Nanometer SiO2 and PVA (polyvinyl alcohol) fiber reinforced geopolymer mortar

A fiber-reinforced, geopolymer technology, applied in the field of nano-SiO2 and PVA fiber-reinforced geopolymer mortar, to achieve low permeability, strengthen impermeability, and improve the effect of early compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Nanometer SiO 2 and PVA fiber reinforced polymer mortar preparation raw materials

[0021] Prepare nano-SiO in this embodiment 2 The materials used for geopolymer mortar reinforced with PVA fiber mainly include water, metakaolin, fly ash, water glass, sodium hydroxide, quartz sand, PVA fiber, nano-SiO 2 , water reducing agent, etc., the performance indicators of the raw materials used meet the test requirements, as follows:

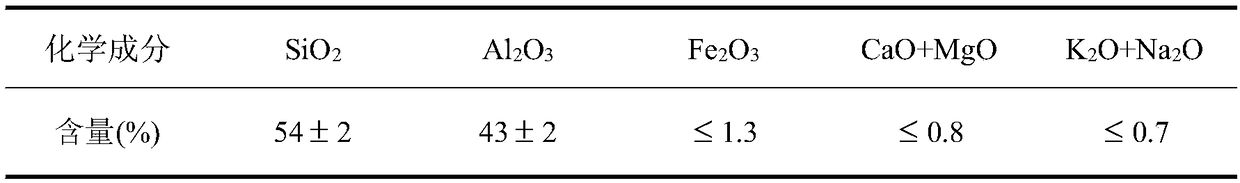

[0022] Metakaolin: The test uses metakaolin produced by Shijiazhuang Chenxing Industrial Co., Ltd., and its chemical composition and physical properties are shown in Table 1 and Table 2.

[0023] Table 1 Main chemical components of metakaolin

[0024]

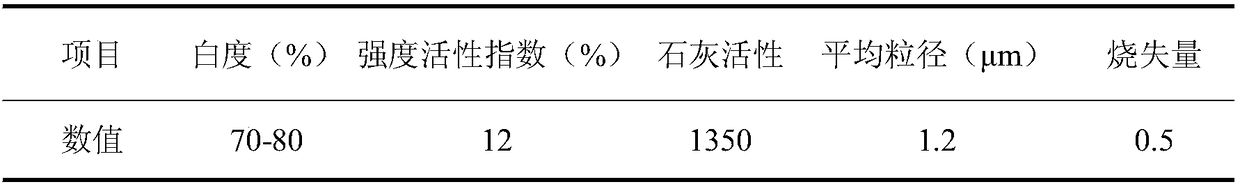

[0025] Table 2 Main physical properties of metakaolin

[0026]

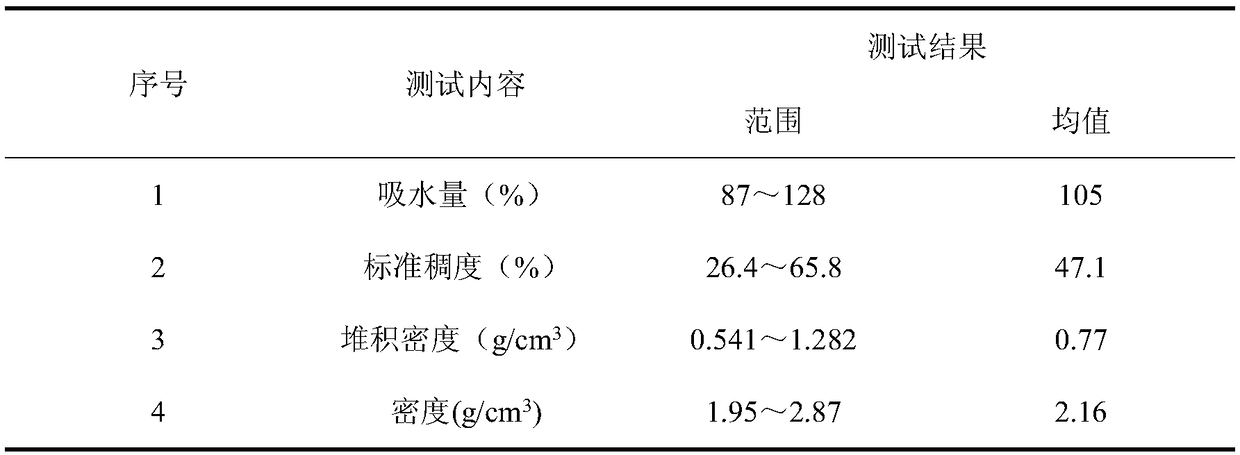

[0027] Fly ash: Class I fly ash produced by Datang Luoyang Thermal Power Co., Ltd. was used in the test of the present invention. The main physical properties are shown in Table 3.

[0028] Table 3 main physical pr...

Embodiment 2

[0048] Example 2 Nano SiO 2 Mixing ratio design with PVA fiber reinforced geopolymer mortar

[0049] The embodiment of the present invention investigates PVA fiber dosage, nano-SiO 2 The effect of doping factor on nano-SiO 2 and PVA fiber-reinforced geopolymer mortar mechanical properties, so the control variable method is used in the mix ratio design, that is, the fixed water-cement ratio, cement-sand ratio, water glass modulus and gel ratio (alkali activator and gel Material ratio) and only change the PVA fiber content or nano-SiO 2 dosage.

[0050] The optimum proportioning and consumption of NaOH and water glass required for polymer synthesis of the embodiment of the present invention compound ratio design, the water-to-cement ratio (the ratio of the water contained in the added water and the alkali activator to the gelled material mass) is determined to be 0.65, The mortar ratio is 1:1. Fly ash replaces 30% quality metakaolin in an equal amount, and the alkali activa...

Embodiment 3

[0059] Example 3 Nano SiO 2 and PVA fiber reinforced geopolymer mortar preparation process

[0060] In the preparation of nano-SiO 2 and PVA fiber-reinforced polymer mortar, to ensure that nano-SiO 2 , PVA fibers can be evenly distributed and freely dispersed in the matrix, in order to obtain a repair mortar material with good mechanical properties, in order to meet the test requirements, it is necessary to choose a suitable preparation method and process, nano-SiO 2 And PVA fiber reinforced geopolymer mortar composite molding process concrete steps are as follows:

[0061] (1) Material pretreatment: Weigh raw material water, metakaolin, fly ash, quartz sand, alkali activator, PVA fiber, nano-SiO 2 , water reducing agent;

[0062] (2) Nano SiO 2 and PVA fiber-reinforced polymer mortar: the metakaolin, fly ash and quartz sand in step (1) were stirred in a mixer for 2 minutes, and under the condition of constant stirring, an alkali activator was added, and the stirring was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com