A sec-butanol production process

A production process, the technology of sec-butanol, is applied in the preparation of organic compounds, the reaction preparation of carboxylic acid/symmetric anhydride and saturated hydrocarbon, organic chemistry, etc. It can solve the problems of high hydrogen mole, high temperature and low catalyst space velocity, etc. Achieve the effects of increasing the space velocity, reducing the serious corrosion of equipment, and reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

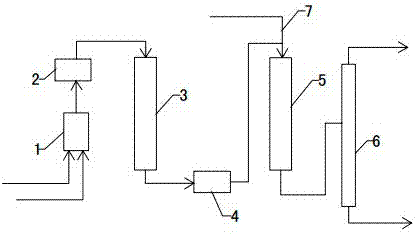

[0026] Adopt above-mentioned attached of the present invention figure 1 The process flow shown: Propionic acid and carbon four are used as raw materials, the content of n-butene in carbon four is 85%, resin is used as a catalyst, a fixed-bed reactor is used, the reaction temperature is 70°C, and the conversion rate of n-butene is 52.5% . Using the sec-butyl propionate generated by the reaction as the raw material, the ester hydrogenation process is used to produce sec-butanol, and the catalyst used is Cu-Pt-Al 2 o 3 , where the mass fraction of Pt is 0.12wt%, the mass fraction of Cu is 32.3wt%, and the rest is alumina, the reaction temperature is 190°C, and the mass space velocity is 1.0h -1 , the conversion rate of sec-butyl propionate is 98%, the yield of sec-butanol is 95.5%, and the single pass conversion rate of n-butene in the invention process is 51.45%.

Embodiment 2

[0028] Adopt above-mentioned attached of the present invention figure 1 The process flow shown: Propionic acid and n-butene are used as raw materials, the content of n-butene in C4 is 25%, resin is used as a catalyst, a fixed-bed reactor is used, the reaction temperature is 70°C, and the conversion rate of n-butene is 51.5%. . The sec-butyl propionate generated by the reaction is used as the raw material, and the catalyst used is Cu-Pt-Al2 o 3 , wherein the mass fraction of Pt is 0.10wt%, the mass fraction of Cu is 33.9wt%, and the rest is alumina, the reaction temperature is 200°C, and the mass space velocity is 0.8h -1 , the conversion rate of sec-butyl propionate is 96%, the yield of sec-butanol is 94.5%, and the single pass conversion rate of n-butene in the invention process is 49.44%.

Embodiment 3

[0030] Adopt above-mentioned attached of the present invention figure 1 The process flow shown: Propionic acid and n-butene are used as raw materials, the content of n-butene in C4 is 45%, resin is used as a catalyst, a fixed-bed reactor is used, the reaction temperature is 90°C, and the conversion rate of n-butene is 53.5%. . The sec-butyl propionate generated by the reaction is used as the raw material, and the catalyst used is Cu-Pt-Al 2 o 3 , where the mass fraction of Pt is 0.40wt%, the mass fraction of Cu is 50wt%, and the rest is alumina, the reaction temperature is 180°C, and the mass space velocity is 2h -1 , the conversion rate of sec-butyl propionate is 95.7%, the yield of sec-butanol is 93.5%, and the single-pass conversion rate of n-butene in the invention process is 49.29%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com