Method for separating streams containing cyclohexane and acetic acid, method for producing cyclohexyl acetate, and method for co-producing cyclohexanol and ethanol

A technology for cyclohexyl acetate and cyclohexane, applied in the separation/purification of carboxylic acid compounds, chemical instruments and methods, purification/separation of hydrocarbons, etc. Separation, increasing device investment cost and operating cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

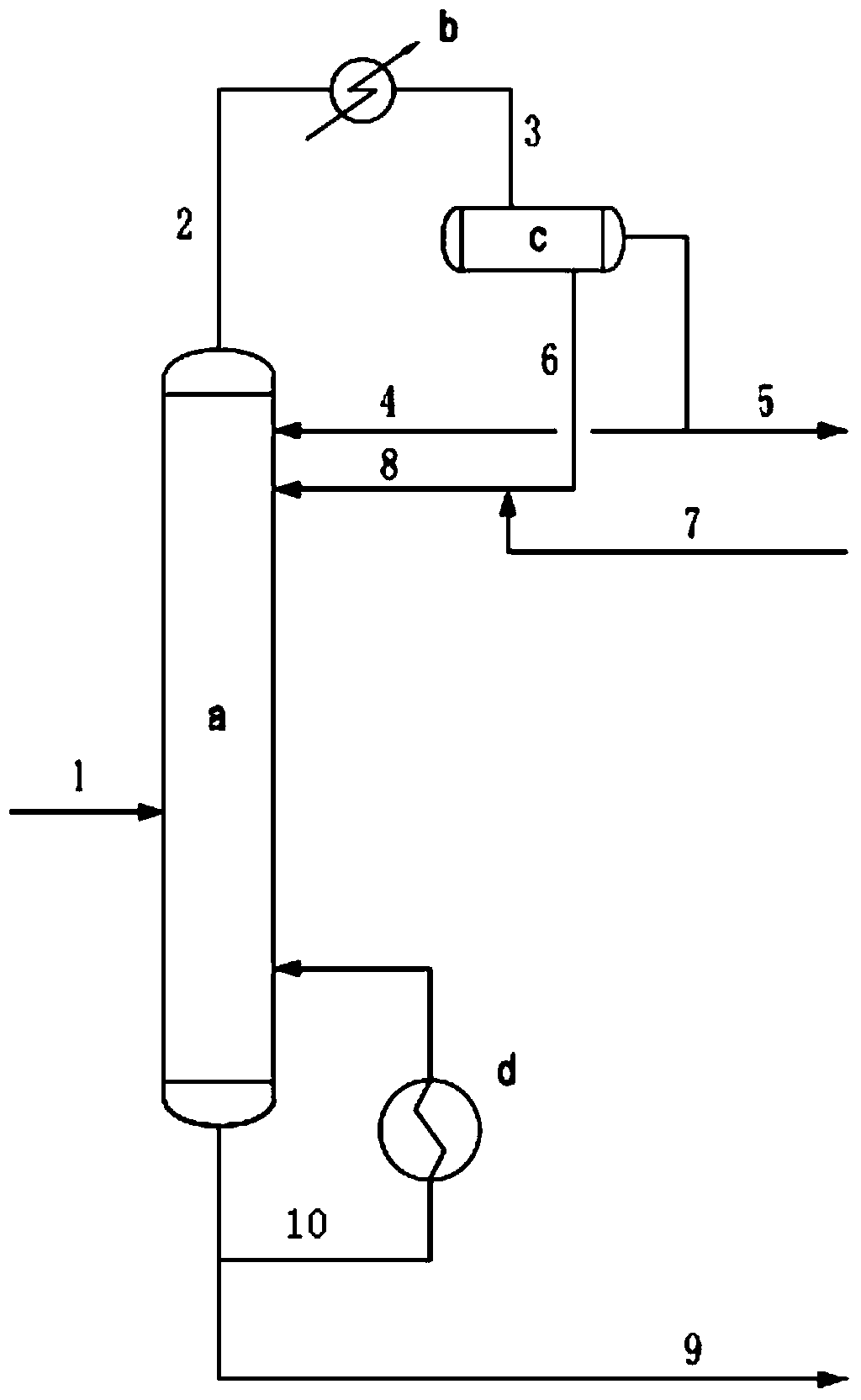

Image

Examples

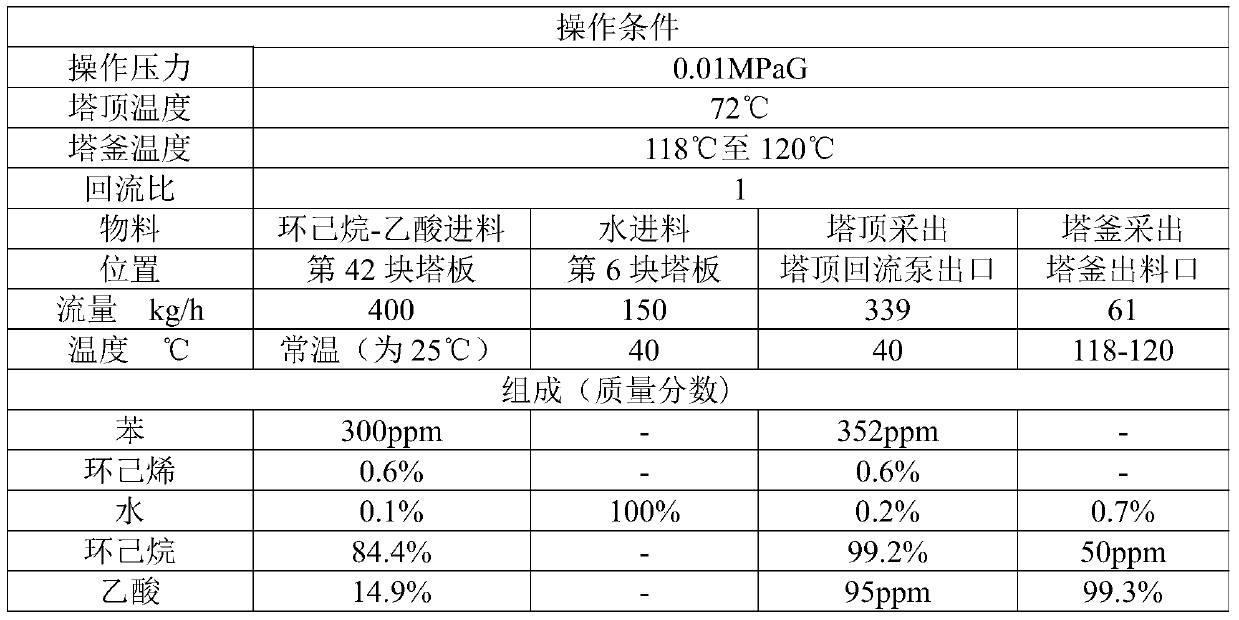

Embodiment 1

[0141] (1) Benzene and hydrogen are injected into the hydrogenation reactor filled with ruthenium particle catalyst at a molar ratio of 1:3, and the hydrogenation reaction of benzene is carried out under the conditions of a reaction temperature of 135 ° C, a pressure of 4.5 MPaG, and a residence time of 15 min. After the hydrogen gas was separated from the reaction product, the liquid product was collected. The collected liquid product was analyzed by gas chromatography, and its composition (mass percentage) was determined to be: 53.3% of benzene, 35.4% of cyclohexene, and 11.3% of cyclohexane. Then, the reaction product is extracted and rectified by using sulfolane as a solvent, and a mixed component of cyclohexene and cyclohexane is obtained at the top of the tower. Carry out gas chromatographic analysis to cyclohexene and cyclohexane, determine the composition (mass percentage content) of the mixed component obtained at the top of the tower to be: cyclohexene 75.7%, cyclohe...

