Patents

Literature

59results about "Preparation by caroxylic acid/anhydride-hydrocarbon reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

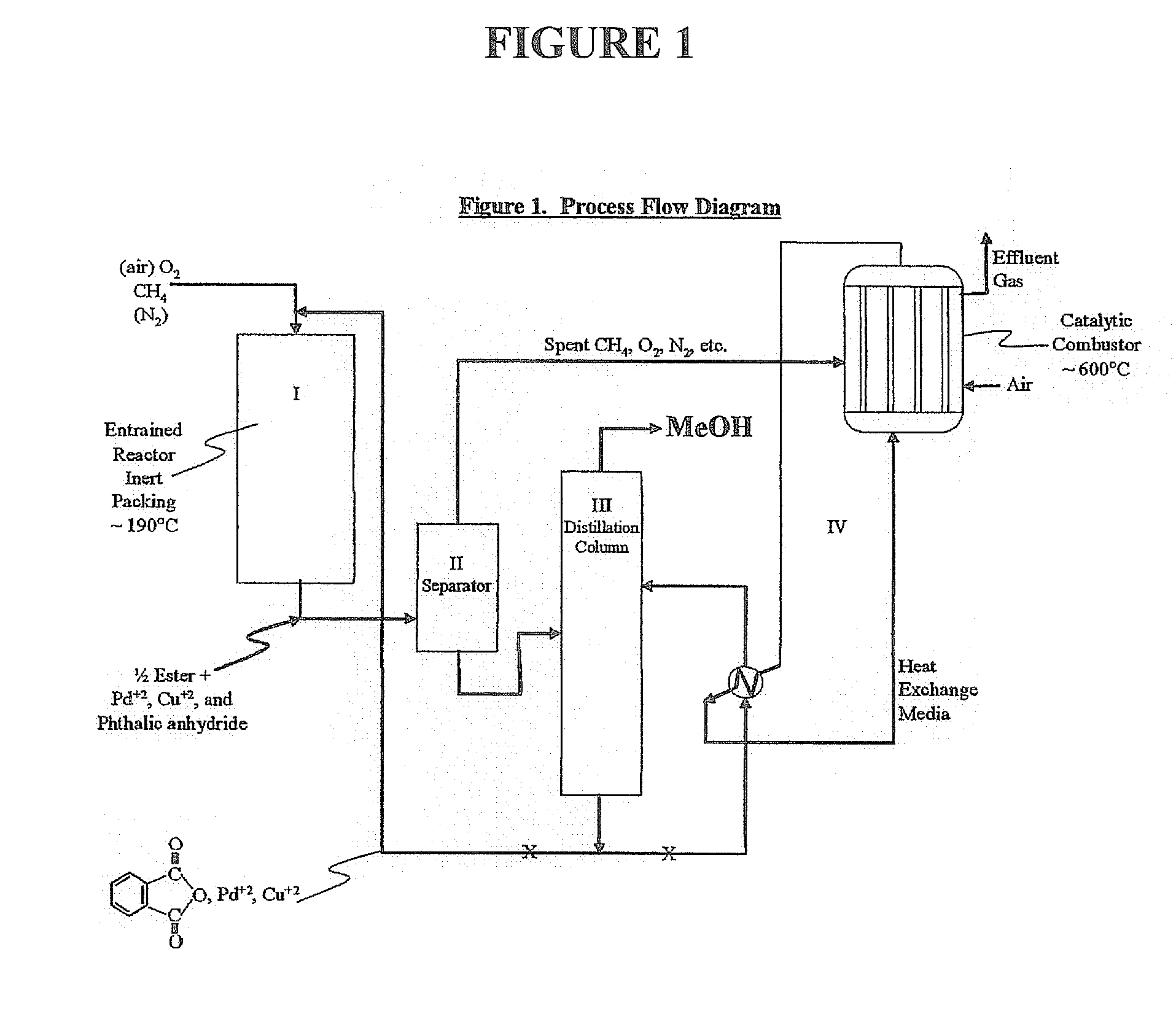

Method for deriving methanol from waste generated methane and structured product formulated therefrom

InactiveUS20060264683A1Less capitolInexpensively separatedPreparation by oxidation reactionsOrganic compound preparationPtru catalystReactive distillation

Methanol is produced from bacterially oxidized waste methane by reaction with Pd+2, Cu+2 air, and molten phthalic anhydride in an entrained oxidizer generating half ester of methyl phthalate which is reaction distilled to prodtice methanol and recycle phthalic anliydride containing the Pd+2,Cu+2 phthalate catalyst.

Owner:RINNOVI

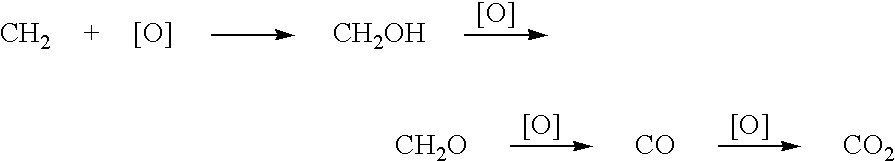

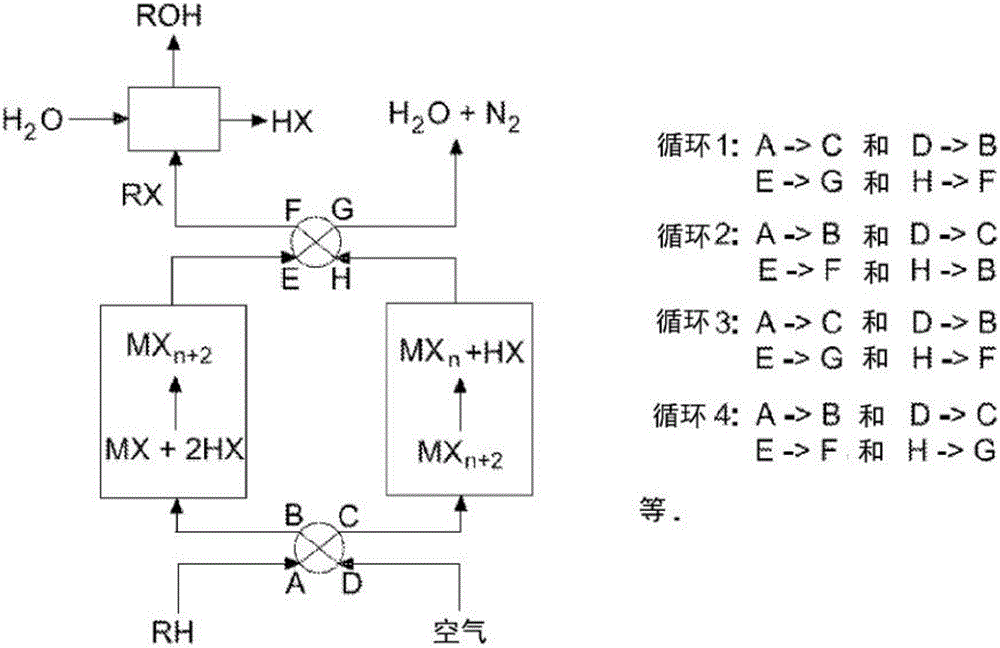

Process for the production of methanol from methane using a metal trifluoroacetate catalyst

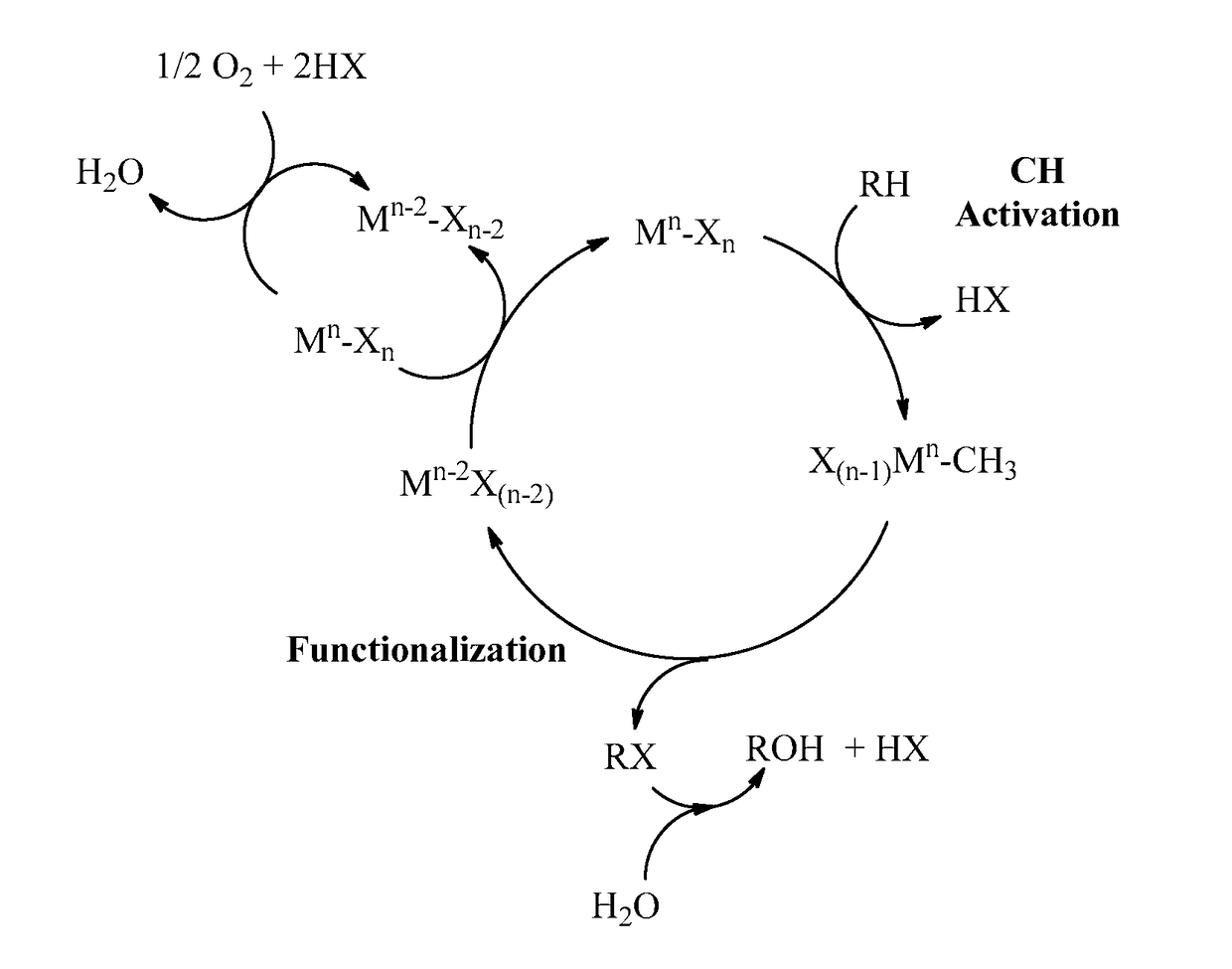

InactiveUS20070149832A1Oxygen-containing compound preparationOrganic compound preparationTrifluoroacetic acidOxidation state

A process for converting methane to methanol using a homogeneous catalyst has been developed. The catalyst is a metal compound having an empirical formula of MxXm where M is a metal such as Pd, Cu, Co, and Mn, X is an anion such as acetate, trifluoroacetate, sulfate, propionate, “m” is the oxidation state of M, and “x” is the anion valence of X. Generally the process involves contacting a gas stream containing methane with the homogeneous catalyst and an oxidant such as hydrogen peroxide at oxidation conditions to produce methyl trifluoroacetate. Finally, the methyl trifluoroacetate is hydrolyzed to give a methanol product stream.

Owner:UOP LLC

Process for the Production of Methanol from Methane using a Supported Transition Metal Catalyst

A process for the selective oxidation of methane to methanol using a supported transition metal catalyst has been developed. Examples of the transition metals which can be used are copper and palladium, while an example of a support is silica. Optionally, the catalyst can contain a modifier component such as cesium. Generally the process involves contacting a gas stream, comprising methane, a solvent such as trifluoroacetic acid and an oxidizing agent such as air or hydrogen peroxide with the catalyst, at oxidation conditions to produce a methyl ester, e.g. methyl trifluoroacetate. Finally, the methyl ester is hydrolyzed to yield a methanol product stream.

