Flame-retardant bio-based polyurethane hose and production method thereof

A production method and bio-based technology, applied in the direction of hose, pipe, pipeline protection, etc., can solve the problems of casualties and other problems, and achieve the effect of excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

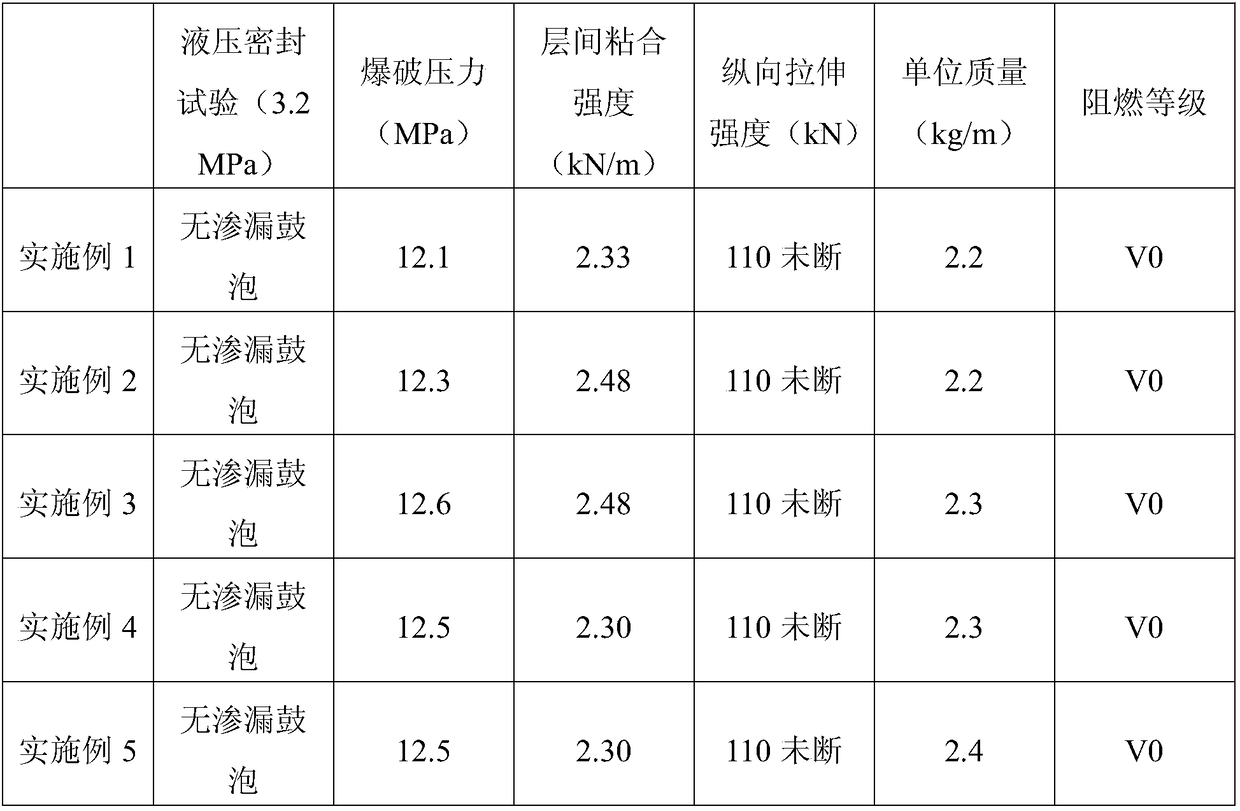

Embodiment 1

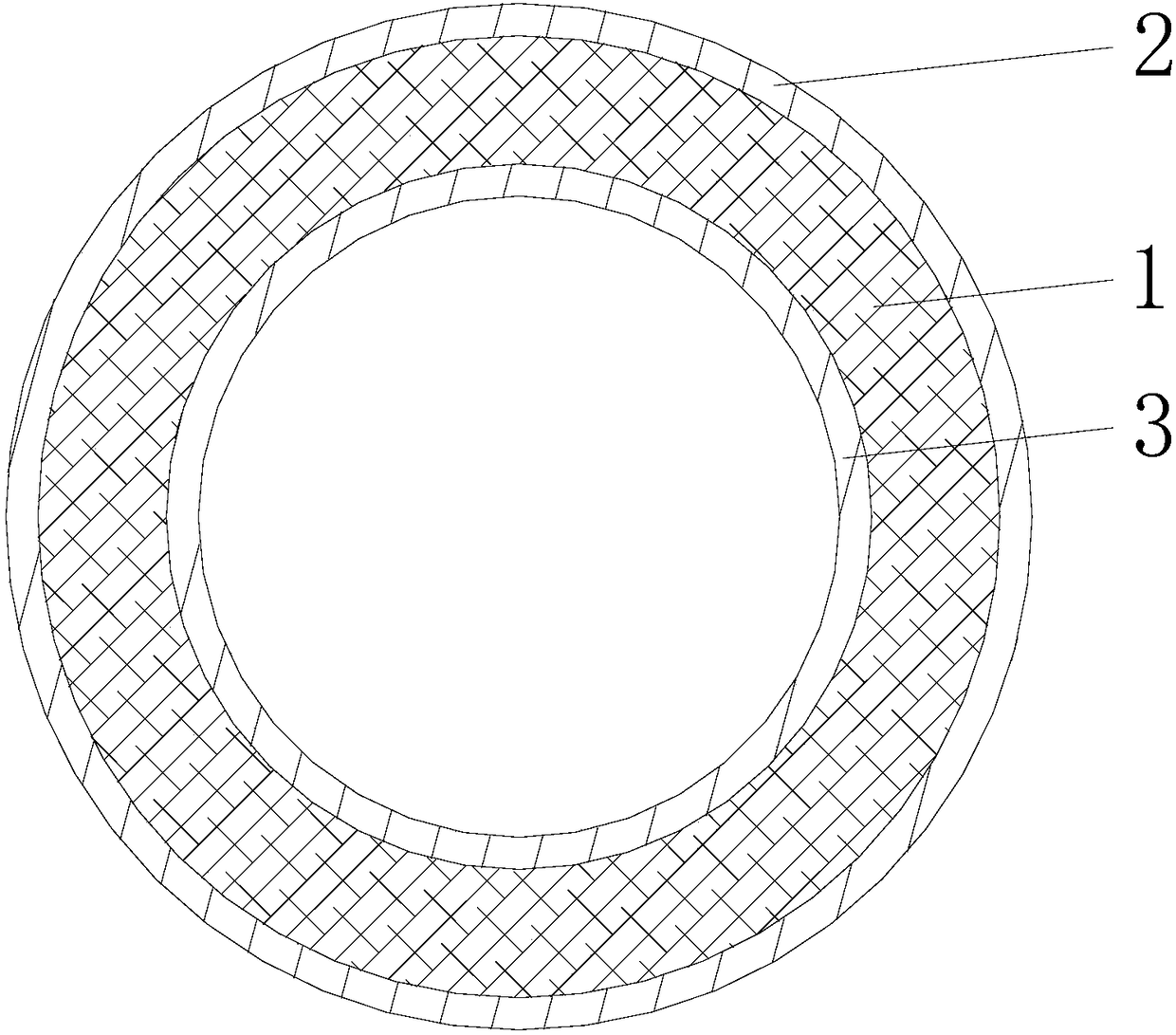

[0034] A flame-retardant bio-based polyurethane hose, as attached figure 1 As shown, it includes the inner rubber layer 3, the outer rubber layer 2, and the tape reinforcement layer 1. The tape reinforcement layer 1 is woven from polyimide fibers, and the inner rubber layer 3 and the outer rubber layer 2 are bio-based polyurethane thermoplastic elastomer.

[0035] The production method of the above-mentioned flame-retardant bio-based polyurethane hose comprises the following steps:

[0036] (1) Soybean oil was blown into nitrogen and kept under mechanical stirring, heated to 180° C., and subjected to Diels Alder cyclization reaction for 6 hours to obtain thermally thickened oil.

[0037] (2) Add the mixed solvent obtained by mixing methanol and dichloromethane at a mass ratio of 45:55 into the heated thickened oil, and the flow rate of the feed is 1m 3 / min of ozone for oxidation reaction, the reaction temperature is -40 °C, use a cold trap to collect the reaction gas, when ...

Embodiment 2

[0044] The same structure as the flame-retardant bio-based polyurethane hose of embodiment 1, the difference lies in the production method, including the following steps:

[0045] (1) Soybean oil was blown into nitrogen and kept under mechanical stirring, heated to 210° C., and subjected to Diels Alder cyclization reaction for 5 hours to obtain thermally thickened oil.

