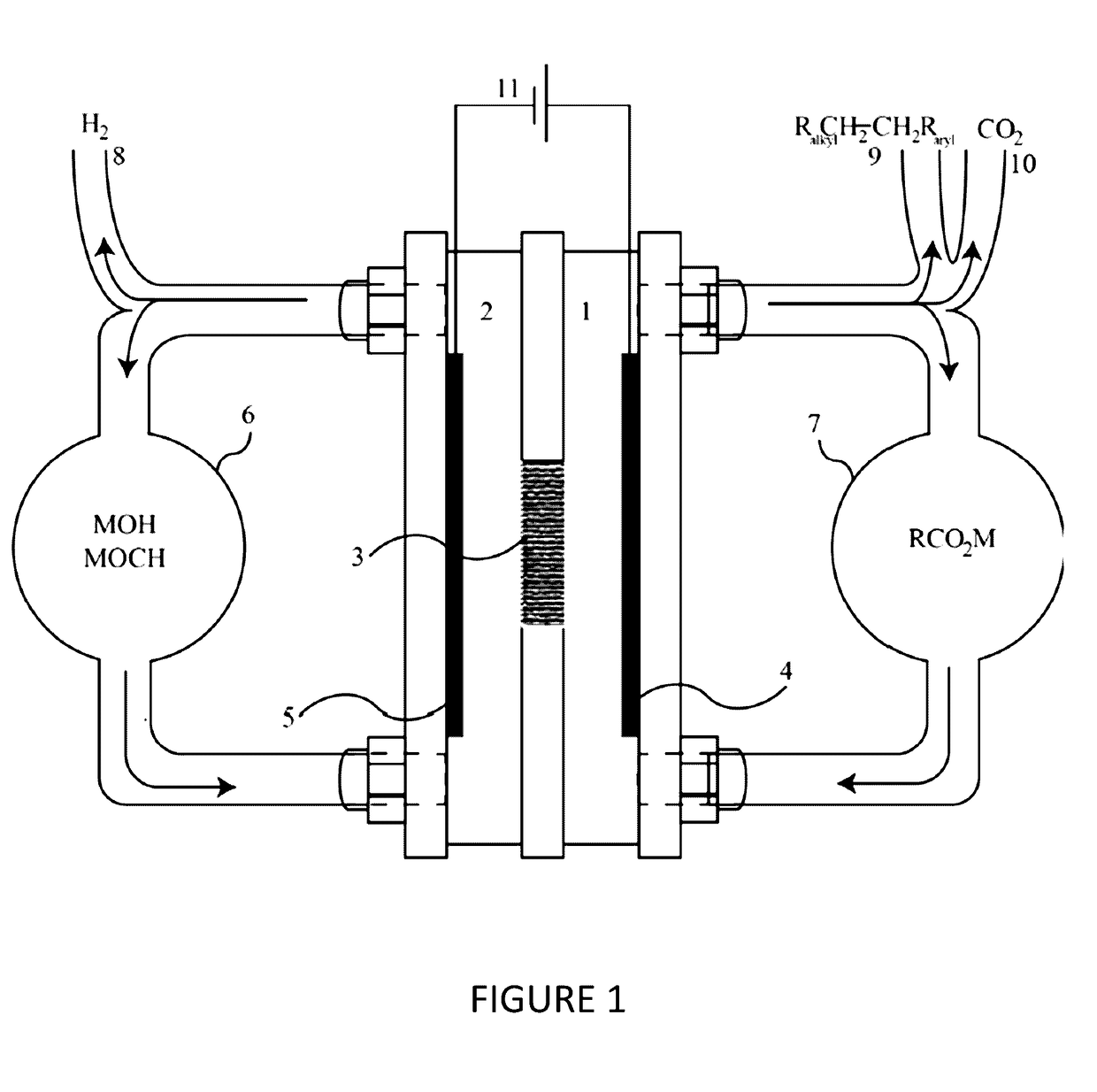

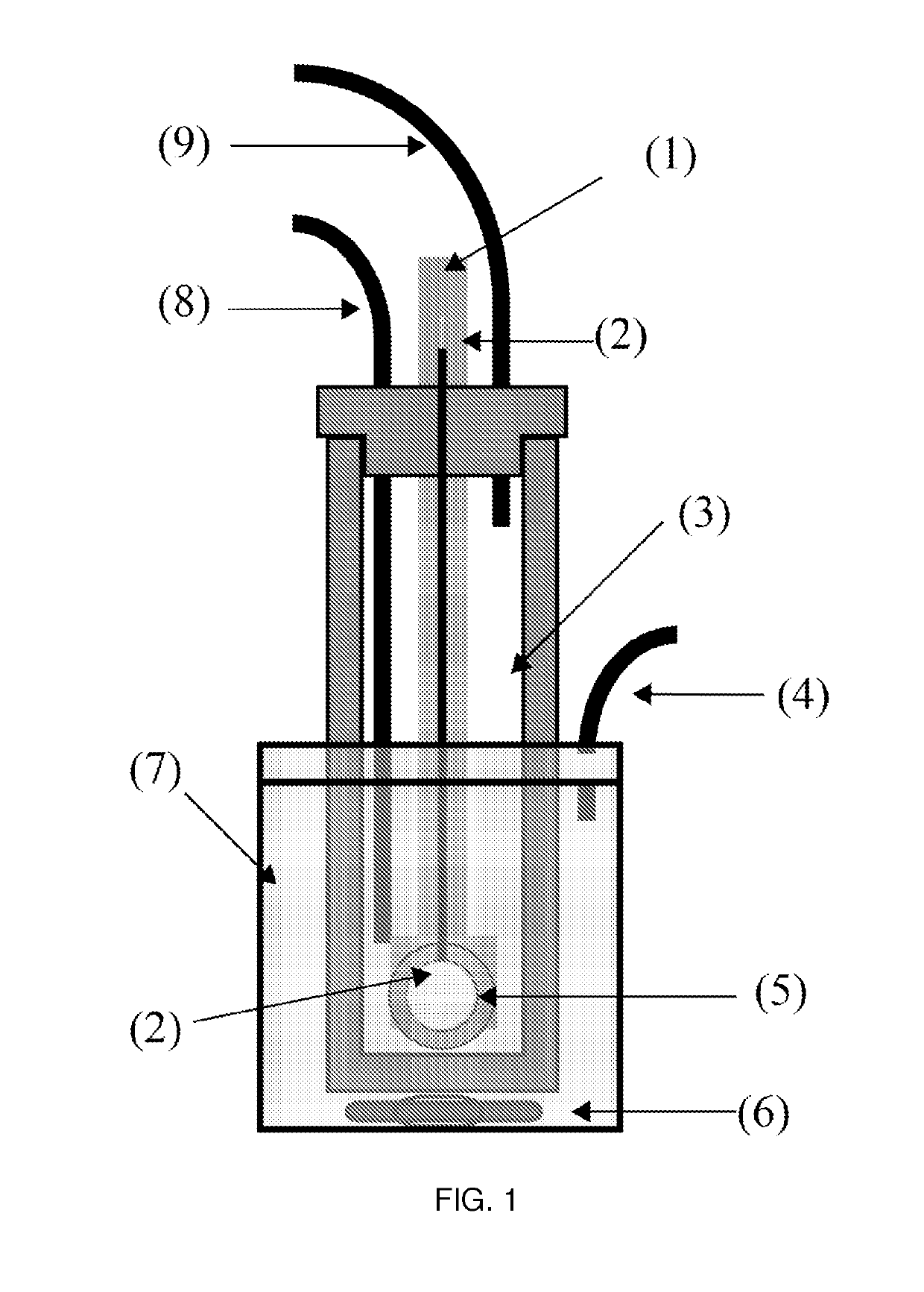

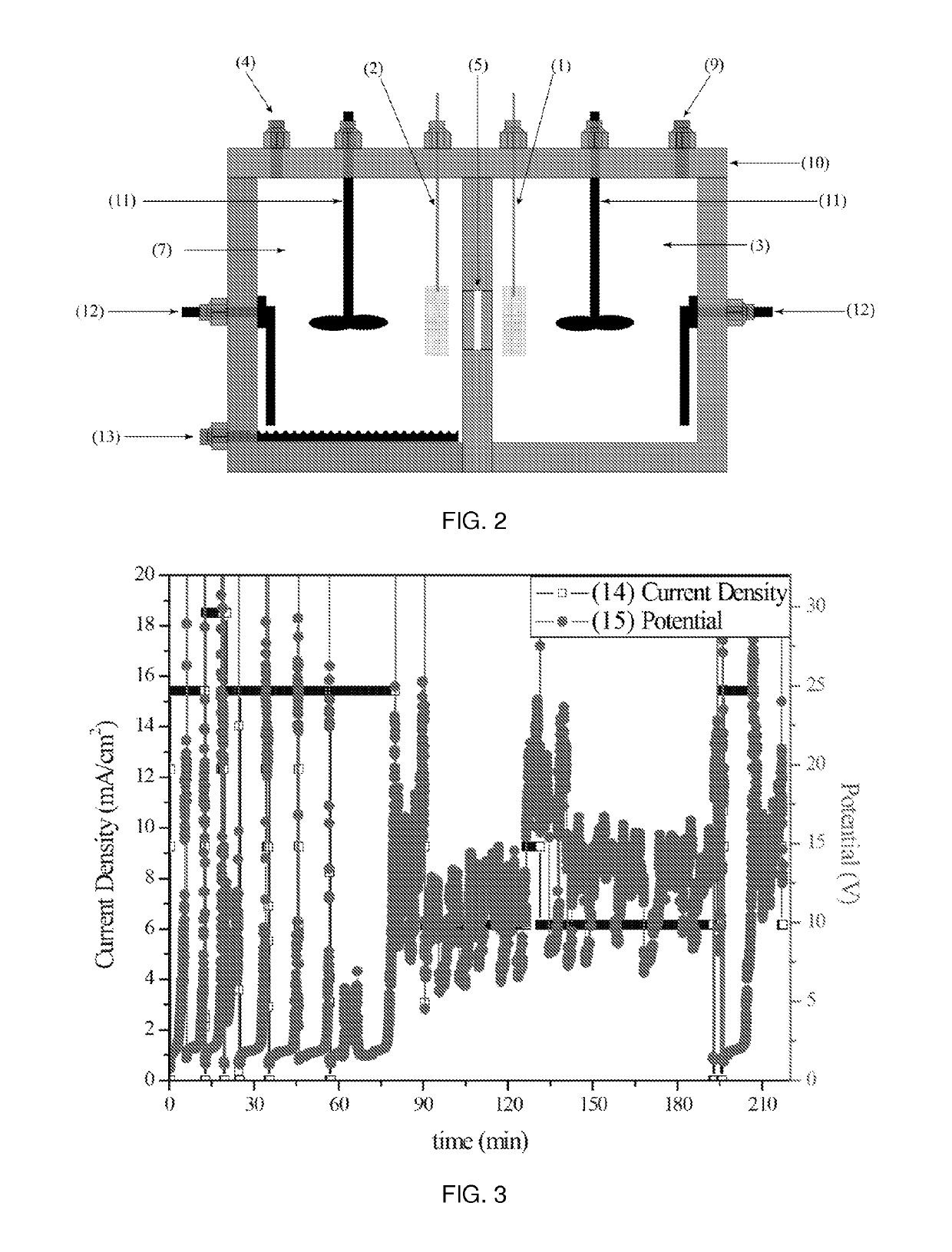

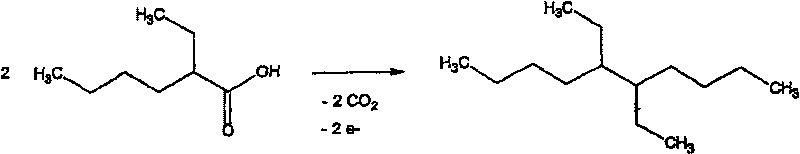

Decarboxylation cell for production of coupled radical products

InactiveUS20110024288A1Avoid mixingLow costCellsElectrolytic organic coupling reactionsAlkali ionsTG - Triglyceride

Owner:CERAMTEC

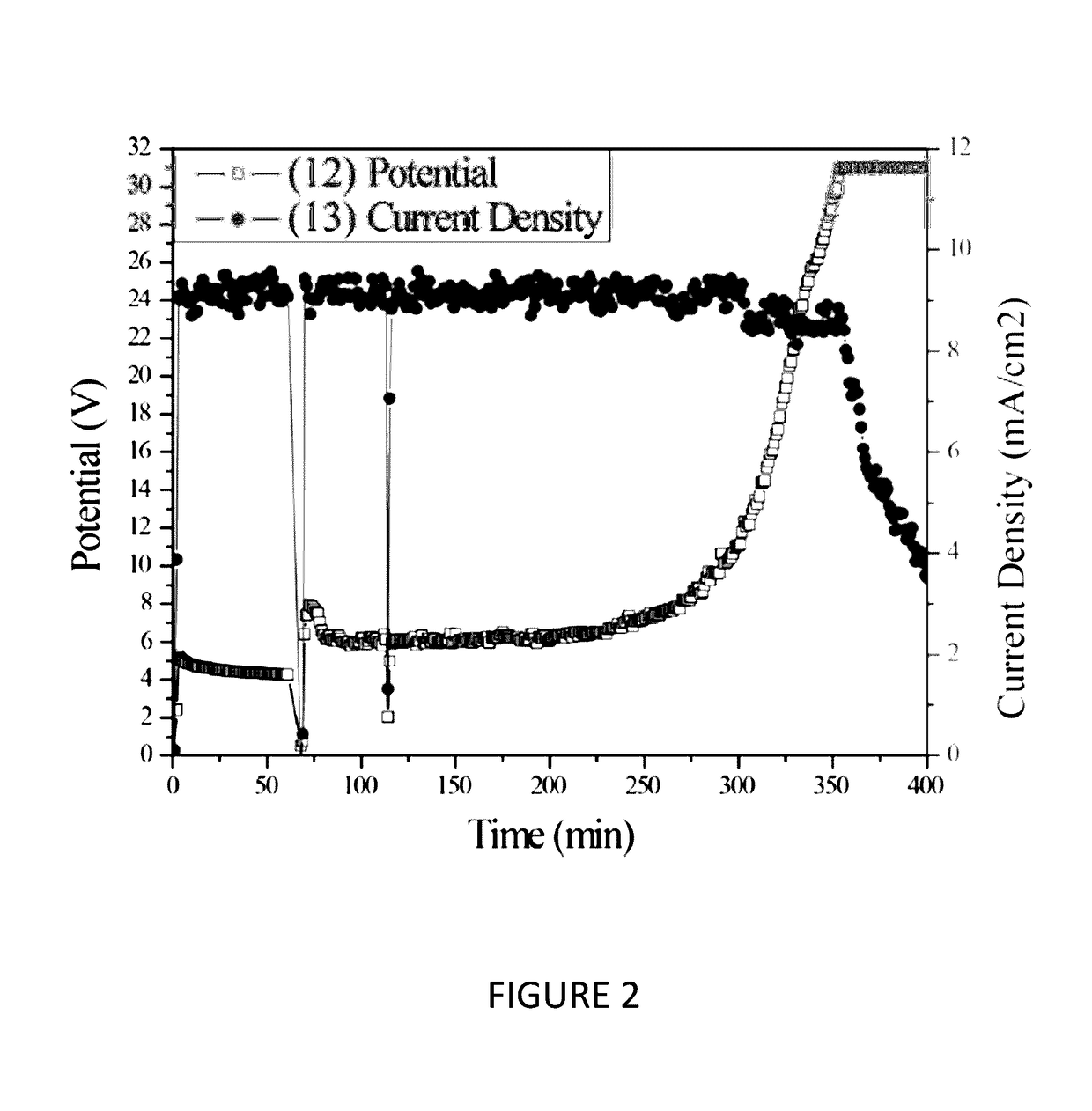

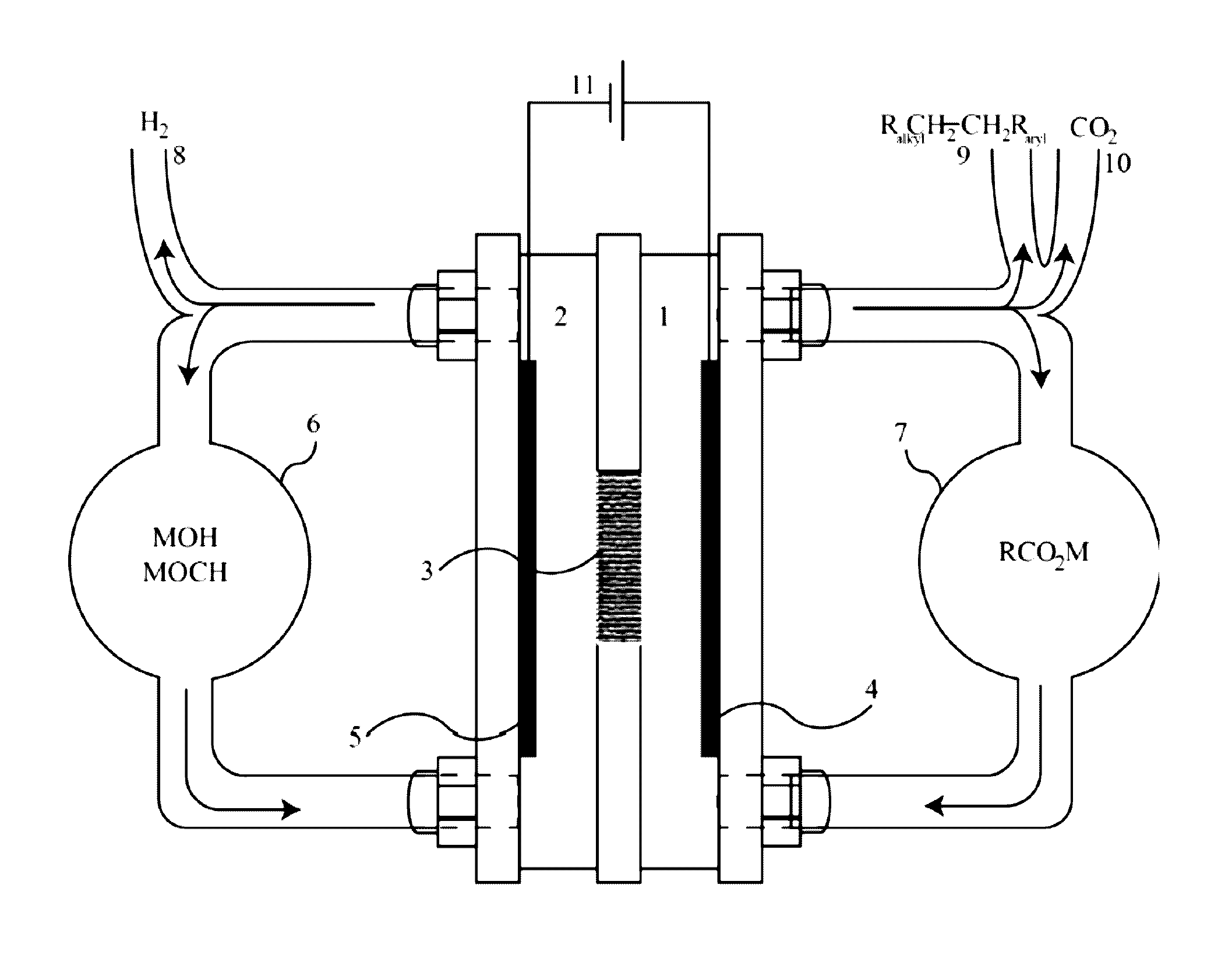

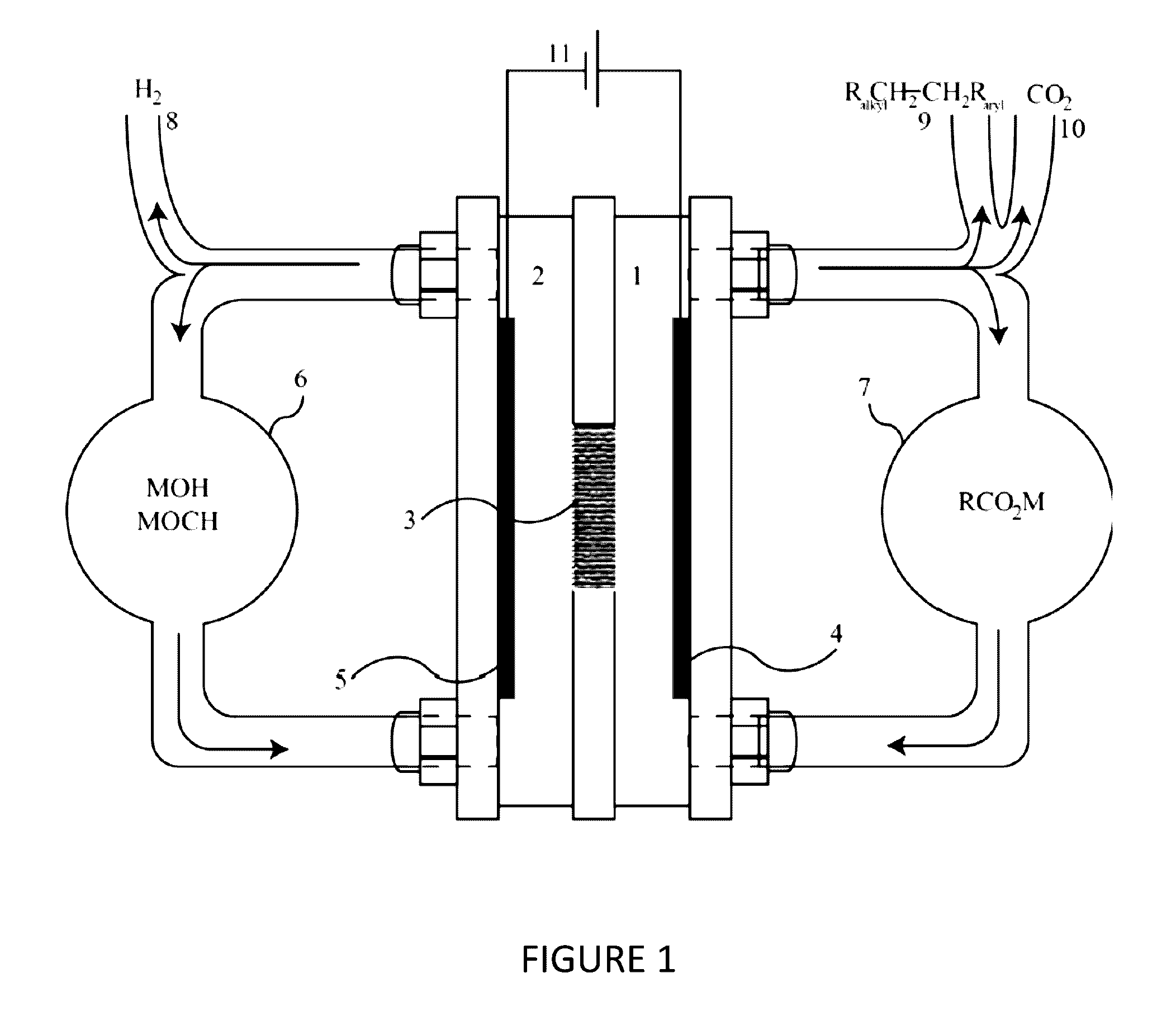

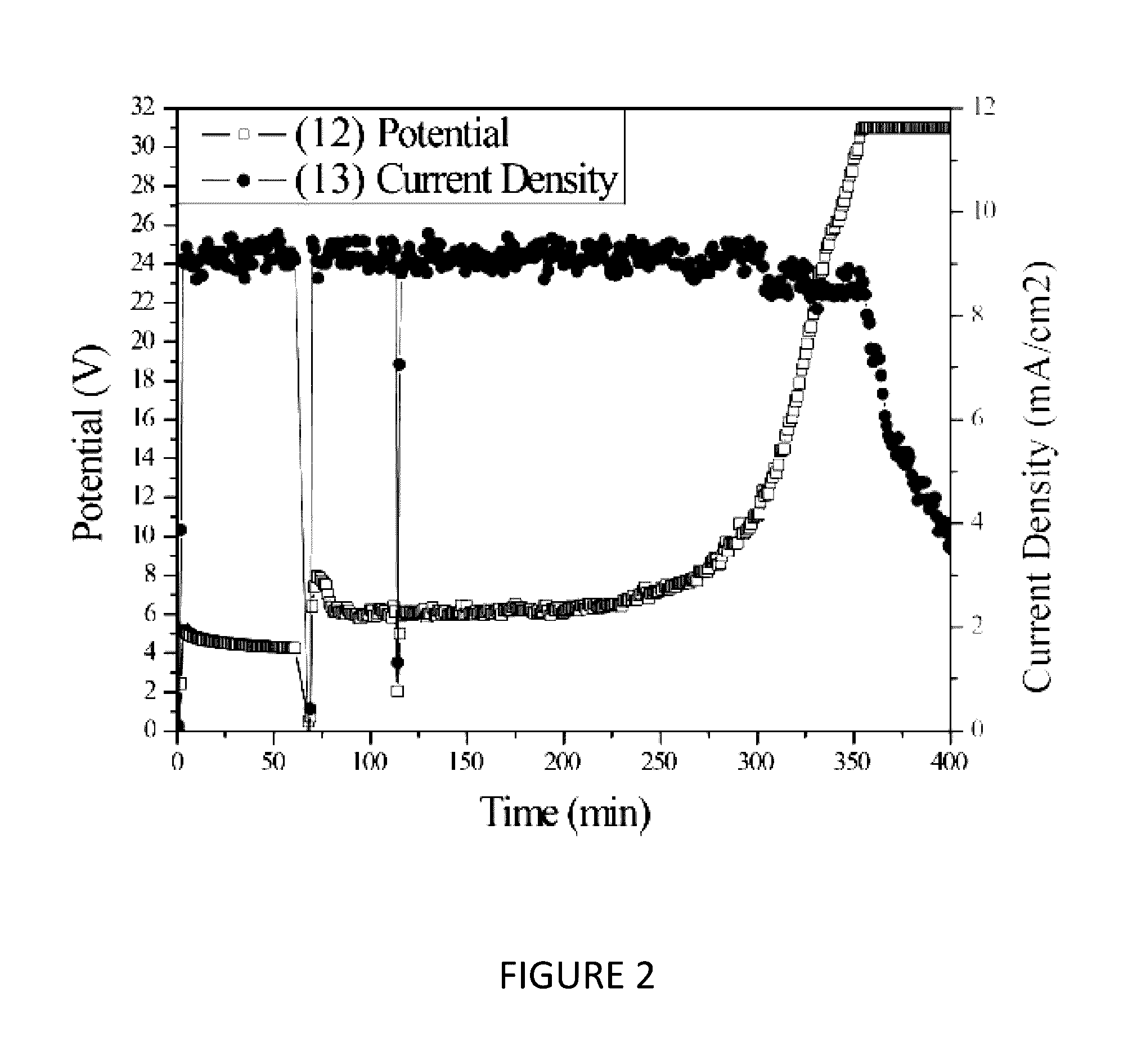

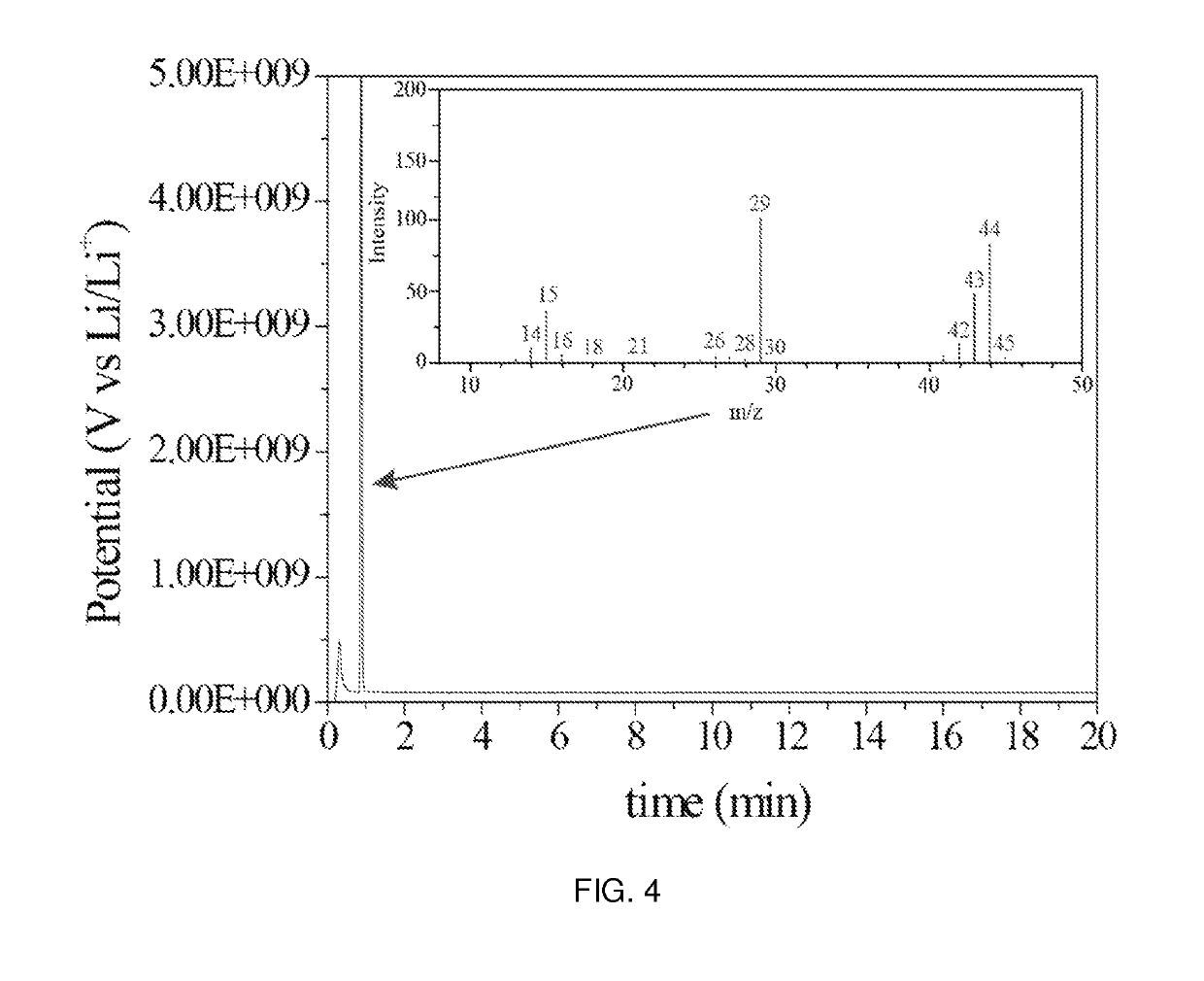

Kolbe electrolysis in a polymer electrolyte membrane reactor

InactiveUS6238543B1Electrolysis componentsElectrolytic organic coupling reactionsPlatinumPolymer electrolytes

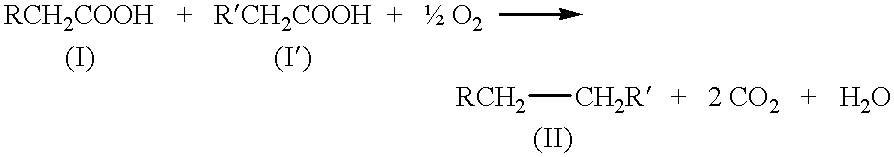

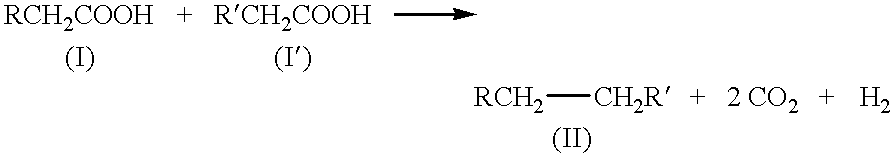

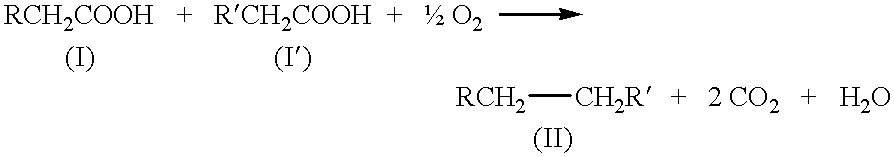

Disclosed is a process, for the electrolytic coupling of carboxylic acids, carried out in a polymer electrolyte membrane reactor. The reactor design (1) discloses the use of gaseous or neat liquid reactants without the use of organic cosolvents, (2) prevents the loss of platinum, and (3) permits the use of oxygen reduction to water as the cathode reaction.

