Method for synthesizing fiber-grade polyphenylene sulfide through adding composite accelerant in intermediate stage

A composite accelerator and polyphenylene sulfide technology, applied in the field of polymer materials, can solve the problems of affecting product quality, prolonging production steps, low molecular weight, etc., and achieve the effects of simplifying the production process, improving production efficiency, and high reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

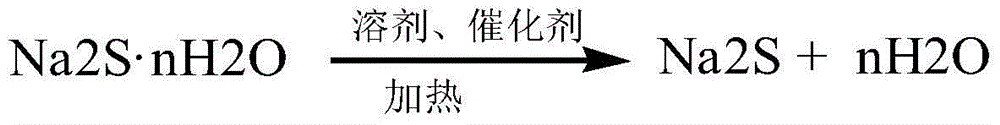

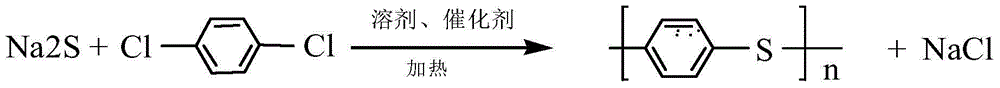

Method used

Image

Examples

Embodiment 1

[0027] Low temperature section: In a 10-liter reactor, add Na 2 S·3H 2 O1000g, catalyst 380g and N-methylpyrrolidone 4200g for dehydration reaction; after dehydration, add p-dichlorobenzene 1200g, fill with nitrogen, airtight, prepolymerize at 220°C for 3h at low temperature.

[0028] Middle temperature section: raise the temperature to 231°C, add 200g of composite accelerator using the differential pressure method, control the pressure in the reactor within the range of 0.40-0.9mpa, and react for 1.5h.

[0029] High-temperature section: Finally, the temperature is raised to 265°C for 3 hours, and the pressure in the reactor remains unchanged in the range of 0.40-0.9mpa.

[0030] The catalyst mentioned above is lithium chloride.

[0031] The above composite accelerator is formed by mixing p-dichlorobenzene, trichlorobenzene and N-methylpyrrolidone in a weight ratio of 0.8:0.5:100.

[0032] The finally obtained polyphenylene sulfide particles are uniform, with a particle siz...

Embodiment 2

[0034] Low temperature section: In a 10-liter reactor, add Na 2 S·3H 2 O1000g, catalyst 400g and N-methylpyrrolidone 3200g for dehydration reaction; after dehydration, add p-dichlorobenzene 1250g, fill with nitrogen, airtight, pre-polymerize at 200°C for 2h at low temperature.

[0035] Middle temperature section: raise the temperature to 240°C, add 250g of composite accelerator using the pressure difference method, control the pressure in the reactor within the range of 0.50-0.9mpa, and react for 1h.

[0036] High-temperature section: Finally, the temperature is raised to 255°C for 3 hours, and the pressure in the reactor remains unchanged within the range of 0.50-0.9mpa.

[0037] The catalyst mentioned above is lithium chloride.

[0038] The above-mentioned composite accelerator is formed by mixing lithium chloride, p-dichlorobenzene, m-dichlorobenzene and N-methylpyrrolidone in a weight ratio of 15:12:5:300.

[0039] The finally obtained polyphenylene sulfide particles ar...

Embodiment 3

[0041] Low temperature section: In a 10-liter reactor, add Na 2 S·3H 2 O1000g, catalyst 400g and N-methylpyrrolidone 3200g for dehydration reaction; after dehydration, add p-dichlorobenzene 1250g, fill with nitrogen, airtight, pre-polymerize at 200°C for 2h at low temperature.

[0042] Middle temperature section: raise the temperature to 240°C, add 250g of composite accelerator using the pressure difference method, control the pressure in the reactor within the range of 0.50-0.9mpa, and react for 1h.

[0043] High-temperature section: Finally, the temperature is raised to 255°C for 3 hours, and the pressure in the reactor remains unchanged within the range of 0.50-0.9mpa.

[0044] The catalyst mentioned above is lithium chloride.

[0045] The above-mentioned composite accelerator is formed by mixing lithium chloride, p-dichlorobenzene, m-dichlorobenzene and trichlorobenzene, and N-methylpyrrolidone in a weight ratio of 7:6:3:200.

[0046] The finally obtained polyphenylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com