Owner:UOP LLC

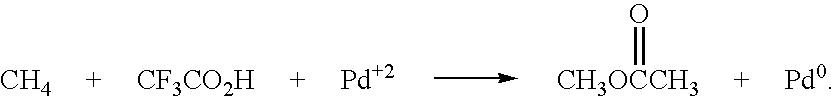

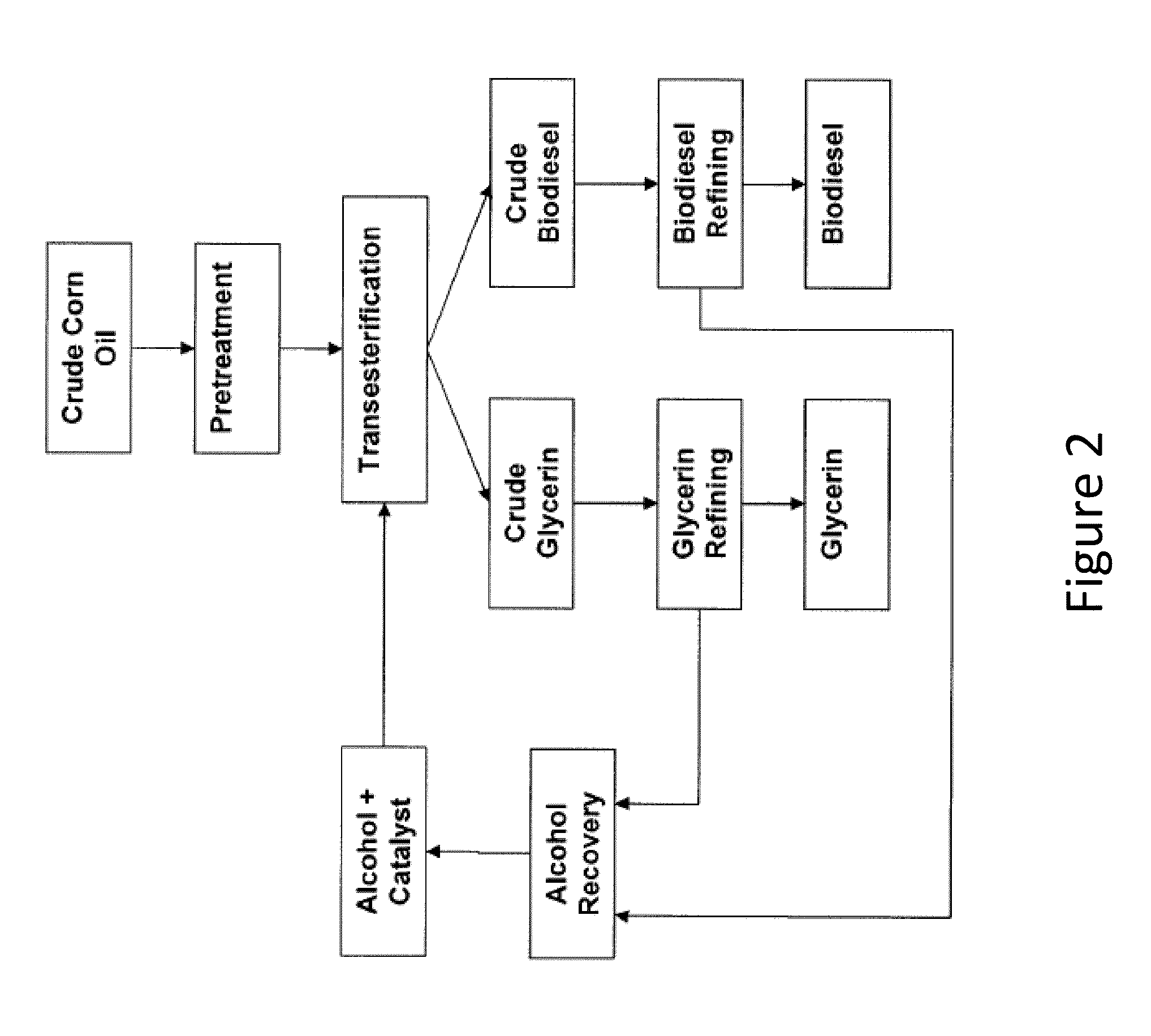

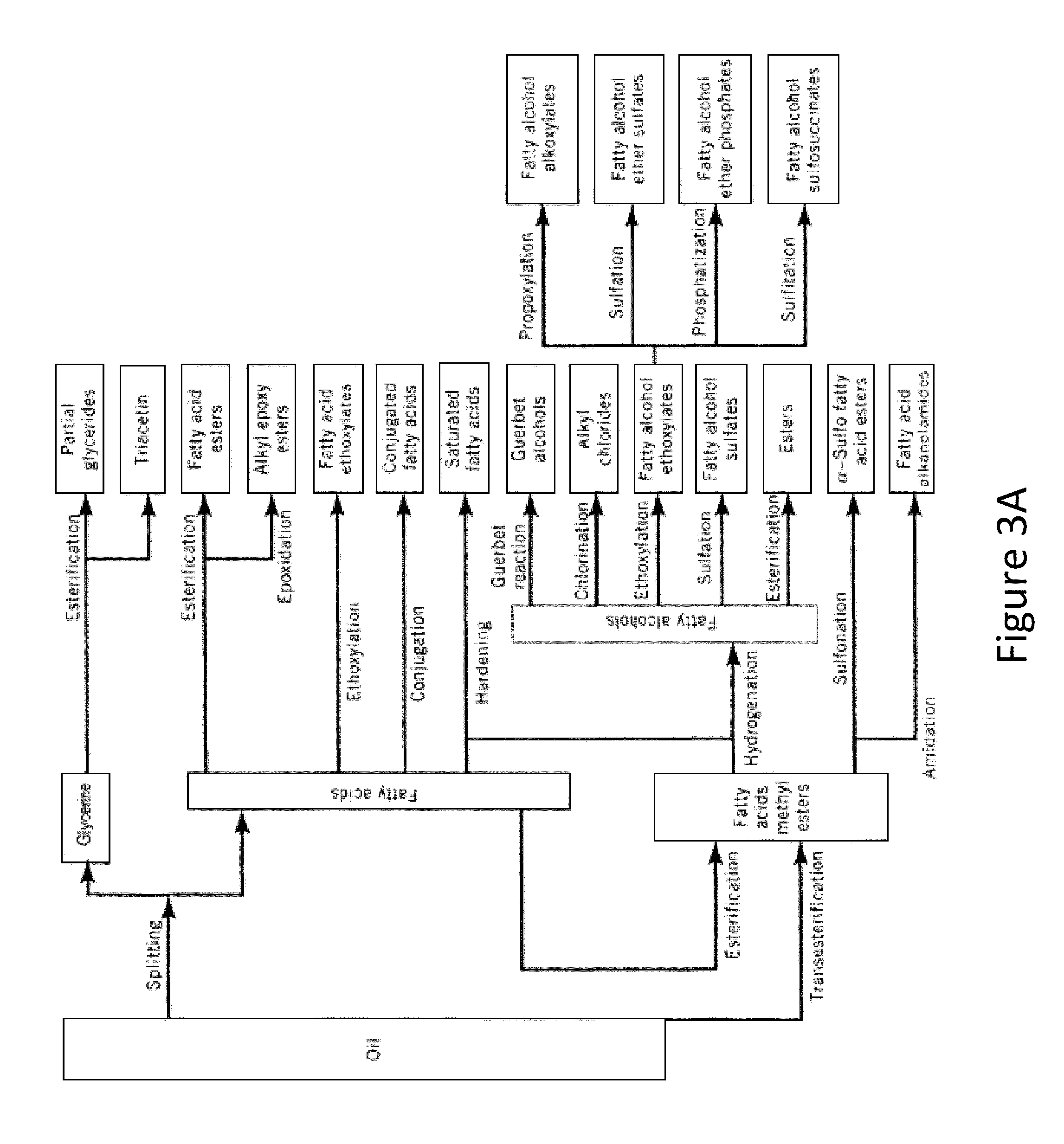

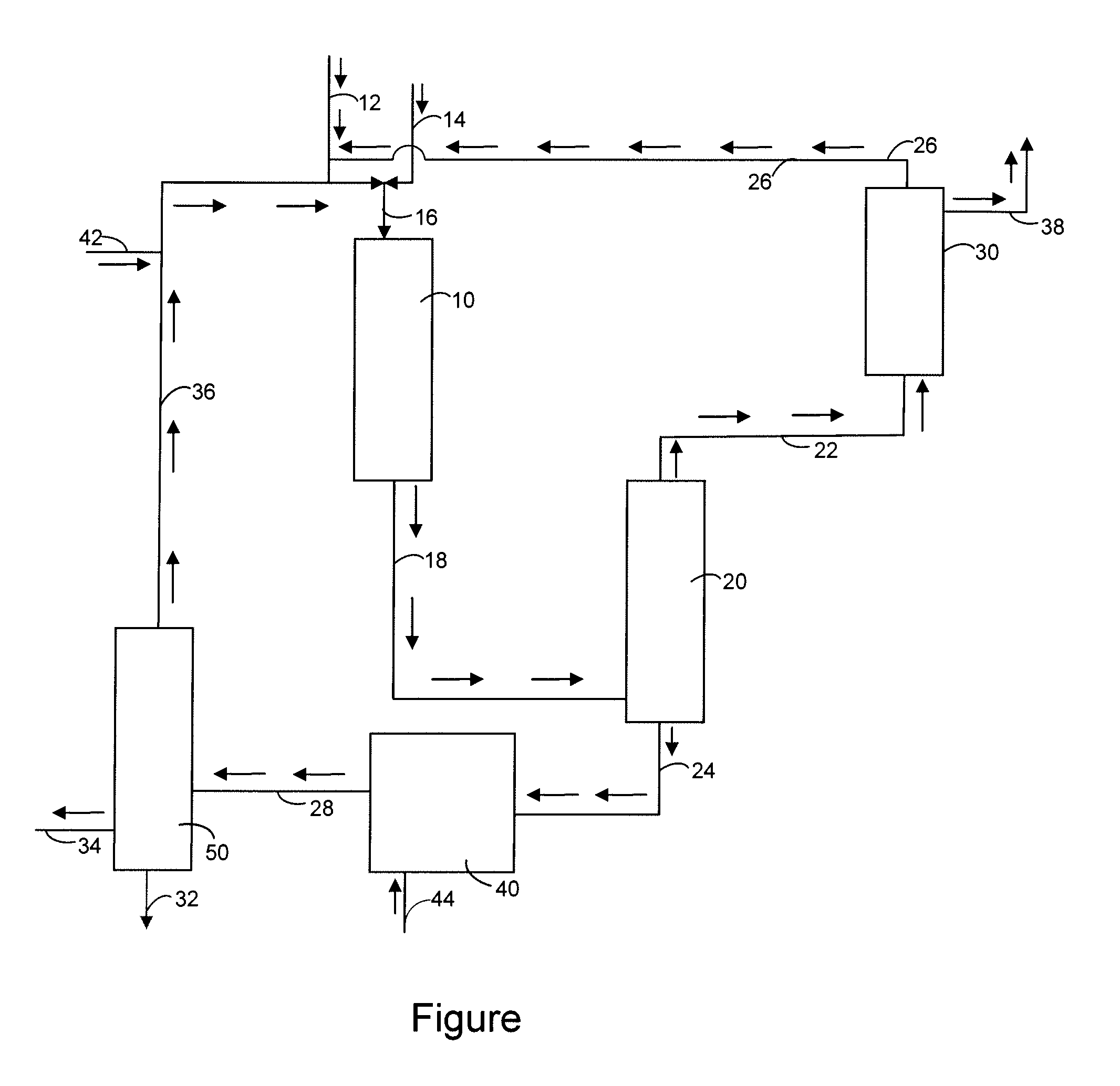

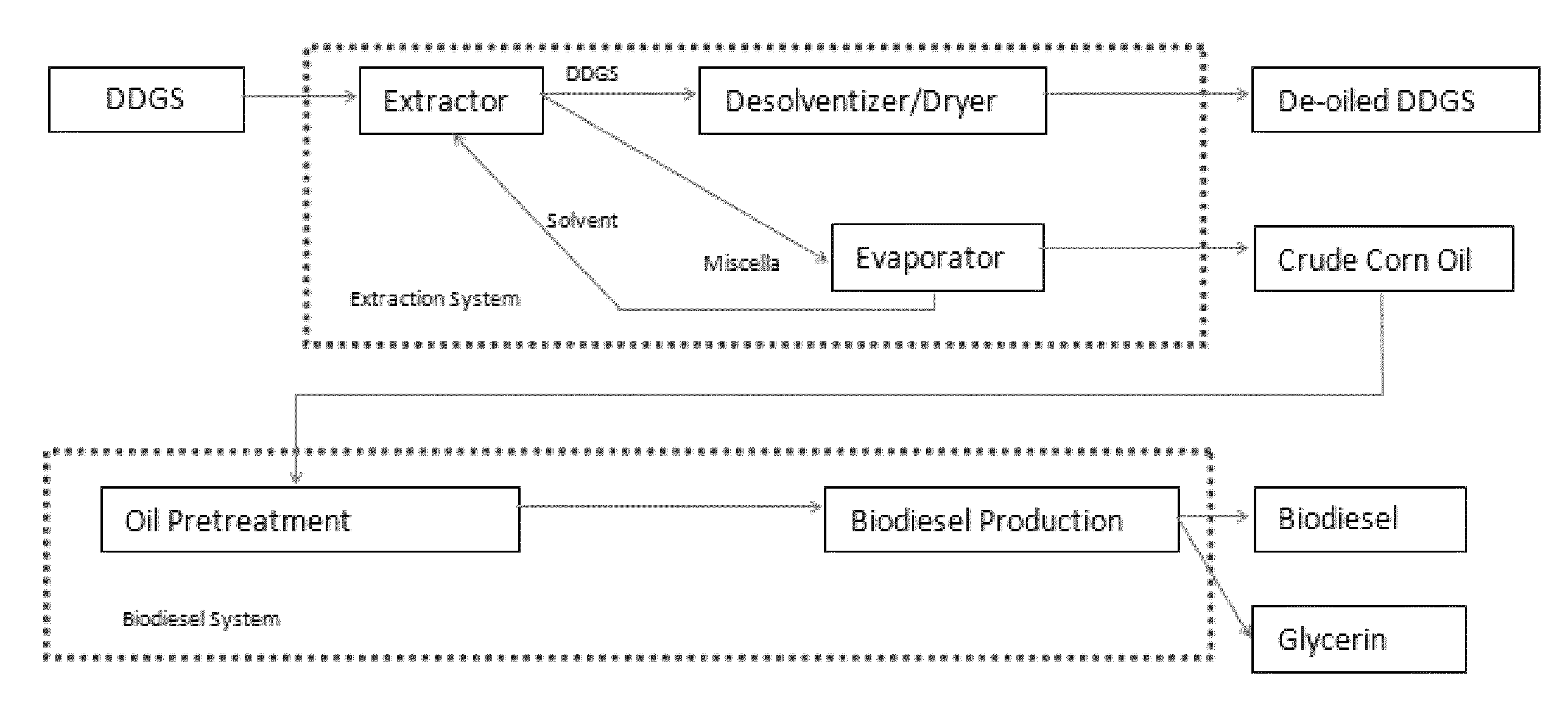

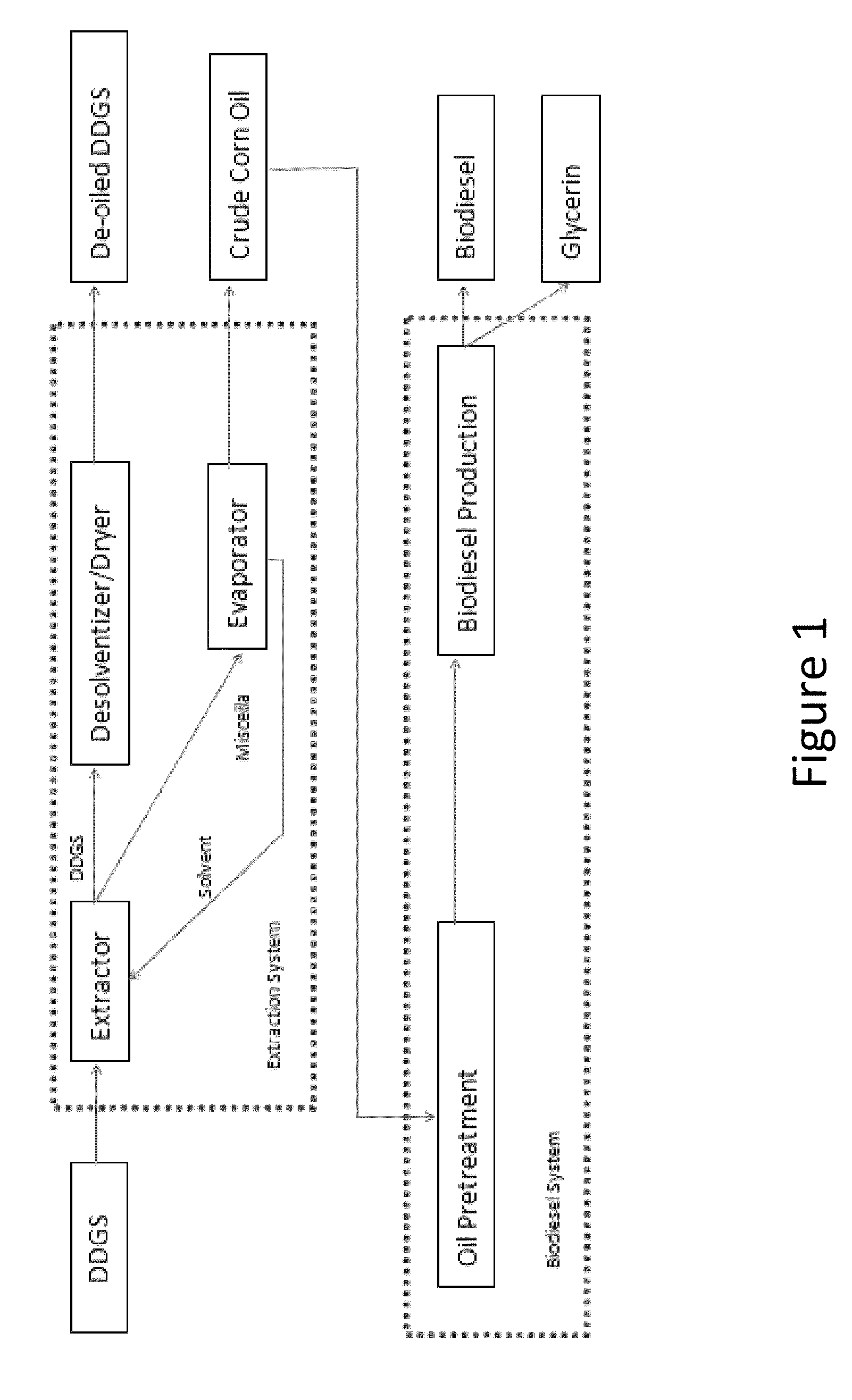

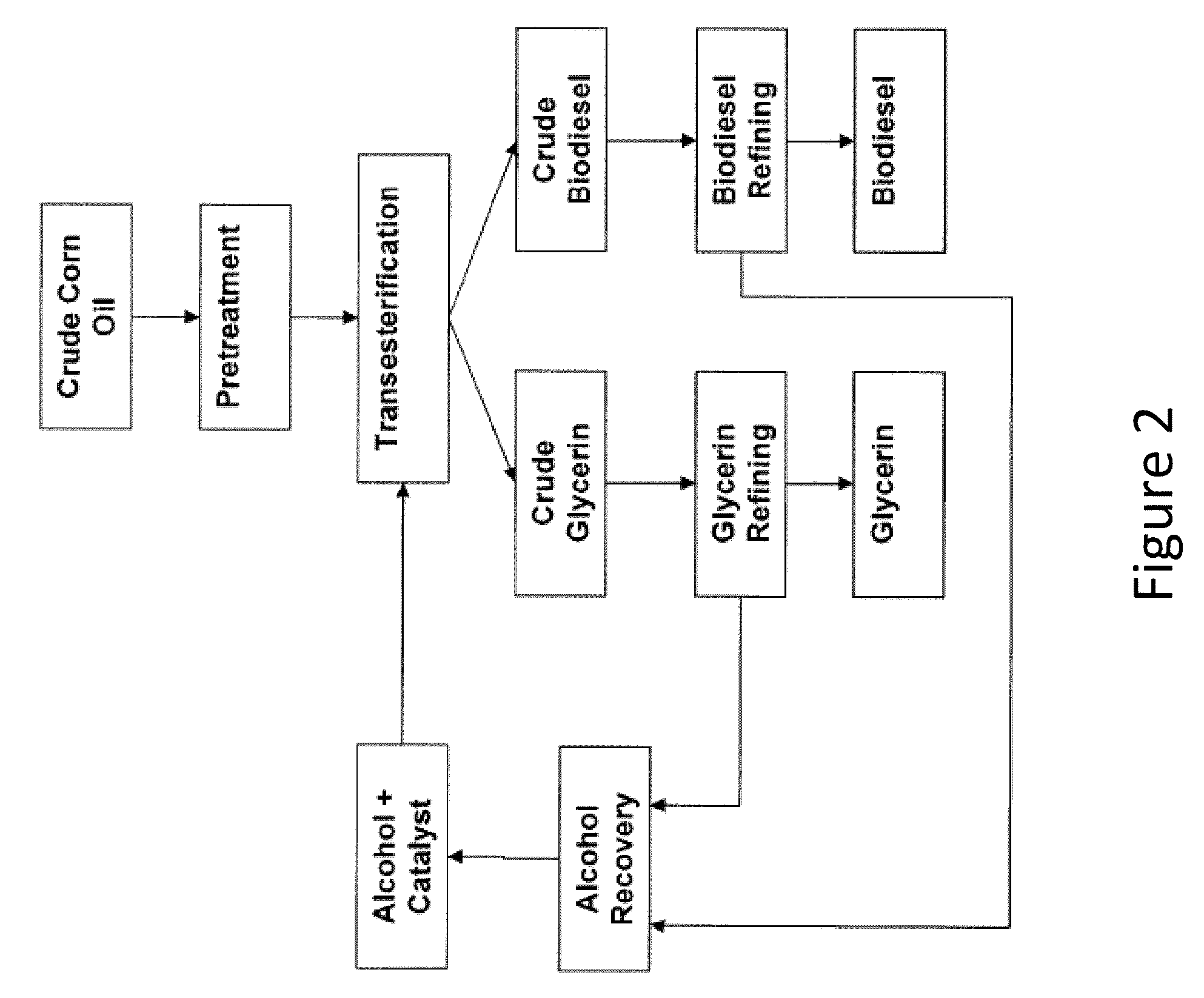

Solvent extraction of oil from distillers dried grains and methods of using extraction products

A process for extraction of crude oil from distillers dried grain solubles and / or distillers dried grains and producing corn distillers meal that may be used as a livestock supplement is disclosed. For example, the corn distillers meal may be used as a crude protein supplement for use in a livestock feed diet or a poultry feed diet. The solvent extracted crude oil may be suitable for oleochemical processing for personal care and home care products, biodiesel production, and / or renewable diesel production from hydro-treating the extracted oil to make green diesel fuel.

Owner:NOVITA NUTRITION

Method for esterifying olefin and organic acid

InactiveCN1600773AFully contactedPromote esterificationPreparation by caroxylic acid/anhydride-hydrocarbon reactionPyridineAlkene

A process for synthesizing ester by alkenes, organic acid, alkyl pyridine end link sulfuric group or ion liquid composed of 1,3-Dialkyl imidazole positive ion and negative ion as reaction mediator and catalyst includes taking reaction alkenes with organic acid by catalyst to get carboxylic ester 1-8 hours in 0.1-2.0 MPA at 50-150 deg.C.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

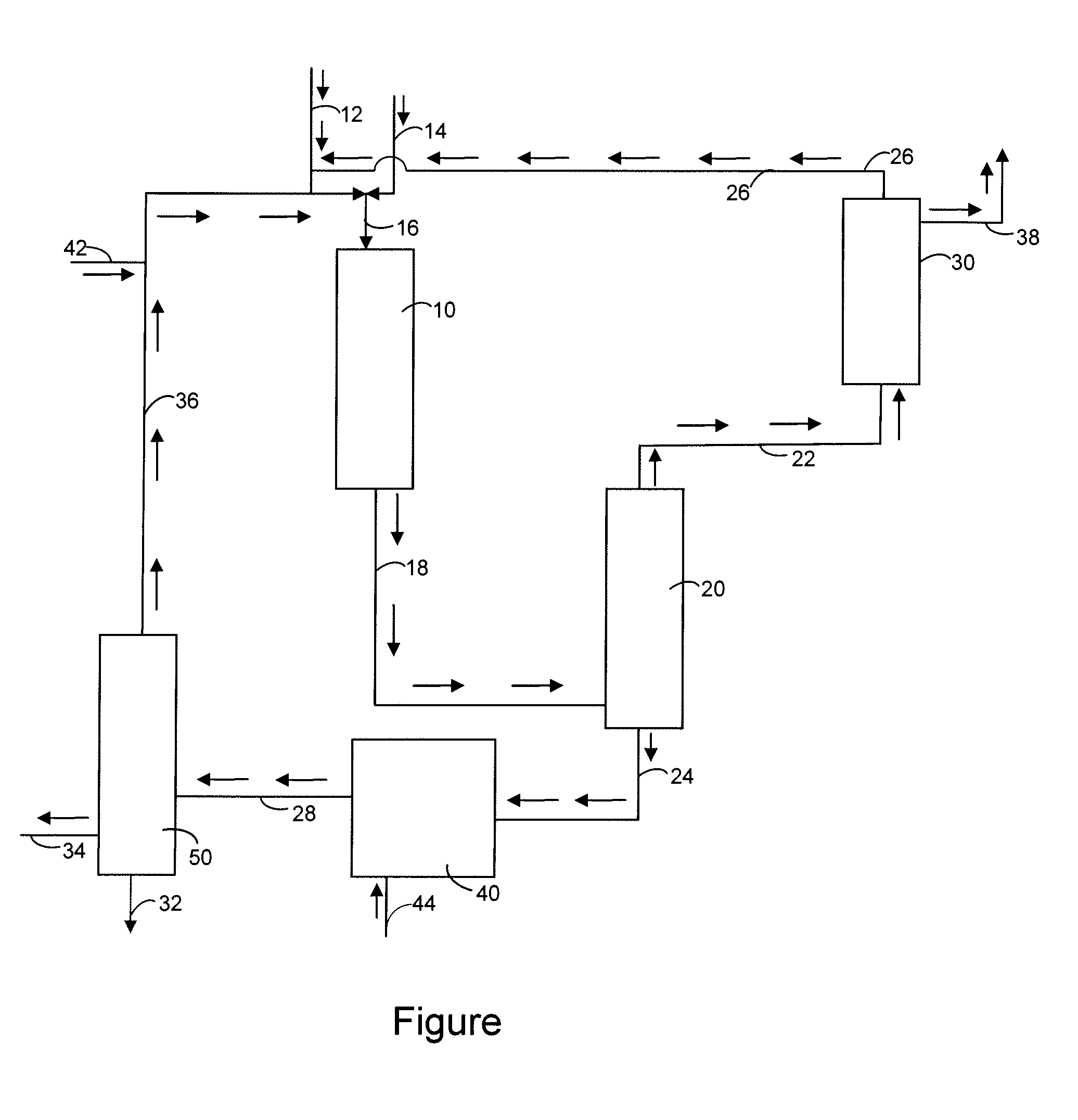

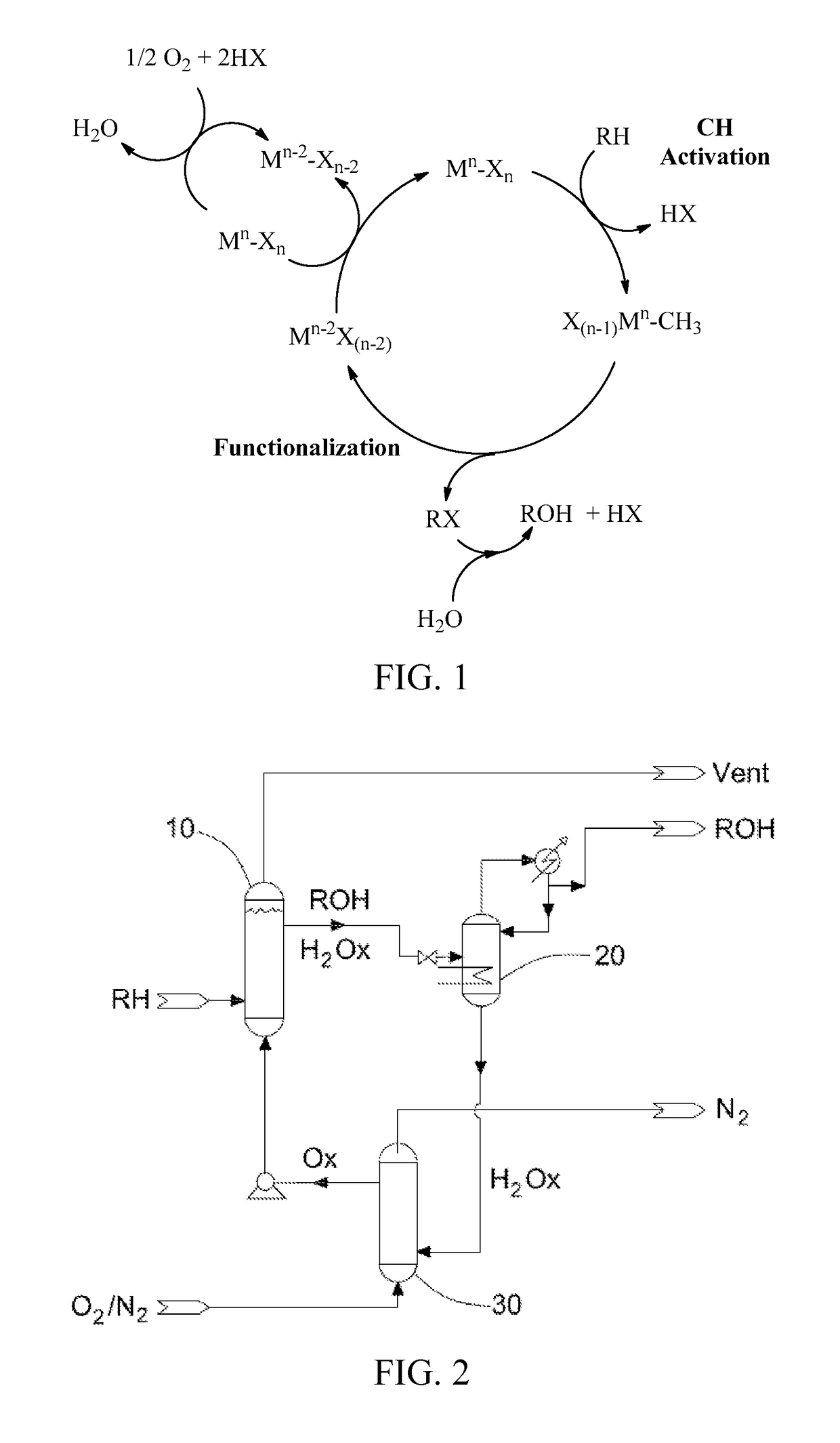

Process for the direct production of methanol from methane

ActiveUS20070149833A1Oxygen-containing compound preparationPreparation by oxidation reactionsMethane productionReaction zone

A process for the production of methanol from methane has been developed. The process involves reacting methane with an oxidant such as oxygen or a peroxide in the presence of a catalyst and a solvent in a reaction zone to produce an effluent stream comprising a methanol product. The effluent stream is next separated into a gaseous stream comprising unreacted methane and carbon dioxide and a liquid stream comprising the methanol product and solvent. Next the gaseous stream is further separated to provide a methane stream which is recycled to the reaction zone. Finally, a methanol stream is isolated and a solvent stream is recycled to the reaction zone.