Owner:EI DU PONT DE NEMOURS & CO +1

Production of Gasoline From Fermentable Feedstocks

ActiveUS20100159553A1Easy to separateImprove isolationElectrolysis componentsBacteriaCatalytic reformingBiodiesel

Compositions and methods for forming hexane, and, optionally, gasoline and / or components of a gasoline composition, from fermentable sugars are disclosed. The sugars are fermented using a bacteria or yeast that predominantly forms butyric acid. The butyric acid is subjected to Kolbe or photo-Kolbe electrolysis to form hexane. The hexane can be subjected to catalytic, reforming and / or isomerization steps to form higher octane products, which are or can be included in gasoline compositions. In one aspect, the fermentable sugars are derived from lignocellulosic materials such as wood products, switchgrass, or agricultural wastes. These materials are delignified to form lignin, cellulose and hemicellulose. The cellulose and hemicellulose are depolymerized to form glycose and xylose, either or both of which can be fermented by the bacteria. The lignin can be used to generate heat energy and / or electric energy for use in one or more process steps, such as the fermentation, product isolation, Kolbe electrolysis, catalytic reforming and / or isomerization steps. Alternatively, the lignin can be converted to synthesis gas, which can then be subjected to Fischer-Tropsch synthesis, or converted to methanol and / or ethanol. Thus, the methods described herein can convert biomass to a fuel composition or fuel additive, which can be used in a conventional gasoline engine, unlike traditional fuels such as ethanol or biodiesel.

Owner:CPS BIOFUELS INC

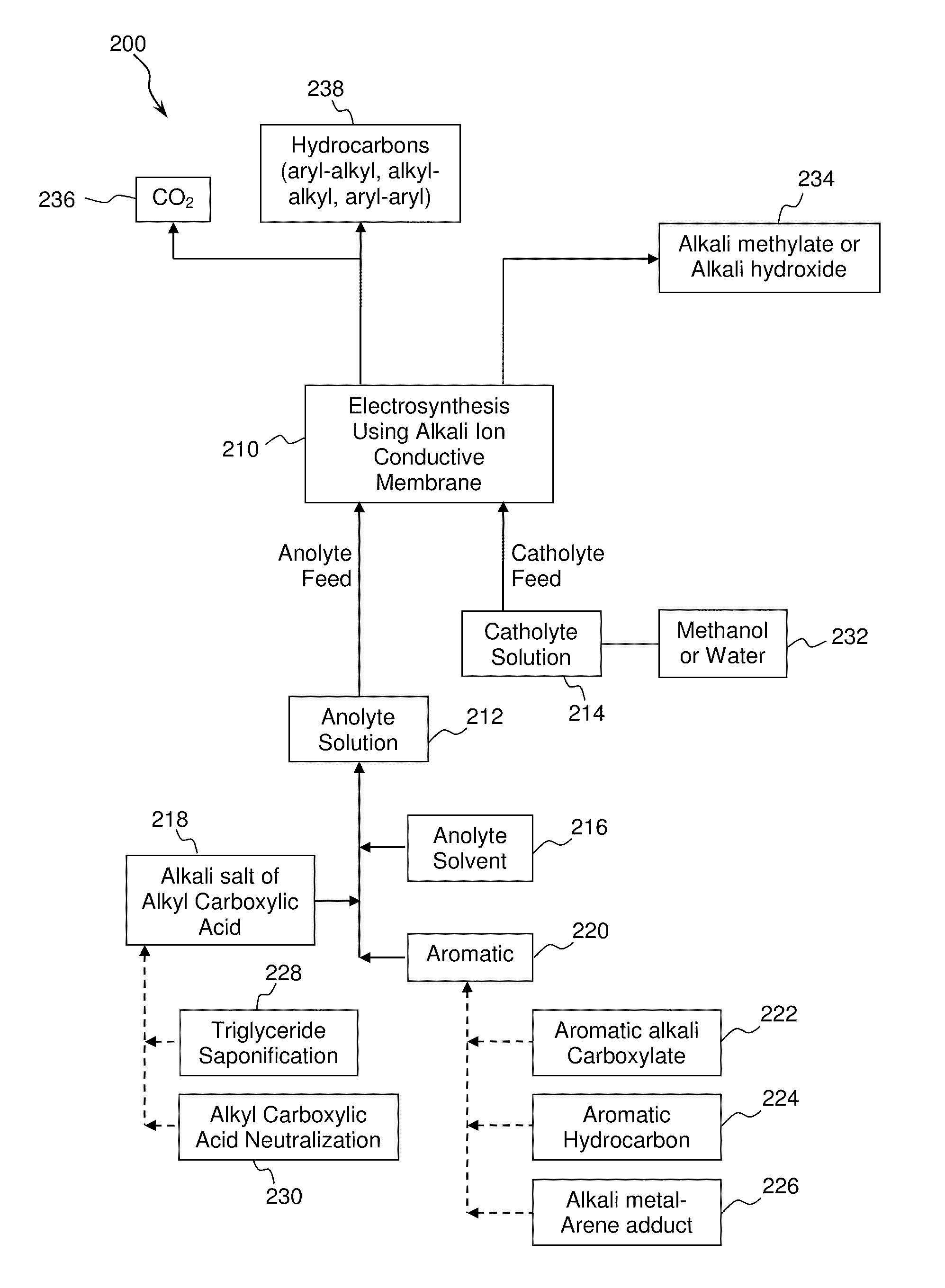

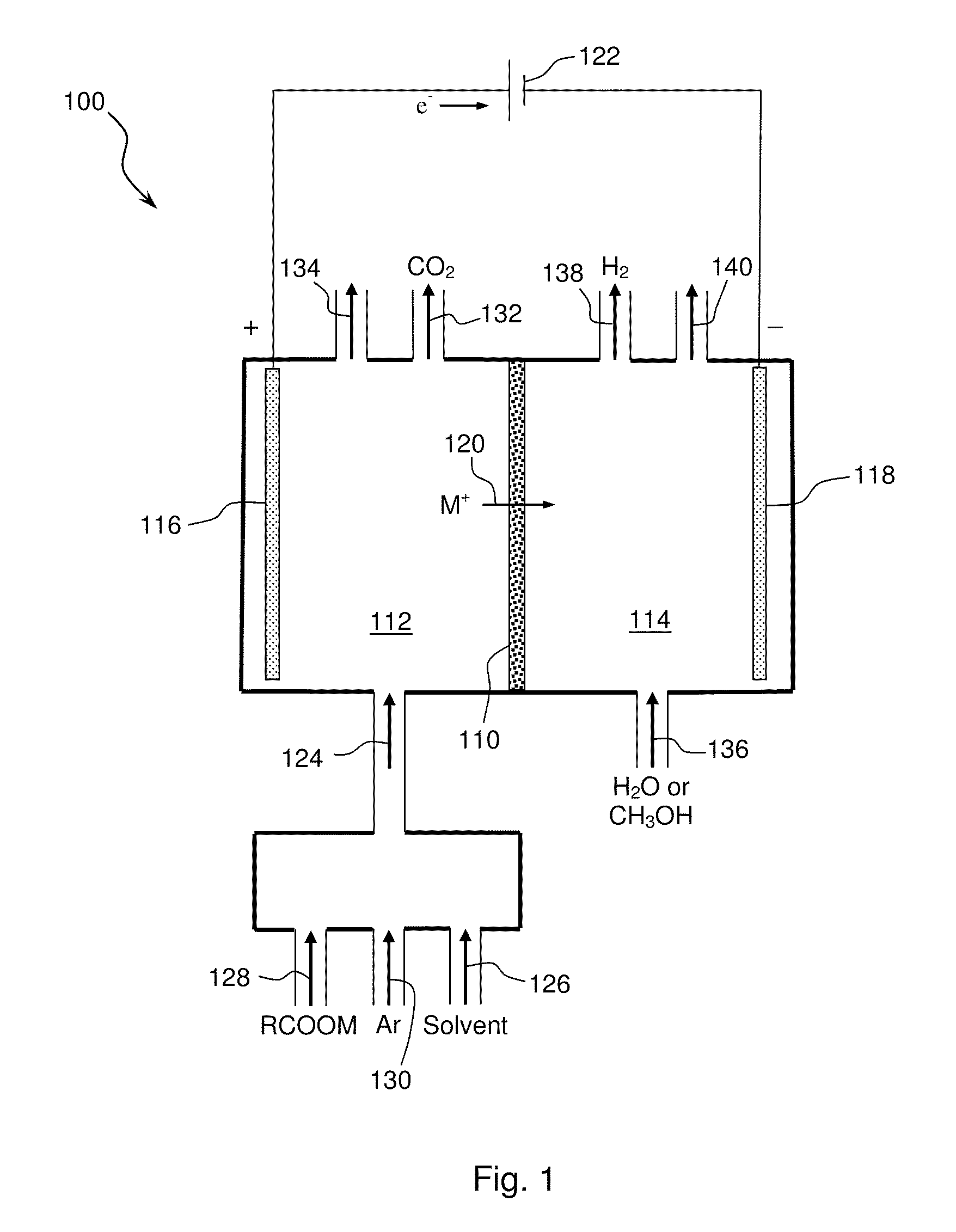

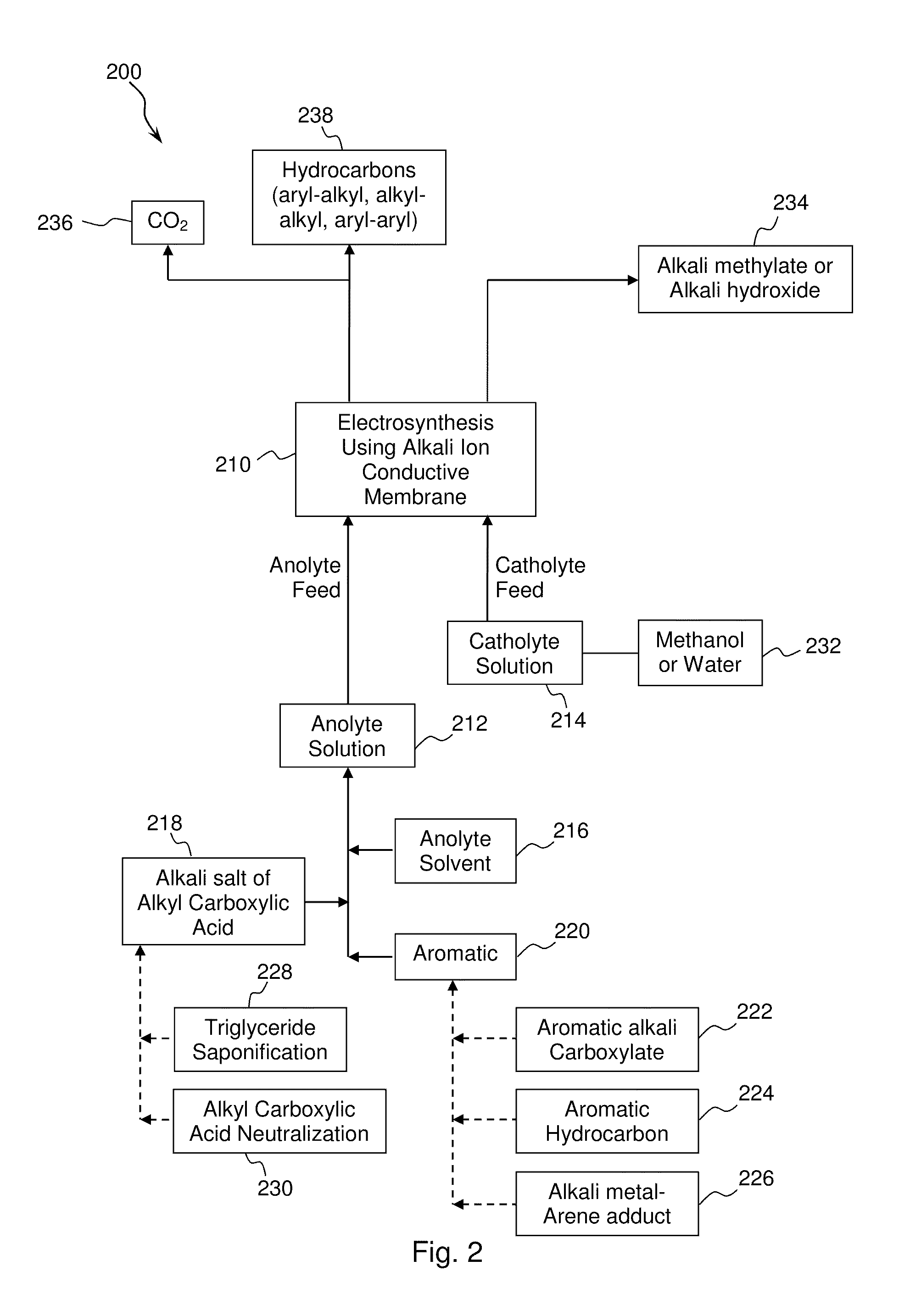

Electrochemical synthesis of aryl-alkyl surfacant precursor

An aryl-alkyl (R—Ar) hydrocarbon is prepared by an electrosynthesis process in an electrolytic cell having an alkali ion conductive membrane positioned between an anolyte compartment configured with an anode and a catholyte compartment configured with a cathode. An anolyte solution containing an alkali metal salt of an alkyl carboxylic acid and an aryl compound is introduced into the anolyte compartment. The aryl compound may include an alkali metal salt of an aryl carboxylic acid, an arene (aromatic) hydrocarbon, or an aryl alkali metal adduct (Ar−M+). The anolyte solution undergoes electrolytic decarboxylation to form an alkyl radical. The alkyl radical reacts with the aryl compound to produce the aryl-alkyl hydrocarbon.

Owner:ENLIGHTEN INNOVATIONS INC

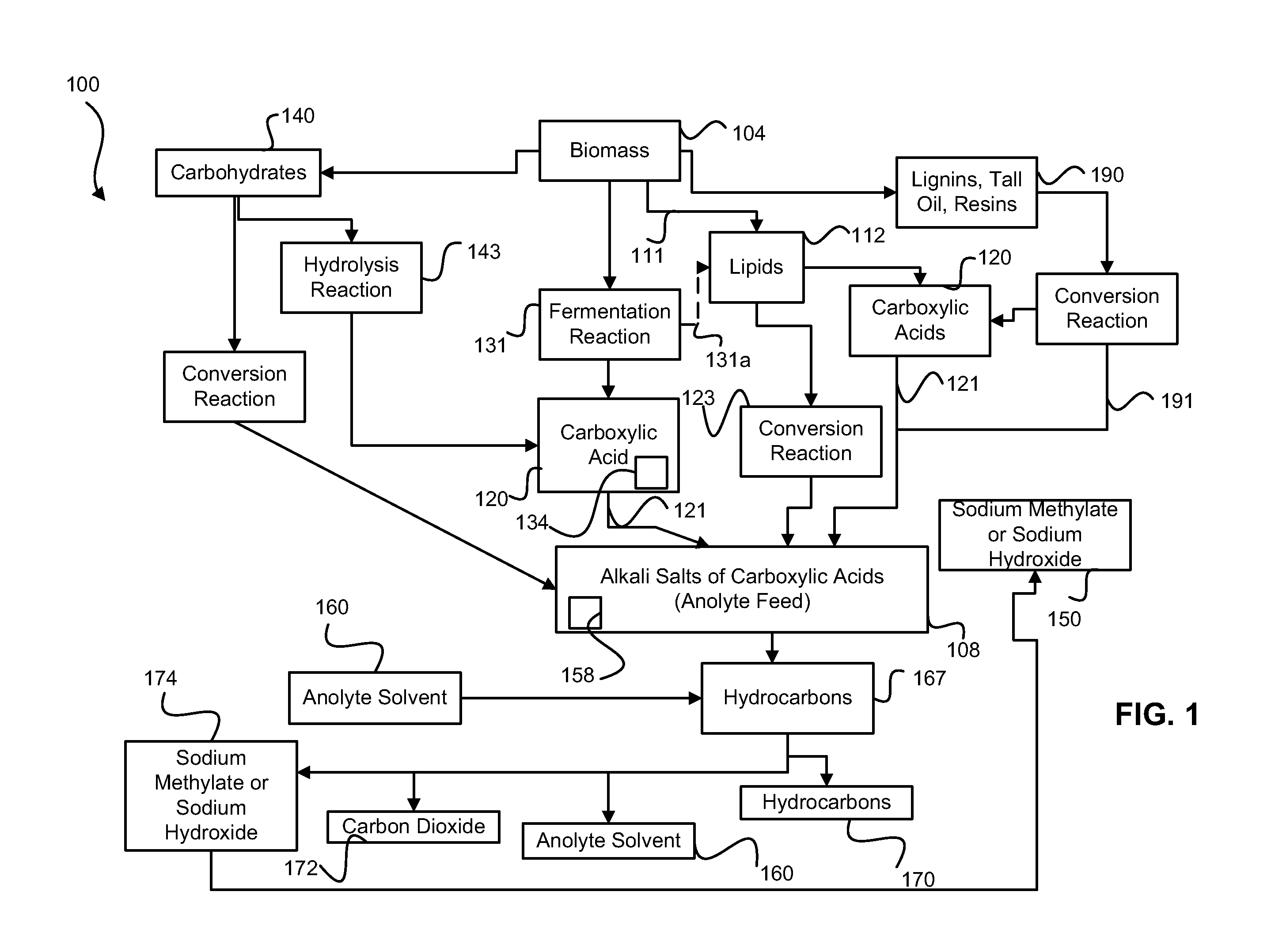

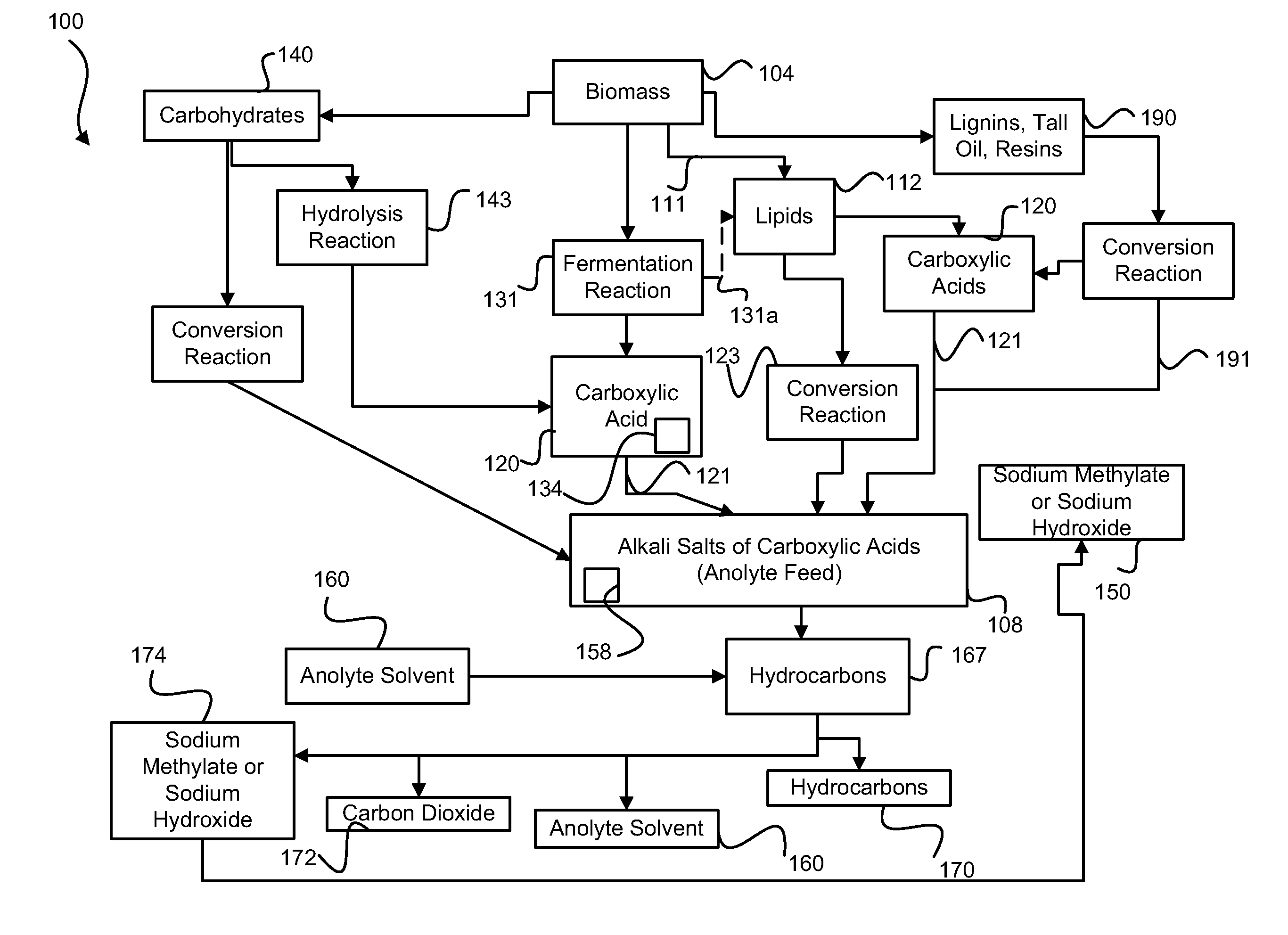

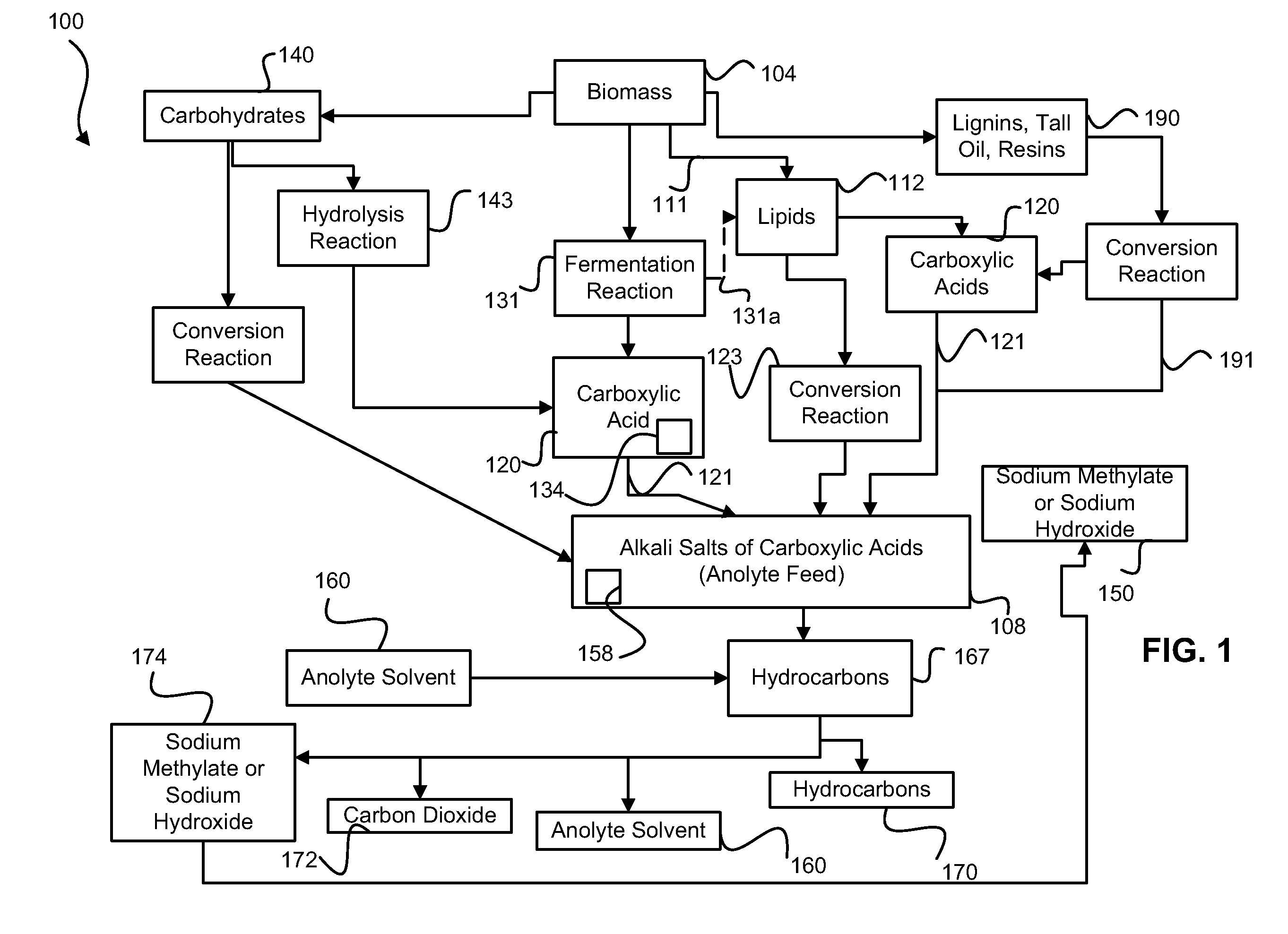

Method of producing coupled radical products from biomass

ActiveUS20110027848A1Avoid mixingLow costCellsPhotography auxillary processesAlkali ionsTG - Triglyceride

