Patents

Literature

31results about How to "Easy purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

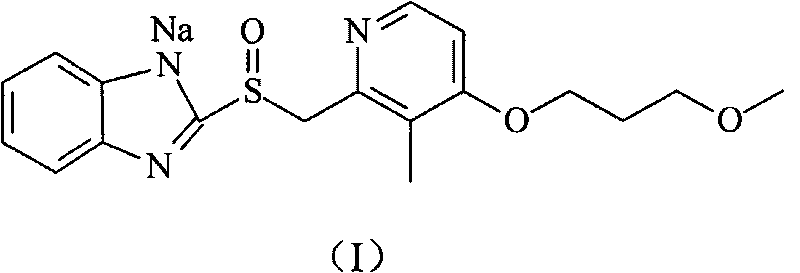

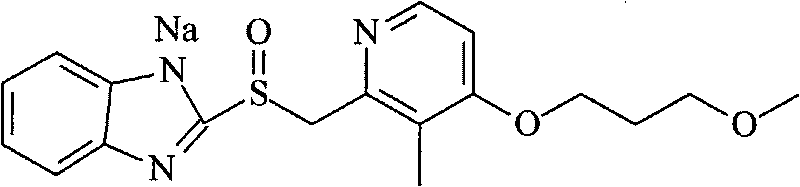

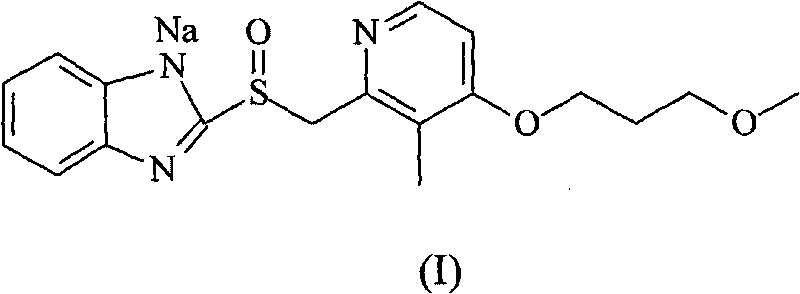

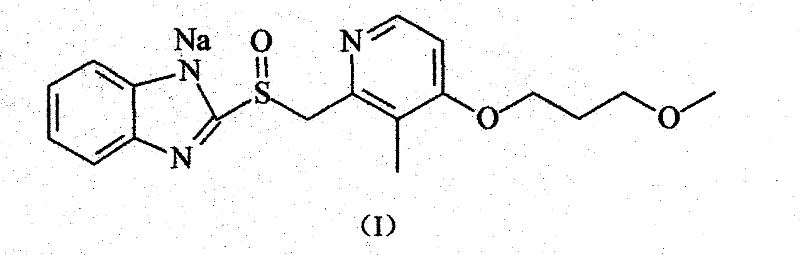

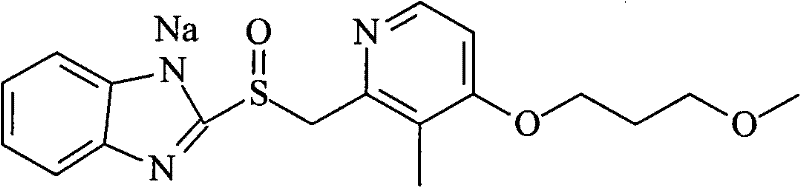

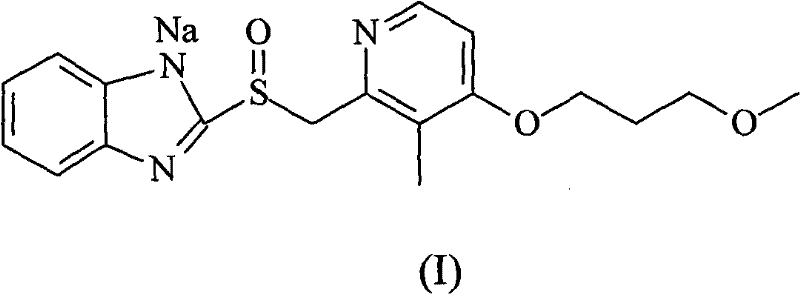

High-purity sodium rabeprazole compound

InactiveCN101704811AOvercome purityOvercome the disadvantages of difficult purificationOrganic chemistryOrganic solventRabeprazole