Owner:UOP LLC

Synthetic method of trimethylolpropane tricaprylate

ActiveCN101445453AHigh selectivityAdvanced and reasonable technologyPreparation by caroxylic acid/anhydride-hydrocarbon reactionMetal/metal-oxides/metal-hydroxide catalystsSTANNOUS OXIDEFiltration

The invention relates to a synthetic method of trimethylolpropane tricaprylate, which belongs to the technical field of esters compound synthesizing in organic chemistry. Taking trimethylolpropane and isocaprylic acid as material, an esterification reaction is preformed in nitrogen gas under the action of metallic oxide catalyst, the trimethylolpropane tricaprylate is obtained after depickle and filtration; the mass ratio of the trimethylolpropane and the isocaprylic acid is 1:3.15-3.95; the metallic oxide catalyst is stannous oxide or ferric oxide or magnesia, and the like, and the adding amount of the catalyst accounts for 0.03 to 0.10 percent by weight of the total weight of the trimethylolpropane and the isocaprylic acid. The invention reasonably selects metal oxide as the catalyst, and the metal oxide does not erode equipment, can be removed by filtration after the reaction is finished and can be recovered for recycle use; and the invention has advanced and reasonable process and less equipment investment through reasonable regulation of the adding amount of the trimethylolpropane and the isocaprylic acid and the proportion of the metal oxide catalyst and the optimal selection of reaction temperature and reaction time.

Owner:ZHEJIANG HUANGMA TECH

Solvent extraction of oil from distillers dried grains and methods of using extraction products

A process for extraction of crude oil from distillers dried grain solubles and / or distillers dried grains and producing corn distillers meal that may be used as a livestock supplement is disclosed. For example, the corn distillers meal may be used as a crude protein supplement for use in a livestock feed diet or a poultry feed diet. The solvent extracted crude oil may be suitable for oleochemical processing for personal care and home care products, biodiesel production, and / or renewable diesel production from hydro-treating the extracted oil to make green diesel fuel.