Owner:ENLIGHTEN INNOVATIONS INC

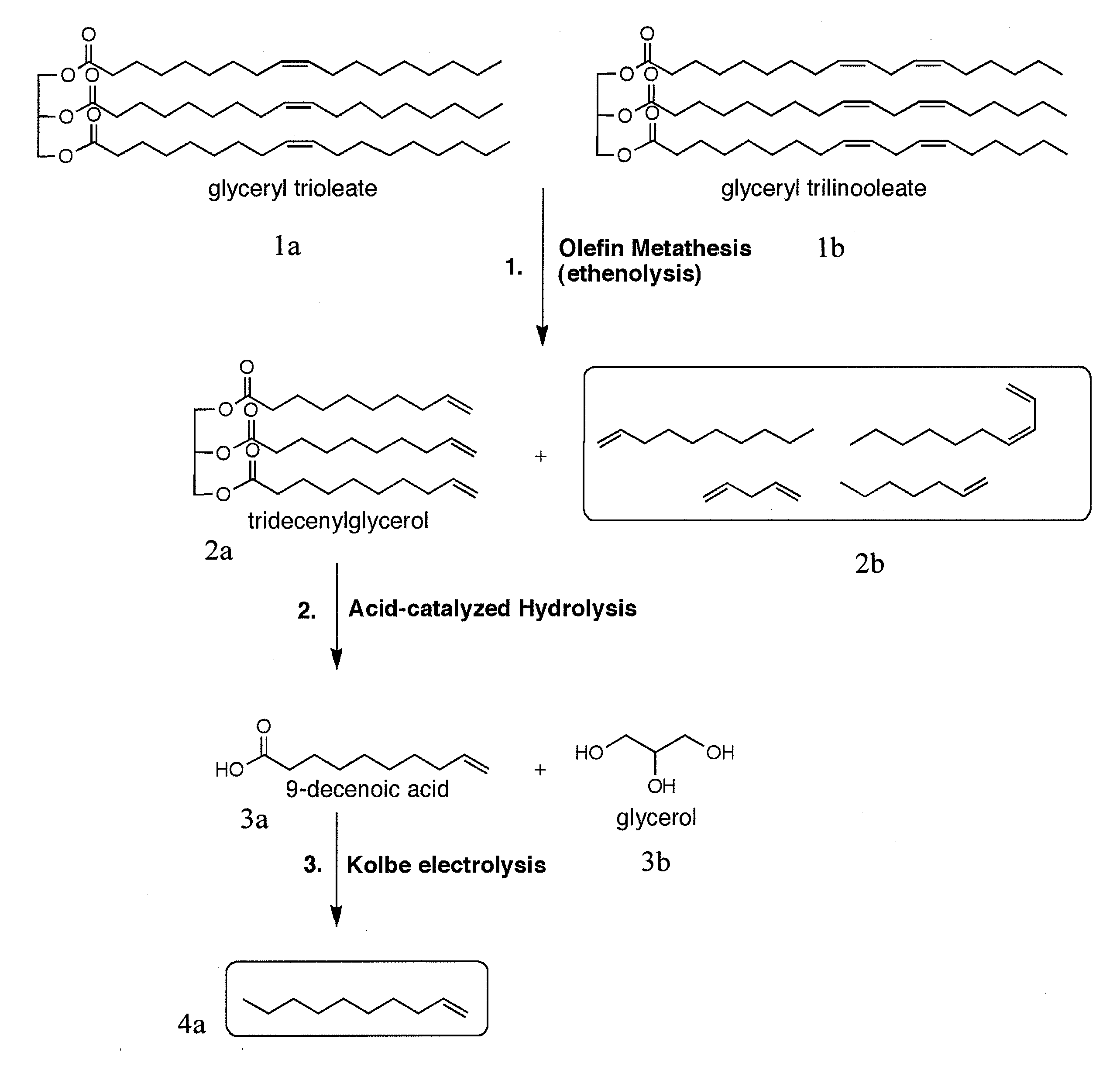

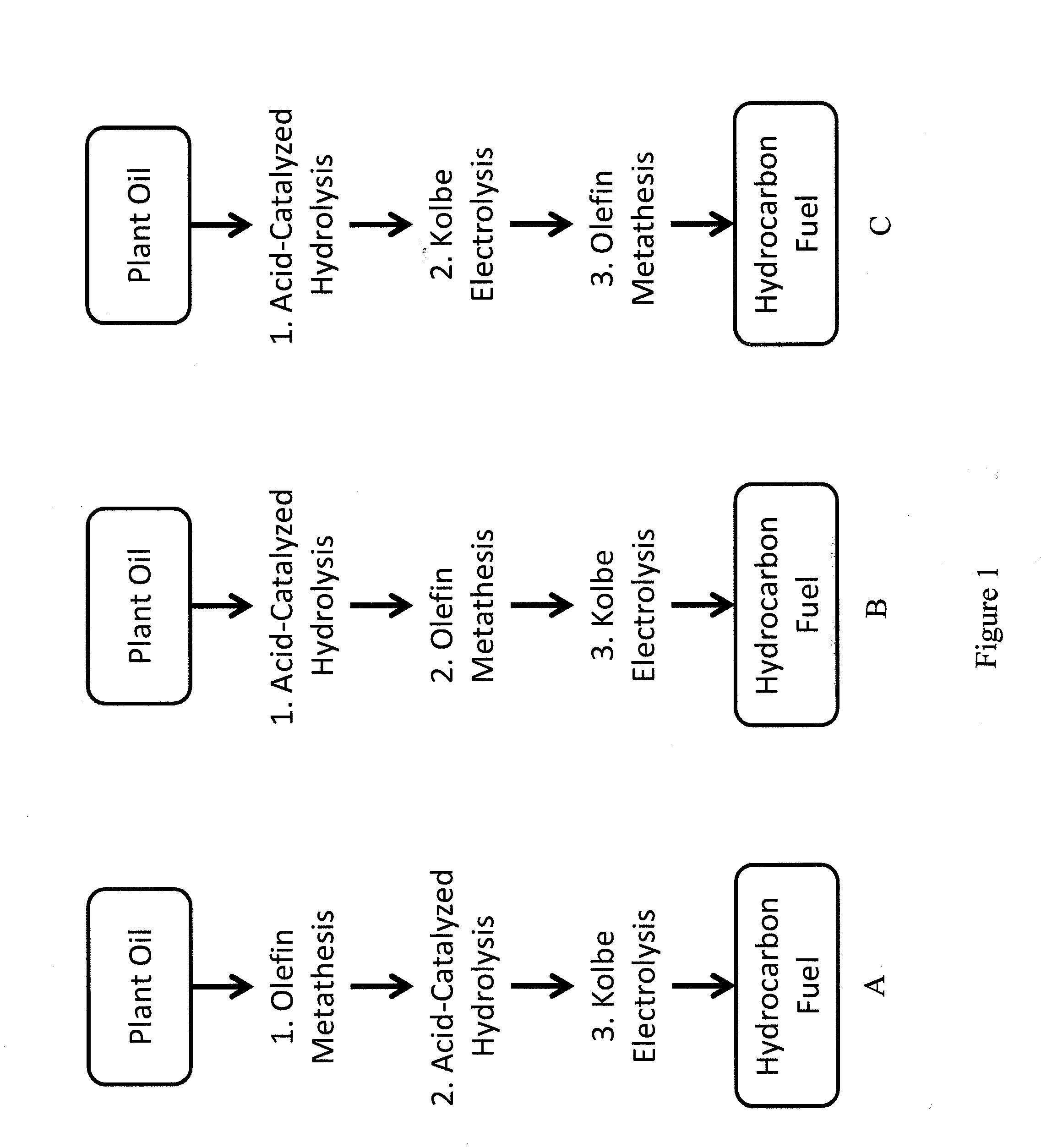

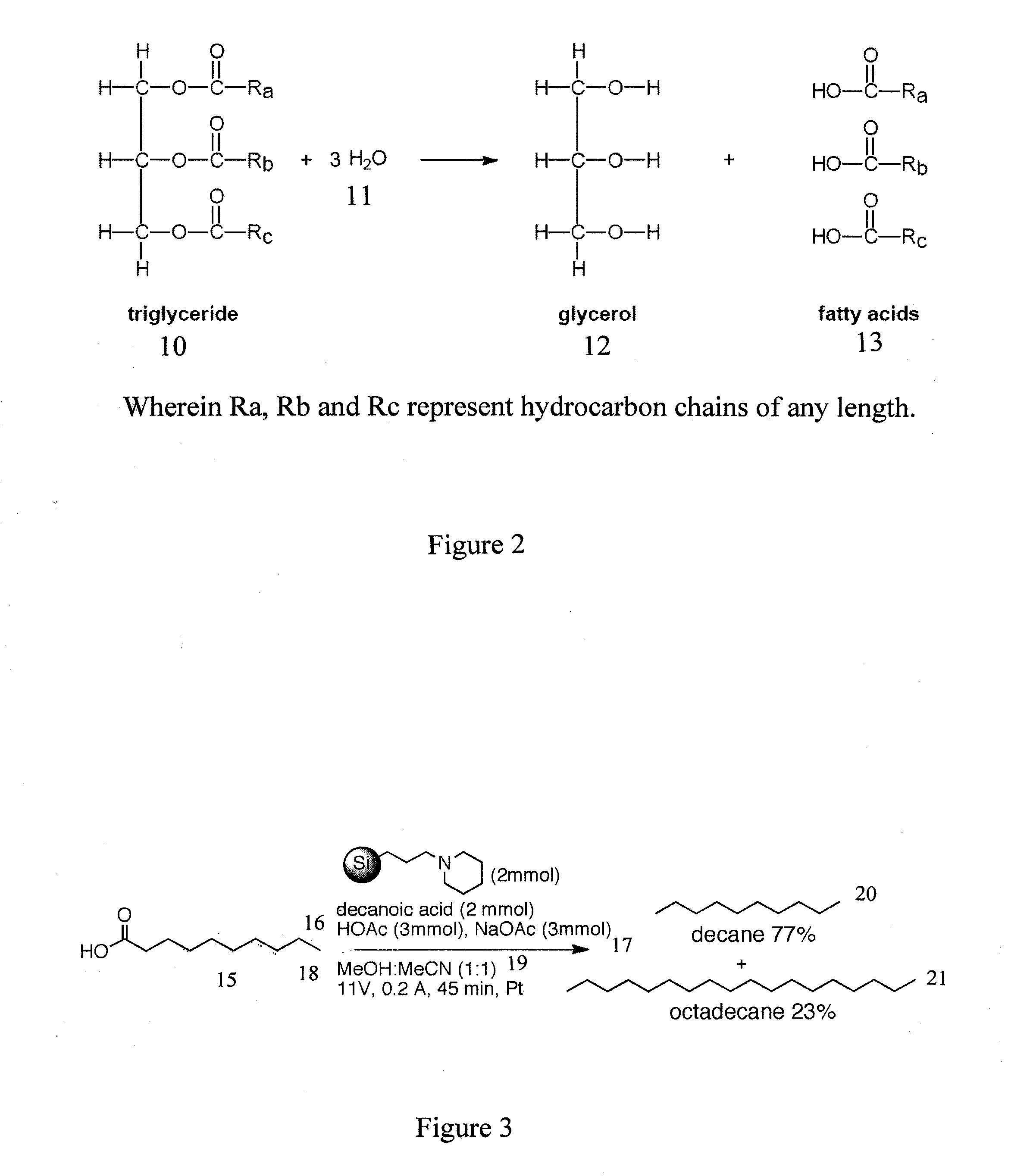

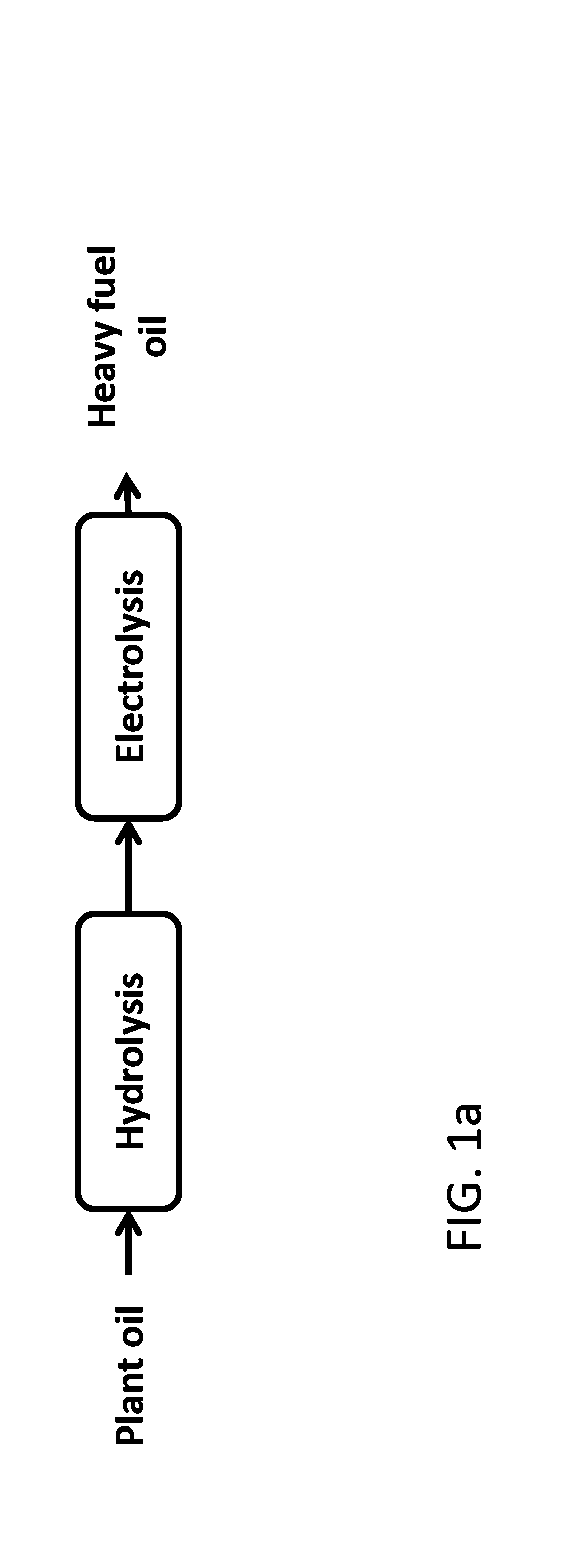

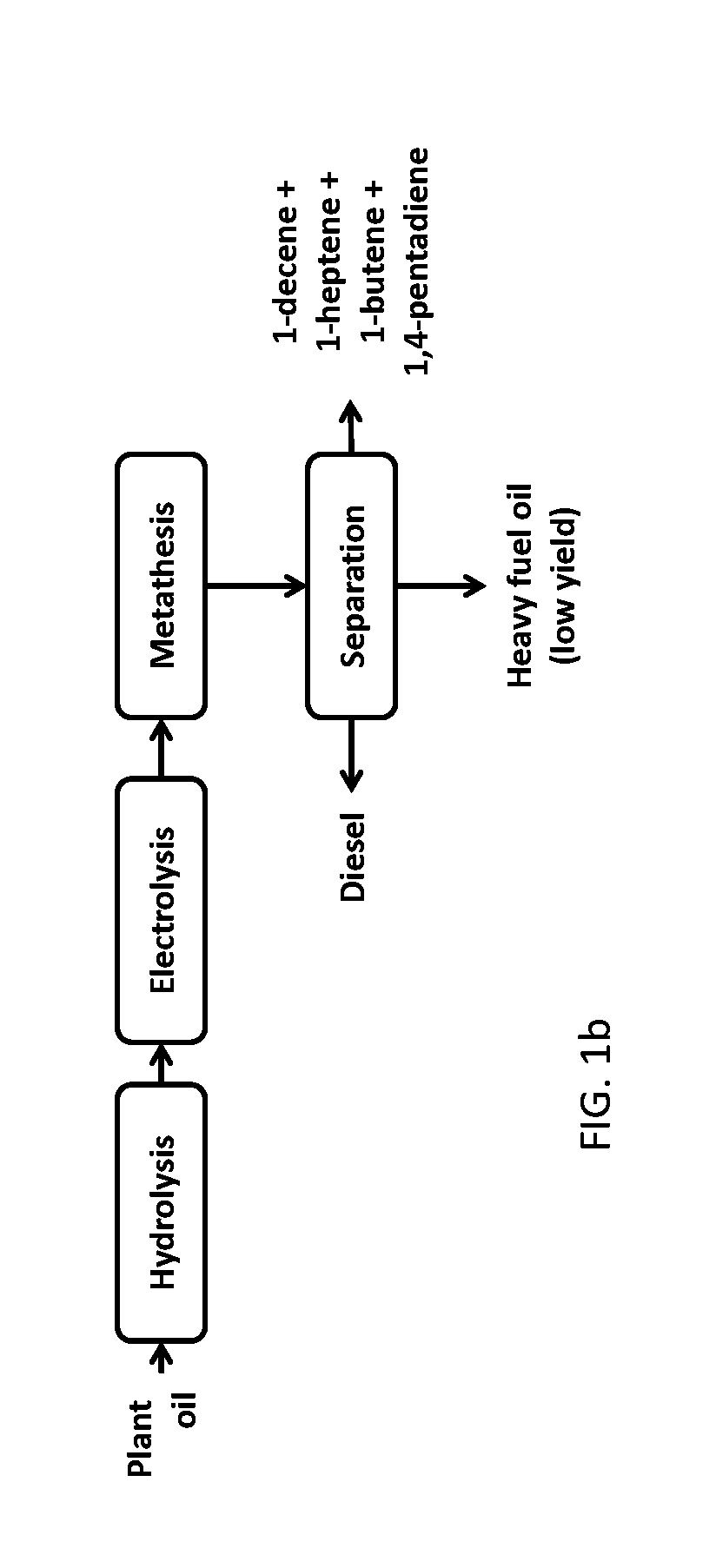

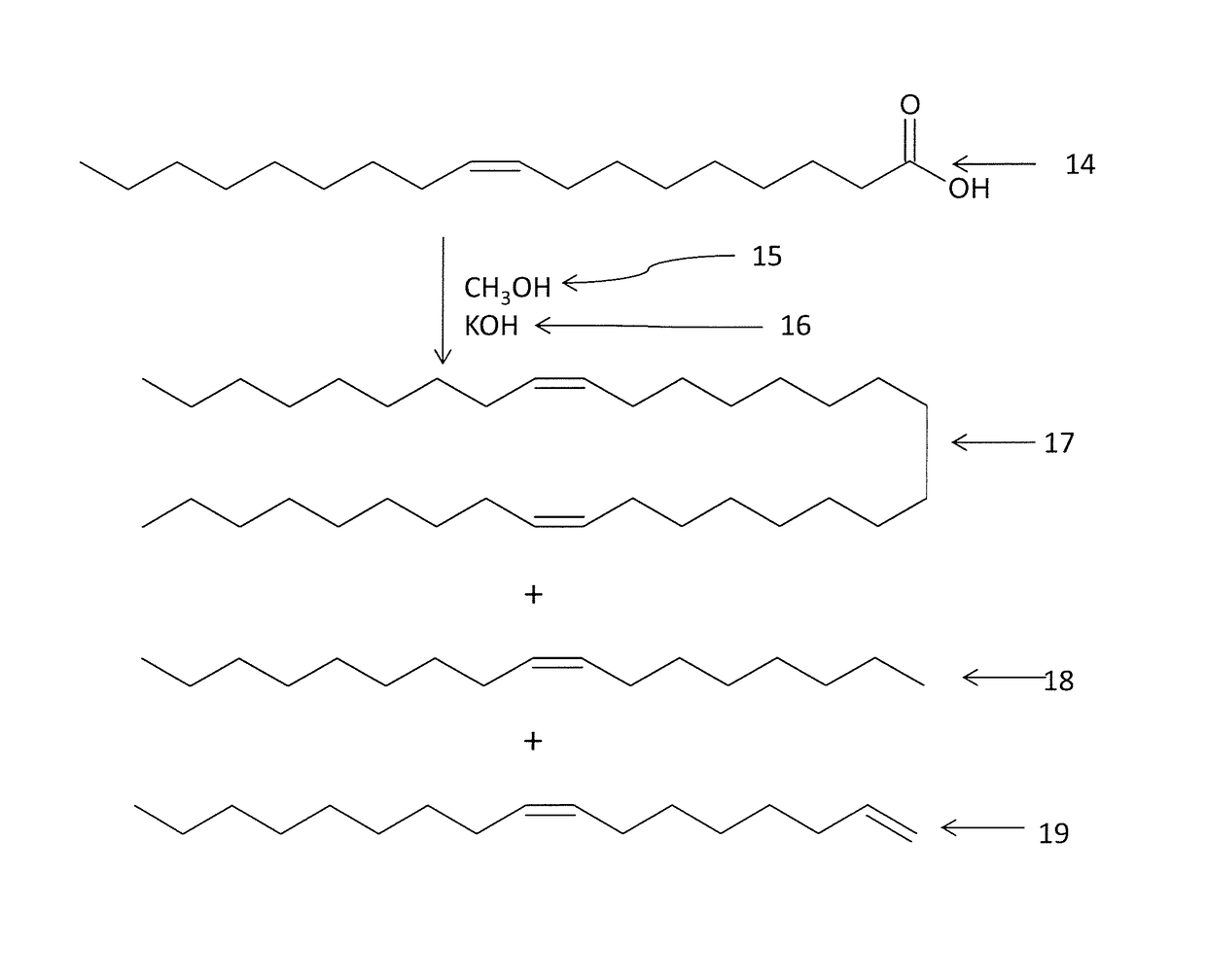

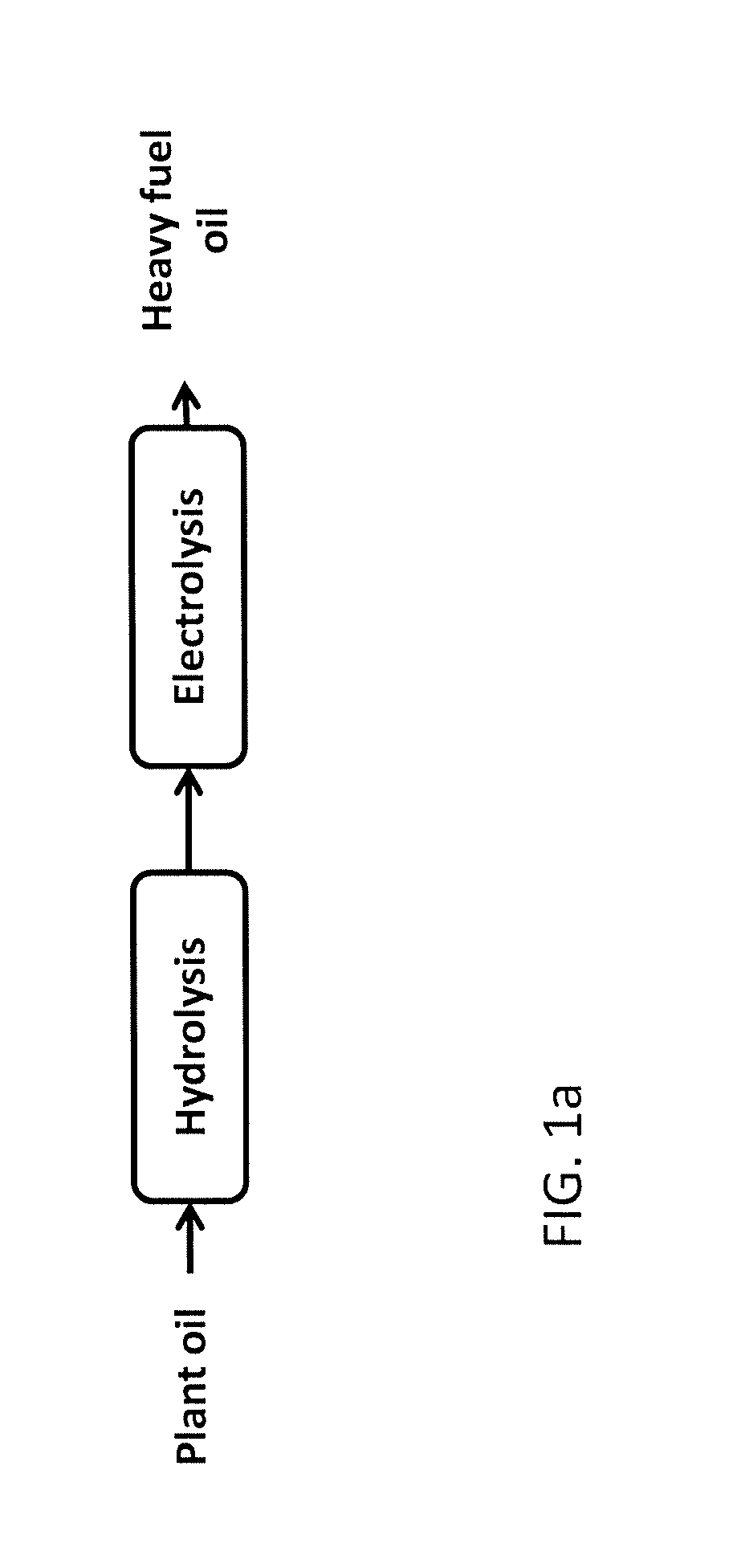

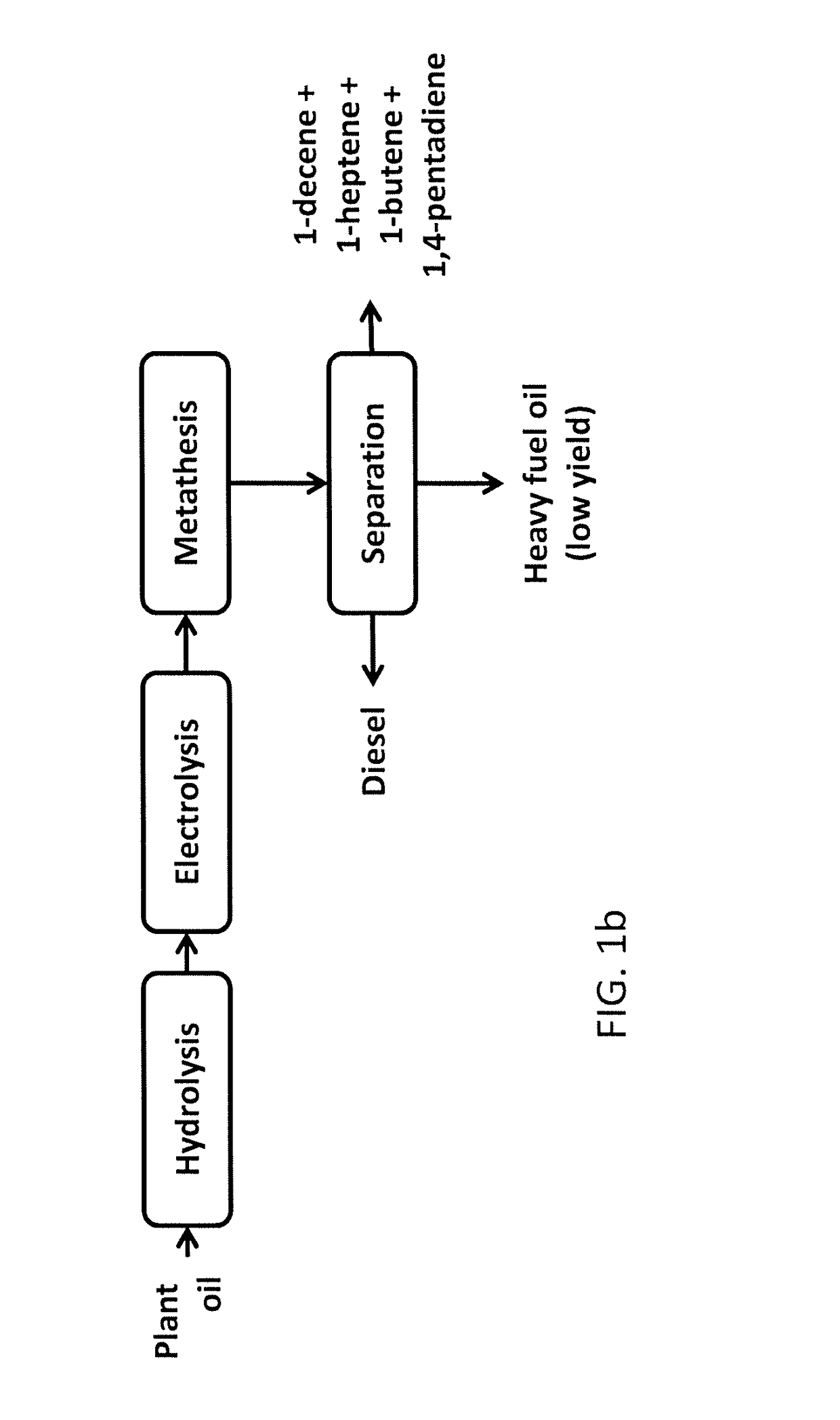

Production of hydrocarbon fuels from plant oil and animal fat

InactiveUS20120197050A1Electrolysis componentsElectrolytic organic coupling reactionsVegetable oilAnimal fat

The present invention relates to fuel compositions and methods of making the same. The fuel compositions include hydrocarbon derived from a biological source selected from plant oil, animal fat and combinations thereof. The hydrocarbon and the fuel compositions are at least substantially oxygen-free. In particular, the fuel compositions are useful in cold temperature environments and as aviation fuel.