Embodiment 2

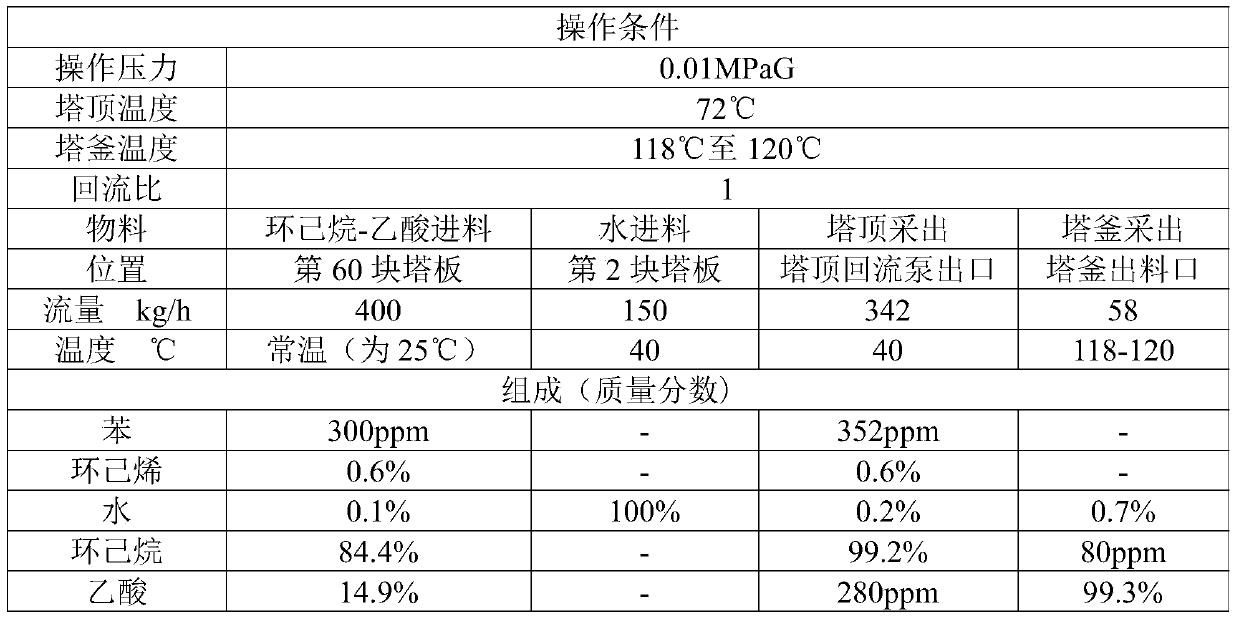

[0150] In this example, the same method as in step (3) of Example 1 is used to separate the mixture stream containing cyclohexane and acetic acid, the difference is that the operating conditions are shown in Table 2. The distillation results are listed in Table 2.

[0151] Table 2

[0152]

Embodiment 3

[0158] (1) The step of providing cyclohexene source

[0159] Benzene and hydrogen are injected into the hydrogenation reactor filled with ruthenium particle catalyst at a molar ratio of 1:3, and the benzene hydrogenation reaction is carried out under the conditions of the reaction temperature of 130°C, the pressure of 5.0MPaG, and the residence time of 20min, and the reaction product is separated After hydrogen evolution, the liquid product was collected. The collected liquid product was analyzed by gas chromatography, and its composition (mass percentage) was determined to be: 50.8% of benzene, 39.4% of cyclohexene, and 9.8% of cyclohexane. Then, the reaction product is extracted and rectified by using sulfolane as a solvent, and a mixed component of cyclohexene and cyclohexane is obtained at the top of the tower. Gas chromatographic analysis was carried out on cyclohexene and cyclohexane, and the composition (mass percentage) of the mixed component obtained at the top of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com