Owner:NOVITA NUTRITION

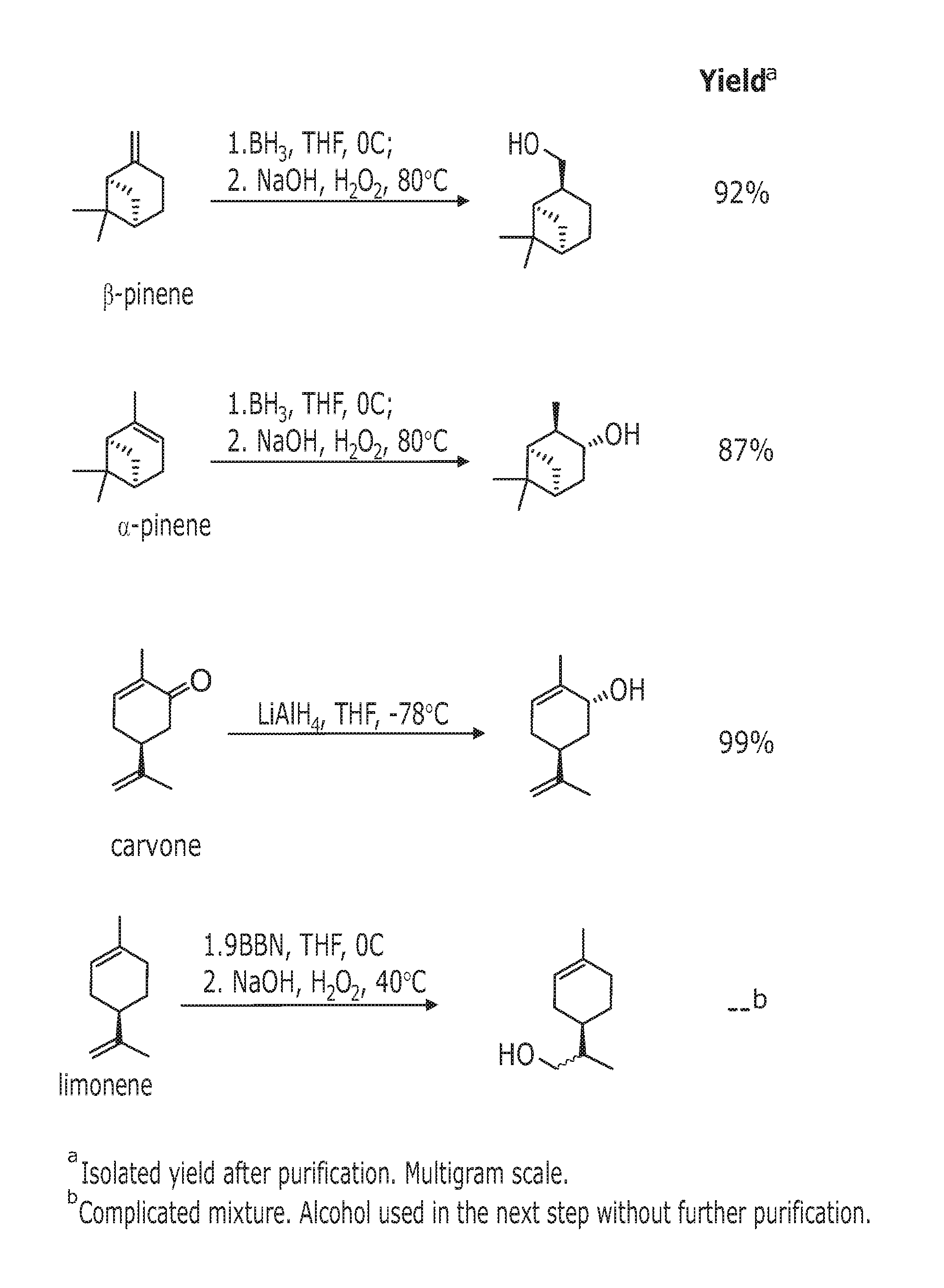

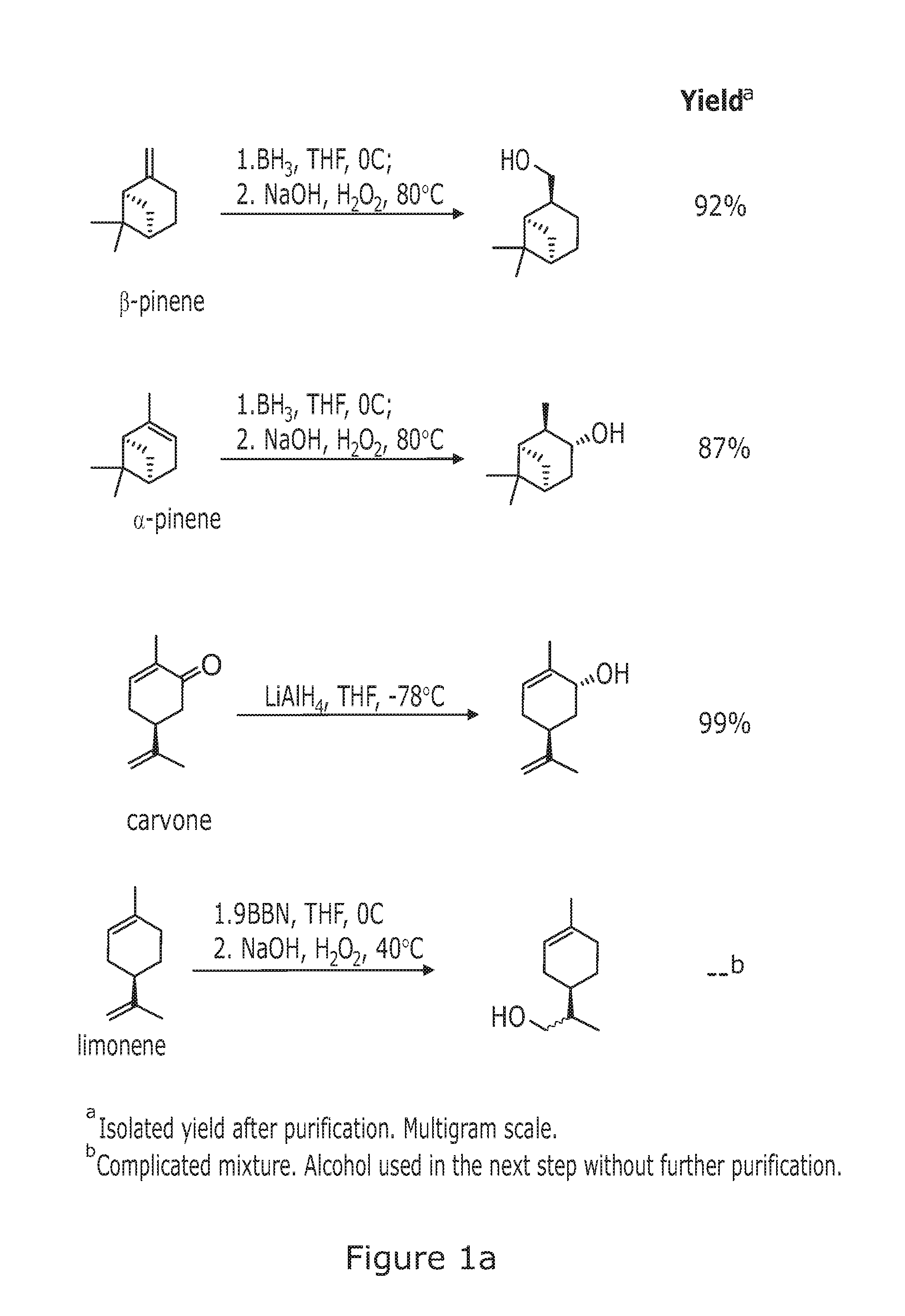

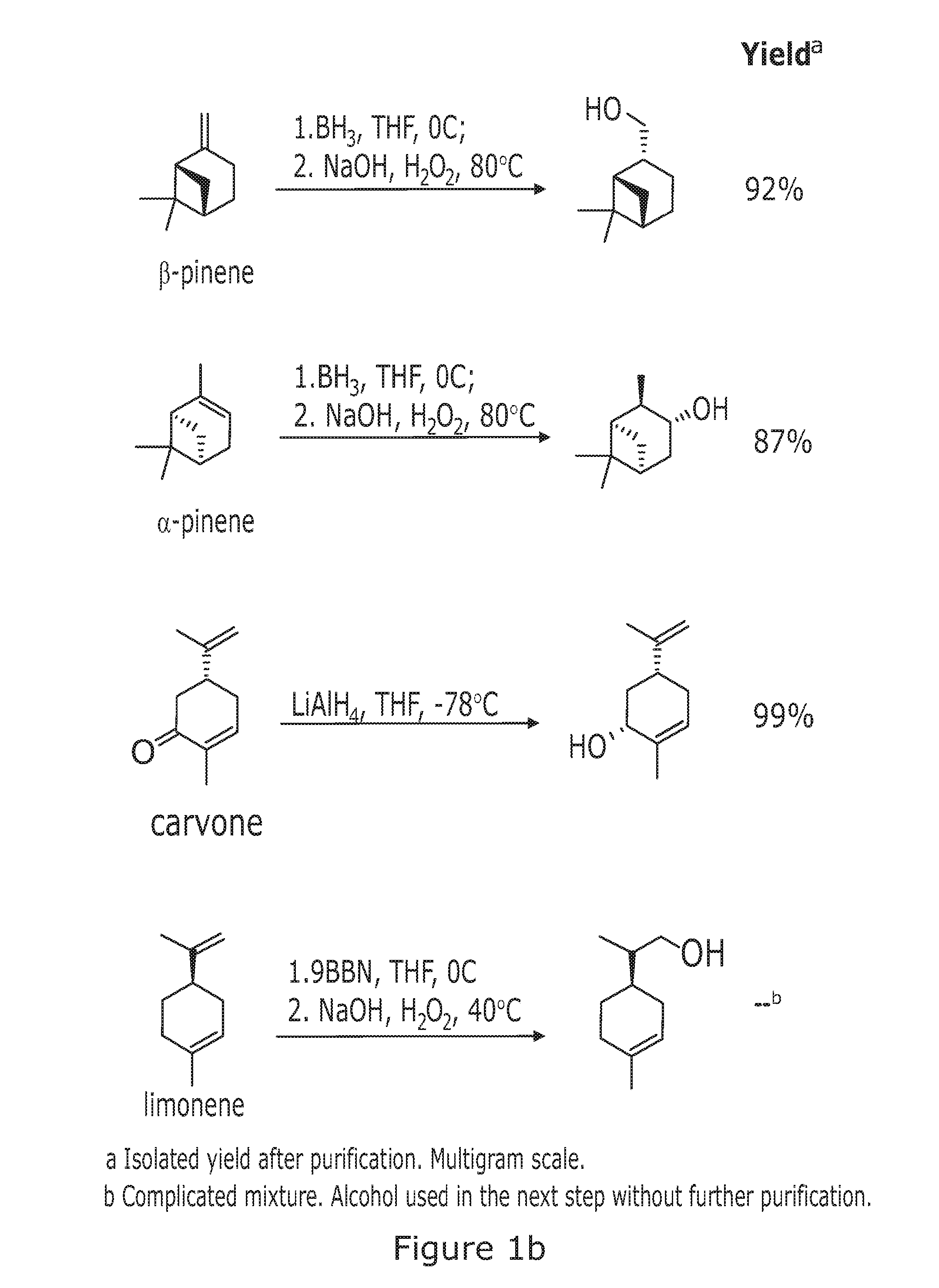

Terpene and terpenoid derivatives containing vinyl groups for the preparation of polymers

InactiveUS20170044282A1Easy to aggregateGood thermomechanical stabilityPreparation from carboxylic acid halidesOrganic compound preparationHydroxy groupMonomer

The invention relates to a method for producing functionalised monomers, the method comprising: a) providing a starting material selected from terpenes and terpenoids; b) forming a derivative of the starting material by incorporation of a hydroxyl group; c) esterifying the hydroxyl group of the derivative to introduce a moiety containing a vinyl group, so as to produce a functionalised monomer. The functionalised monomer can be polymerised to obtain a bio-derived polymer.

Owner:UNIVERSITY OF NOTTINGHAM

Oxidation of Methane to Methanol using a Catalyst Containing a Transition Metal

InactiveUS20080249337A1Oxygen-containing compound preparationPreparation by oxidation reactionsSolventManganese oxide

A process for the oxidation of methane to methanol has been developed. The process involves contacting a gas stream, comprising methane, a solvent and an oxidizing agent with a catalyst at oxidation conditions to produce a methyl ester. Finally, the methyl ester is hydrolyzed to yield a methanol product stream. The catalyst comprises a transition metal component such as manganese oxide and an inorganic oxide such as silica. The transition metal component can be dispersed onto the inorganic oxide.

Owner:UOP LLC

Process for the direct production of methanol from methane

ActiveUS7288684B1Preparation by oxidation reactionsOrganic compound preparationMethane productionReaction zone

Owner:UOP LLC

Oxidation of Methane to Methanol using a Bimetallic Catalyst

InactiveUS20080249198A1Organic compound preparationPreparation by caroxylic acid/anhydride-hydrocarbon reactionManganeseSolvent

A process for the oxidation of methane to methanol has been developed. The process involves contacting a gas stream, comprising methane, a solvent and an oxidizing agent with a bimetallic catalyst at oxidation conditions to produce a methyl ester. Finally, the methyl ester is hydrolyzed to yield a methanol product stream. The bimetallic catalyst comprises at least two transition metal components. One example of the catalytic component is a combination of cobalt and manganese.