Owner:ADVONEX INT CORP

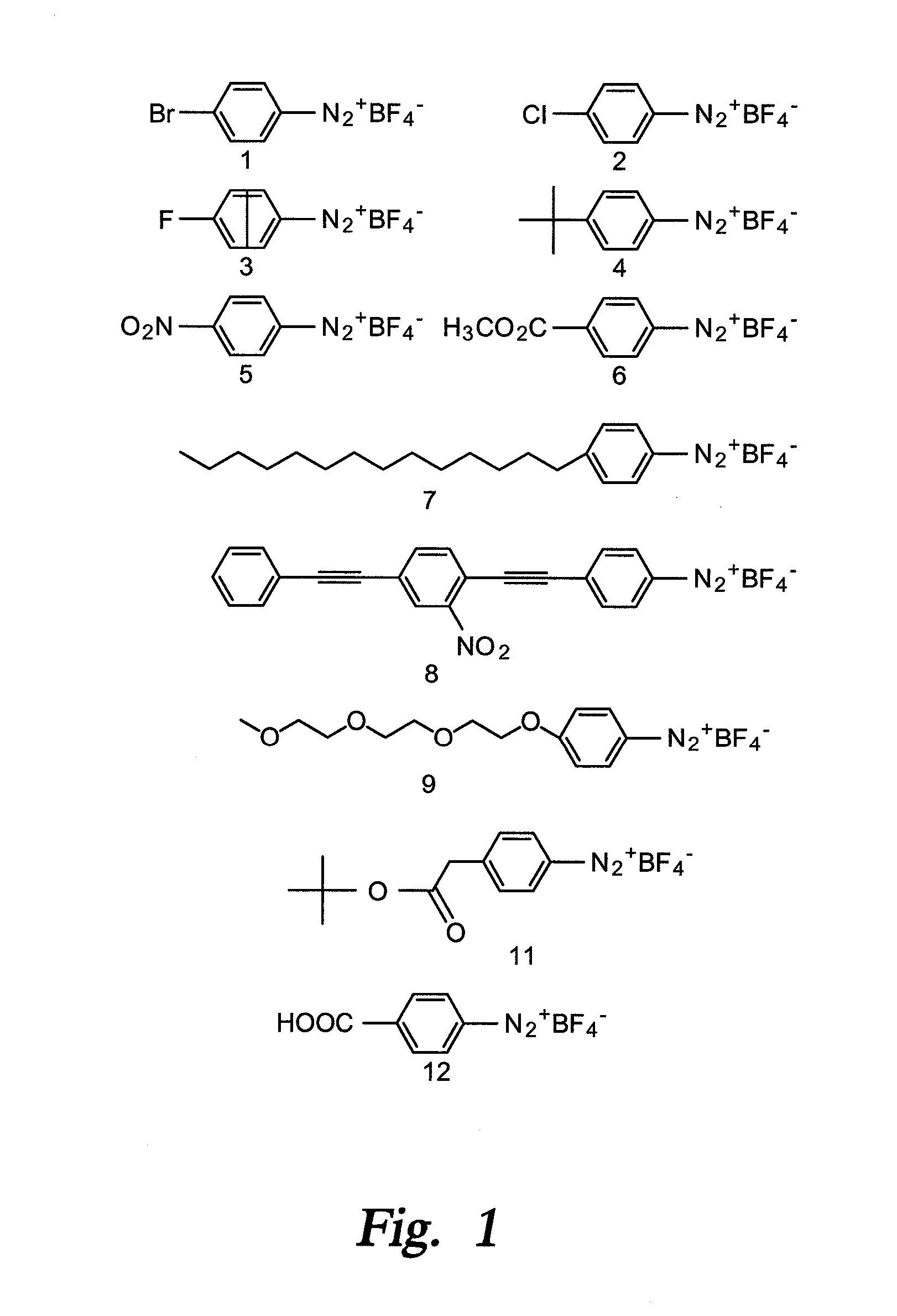

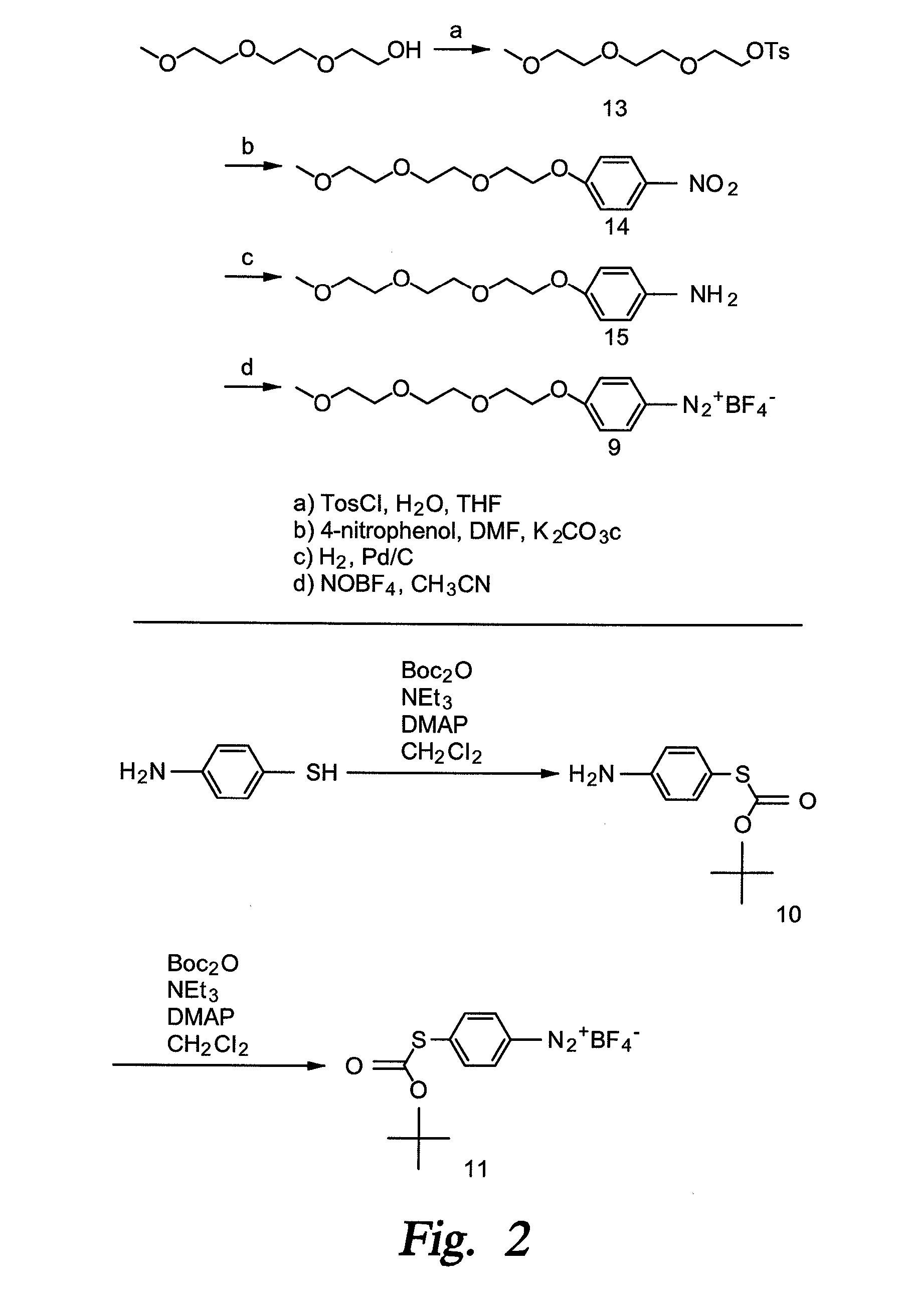

Process for derivatizing carbon nanotubes with diazonium species and compositions thereof

InactiveUS20080093224A1Advantage of scalabilityElectrolysis componentsElectrolytic organic coupling reactionsChemical groupsElectrochemistry

The invention incorporates new processes for the chemical modification of carbon nanotubes. Such processes involve the derivatization of multi- and single-wall carbon nanotubes, including small diameter (ca. 0.7 nm) single-wall carbon nanotubes, with diazonium species. The method allows the chemical attachment of a variety of organic compounds to the side and ends of carbon nanotubes. These chemically modified nanotubes have applications in polymer composite materials, molecular electronic applications, and sensor devices. The methods of derivatization include electrochemical induced reactions, thermally induced reactions (via in-situ generation of diazonium compounds or preformed diazonium compounds), and photochemically induced reactions. The derivatization causes significant changes in the spectroscopic properties of the nanotubes. The estimated degree of functionality is ca. 1 out of every 20 to 30 carbons in a nanotube bearing a functionality moiety. Such electrochemical reduction processes can be adapted to apply site-selective chemical functionalization of nanotubes. Moreover, when modified with suitable chemical groups, the derivatized nanotubes are chemically compatible with a polymer matrix, allowing transfer of the properties of the nanotubes (such as, mechanical strength or electrical conductivity) to the properties of the composite material as a whole. Furthermore, when modified with suitable chemical groups, the groups can be polymerized to form a polymer that includes carbon nanotubes.