[0046] (2) Add the mixed solvent obtained by mixing methanol and dichloromethane at a mass ratio of 45:55 into the heated thickened oil, and the flow rate of the feed is 1m 3 / min ozone for oxidation reaction, the reaction temperature is -30°C, the reaction gas is collected by cold trap, and the reaction is terminated when the liquid in the cold trap turns blue, and the reaction product A is obtained.

[0047] (3) The reaction product A is passed through nitrogen to remove the peroxide first, and then slowly added sodium borohydride to react for 15 minutes, and the reaction temperature is 0° C. to obtain the r...

Embodiment 3

[0053] The same structure as the flame-retardant bio-based polyurethane hose of embodiment 1, the difference lies in the production method, including the following steps:

[0054] (1) Soybean oil was blown into nitrogen and kept mechanically stirred, heated to 250° C., and subjected to Diels Alder cyclization reaction for 4 hours to obtain thermally thickened oil.

[0055] (2) Add the mixed solvent obtained by mixing methanol and dichloromethane at a mass ratio of 45:55 into the heated thickened oil, and the flow rate of the feed is 1m 3 / min of ozone for oxidation reaction, the reaction temperature is -35 ° C, use a cold trap to collect the reaction gas, when the liquid in the cold trap turns blue, the reaction is terminated, and the reaction product A is obtained.

[0056] (3) The reaction product A is passed through nitrogen to remove the peroxide first, and then slowly added sodium borohydride to react for 15 minutes, and the reaction temperature is 0° C. to obtain the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com