Owner:UOP LLC

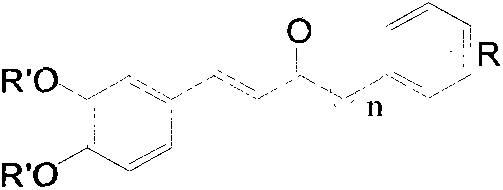

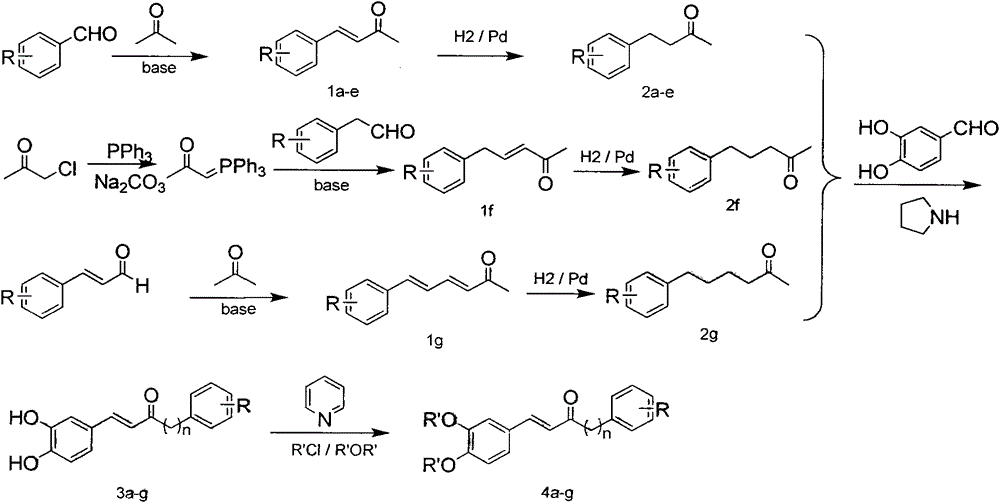

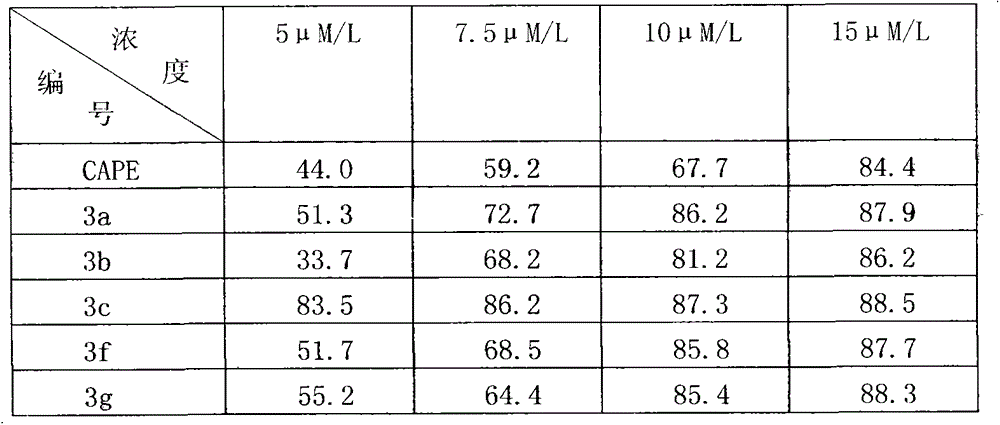

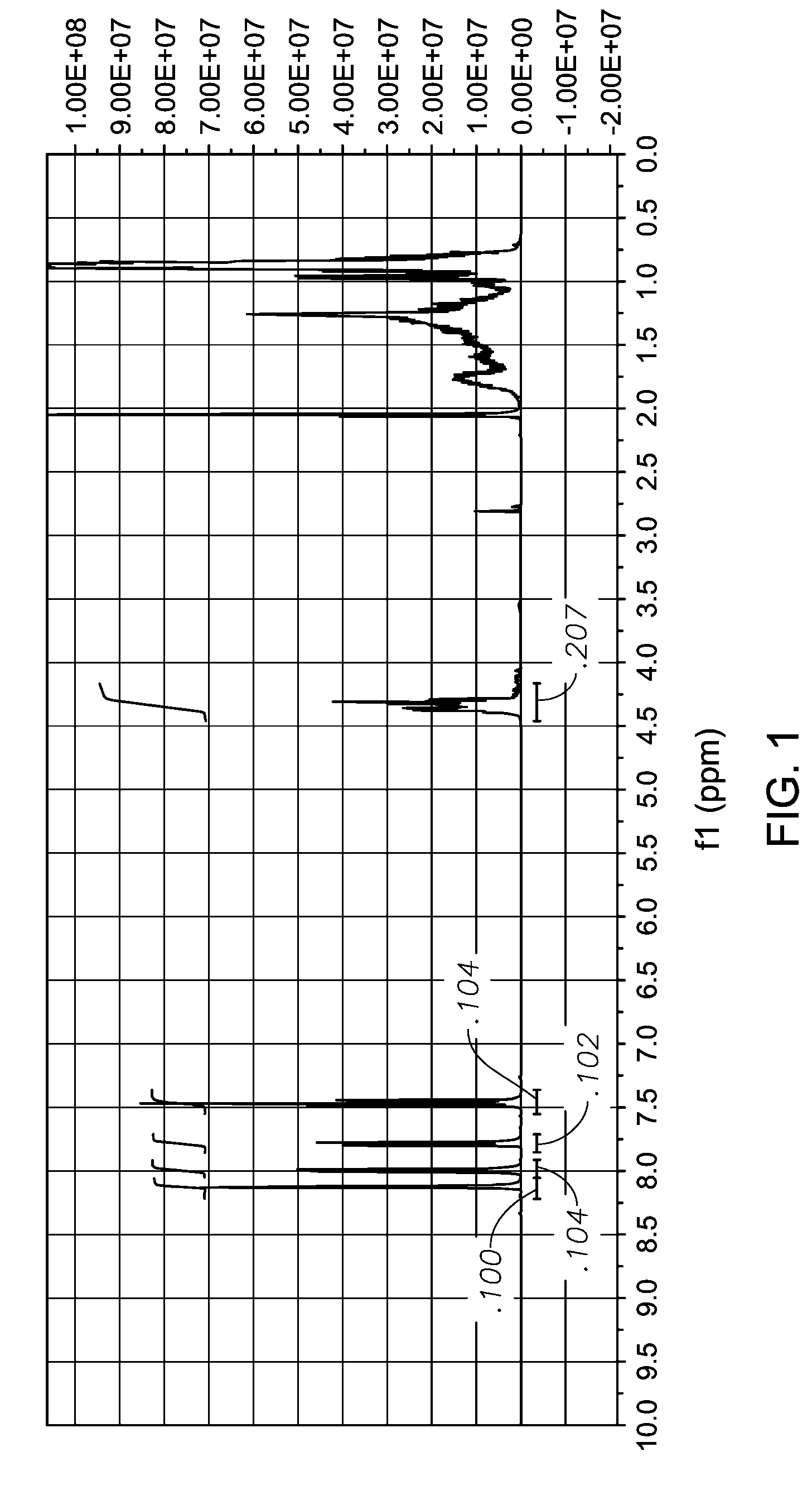

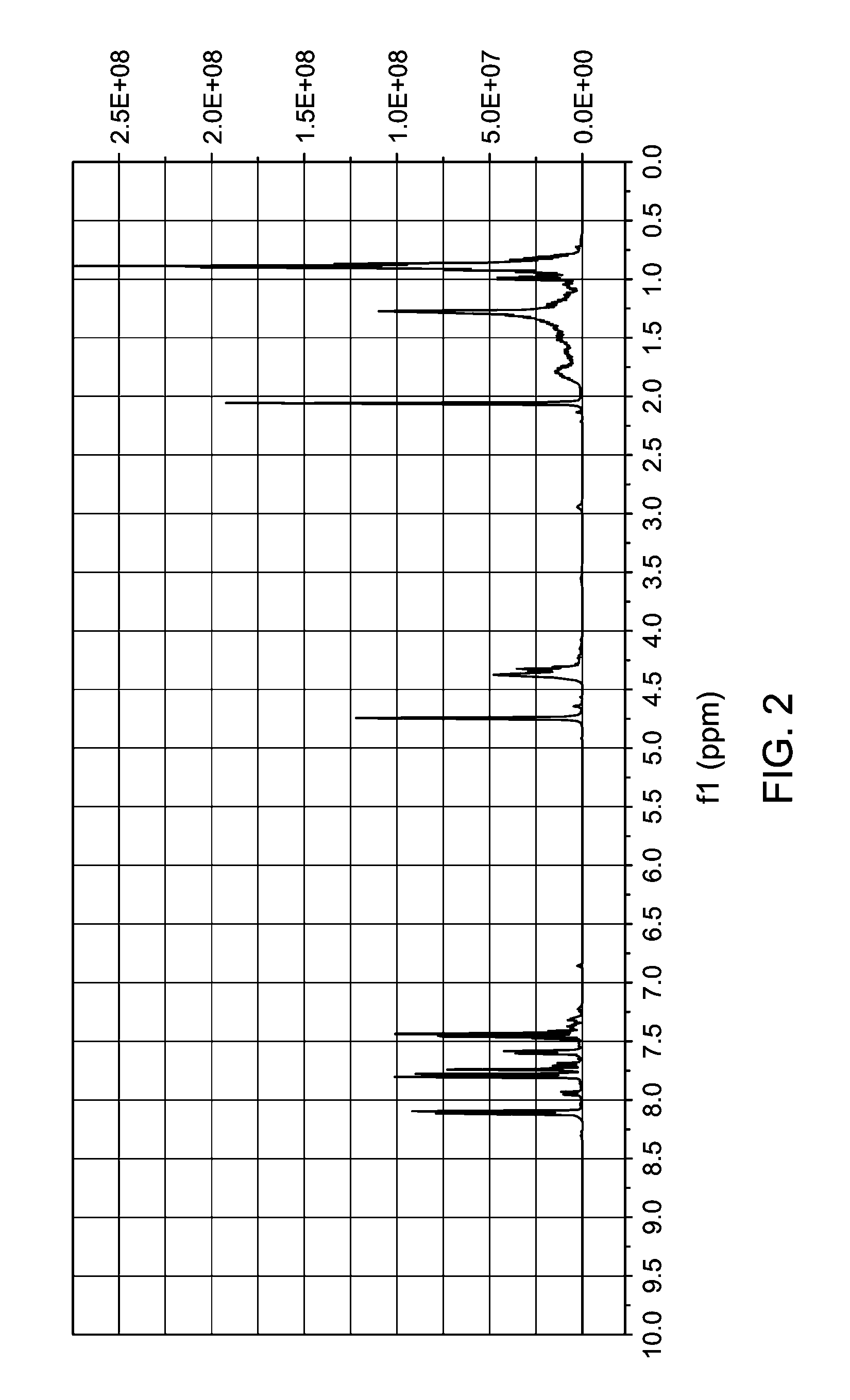

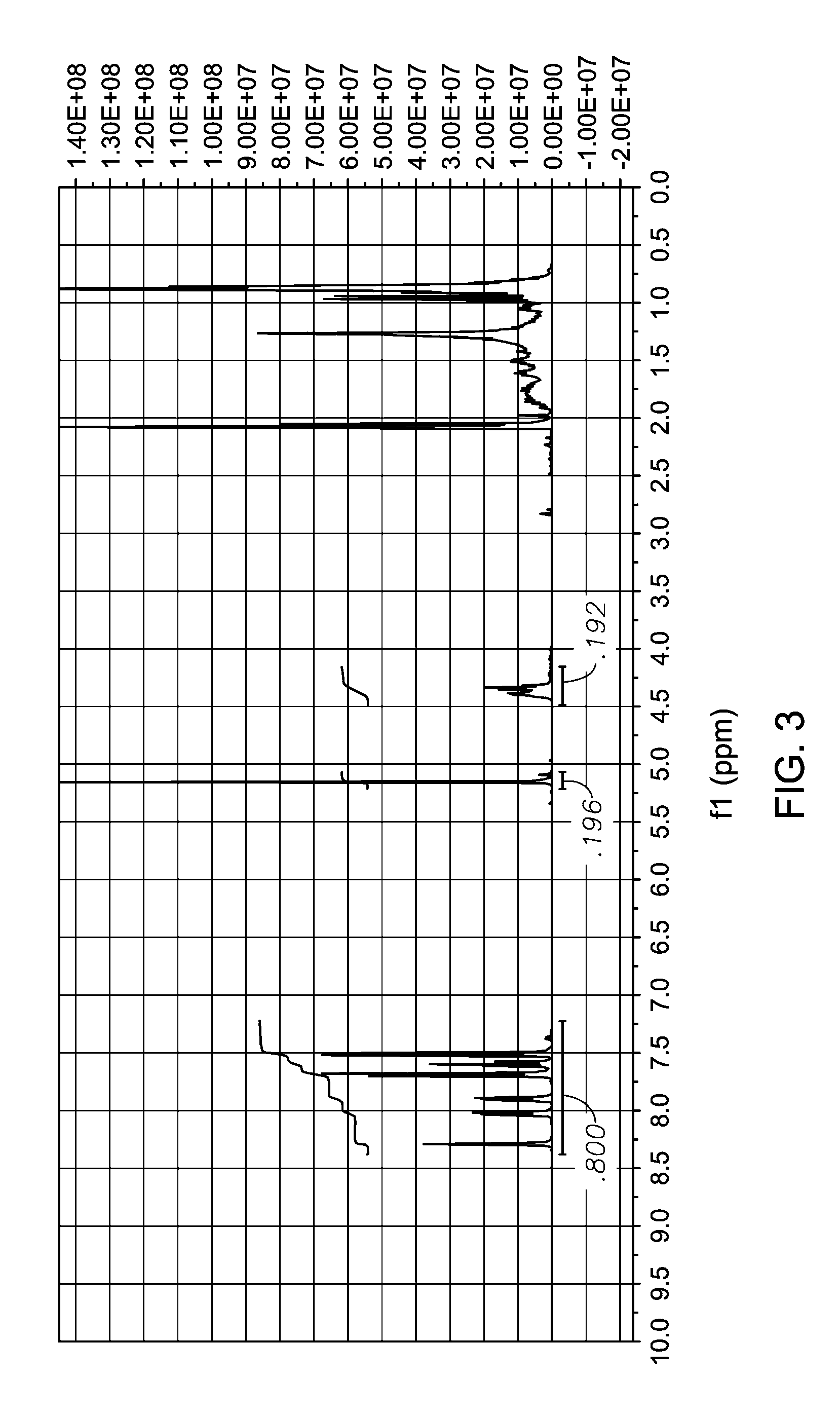

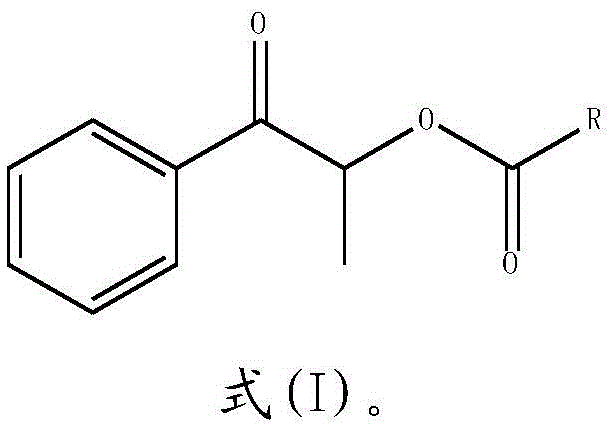

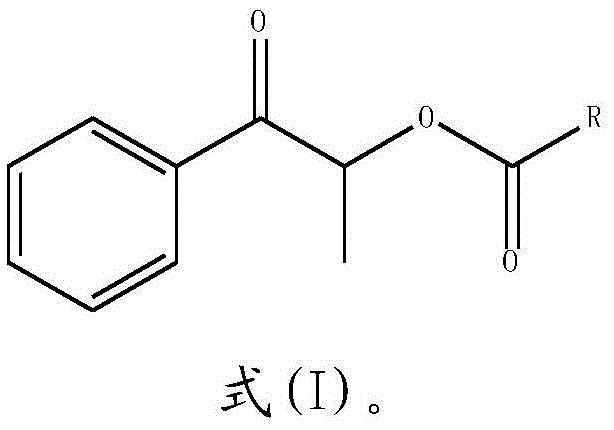

Preparation method of E-3,4-dihydroxyphenylvinyl ketone and application thereof as nerve protection drug

The invention relates to a E-3,4-dihydroxyphenylvinyl ketone compound I having a formula represented in the description and an application thereof in preparation of nerve protection drugs or drug compositions for treating neurodegenerative diseases; wherein definitions of each group in the formula are listed in the description. The invention also relates to a preparation method of the compound.

Owner:PEKING UNIV

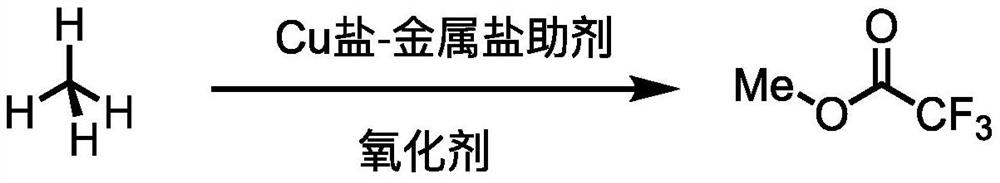

Method for producing trifluoroacetic acid methyl ester by catalytic oxidation of methane

InactiveCN102086152AHigh yieldPreparation by caroxylic acid/anhydride-hydrocarbon reactionChemical industryTrifluoroacetic acid

The invention provides a method for producing trifluoroacetic acid methyl ester by catalytic oxidation of methane, belonging to the technical field of chemical industry. The method is characterized in that in a mixing solvent composed of perfluoroctane or perfluornonane and trifluoroacetic acid, methane is subjected to catalytic oxidation to obtain the trifluoroacetic acid methyl ester by taking oxygen as oxidant and using palladium acetate, benzoquinone and phospho vando molybdic acid as catalysts. In the method, the volume ratio of perfluoroctane or perfluornonane to trifluoroacetic acid is1:1 to 1:10; the total pressure of methane and oxygen is 2.0-5.0 MPa, and the partial pressure ratio of methane to oxygen (1.6-10):1; and reaction is carried out for 1-12 hours at the temperature of 40-120 DEG C to produce the trifluoroacetic acid methyl ester. Compared with the method using single solvent trifluoroacetic acid, the method provided by the invention has the advantage of obviously improved yield of trifluoroacetic acid methyl ester.

Owner:BEIJING UNIV OF CHEM TECH

Biphenyl Esters, Their Production and Their Use in the Manufacture of Plasticizers

ActiveUS20150361027A1Attractive combinationReduce volatilityOrganic compound preparationPreparation by caroxylic acid/anhydride-hydrocarbon reactionPlasticizerMethyl group

A biphenyl diester useful as a plasticizer having the formula (I):wherein R1 is an alkyl group having 5 to 15 carbon atoms and R2 is a methyl group or a phenyl group.