Owner:RICE UNIV

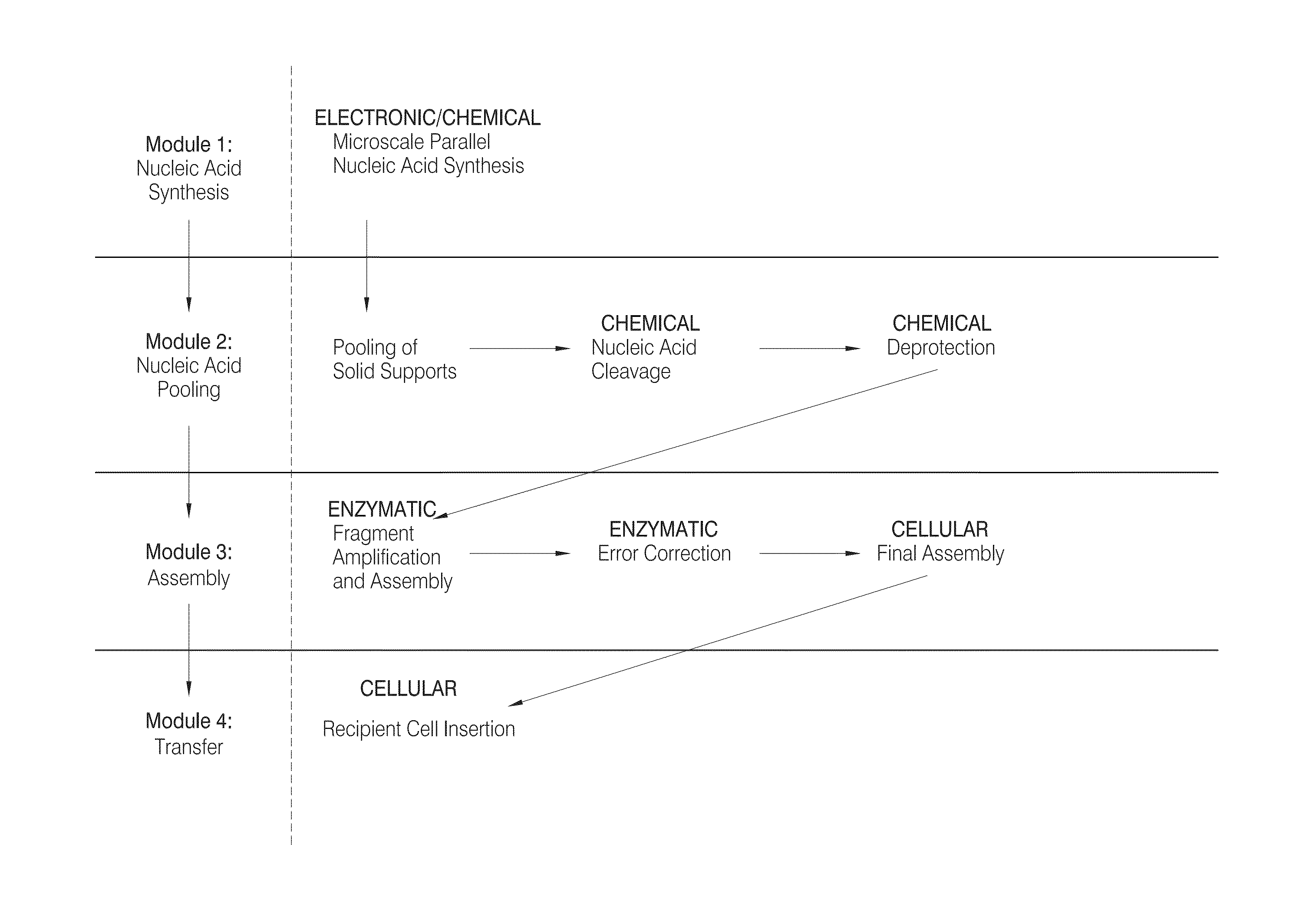

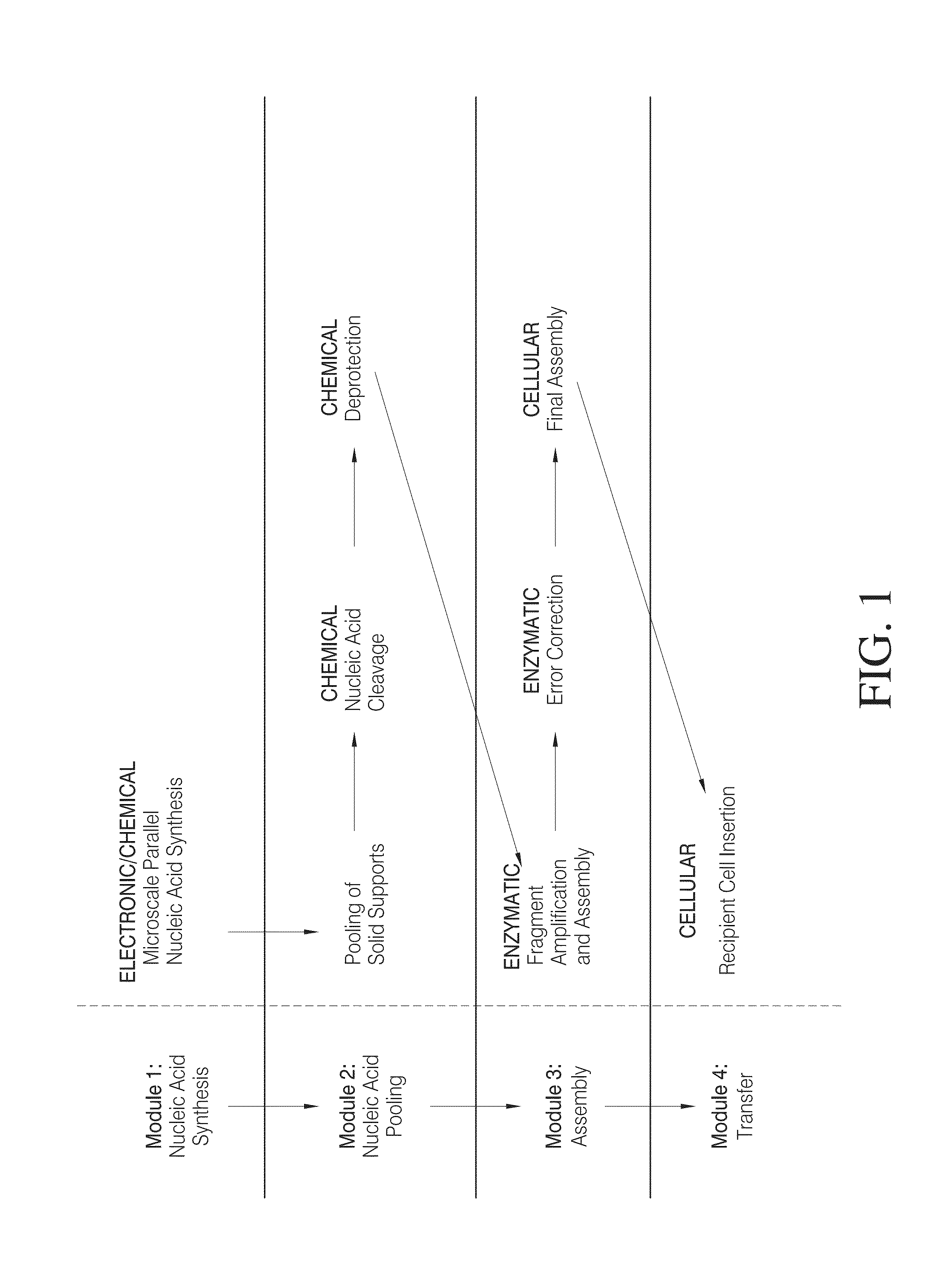

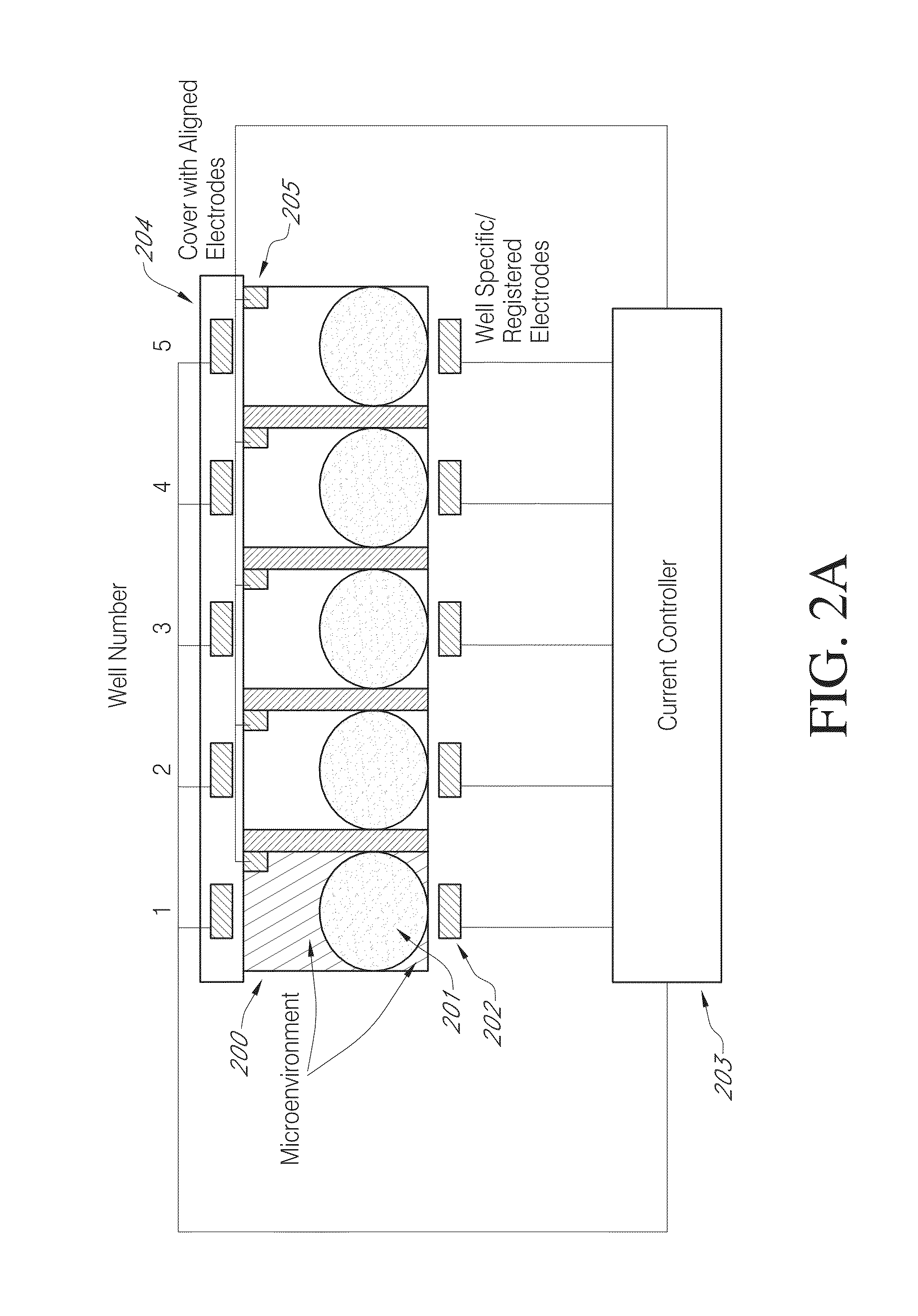

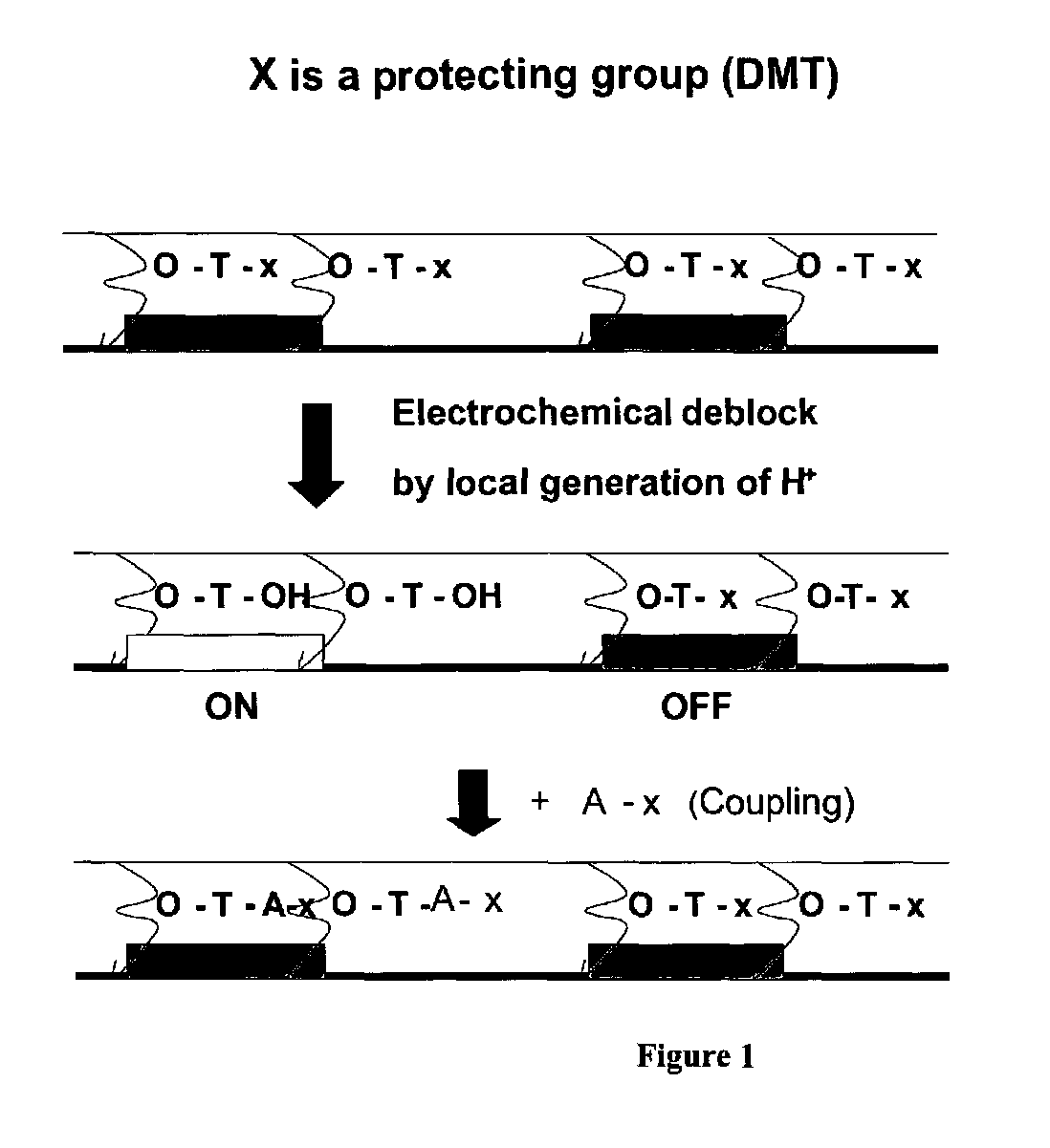

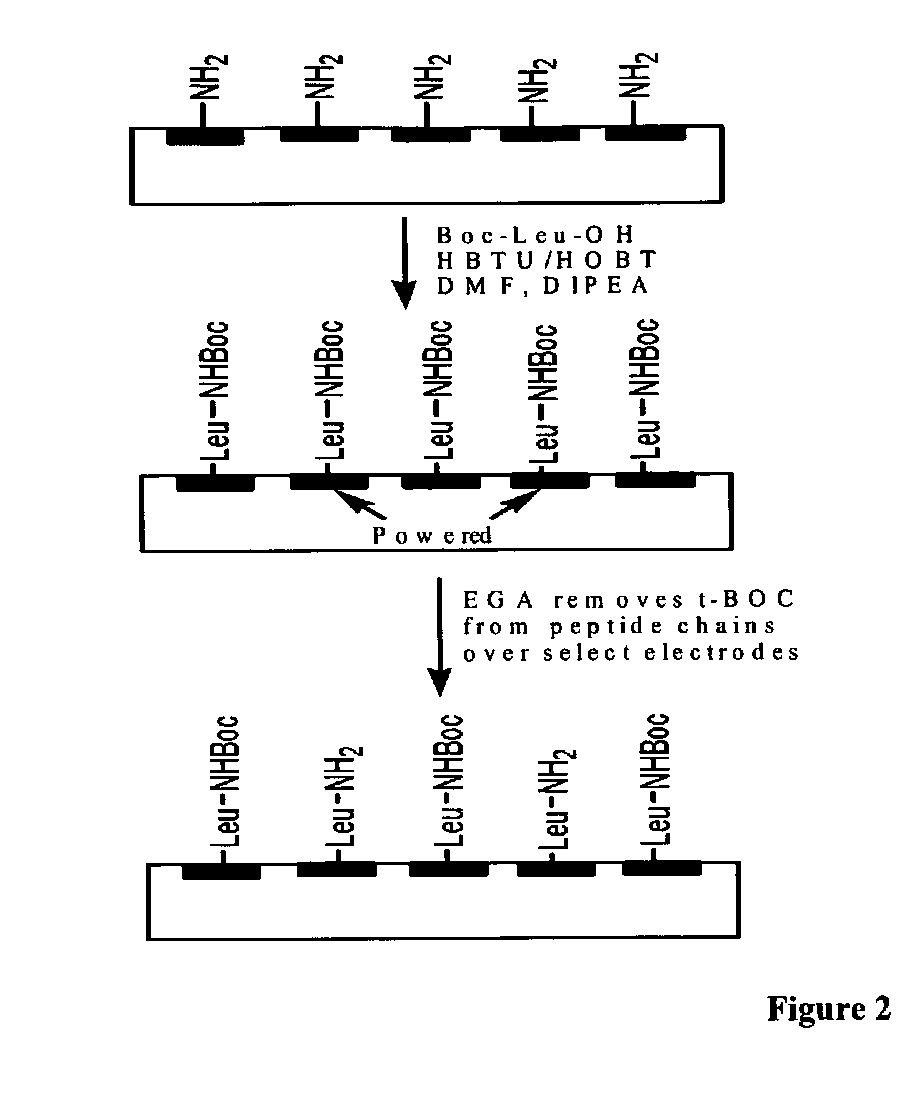

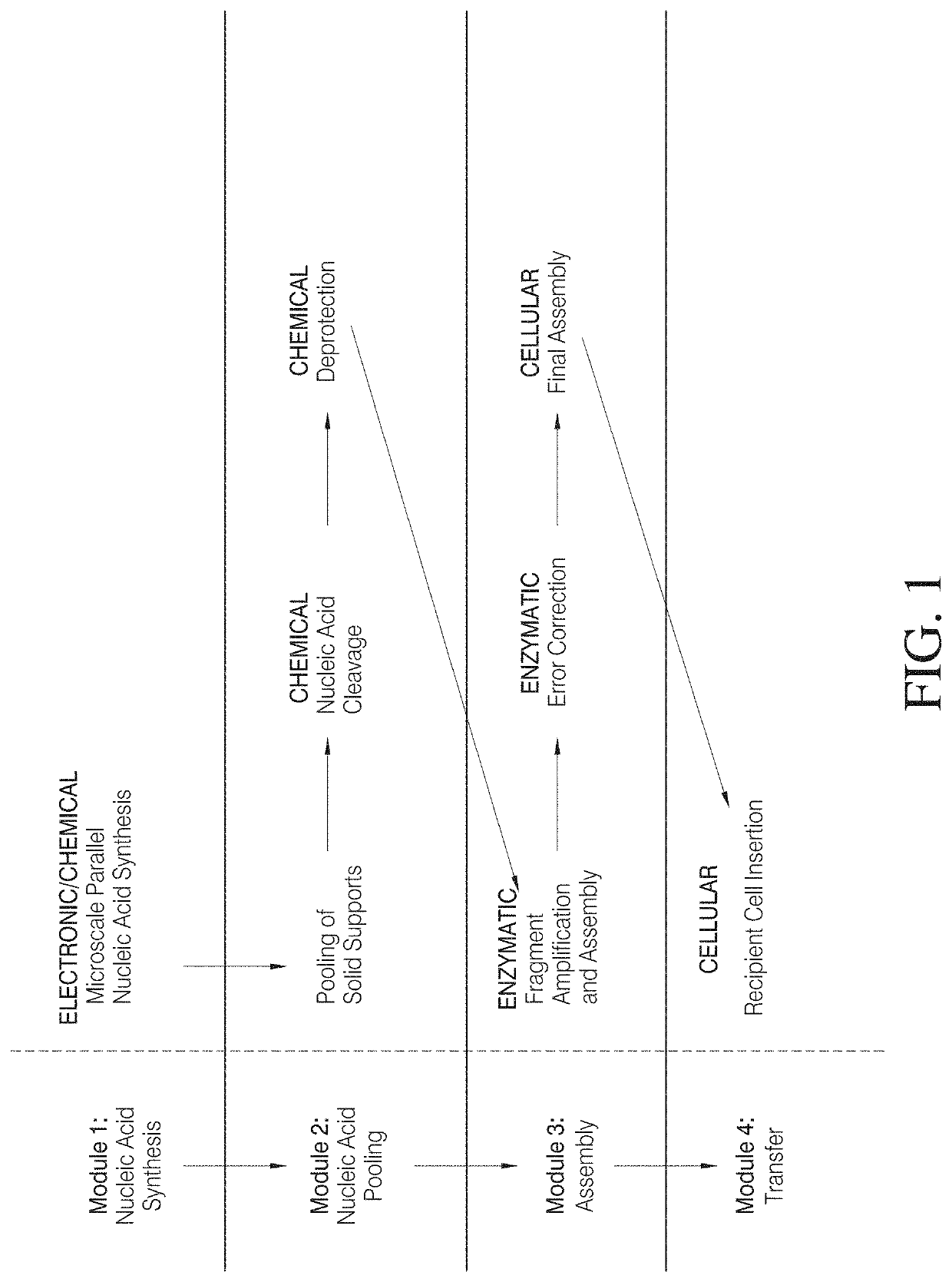

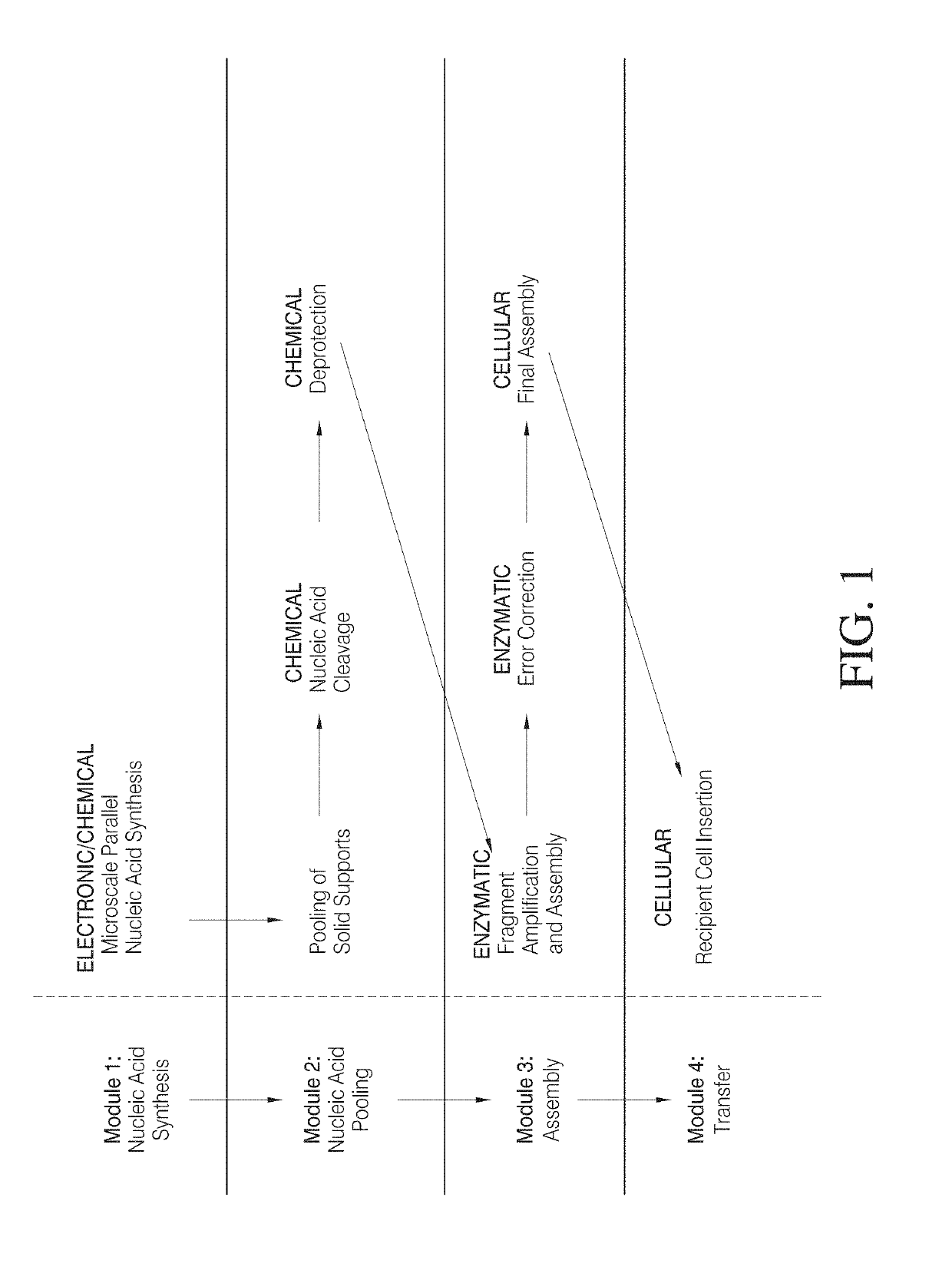

High efficiency, small volume nucleic acid synthesis

The disclosure generally relates to compositions and methods for the production of nucleic acid molecules. In some aspects, the invention allows for the microscale generation of nucleic acid molecules, optionally followed by assembly of these nucleic acid molecules into larger molecules. In some aspects, the invention allows for efficient production of nucleic acid molecules (e.g., large nucleic acid molecules such as genomes).

Owner:LIFE TECH AS +2

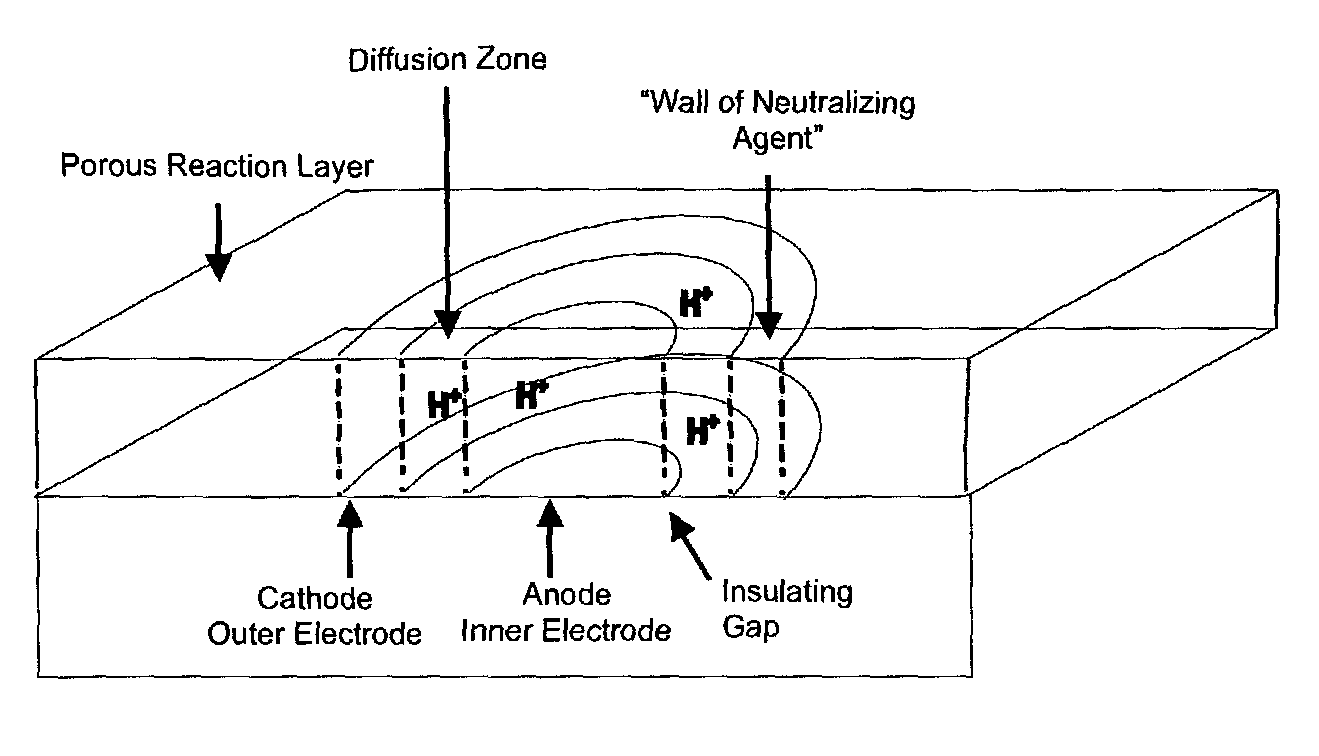

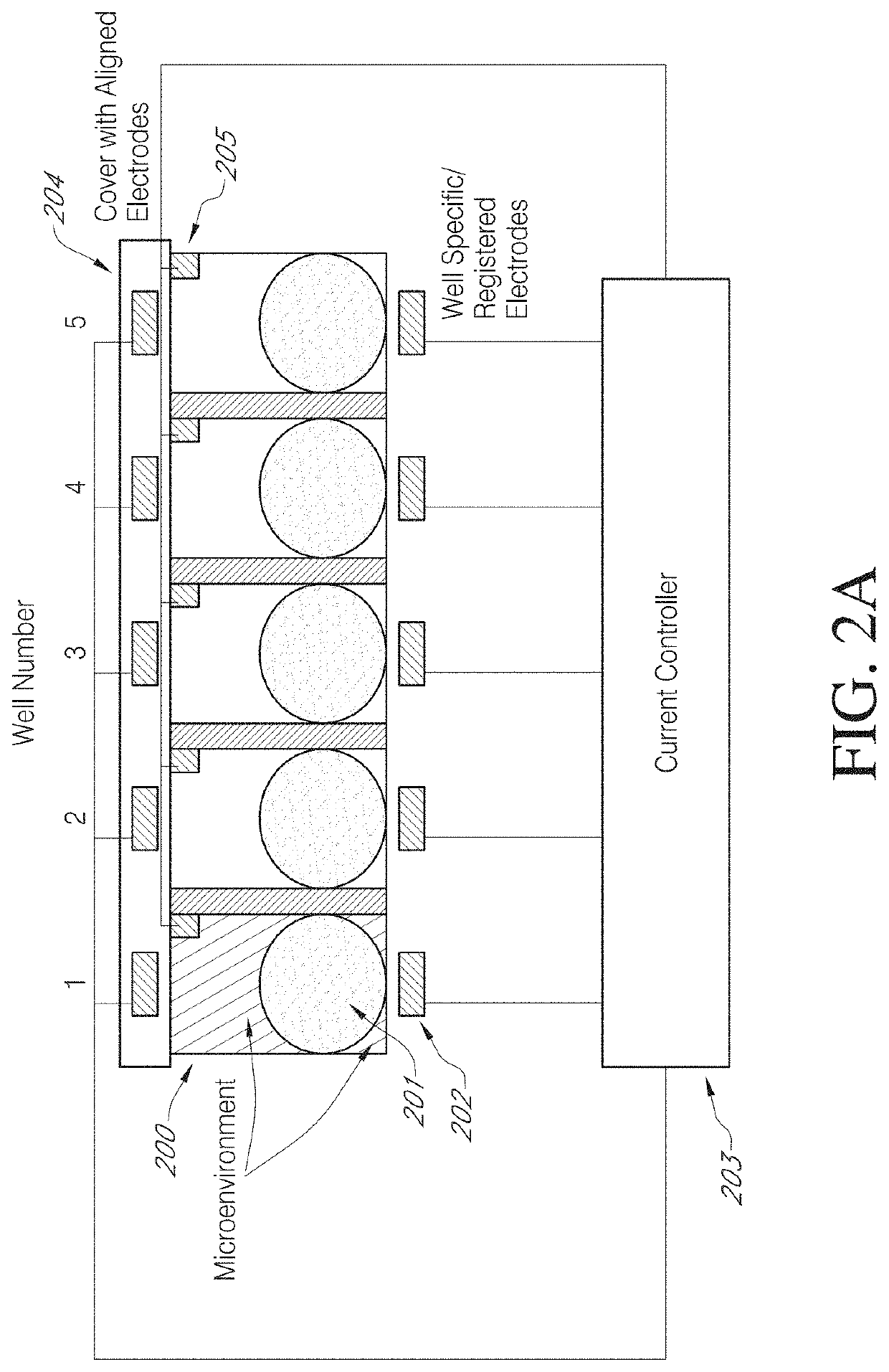

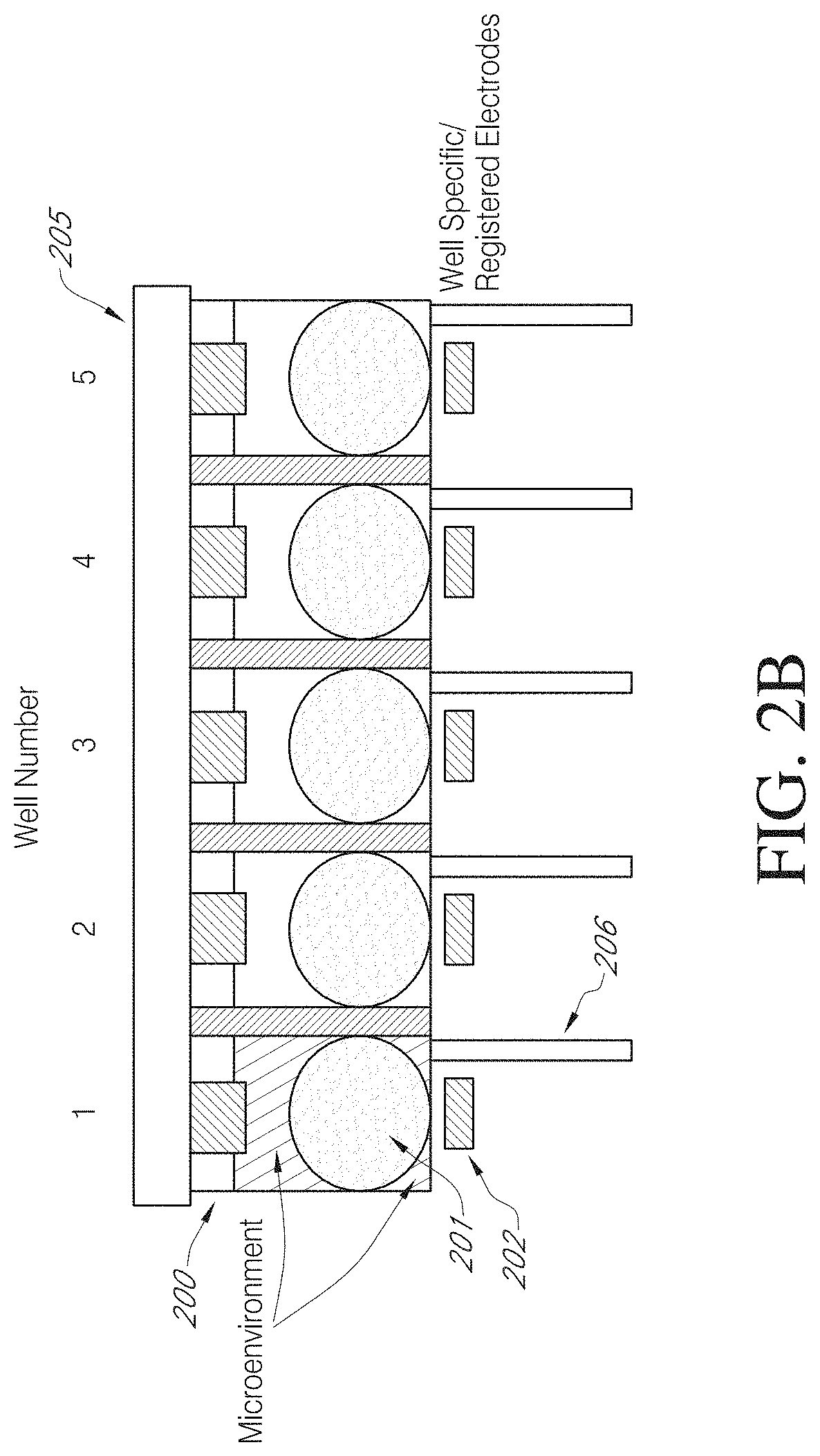

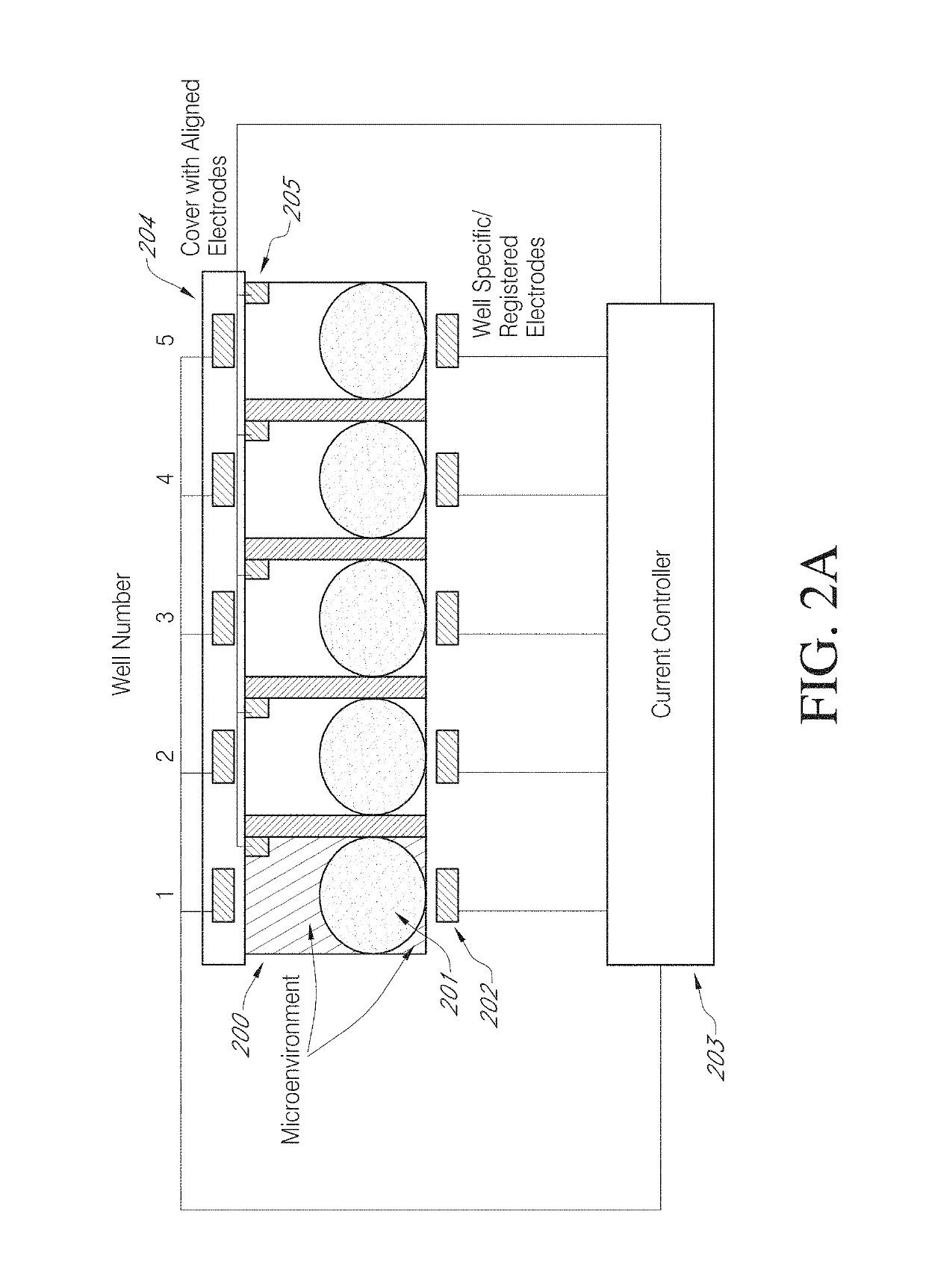

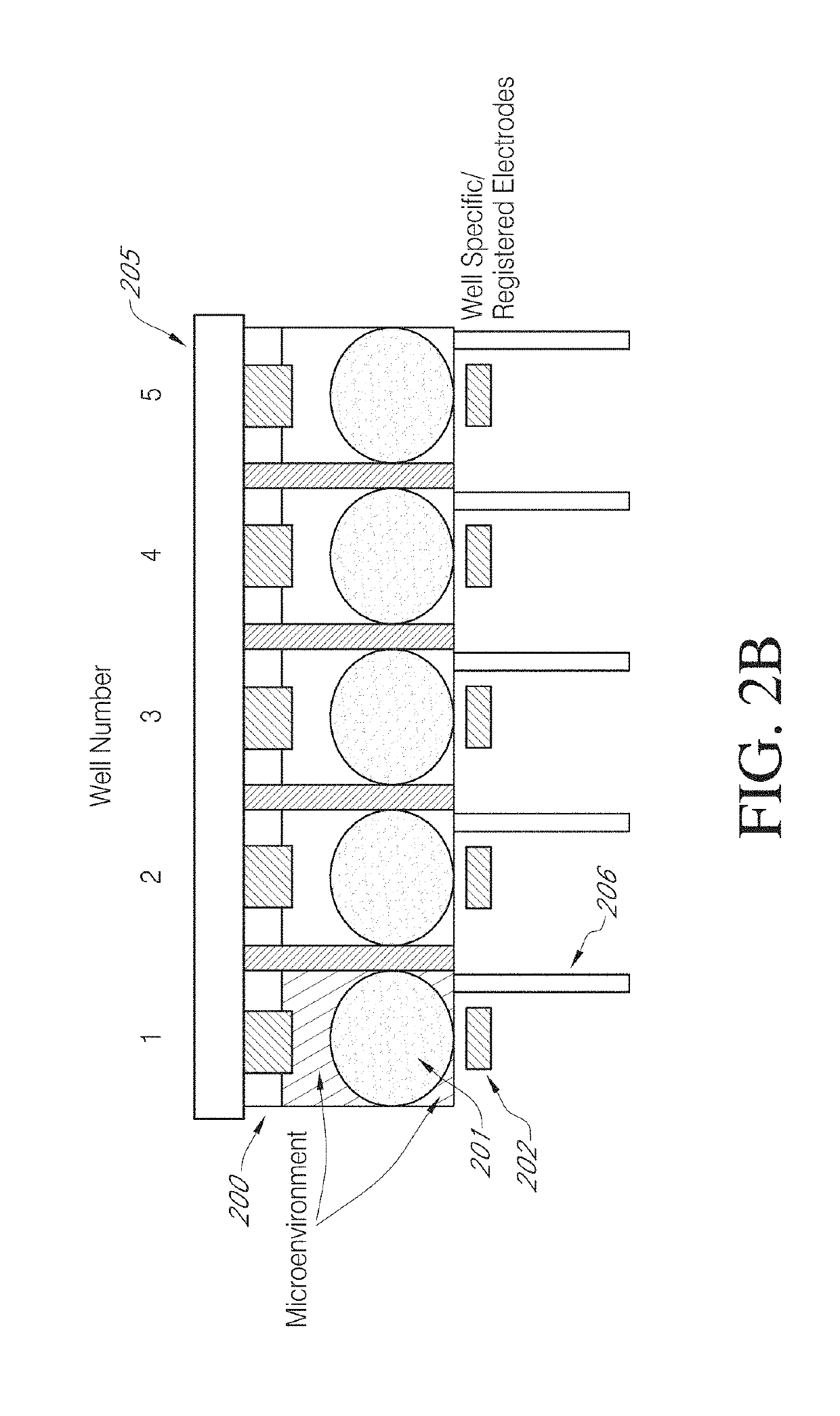

Neutralization and containment of redox species produced by circumferential electrodes

There is disclosed an electrode array architecture employing continuous and discontinuous circumferential electrodes. There is further disclosed a process for the neutralization of acid generated at anode(s) by base generated at cathode(s) circumferentially located to each other so as to confine a region of pH change. The cathodes can be displayed as concentric rings (continuous) or as counter electrodes in a cross pattern (discontinuous). In this way reagents, such as acid, generated in a center electrode are countered (neutralized) by reagents, such as base, generated at the corners or at the outer ring.

Owner:CUSTOM ARRAY

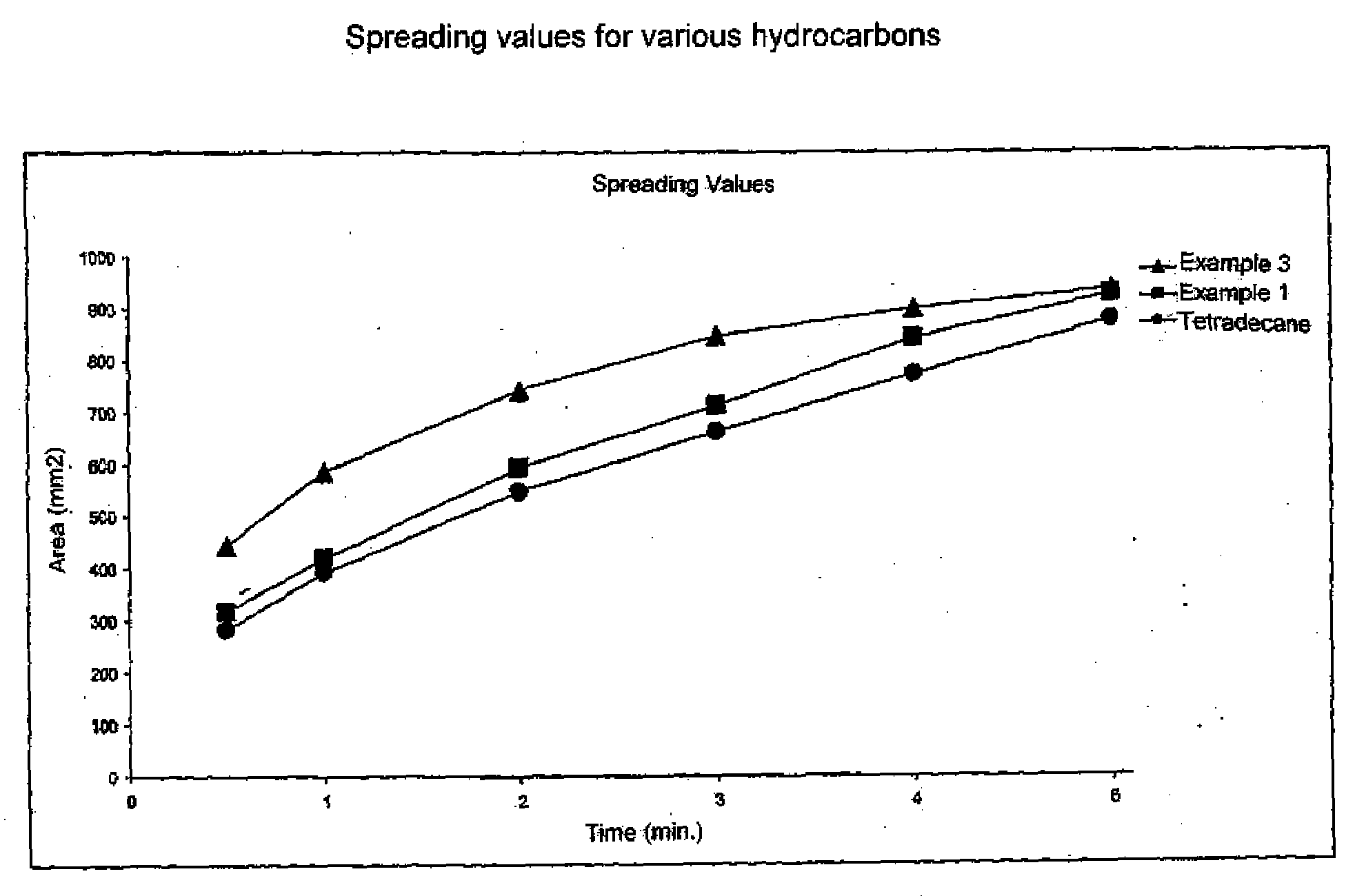

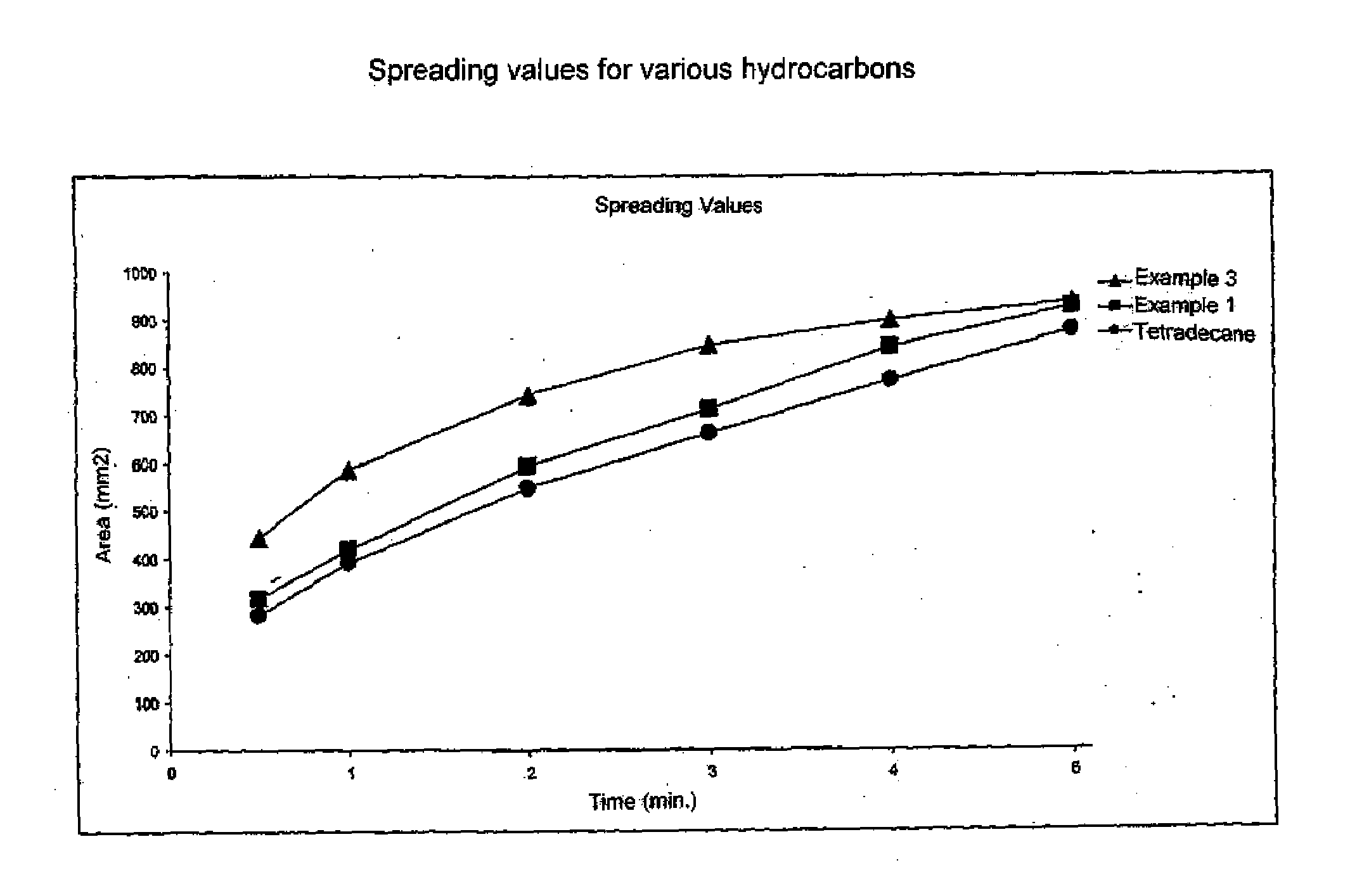

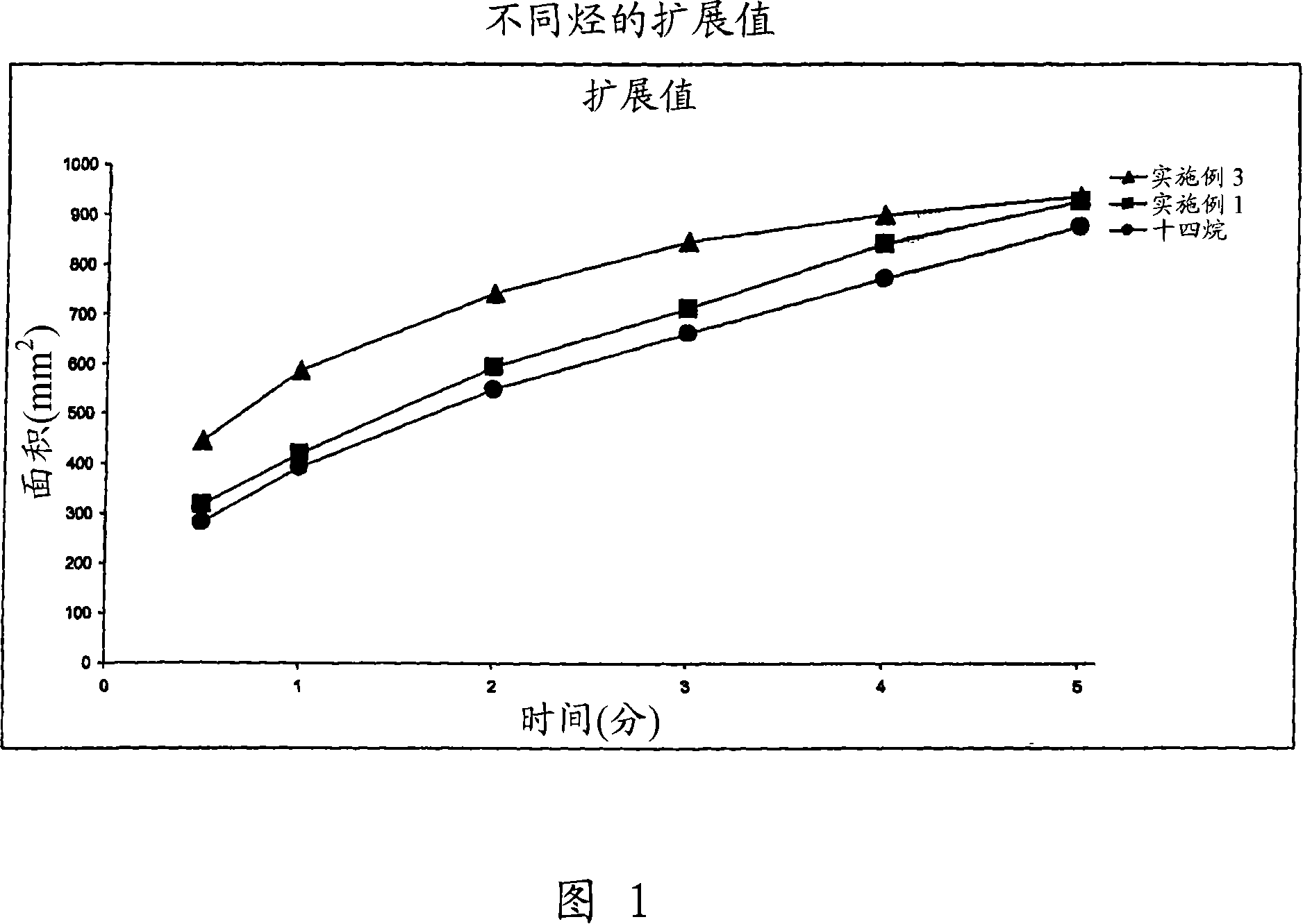

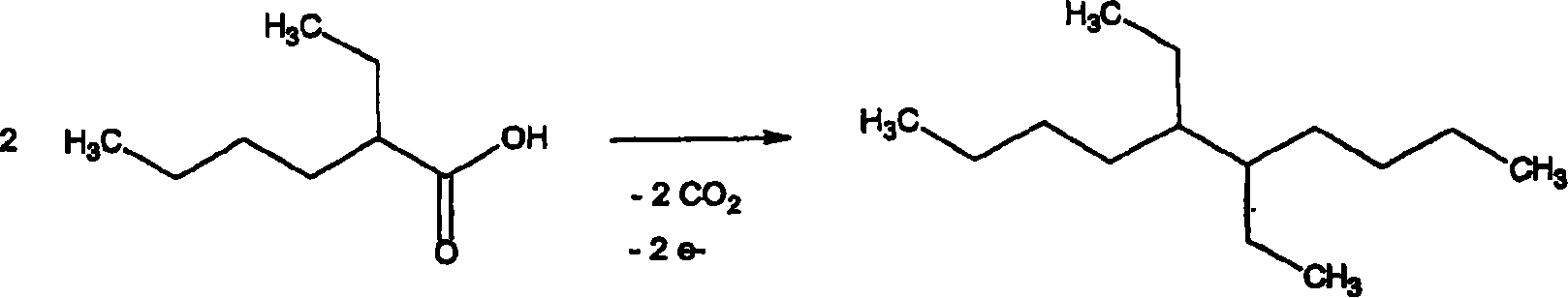

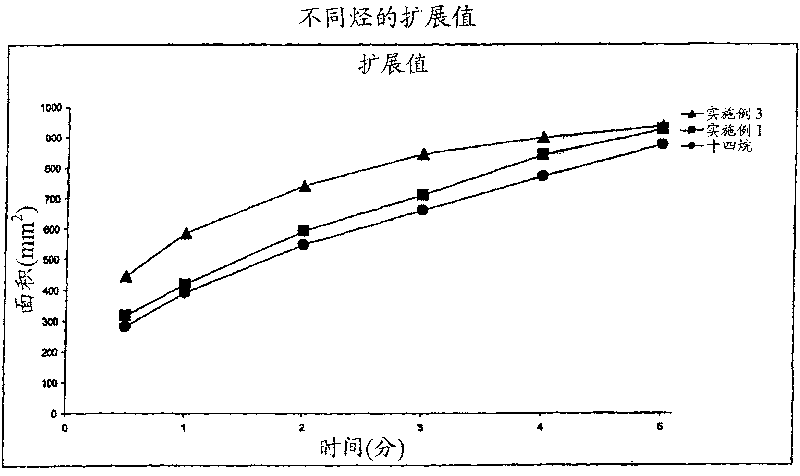

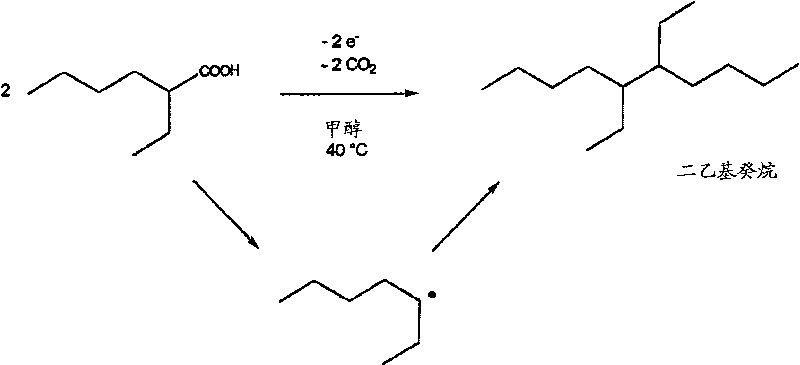

Emollients and Cosmetic Compositons Based on Specific Branched Hydrocarbons

InactiveUS20080161418A1Improve spreading qualityIncrease productionBiocideCosmetic preparationsBranched chain fatty acidsHydrocarbon

A cosmetic or pharmaceutical composition is provided. The composition contains a mixture of oils prepared by Kolbe electrolysis of branched chain fatty acids and mixtures of branched chain fatty acids with straight chain fatty acids. The fatty acids containing from 3 to 26 carbon atoms. The oils are a mixture of oils with different spreading rates (spreading cascade).

Owner:COGNIS IP MANAGEMENT GMBH

Production of gasoline from fermentable feedstocks

ActiveUS8241881B2Easy to separateImprove isolationElectrolysis componentsBacteriaCatalytic reformingBiodiesel

Compositions and methods for forming hexane, and, optionally, gasoline and / or components of a gasoline composition, from fermentable sugars are disclosed. The sugars are fermented using a bacteria or yeast that predominantly forms butyric acid. The butyric acid is subjected to Kolbe or photo-Kolbe electrolysis to form hexane. The hexane can be subjected to catalytic, reforming and / or isomerization steps to form higher octane products, which are or can be included in gasoline compositions. In one aspect, the fermentable sugars are derived from lignocellulosic materials such as wood products, switchgrass, or agricultural wastes. These materials are delignified to form lignin, cellulose and hemicellulose. The cellulose and hemicellulose are depolymerized to form glycose and xylose, either or both of which can be fermented by the bacteria. The lignin can be used to generate heat energy and / or electric energy for use in one or more process steps, such as the fermentation, product isolation, Kolbe electrolysis, catalytic reforming and / or isomerization steps. Alternatively, the lignin can be converted to synthesis gas, which can then be subjected to Fischer-Tropsch synthesis, or converted to methanol and / or ethanol. Thus, the methods described herein can convert biomass to a fuel composition or fuel additive, which can be used in a conventional gasoline engine, unlike traditional fuels such as ethanol or biodiesel.

Owner:CPS BIOFUELS INC

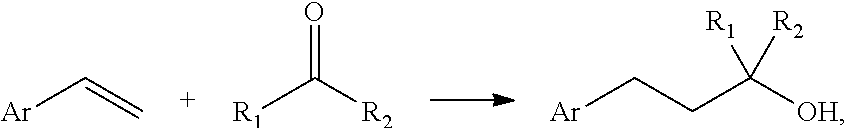

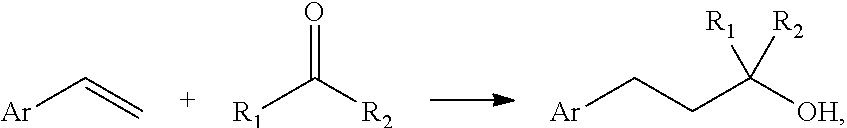

Process for preparing alcohols by electrochemical reductive coupling

ActiveUS20170233874A1Electrolysis componentsElectrolytic organic coupling reactionsAlcoholPhenyl group

Alcohols are prepared by electrochemical reductive coupling of an aromatic vinyl compound and a carbonyl compound in a process which comprises electrolyzing an electrolyte solution in an electrochemical cell, the electrolyte solution comprising the aromatic vinyl compound, the carbonyl compound and a non-aqueous protic solvent, such as methanol, wherein the electrolyte solution is in contact with a carbon-based cathode Styrene is reacted with acetone to prepare 2-methyl-4-phenyl-2-butanol.

Owner:BASF AG

High efficiency, small volume nucleic acid synthesis

The disclosure generally relates to compositions and methods for the production of nucleic acid molecules. In some aspects, the invention allows for the microscale generation of nucleic acid molecules, optionally followed by assembly of these nucleic acid molecules into larger molecules. In some aspects, the invention allows for efficient production of nucleic acid molecules (e.g., large nucleic acid molecules such as genomes).

Owner:LIFE TECH AS +2

Method for making poly(hydridocarbyne)

InactiveUS9035017B2Avoid decompositionPromote productionTeeth fillingPretreated surfacesElectrochemical responseHalomethane

Owner:EPIC VENTURES

Emollients and cosmetic compositions based on special branched hydrocarbons

The present invention relates to a cosmetic and / or pharmaceutical composition containing hydrocarbons prepared by Kolber electrolysis of (a) at least one branched C6-C26 fatty acid or (b) at least one branched C6-C26 fatty acid. It is prepared from a mixture of linear C3-C26 fatty acids and at least one branched C4-C26 fatty acid. This compound is characterized by being a highly expandable oil component.

Owner:COGNIS IP MANAGEMENT GMBH

Custom ionic liquid electrolytes for electrolytic decarboxylation

ActiveUS20170088962A1CellsElectrolytic organic coupling reactionsSimple Organic CompoundsOrganic compound

Methods, equipment, and reagents for preparing organic compounds using custom electrolytes based on different ionic liquids in electrolytic decarboxylation reactions are disclosed.

Owner:ENLIGHTEN INNOVATIONS INC

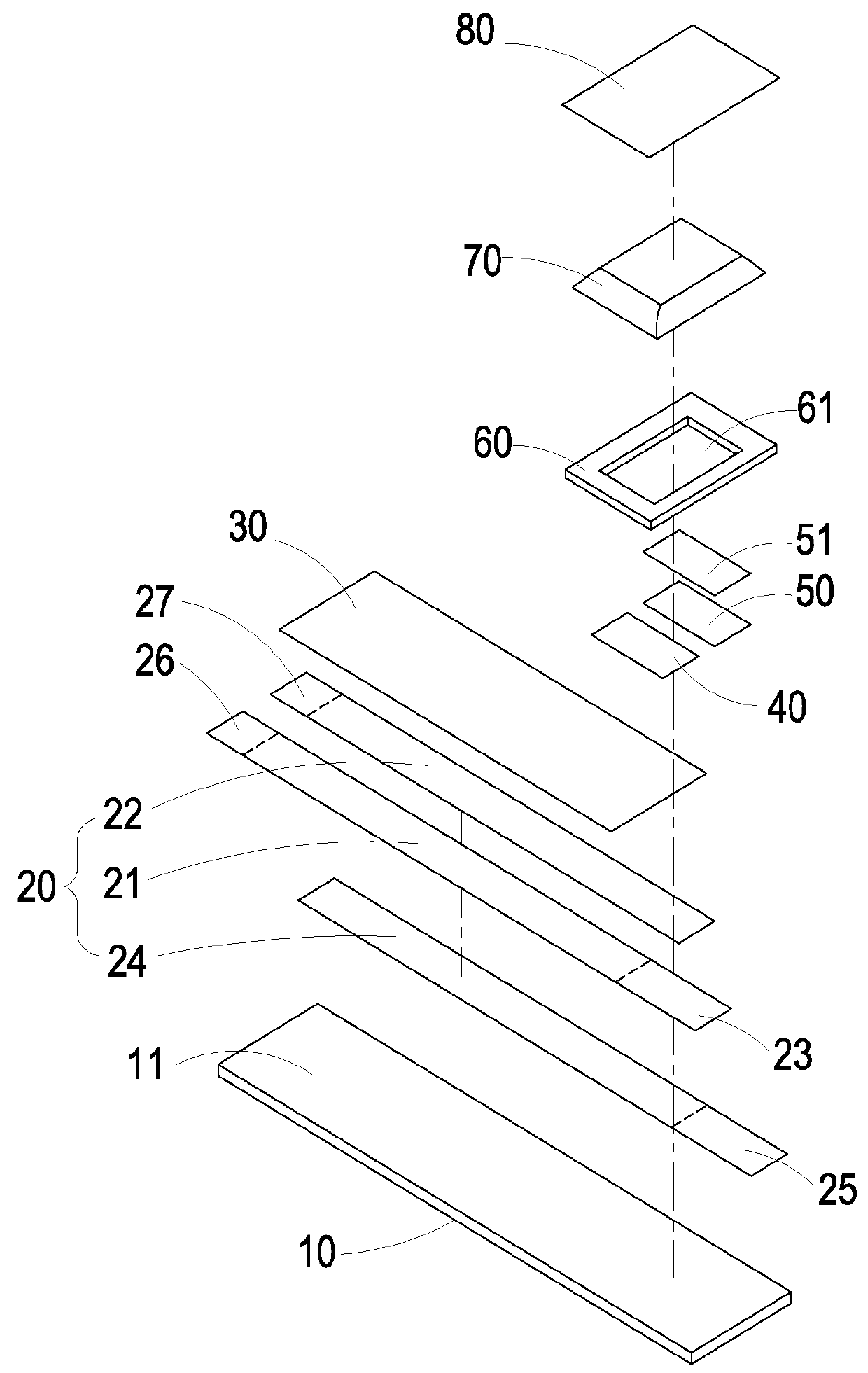

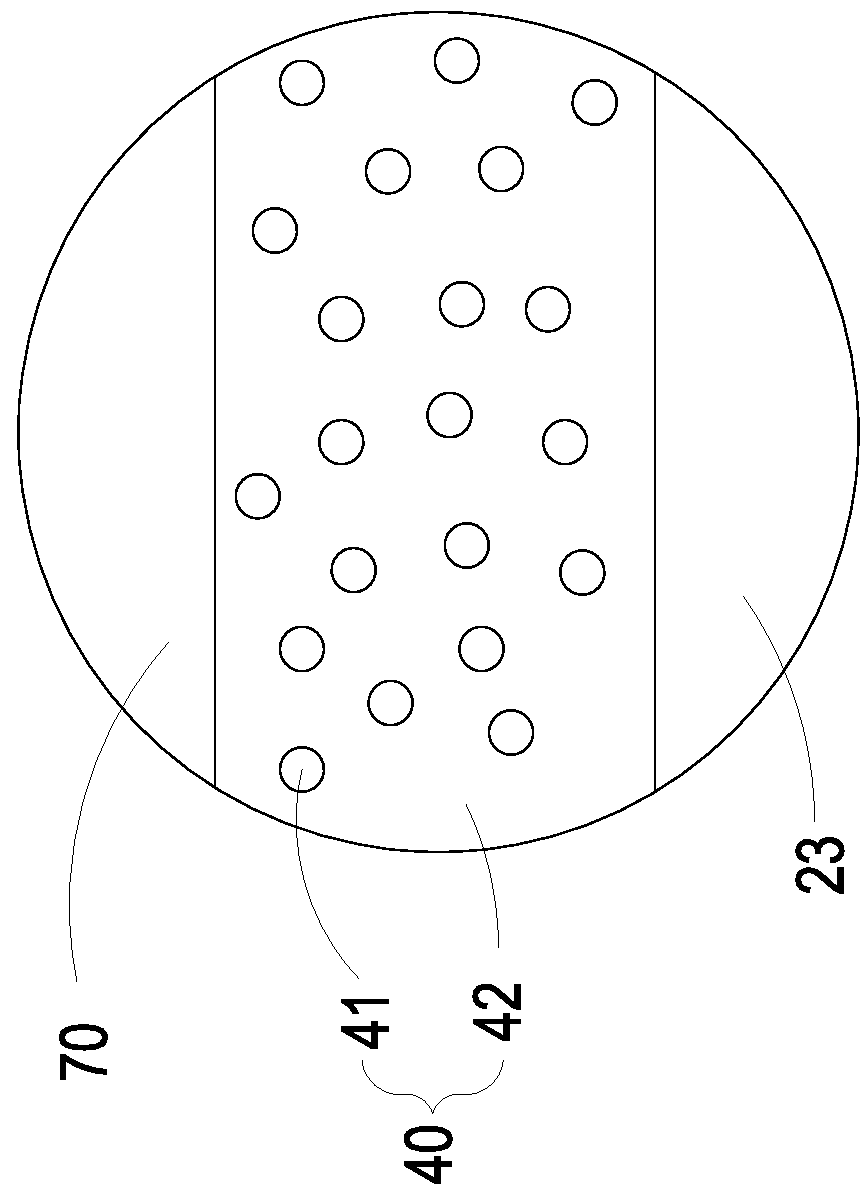

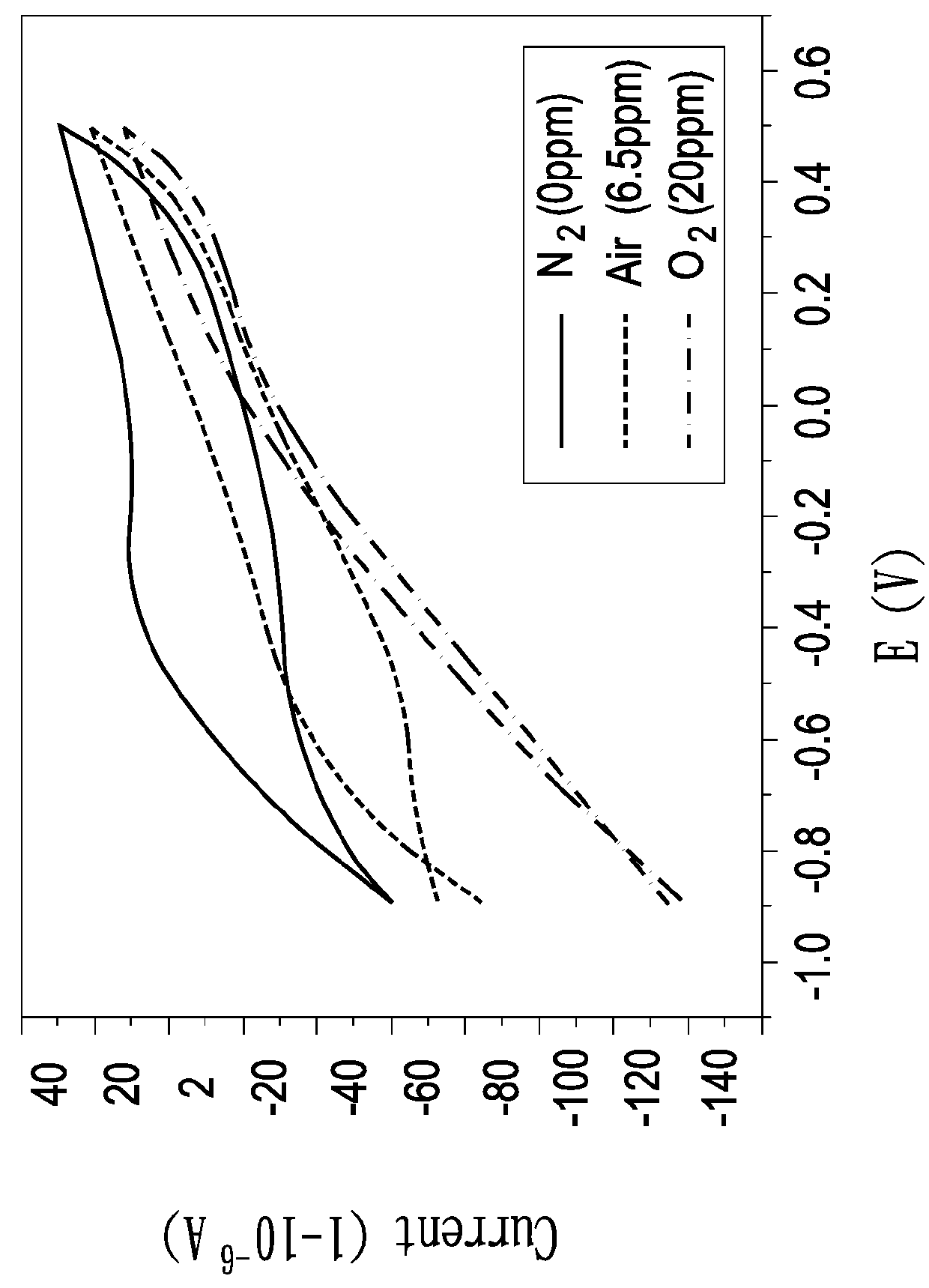

Planar dissolved oxygen sensing electrode and manufacturing method thereof

InactiveUS20180105941A1Improve sensing sensitivityLower the volumeElectrolysis componentsElectrolytic organic coupling reactionsWater qualityReaction zone

A planar dissolved oxygen sensing electrode for water quality monitoring and a manufacturing method thereof are provided. The sensing electrode includes an insulating base plate, an electric-conductive layer, an oxygen sensing layer, a reference sensing layer, and an electrolyte layer. The electric-conductive layer is disposed on the planar surface of the insulating base plate. The electric-conductive layer includes a first conductive part, a second conductive part, a first reaction zone and a second reaction zone. The first conductive part and the second conductive part are connected to the first reaction zone and the second reaction zone, respectively. The oxygen sensing layer disposed on the first reaction zone includes plural catalyst particles dispersed in the polymer matrix. The reference sensing layer is disposed on the second reaction zone. The electrolyte layer is disposed on the oxygen sensing layer and the reference sensing layer.