Owner:EXXONMOBIL CHEM PAT INC

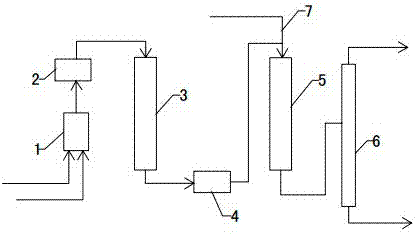

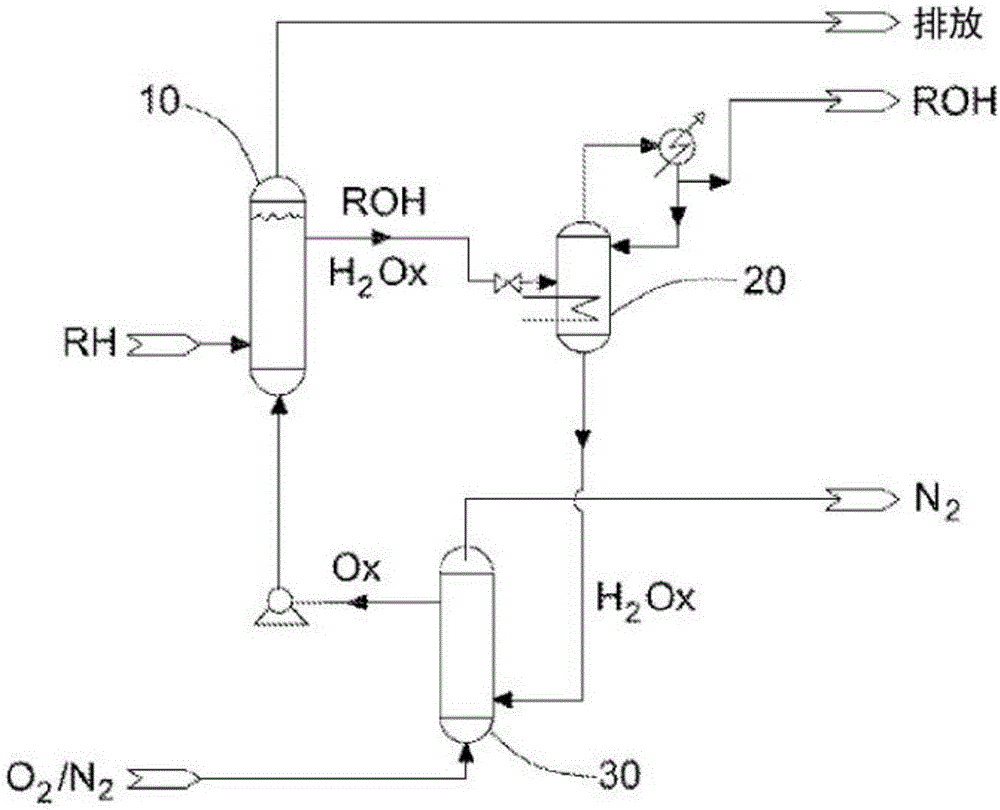

A sec-butanol production process

ActiveCN107540522AImprove economyWell mixedOrganic compound preparationPreparation by caroxylic acid/anhydride-hydrocarbon reactionPropanoic acidOrganic synthesis

The invention provides a sec-butanol production process and belongs to the technical field of organic synthesis. The process is characterized in that the process comprises steps of subjecting propionic acid and C4 to an esterification reaction firstly; preheating a material mixture obtained by esterification and hydrogen; then performing a hydrogenation reaction; controlling the mole ratio of thehydrogen to the material mixture; and subjecting a material discharged from a hydrogenation reactor to separation by rectification through a separating column to obtain sec-butanol; and a double-atomcatalyst including a copper base and a platinum group element is adopted so that the reaction temperature can be reduced and the mass space velocity can be increased. The process lowers the temperature of the ester hydrogenation reaction, increases the space velocity, and increase the economical efficiency of a process of preparing sec-butanol through ester hydrogenation. In addition, severe equipment corrosion, more side reactions, difficult product separation and much waste water in a sec-butanol production process are reduced.

Owner:CHINA PETROLEUM & CHEM CORP

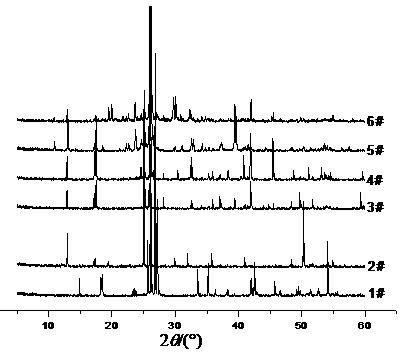

Method for preparing sodium bisulfate/attapulgite clay composite solid acid catalyst

InactiveCN102133535AIncrease added valueTake advantage ofPhysical/chemical process catalystsPreparation by caroxylic acid/anhydride-hydrocarbon reactionSolid acidSodium bisulfate

The invention discloses a method for preparing a sodium bisulfate / attapulgite clay composite solid acid catalyst, wherein the solid acid catalyst is respectively prepared through a solution dipping method and a thermal dispersion method by using sodium bisulfate monohydrate and attapulgite clay as raw materials. The solution dipping method comprises the following steps of: intermittently adding a sodium bisulfate solution and the attapulgite clay to a cylindrical glass container under the condition of stirring, dipping for a certain time after feeding, introducing the mixture to a dryer or conveying the mixture to the dryer after suction filtering, and stirring and heating until the mixture is dried to obtain the composite catalyst. The thermal dispersion method comprises the following steps of: intermittently adding the sodium bisulfate monohydrate and the attapulgite clay to a cylindrical glass container under the condition of stirring, raising the temperature to be higher than the melting point of sodium bisulfate, and after feeding, stirring the mixture and stopping stirring when the mixture is changed from a viscous state to a powdered state to obtain the composite catalyst. With the adoption of the method, low-cost attapulgite clay resources are fully used, the catalytic effect is improved, and the composite solid acid catalyst is not easy to agglomerate and convenient for shaping, storage, transportation and industrial application.

Owner:HUAIYIN TEACHERS COLLEGE +1

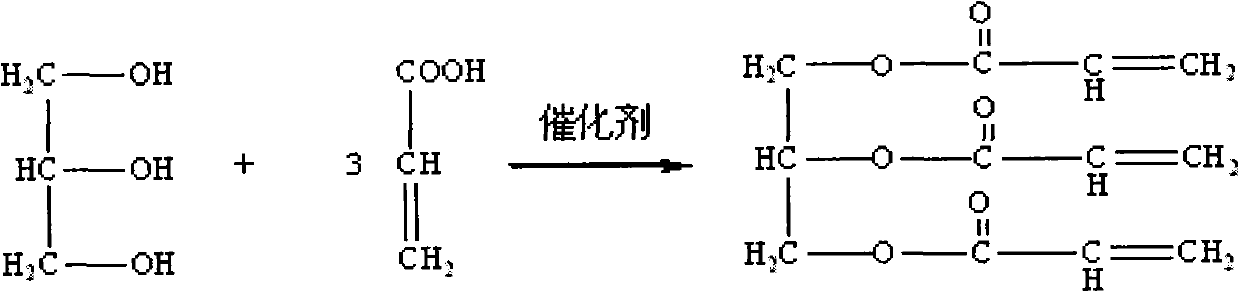

Preparation method of 1, 2, 3-glycerin triacrylate

InactiveCN102557935AReduce pollutionSimple and safe operationPreparation by caroxylic acid/anhydride-hydrocarbon reactionAlkaneHeteropoly acid

The invention discloses a preparation method of 1, 2, 3-glycerin triacrylate, which uses bio-based material (1, 2, 3-glycerin) as a raw material, overcomes the space reaction steric hindrance of three hydroxyl radicals of the molecule and esterifies the hydroxyl radicals of three carbon atoms completely. Esterification reaction is carried out on the 1, 2, 3-glycerin and crylic acid under the existence of a catalyst, a polymerization inhibitor and a water-carrying agent, and then the target product (1, 2, 3-glycerin triacrylate) provided by the invention is obtained. The preparation method has the advantages that since solid acid or heteropoly acid is used as the catalyst and environmentally-friendly alkane is used as the water-carrying agent, the operation is safe and simple, the corrosion to equipment is avoided and the pollution to the environment is reduced.

Owner:BEIJING UNIV OF CHEM TECH

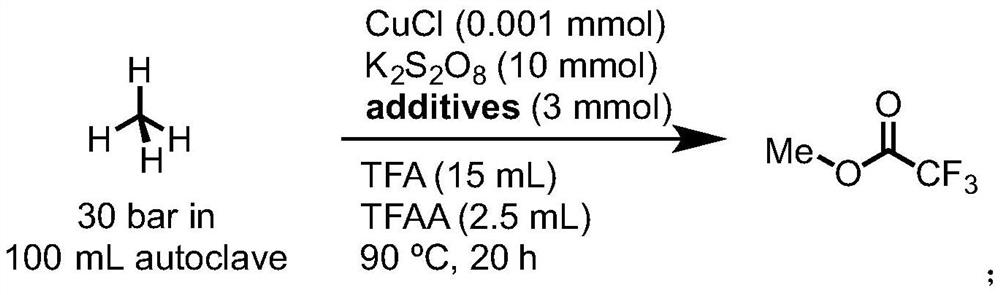

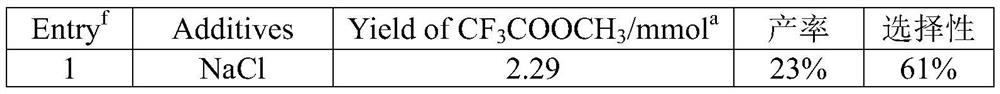

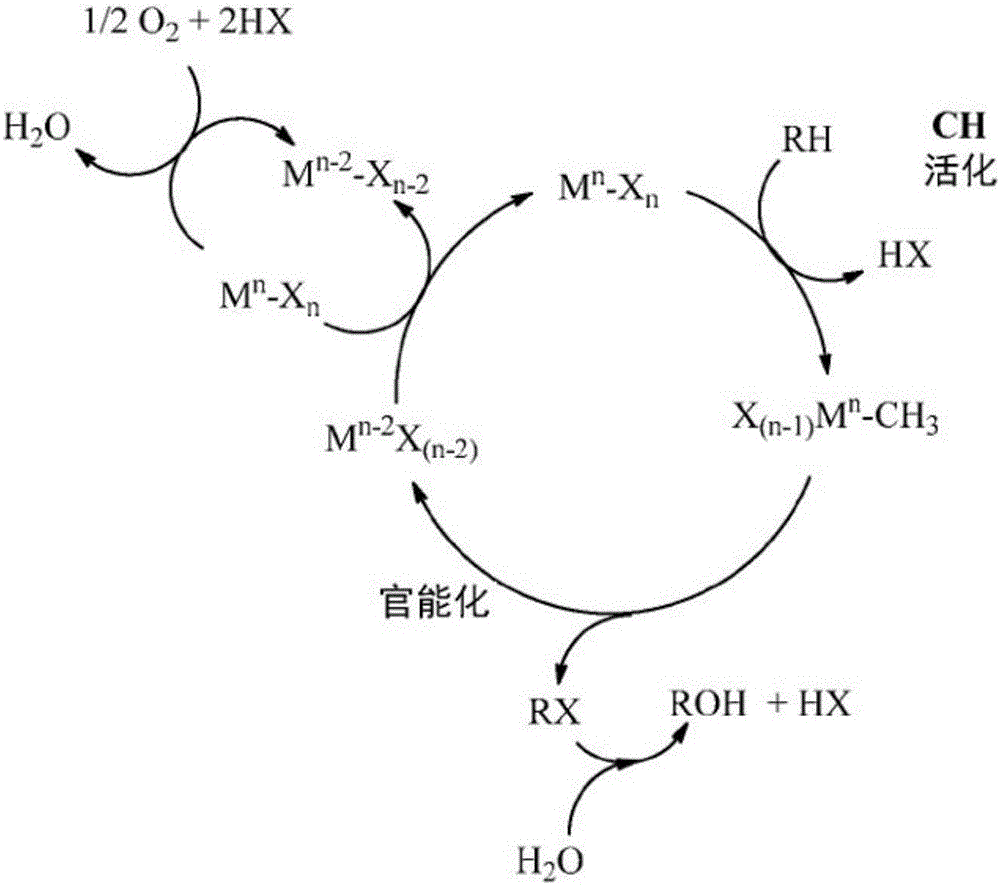

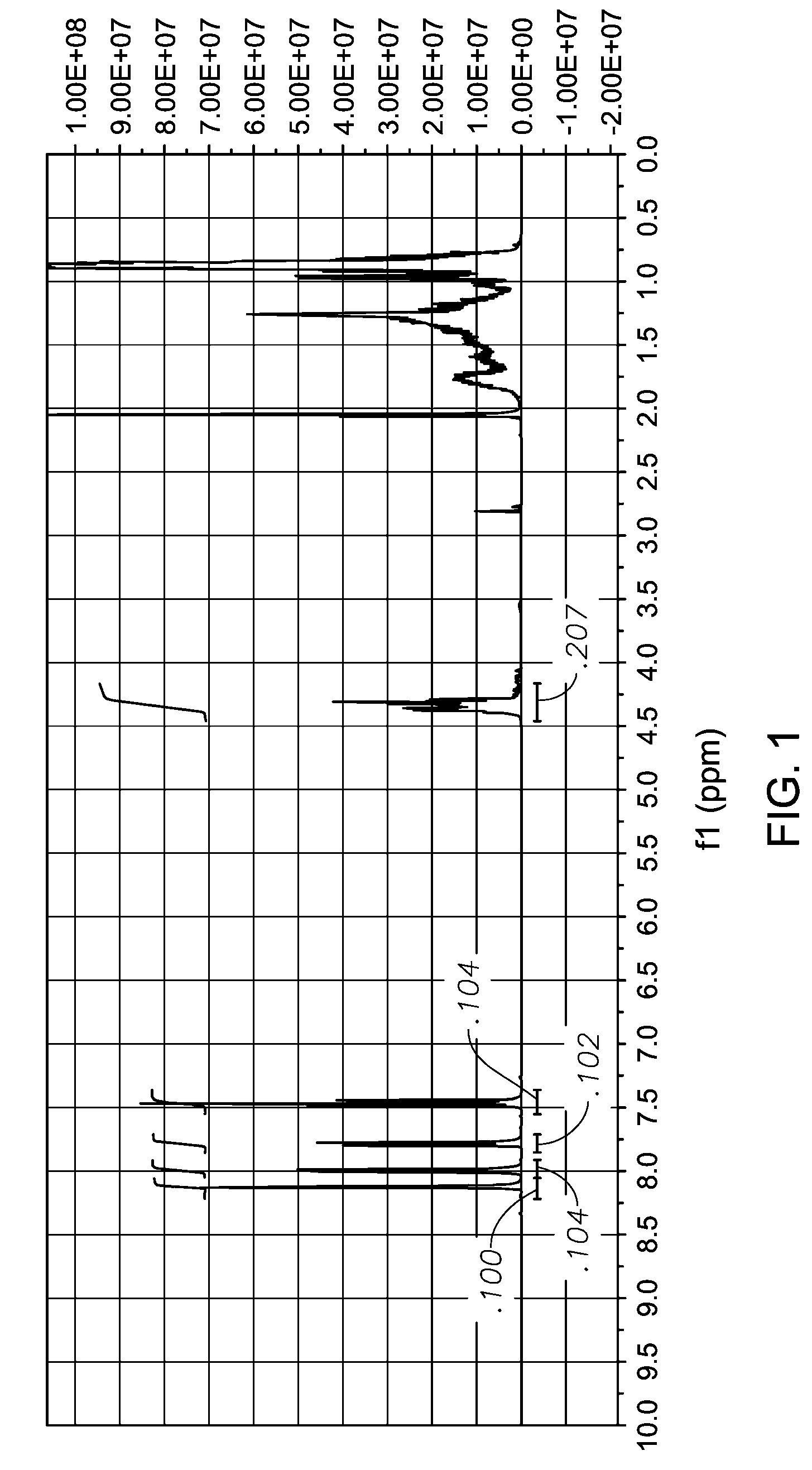

A kind of method of alkane selective catalytic oxidation reaction

ActiveCN111747847BHigh reactivityReduce dosagePreparation by caroxylic acid/anhydride-hydrocarbon reactionOrganic-compounds/hydrides/coordination-complexes catalystsAlkanePtru catalyst

The invention discloses a method for the selective reaction of highly efficient catalytic oxidation of alkanes. Taking alkane as raw material, in trifluoroacetic acid and / or trifluoroacetic anhydride system, using copper salt-metal salt as catalytic system, reacting in the presence of oxidant, and selective catalytic oxidation reaction occurs; wherein the metal salt is lithium salt, One or more of sodium, potassium, cesium, calcium or magnesium salts. The metal salt of the present invention, as a catalyst assistant, is used in combination with a copper salt to significantly improve the reaction activity of the catalyst in the catalytic oxidation of alkanes, while ensuring high product yield, significantly reducing the amount of the catalyst and improving its catalytic efficiency. Taking methane as an example, using the above method to prepare methane trifluoroacetic acid, the highest yield is about 72%, and the selectivity is about 92%. The reaction process conditions are relatively mild, and the reaction can be performed at 90 degrees, and the obtained methyl trifluoroacetate can be subjected to various transformations according to literature methods, such as hydrolysis into trifluoroacetic acid and methanol.