Owner:AKUBIC CAYMAN LTD

High productivity Kolbe reaction process for transformation of fatty acids derived from plant oil and animal fat

ActiveUS8961775B2Improve productivityReduce voltageElectrolysis componentsRefining to change hydrocarbon structural skeletonVegetable oilKerosene

Owner:ALTRANEX CORPORATION

Custom ionic liquid electrolytes for electrolytic decarboxylation

ActiveUS9493882B2CellsElectrolytic organic coupling reactionsSimple Organic CompoundsDecarboxylation

Methods, equipment, and reagents for preparing organic compounds using custom electrolytes based on different ionic liquids in electrolytic decarboxylation reactions are disclosed.

Owner:ENLIGHTEN INNOVATIONS INC

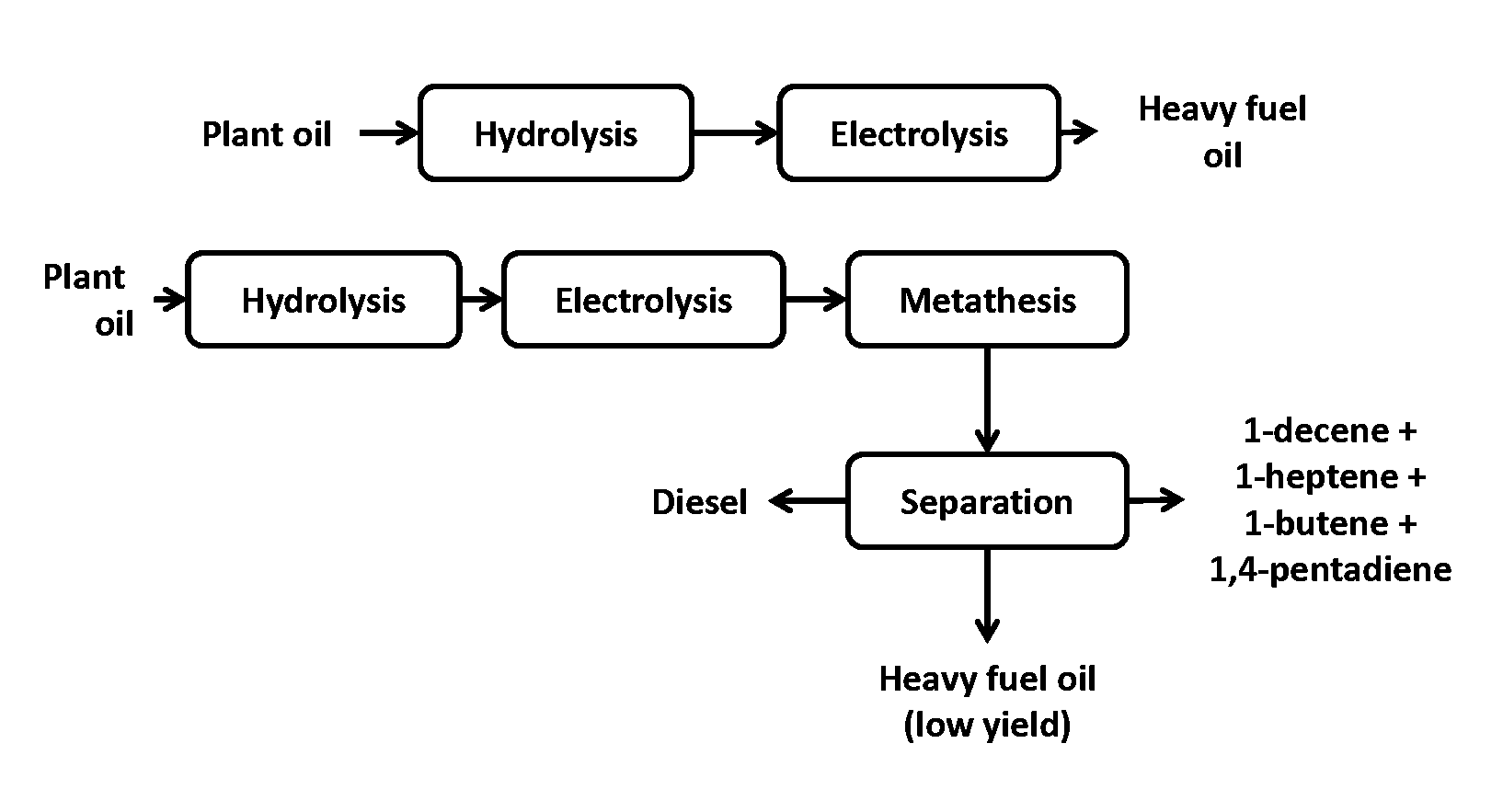

Production of hydrocarbons from plant oil and animal fat

ActiveUS9611554B2Wasteful electrical usageImprove productivityHydrocarbon by isomerisationElectrolysis componentsVegetable oilKerosene

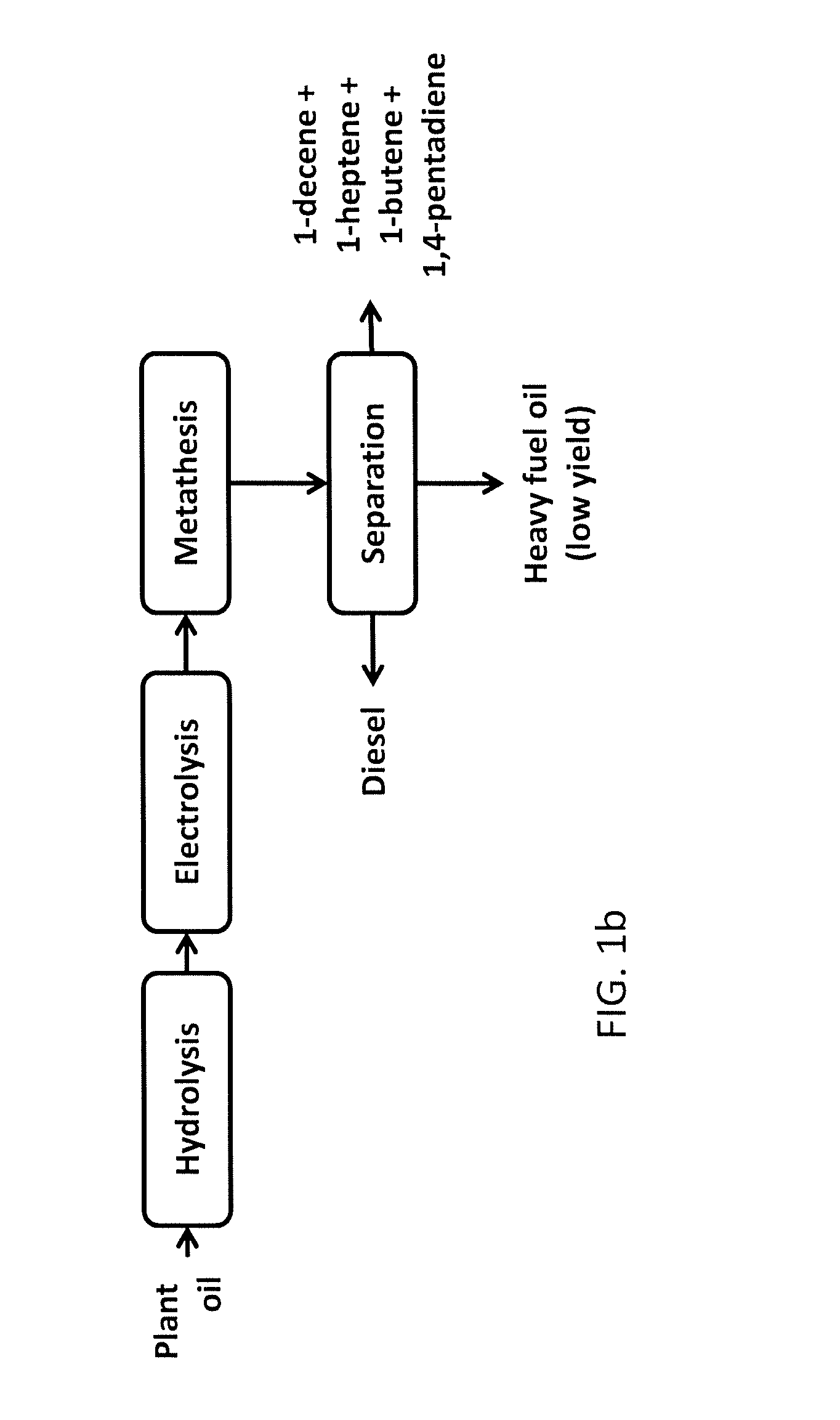

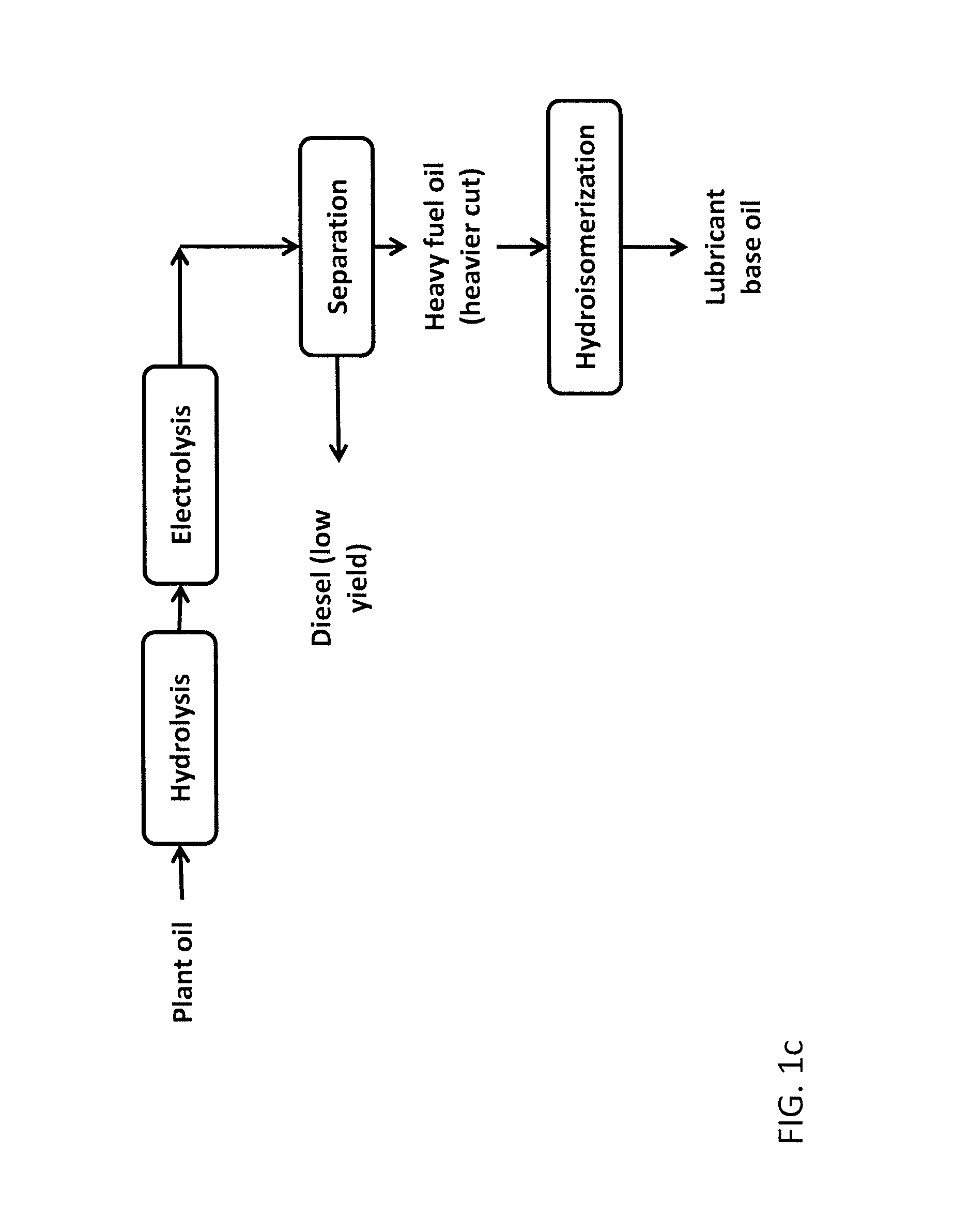

Oils from plants and animal fats are hydrolyzed to fatty acids for a Kolbe reaction. The invention relates to a high productivity Kolbe reaction process for electrochemically decarboxylating C4-C28 fatty acids derived from sources selected based on their saturated and unsaturated fatty acid content in order to lower anodic passivation voltage during synthesis of C6-C54 hydrocarbons. The C6-C54 hydrocarbons may undergo olefin metathesis and / or hydroisomerization reaction processes to synthesize heavy fuel oil, diesel fuel, kerosene fuel, lubricant base oil, and linear alpha olefin products useful as precursors for polymers, detergents, and other fine chemicals.

Owner:ADVONEX INT CORP

Production of hydrocarbons from plant oil and animal fat

ActiveUS20160076157A1Wasteful electrical usageImprove productivityElectrolysis componentsElectrolytic organic coupling reactionsVegetable oilKerosene

Oils from plants and animal fats are hydrolyzed to fatty acids for a Kolbe reaction. The invention relates to a high productivity Kolbe reaction process for electrochemically decarboxylating C4-C28 fatty acids derived from sources selected based on their saturated and unsaturated fatty acid content in order to lower anodic passivation voltage during synthesis of C6-C54 hydrocarbons. The C6-C54 hydrocarbons may undergo olefin metathesis and / or hydroisomerization reaction processes to synthesize heavy fuel oil, diesel fuel, kerosene fuel, lubricant base oil, and linear alpha olefin products useful as precursors for polymers, detergents, and other fine chemicals.

Owner:ADVONEX INT CORP

High efficiency, small volume nucleic acid synthesis

The disclosure generally relates to compositions and methods for the production of nucleic acid molecules. In some aspects, the invention allows for the microscale generation of nucleic acid molecules, optionally followed by assembly of these nucleic acid molecules into larger molecules. In some aspects, the invention allows for efficient production of nucleic acid molecules (e.g., large nucleic acid molecules such as genomes).

Owner:LIFE TECH AS +2

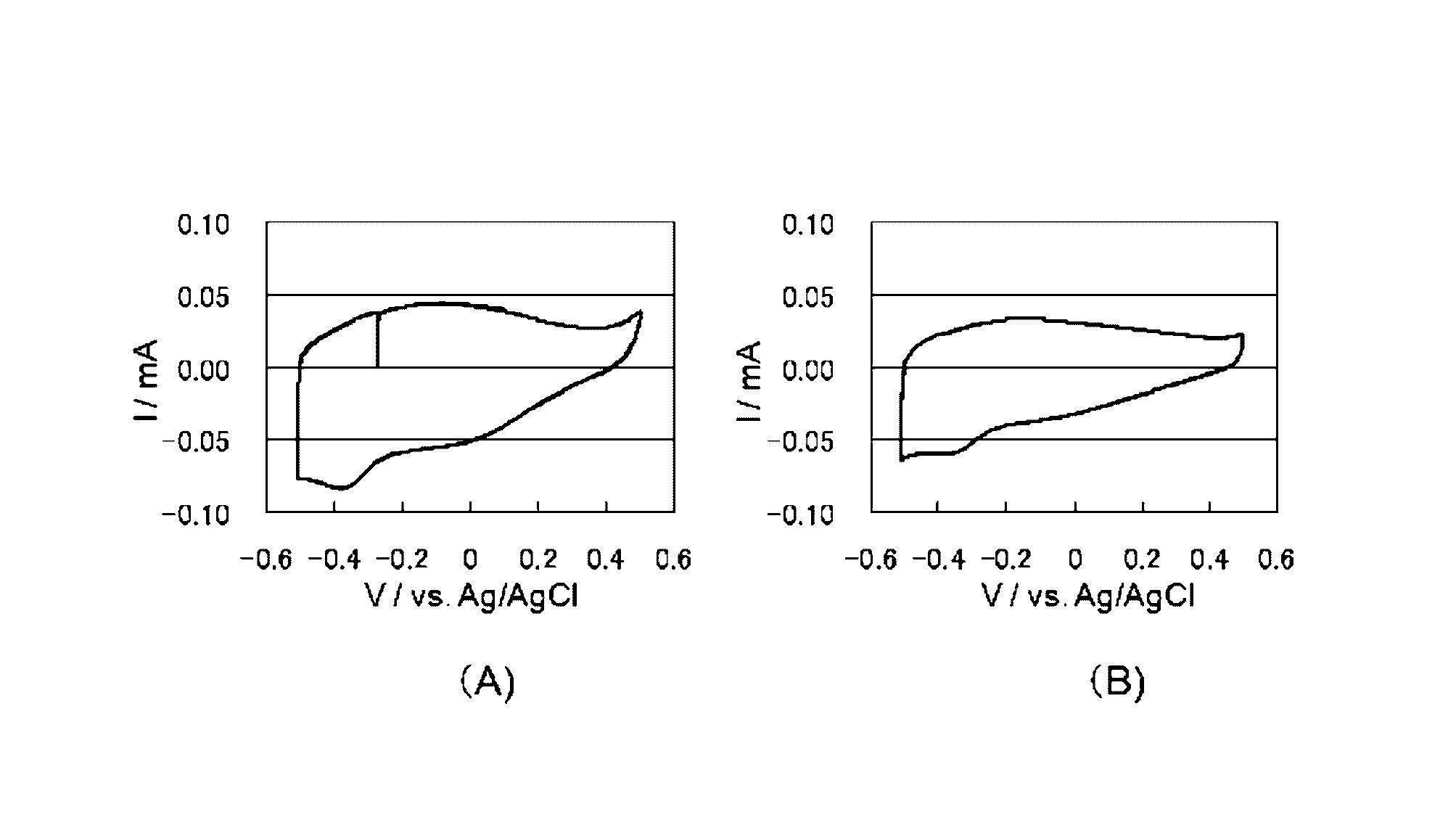

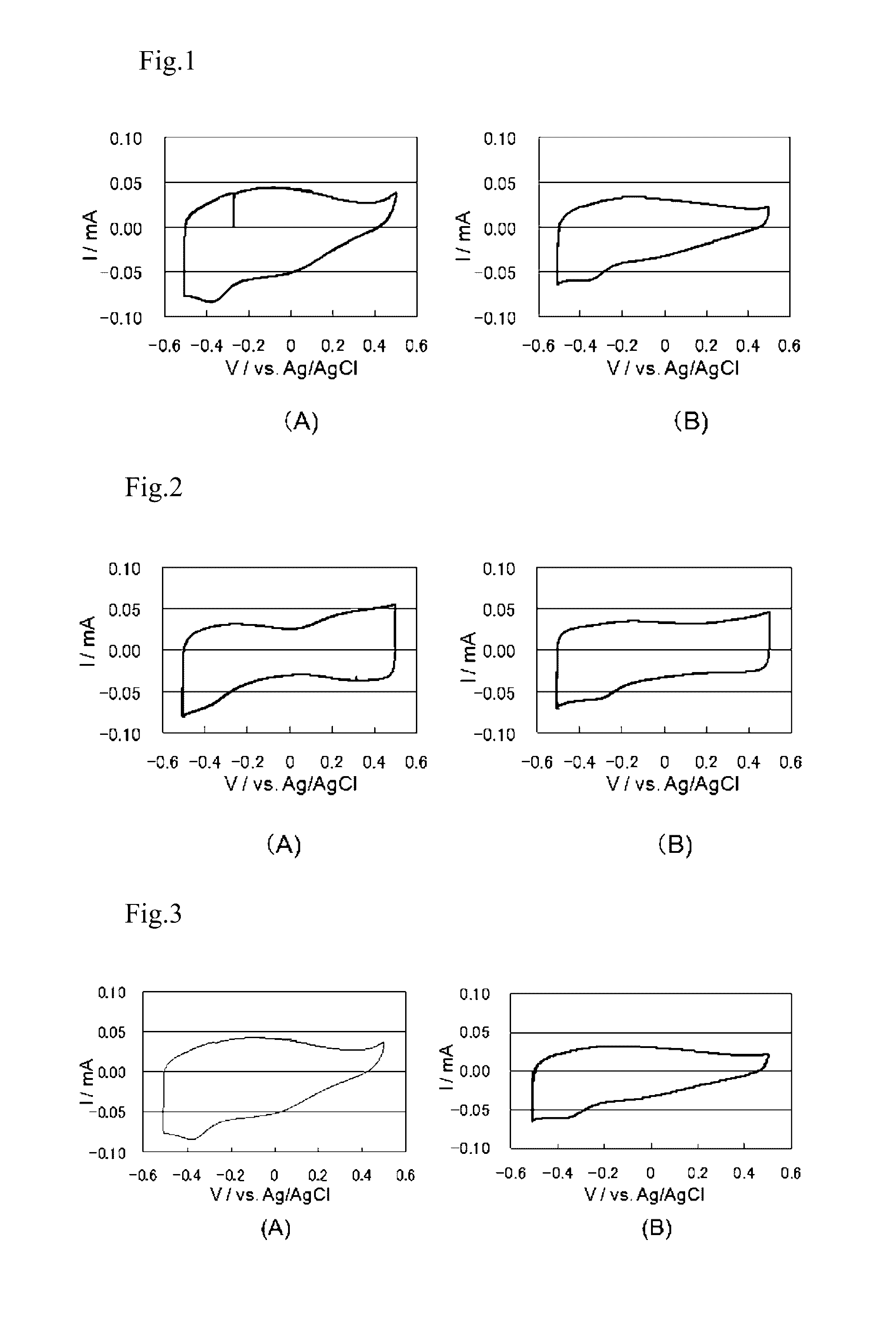

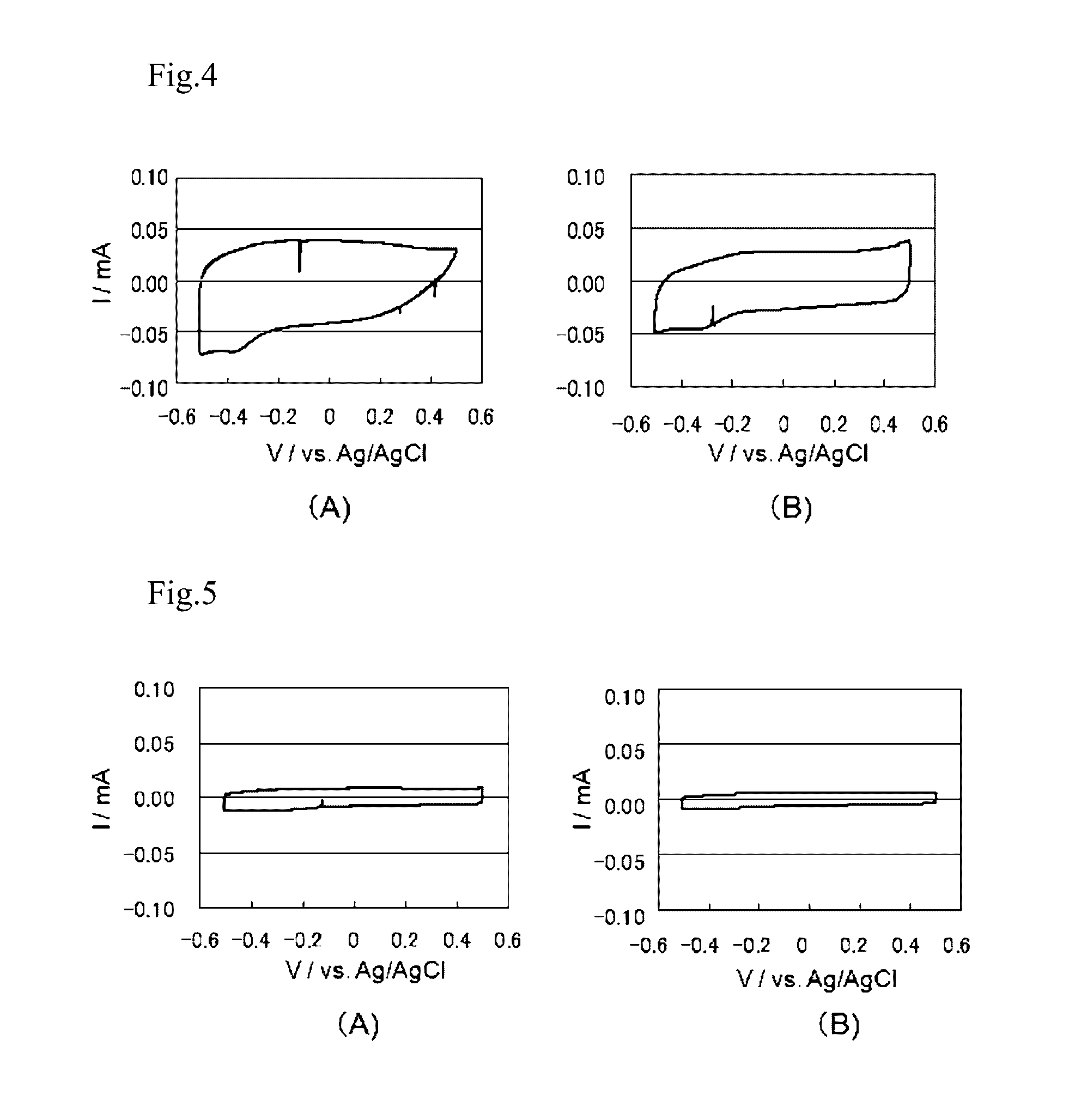

Polymerization solution, conductive polymer film obtained from the polymerization solution, polymer electrode, and solid electrolytic capacitor

ActiveUS9562293B2Big burden to solveImprove electrochemical activityConductive layers on insulating-supportsElectrolysis componentsSupporting electrolyteElectrolysis

Disclosed is a polymerization solution for electrolytic polymerization having a small environmental load, having excellent economic efficiency and capable of producing a conductive polymer exhibiting excellent heat resistance. The polymerization solution has: a solvent consisting of 100 to 80% by mass of water and 0 to 20% by mass of an organic solvent; at least one monomer selected from the group consisting of 3,4-disubstituted thiophenes; and at least one organic non-sulfonate supporting electrolyte having an anion with the molecular weight of 200 or more. A conductive polymer film densely filled with polymer particles is obtained by performing electrolytic polymerization using the polymerization solution. A polymer electrode provided with the conductive polymer film exerts excellent heat resistance and the electrochemical activity of the polymer electrode will hardly deteriorate even when being subjected to high temperatures. Moreover, a solid electrolyte capacitor containing the conductive polymer layer obtained by performing electrolytic polymerization using the polymerization solution exhibits low dielectric loss and equivalent series resistance and exerts excellent heat resistance.

Owner:NIPPON CHIMI CON CORP

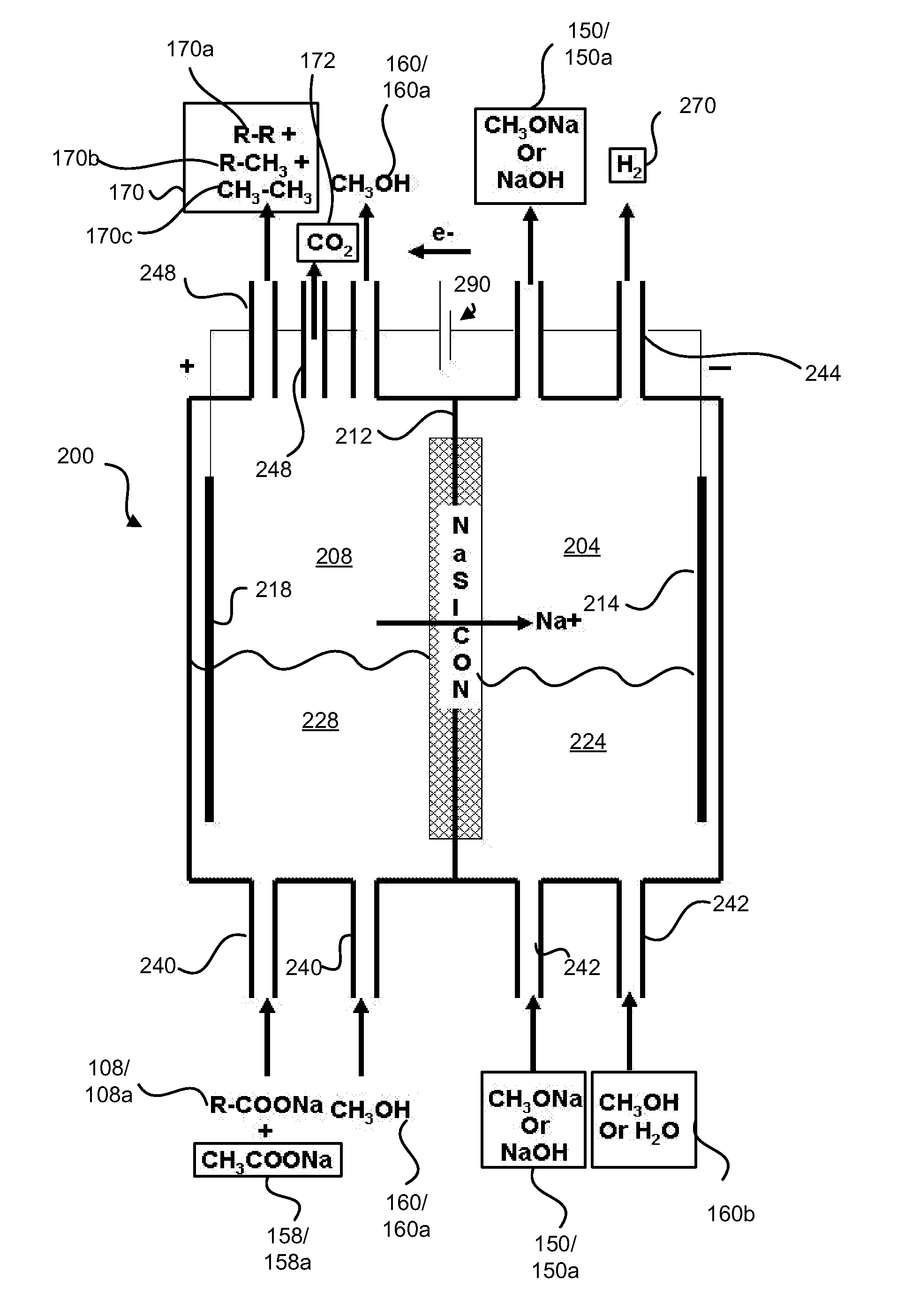

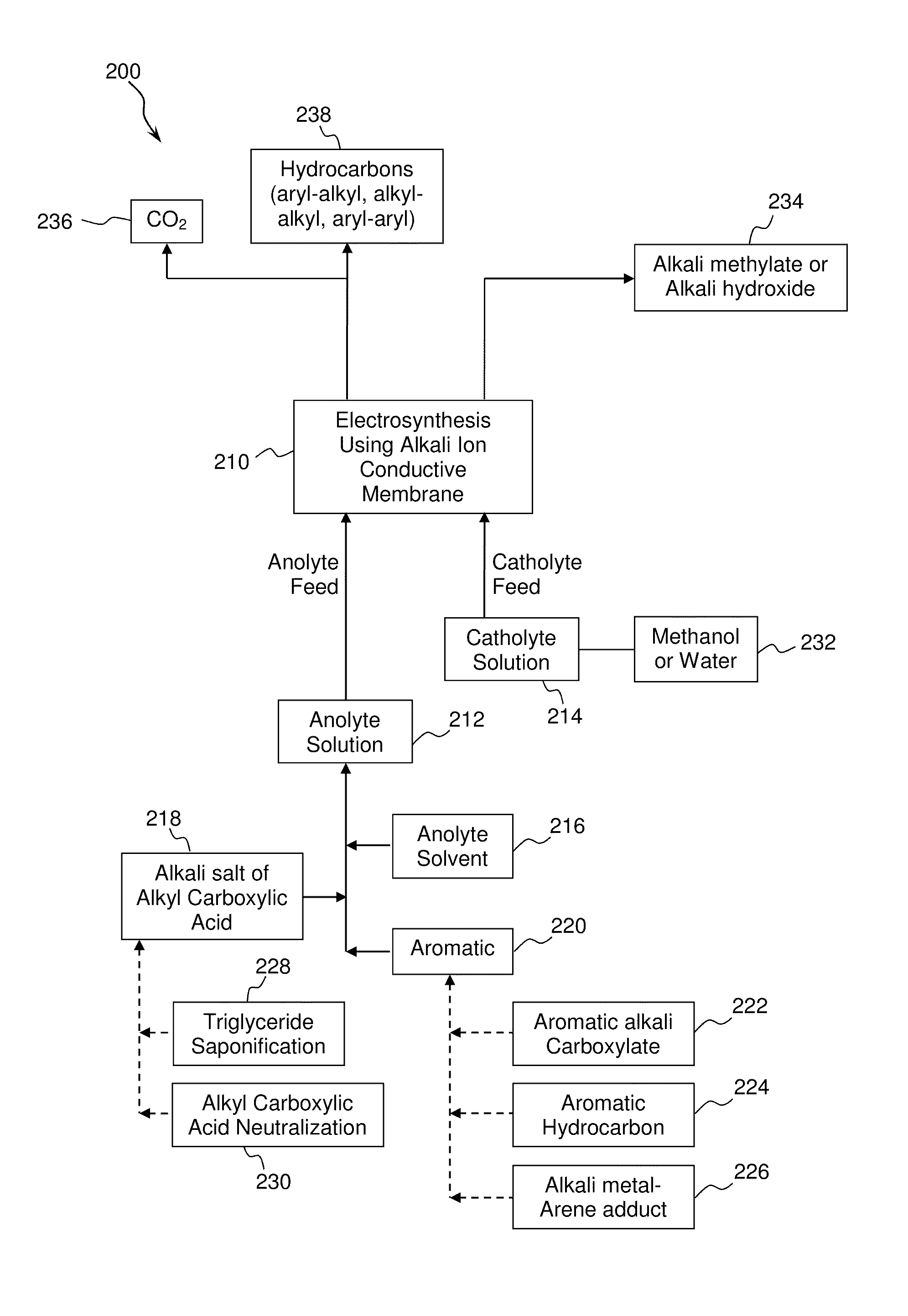

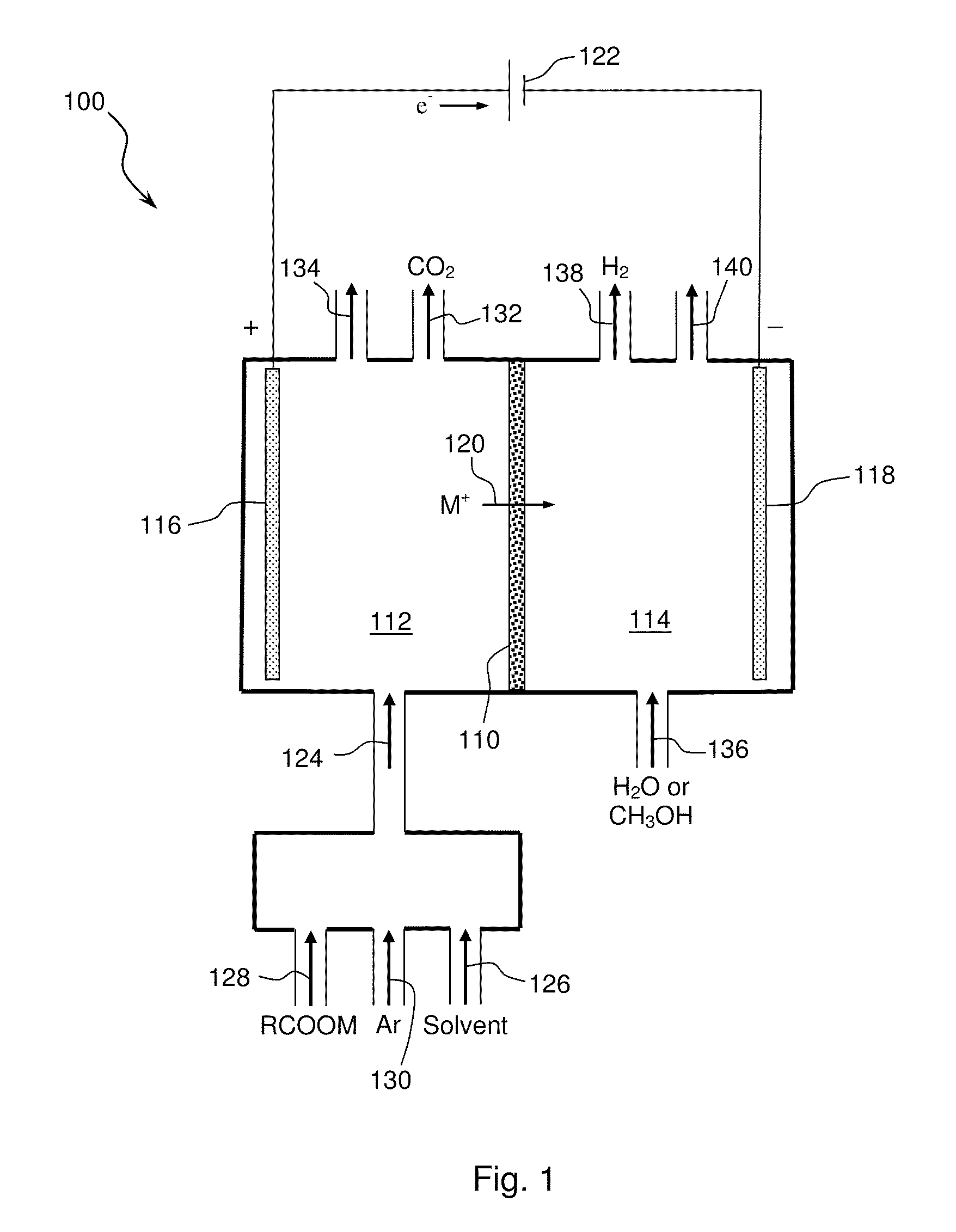

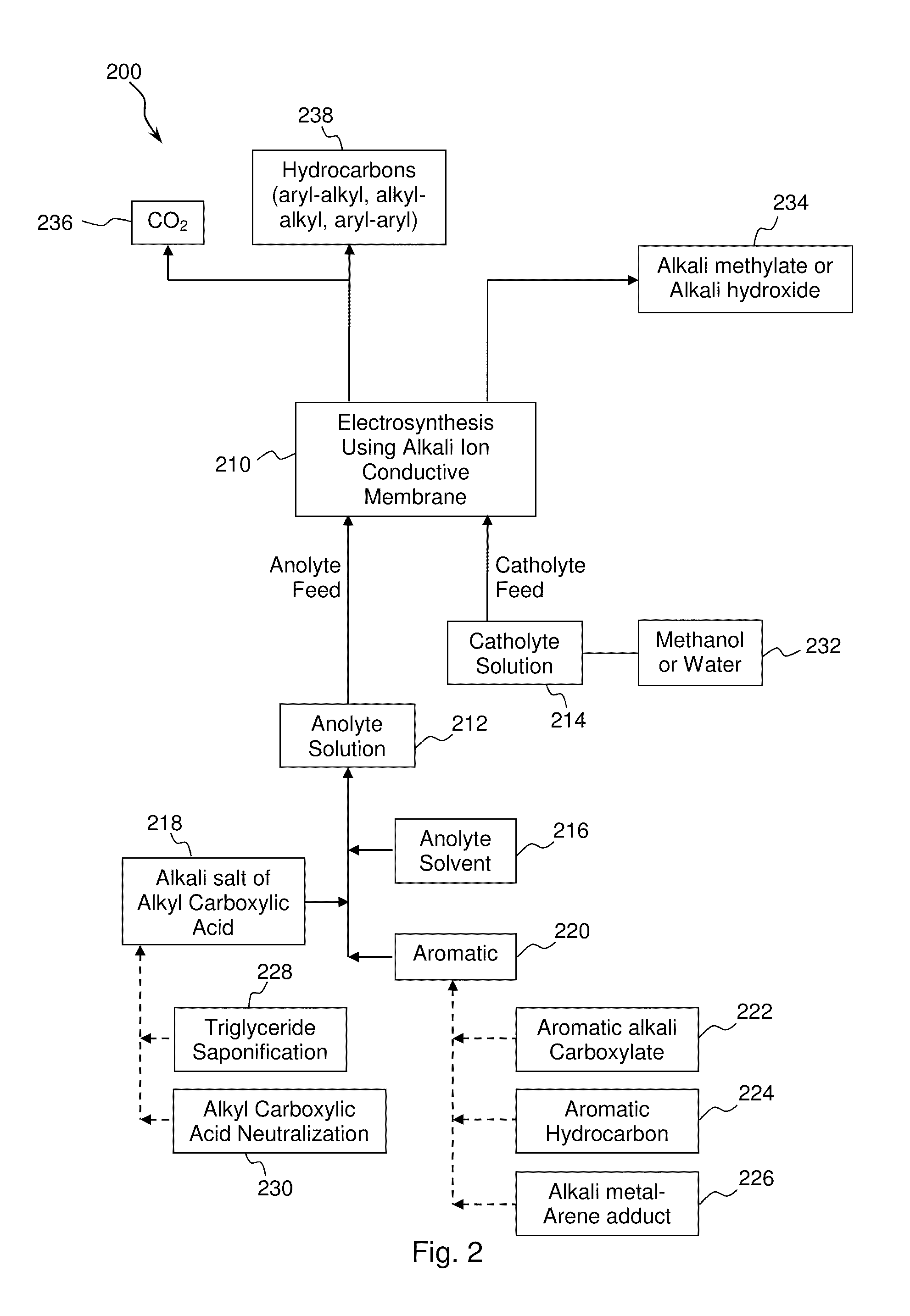

Electrochemical synthesis of aryl-alkyl surfacant precursor

An aryl-alkyl (R—Ar) hydrocarbon is prepared by an electrosynthesis process in an electrolytic cell having an alkali ion conductive membrane positioned between an anolyte compartment configured with an anode and a catholyte compartment configured with a cathode. An anolyte solution containing an alkali metal salt of an alkyl carboxylic acid and an aryl compound is introduced into the anolyte compartment. The aryl compound may include an alkali metal salt of an aryl carboxylic acid, an arene (aromatic) hydrocarbon, or an aryl alkali metal adduct (Ar−M+). The anolyte solution undergoes electrolytic decarboxylation to form an alkyl radical. The alkyl radical reacts with the aryl compound to produce the aryl-alkyl hydrocarbon.

Owner:ENLIGHTEN INNOVATIONS INC

Molten carboxylate electrolytes for electrochemical decarboxylation processes

Molten salt electrolytes are described for use in electrochemical synthesis of hydrocarbons from carboxylic acids. The molten salt electrolyte can be used to synthesize a wide variety of hydrocarbons with and without functional groups that have a broad range of applications. The molten salt can be used to synthesize saturated hydrocarbons, diols, alkylated aromatic compounds, as well as other types of hydrocarbons. The molten salt electrolyte increases the selectivity, yield, the energy efficiency and Coulombic efficiency of the electrochemical conversion of carboxylic acids to hydrocarbons while reducing the cell potential required to perform the oxidation.

Owner:ENLIGHTEN INNOVATIONS INC

Emollients and cosmetic compositions based on special branched hydrocarbons

Cosmetic and / or pharmaceutical composition (I) comprises 10C hydrocarbon, which is obtained by kolbe electrolysis of at least one branched 6-26C fatty acids or a mixture of at least one linear 3-26C fatty acids and / or branched 4-26C fatty acids. An independent claim is also included for the preparation of (I). - ACTIVITY : Dermatological. - MECHANISM OF ACTION : None given.

Owner:COGNIS IP MANAGEMENT GMBH

Process for preparing alcohols by electrochemical reductive coupling

InactiveUS10370767B2Electrolysis componentsElectrolytic organic coupling reactionsAlcoholPhenyl group

Alcohols are prepared by electrochemical reductive coupling of an aromatic vinyl compound and a carbonyl compound in a process which comprises electrolyzing an electrolyte solution in an electrochemical cell, the electrolyte solution comprising the aromatic vinyl compound, the carbonyl compound and a non-aqueous protic solvent, such as methanol, wherein the electrolyte solution is in contact with a carbon-based cathode. Styrene is reacted with acetone to prepare 2-methyl-4-phenyl-2-butanol.

Owner:BASF AG

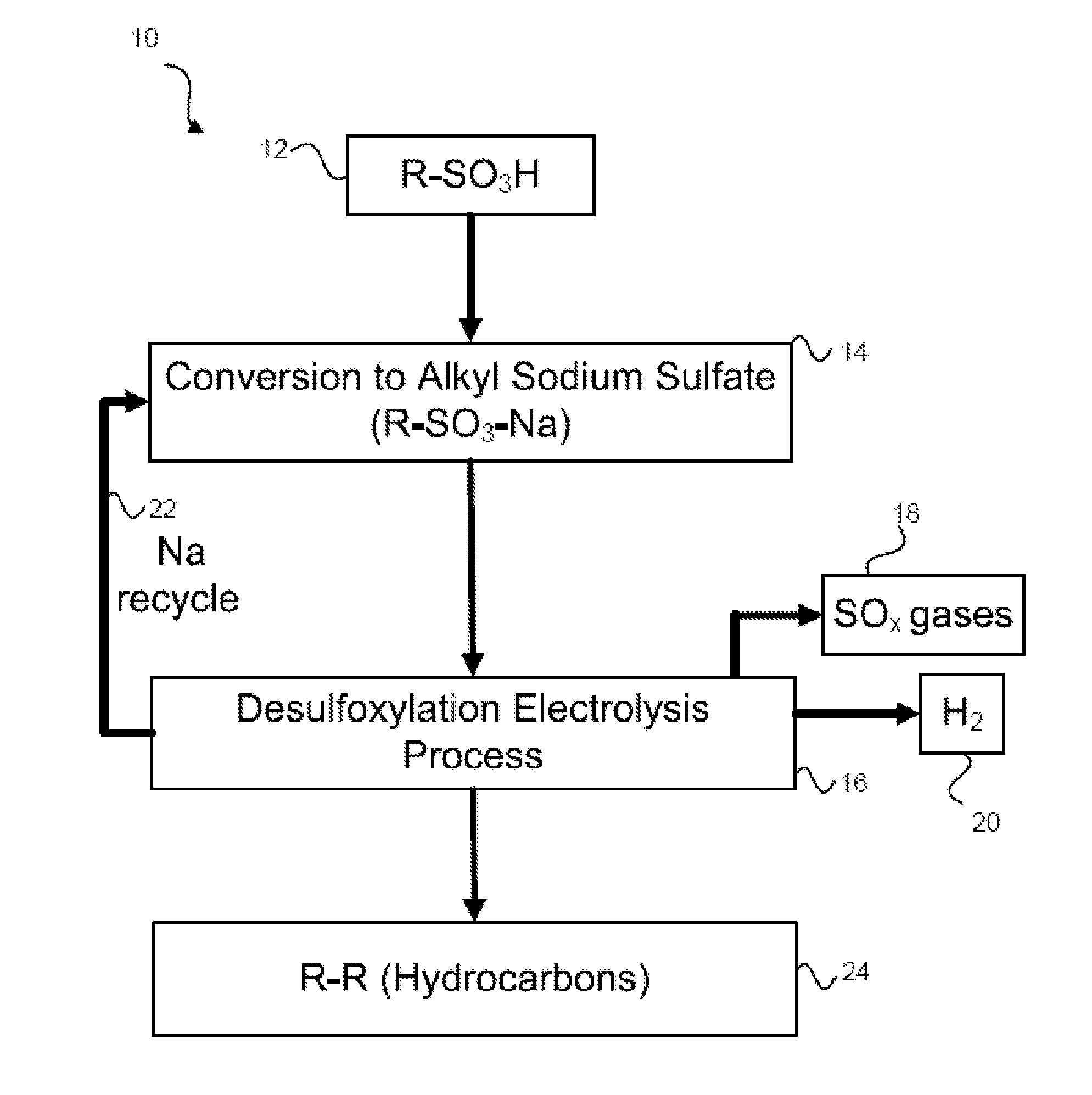

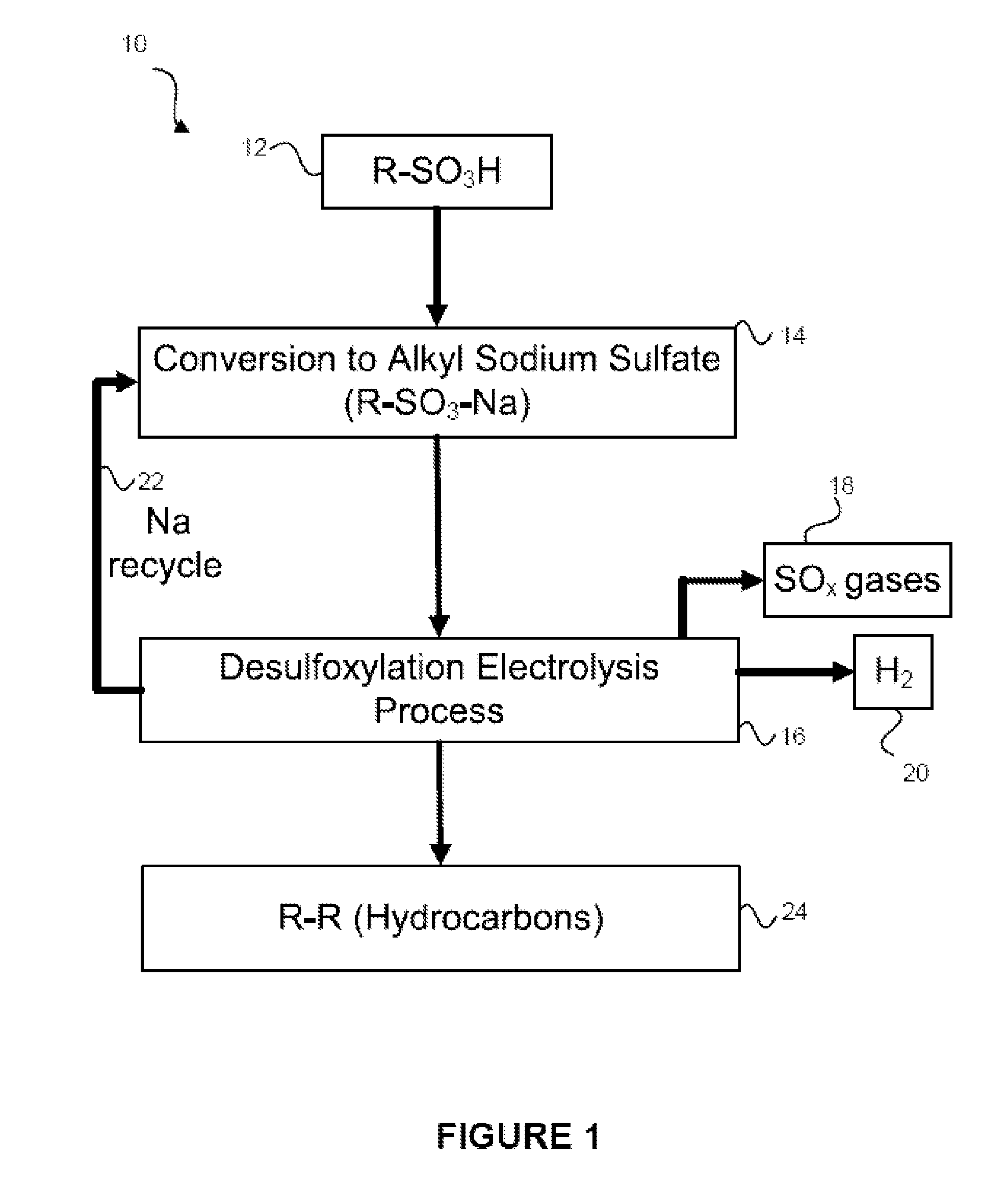

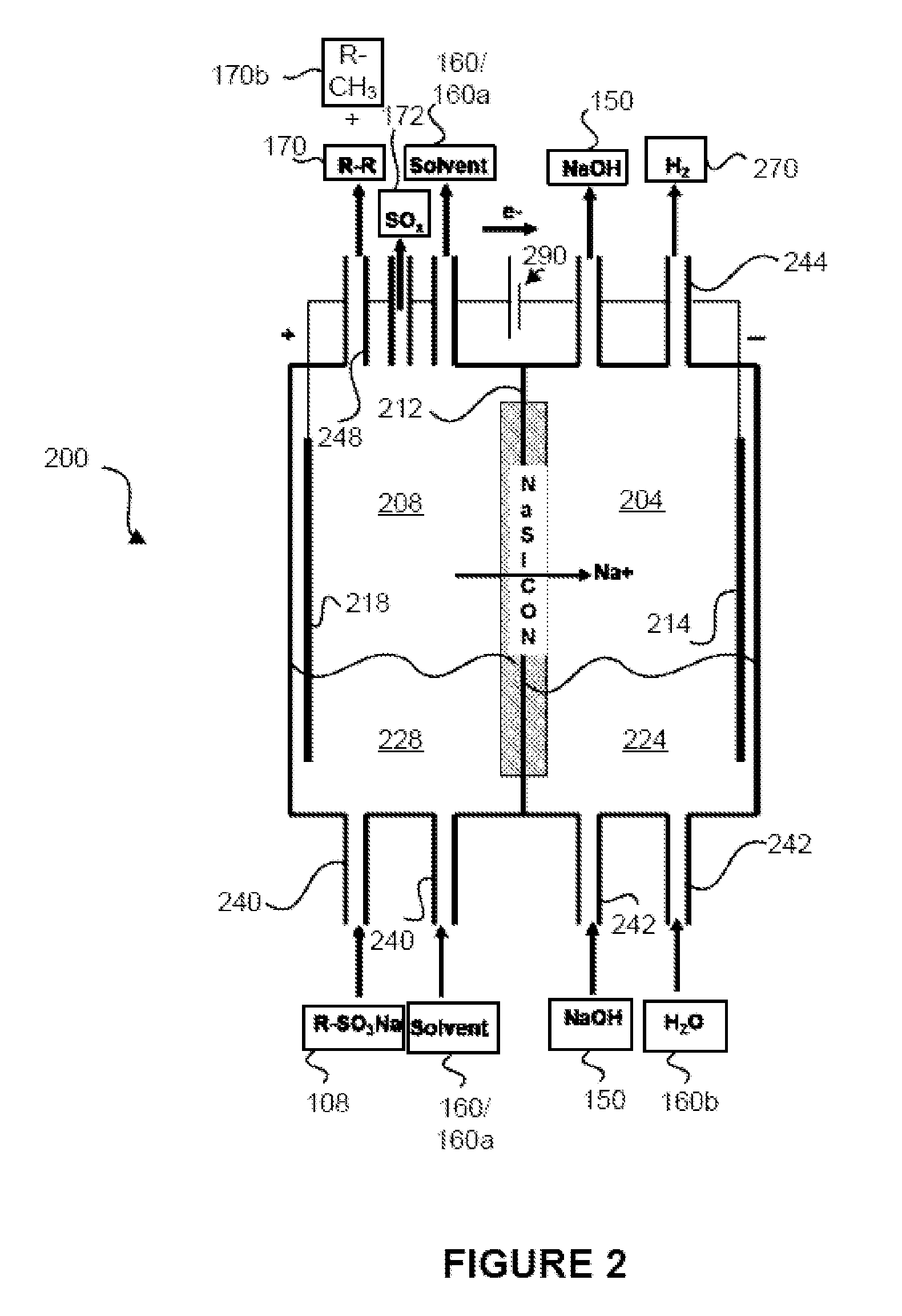

Method of producing coupled radical products via desulfoxylation

ActiveUS9206515B2Low costImprove conductivityCellsElectrolytic organic coupling reactionsAlkali ionsSodium salt

A method that produces coupled radical products. The method involves obtaining a sodium salt of a sulfonic acid (R—SO3—Na). The alkali metal salt is then used in an anolyte as part of an electrolytic cell. The electrolytic cell may include an alkali ion conducting membrane (such as a NaSICON membrane). When the cell is operated, the alkali metal salt of the sulfonic acid desulfoxylates and forms radicals. Such radicals are then bonded to other radicals, thereby producing a coupled radical product such as a hydrocarbon. The produced hydrocarbon may be, for example, saturated, unsaturated, branched, or unbranched, depending upon the starting material.

Owner:ENLIGHTEN INNOVATIONS INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com