Owner:SUN YAT SEN UNIV

Method for preparing tert-butyl acetate from acetic acid and iso-butane

ActiveCN105367422AHigh selectivityRaw materials are cheap and easy to getPreparation by caroxylic acid/anhydride-hydrocarbon reactionOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidTert-Butyl acetate

The invention provides a method for preparing tert-butyl acetate from acetic acid and iso-butane. The method includes the steps that acetic acid and iso-butane are reacted in the presence of a catalyst and an oxidizing agent, and tert-butyl acetate is produced. The method for preparing tert-butyl acetate from acetic acid and iso-butane overcomes the defects of the prior art, raw materials are cheap and easy to get, energy consumption is low, the selectivity of tert-butyl acetate is high, and economic benefits are more remarkable.

Owner:HUNAN ZHONGCHUANG CHEM

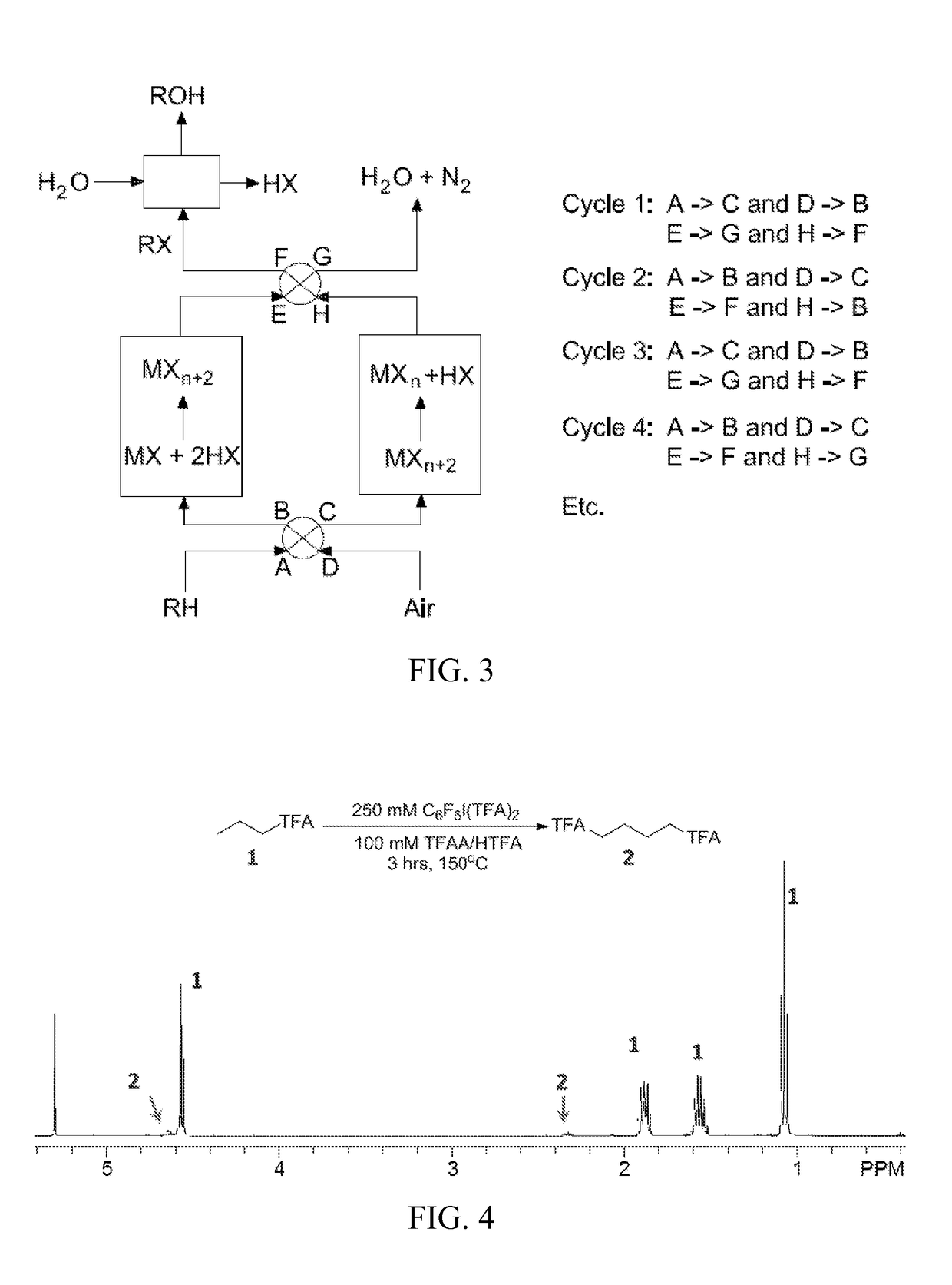

Process for the functionalization of heteroalkanes and arenes

InactiveCN106687439AHigh affinityIncreased affinity of products of higher alkanesPreparation rom asymmetrical anhydridesPreparation by oxidation reactionsMetalloleHydrogen atom

Provided are methods and materials for the functionalization of a heteroalkane or arene using an oxidizing electrophile as a stoichiometric agent or catalyst. The reaction involves the replacement of a hydrogen atom on an sp3-hybridized carbon atom of the heteroalkane or of a hydrogen atom on an sp2-hybridized carbon atom of the arene. A main group element organometallic intermediate is formed that undergoes further conversion to a functionalized heteroalkane or arene.

Owner:THE SCRIPPS RES INST

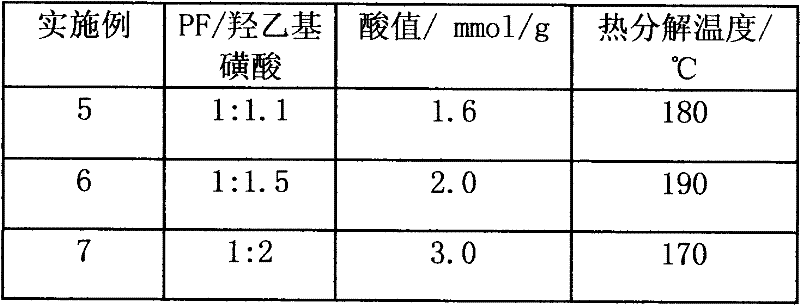

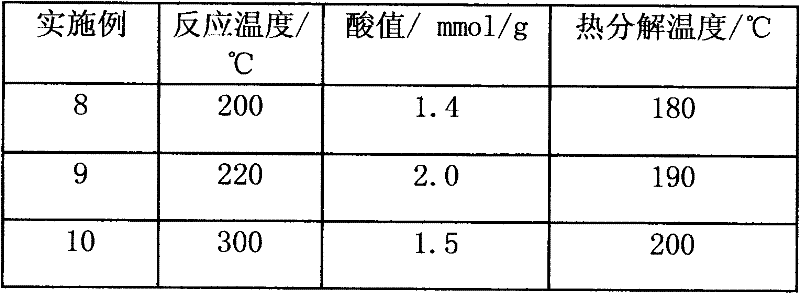

Phenolic resin based solid acid, preparation method and application thereof

InactiveCN102125873AImprove thermal stabilityHigh acid value of solid acidOrganic compound preparationPreparation by caroxylic acid/anhydride-hydrocarbon reactionChemical synthesisAcid value

The invention discloses a phenolic resin based solid acid, a preparation method and application thereof, belonging to the technical field of chemical synthesis. The preparation method is characterized by comprising the steps of: with phenolic resin as a raw material and isethionic acid with a mass ratio of 1:0.5-1:2 with the raw material as an active molecule, undergoing a condensation reaction for 2-32h at a temperature of 180-300 DEG C, after the reaction is ended, adding hot water with the temperature of above 80 DEG C in the product for washing, filtering to remove free acidic matters, and then drying in a drying oven with the temperature of 120 DEG C to obtain the phenolic resin based solid acid. The phenolic resin based solid acid prepared in the invention has the advantages of highheat stability, high acid value, good catalytic activity, capability of being repeated in use, and the like.

Owner:SHAOXING UNIVERSITY

Method for synthesizing benzyl acetate

InactiveCN1438212ANo pollution in the processPreparation by caroxylic acid/anhydride-hydrocarbon reactionAcetic acidMetallole

The invention is a new method of synthesizing benzyl acetate. Its character: adopting methylbenzene as raw material, acetic acid as solvent and cobalt complex as catalyzer and using molecular oxygen to directly oxidize the methylbenzene to synthesize it.

Owner:DALIAN UNIV OF TECH

Process for the functionalization of heteroalkanes and arenes

ActiveUS20170275222A1Improve stabilityLow costPreparation rom asymmetrical anhydridesPreparation by oxidation reactionsMain group elementHydrogen atom

Provided are methods and materials for the functionalization of a heteroalkane or arene using an oxidizing electrophile as a stoichiometric agent or catalyst. The reaction involves the replacement of a hydrogen atom on an sp3-hybridized carbon atom of the heteroalkane or of a hydrogen atom on an sp2-hybridized carbon atom of the arene. A main group element organometallic intermediate is formed that undergoes further conversion to a functionalized heteroalkane or arene.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Biphenyl esters, their production and their use in the manufacture of plasticizers

ActiveUS9556103B2Attractive combinationReduce volatilityOrganic compound preparationPreparation by caroxylic acid/anhydride-hydrocarbon reactionPlasticizerMethyl group

A biphenyl diester useful as a plasticizer having the formula (I):wherein R1 is an alkyl group having 5 to 15 carbon atoms and R2 is a methyl group or a phenyl group.

Owner:EXXONMOBIL CHEM PAT INC

Process for producing organic compound using nitrite

InactiveCN1443734APreparation by oxidation reactionsOrganic compound preparationSimple Organic CompoundsNitrite

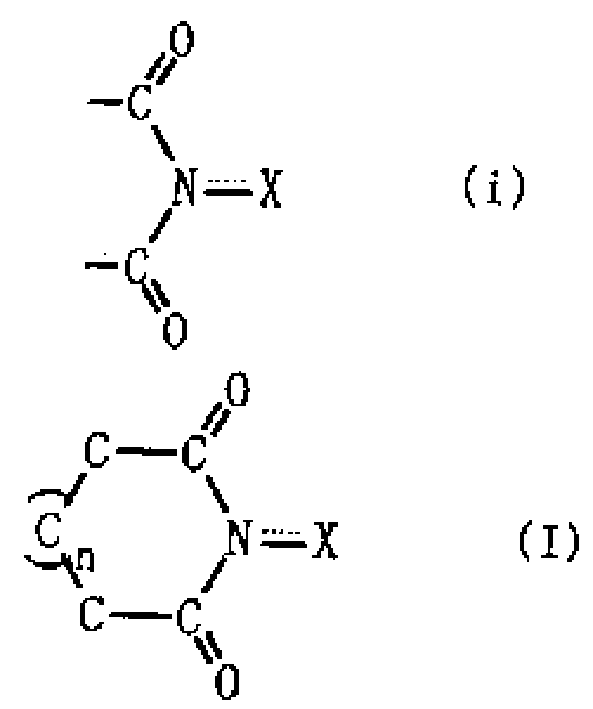

A method for producing an organic compound by making at least one of (A) a compound capable of generating free radicals and (B) an ester and a salt of nitrous acid have, in its ring structure, compositionally represented by the above formula (i) The nitrogen-containing cyclic compound of the skeleton is reacted in the presence of the ring compound, wherein X is one of an oxygen atom and an -OR group, and wherein R is one of a hydrogen atom and a hydroxyl protection group. Examples of nitrogen-containing cyclic compounds include cyclic imide compounds having a cyclic imide skeleton represented by the above formula (I), wherein n is one of 0 and 1; X is one of an oxygen atom and an -OR group species, and wherein R is one of a hydrogen atom and a hydroxyl protecting group.

Owner:DAICEL CHEM IND LTD

Synthesizing method of propiophenone compound

ActiveCN105646220AEasy to operateThe synthetic route is simplePreparation by caroxylic acid/anhydride-hydrocarbon reactionOrganic acidOrganic solvent

The invention provides a synthesizing method of a propiophenone compound, and belongs to the technical field of organic synthesizing. The synthesizing method has the advantages that the reaction steps for synthesizing the propiophenone compound can be simplified, and the reaction cost is reduced. The synthesizing method of the propiophenone compound comprises the following steps of adding propylbenzene, organic acid, iodine and tert-butyl hydroperoxide into a reaction kettle, and reacting for 8-24h at the temperature of 80-120 DEG C; after the reaction is finished, extracting a reaction solution by an organic solvent, and drying, so as to obtain the propiophenone compound. The synthesizing method can be used for the synthesizing and preparation of the propiophenone compound.

Owner:吉林中科研伸科技有限公司

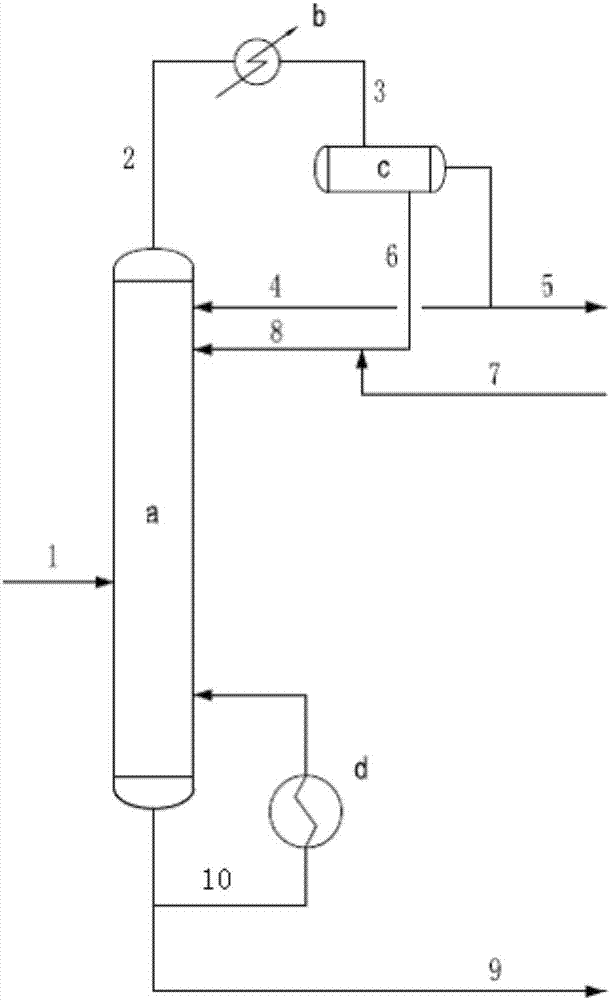

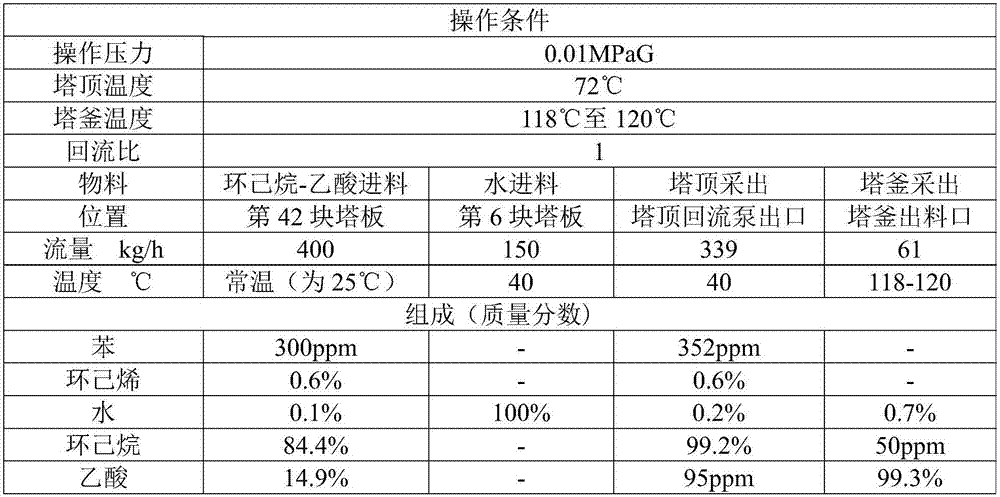

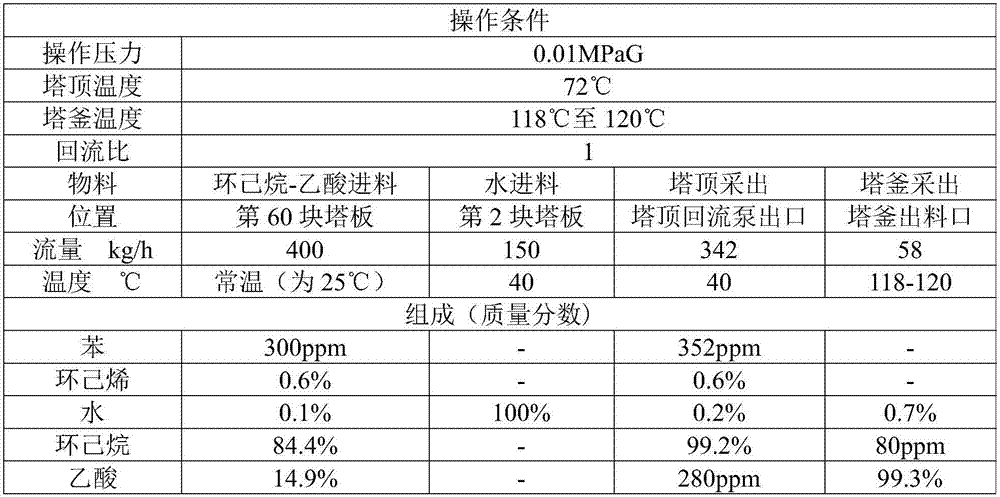

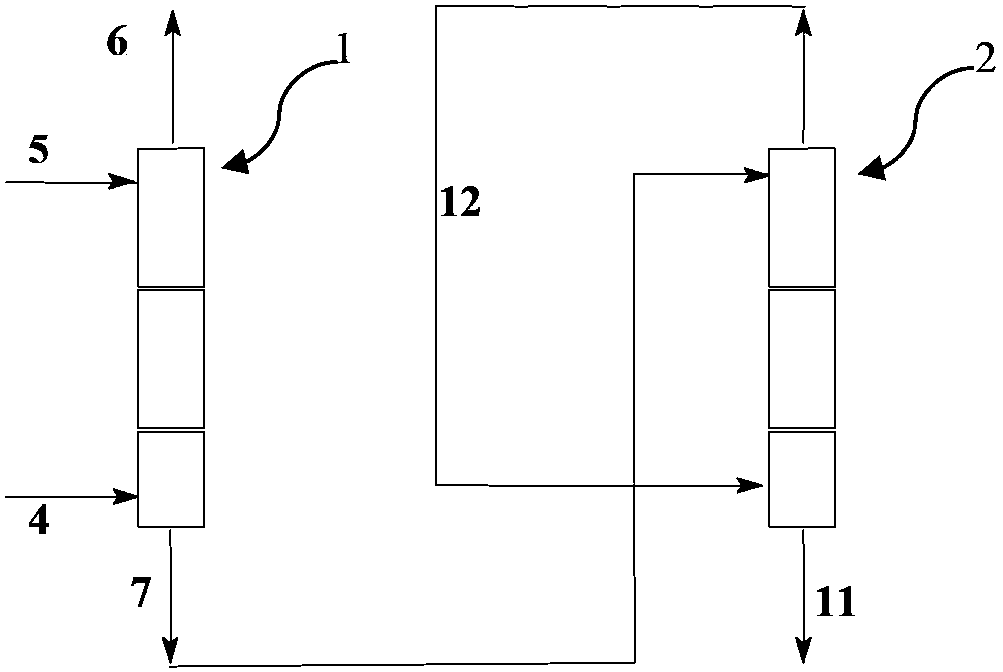

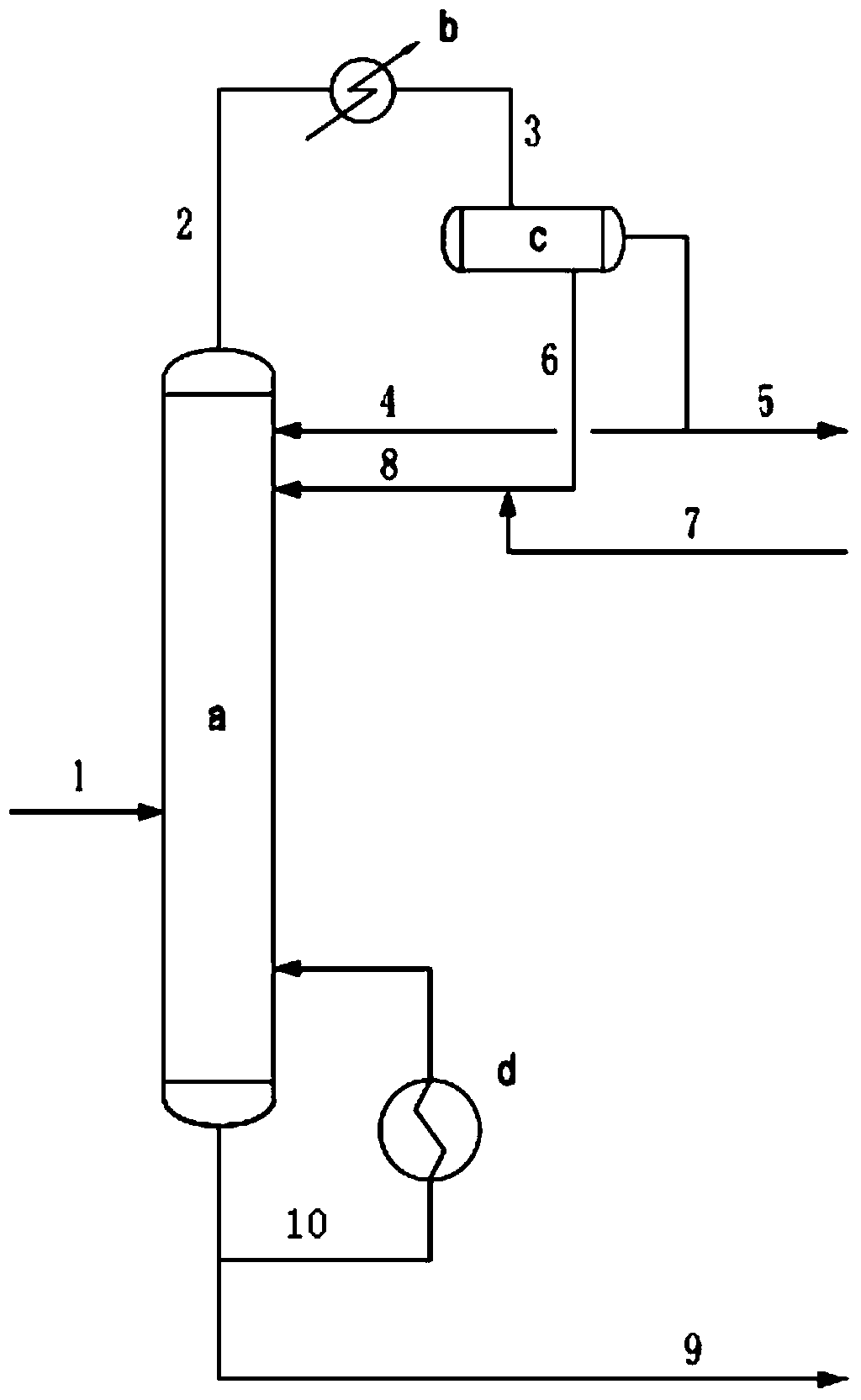

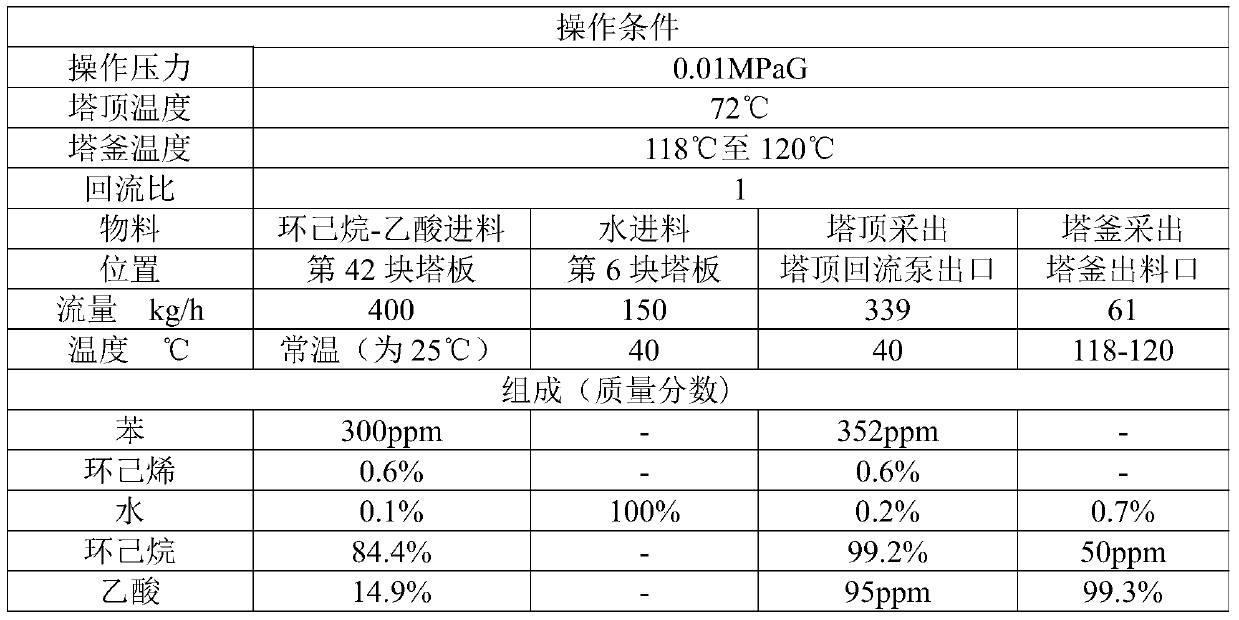

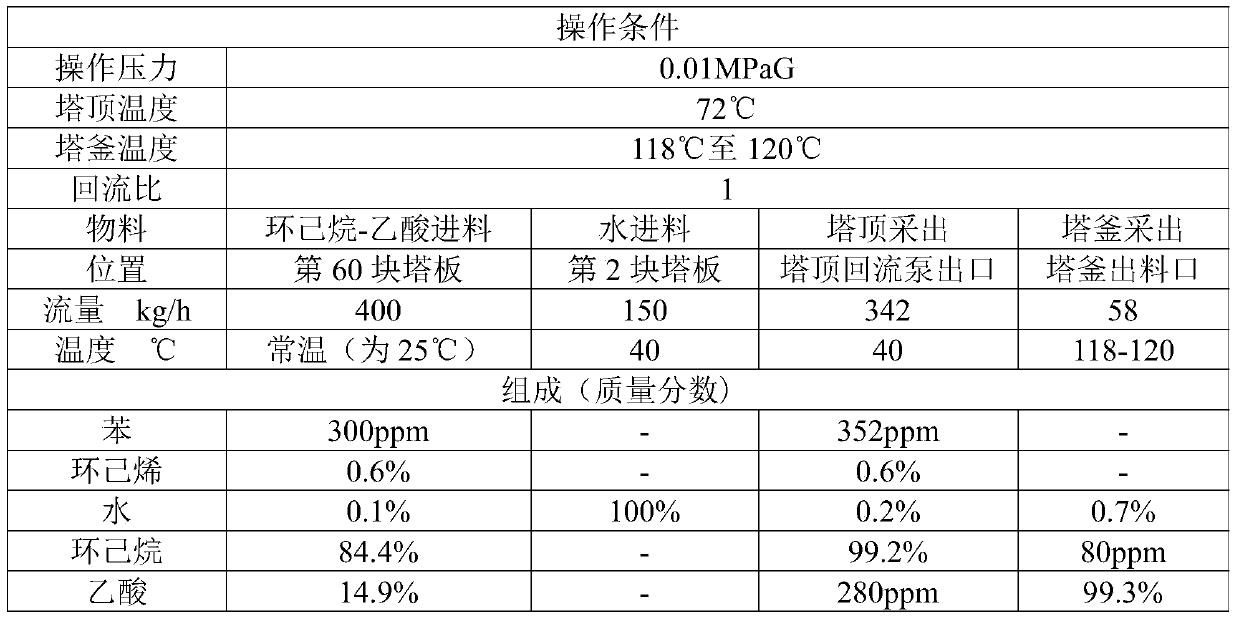

Separation method of material flow containing cyclohexane and acetic acid, production method of cyclohexyl acetate and method for simultaneous production of cyclohexanol and ethanol

ActiveCN107226771AReduce contentOrganic compound preparationPreparation by caroxylic acid/anhydride-hydrocarbon reactionAcetic acidOil phase

The invention discloses a separation method of a material flow containing cyclohexane and acetic acid. The separation method comprises the following steps: performing azeotropic distillation on a raw material flow containing cyclohexane and acetic acid and an azeotropic agent in a distillation tower to obtain an azeotrope-containing distillate and an acetic acid-containing bottom product, wherein the azeotropic agent is water, and the azeotrope is a water-cyclohexane azeotrope; and optionally separating the distillate into an oil phase and a water phase to respectively obtain the cyclohexane and the water. The invention also discloses a production method of cyclohexyl acetate adopting the separation method and a method for simultaneous production of cyclohexanol and ethanol adopting the separation method. The acetic acid content in the cyclohexane obtained by the separation method is low. Besides, the cyclohexane-water azeotrope separated out can be further separated through conventional sedimentation, and the water separated out can be directly recycled as the azeotropic agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing sec-butyl acetate through utilizing etherification C4 fraction

ActiveCN103508884AEasy purityHigh purityOrganic compound preparationPreparation by caroxylic acid/anhydride-hydrocarbon reactionAlkaneEther

The invention discloses a method for preparing sec-butyl acetate through utilizing an etherification C4 fraction. The method comprises the following steps: 1, allowing the etherification C4 fraction containing butylene to contact with excess acetic acid in the presence of a catalyst to obtain crude sec-butyl acetate containing acetic acid; and 2, allowing the residual n-butylene to contact with the crude sec-butyl acetate containing acetic acid in the presence of the catalyst to obtain highly pure sec-butyl acetate. The highly pure sec-butyl acetate can be obtained through two steps by using the present catalyst via the method, so the process flow is simple; olefins and alkanes in the etherification C4 fraction are separated, and the highly-pure sec-butyl acetate can be obtained without a separation step; and the adoption of the etherification C4 fraction as a raw material improves the utilization rate of the C4 fraction and greatly reduces the production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating streams containing cyclohexane and acetic acid, method for producing cyclohexyl acetate, and method for co-producing cyclohexanol and ethanol

ActiveCN107226771BReduce contentOrganic compound preparationPreparation by caroxylic acid/anhydride-hydrocarbon reactionAcetic acidCyclohexanol

The invention discloses a separation method of a material flow containing cyclohexane and acetic acid. The separation method comprises the following steps: performing azeotropic distillation on a raw material flow containing cyclohexane and acetic acid and an azeotropic agent in a distillation tower to obtain an azeotrope-containing distillate and an acetic acid-containing bottom product, wherein the azeotropic agent is water, and the azeotrope is a water-cyclohexane azeotrope; and optionally separating the distillate into an oil phase and a water phase to respectively obtain the cyclohexane and the water. The invention also discloses a production method of cyclohexyl acetate adopting the separation method and a method for simultaneous production of cyclohexanol and ethanol adopting the separation method. The acetic acid content in the cyclohexane obtained by the separation method is low. Besides, the cyclohexane-water azeotrope separated out can be further separated through conventional sedimentation, and the water separated out can be directly recycled as the azeotropic agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Hydroxy group formation/introduction Oxygen compounds preparation by hydrocarbon oxidation Preparation by hydroxy group addition Oxygen compounds preparation by reduction Hydroxy compound preparation Aldehyde active ingredients Animal repellants Plant growth regulators Biofuels Solid sorbent liquid separation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com