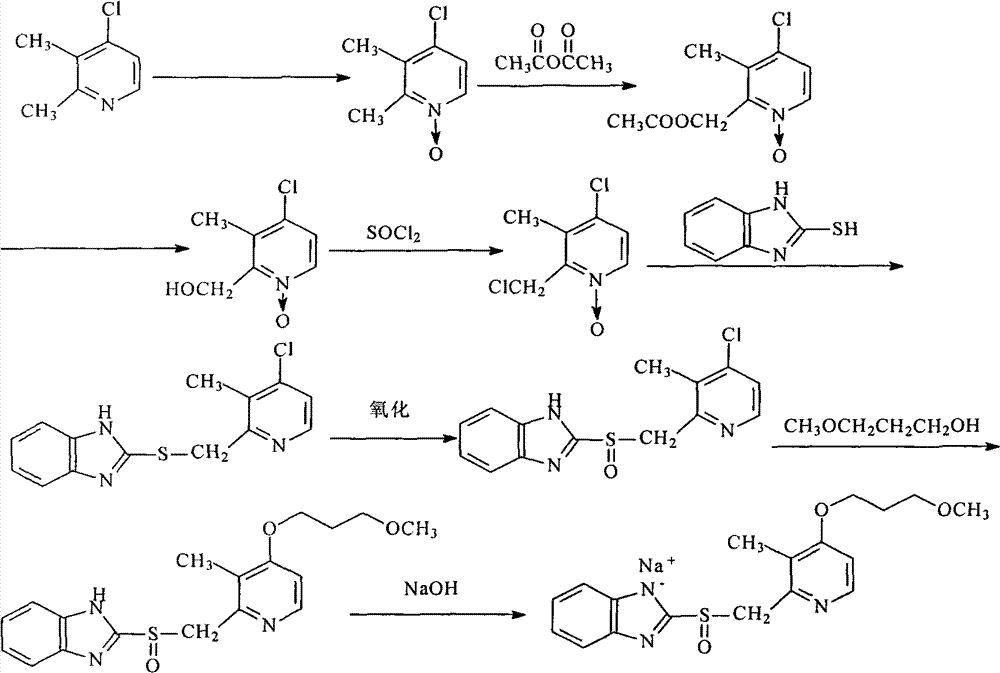

The invention relates to a high-purity sodium rabeprazole compound, belonging to the technical field of medicine. The method includes the following steps: dissolving crude sodium rabeprazole synthesized by the reaction of rabeprazole and sodium hydroxide in water, adjusting pH value to be faintly acid to neutral by using solid acid salt, and collecting precipitated solid; after dissolving the solid with organic solvent, conducting elution and purification by using eluting agent through macroporous adsorption resin, and collecting eluent; and adjusting the pH value of the eluent to be alkaline, and collecting the precipitated solid to obtain the pure sodium rabeprazole.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

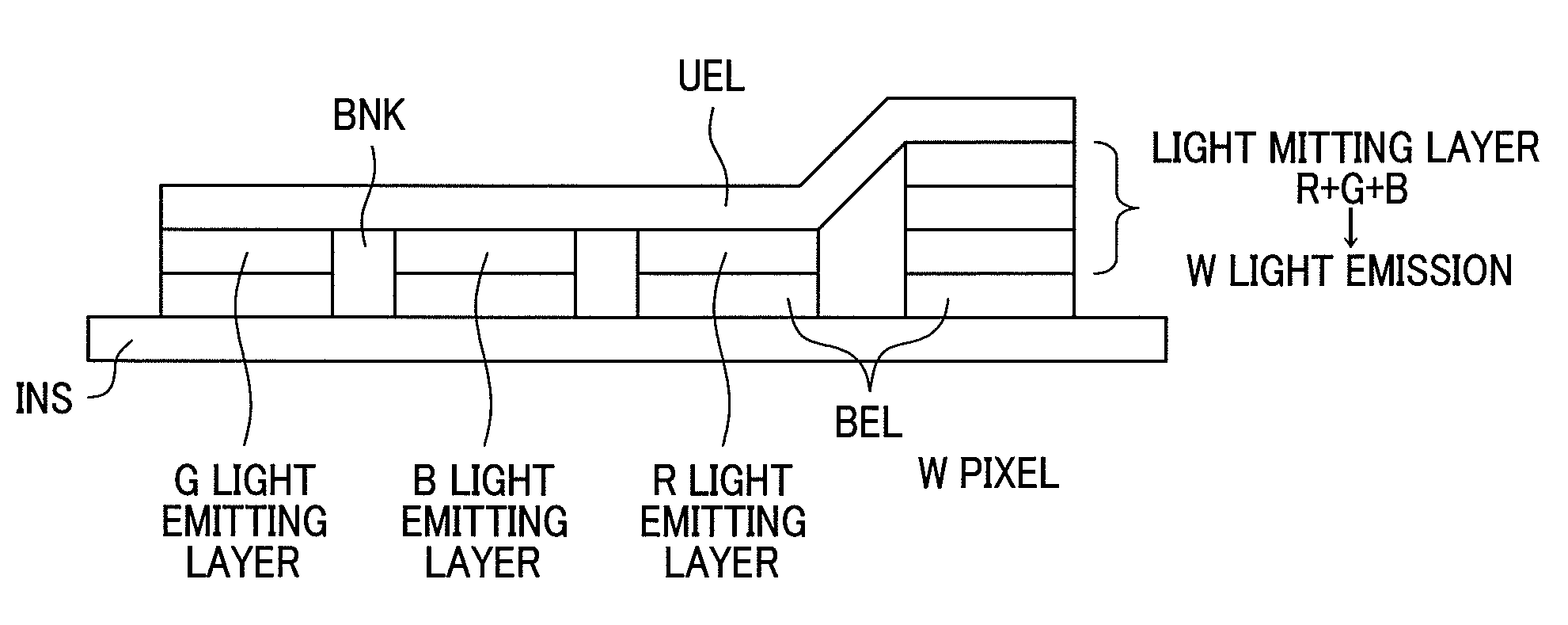

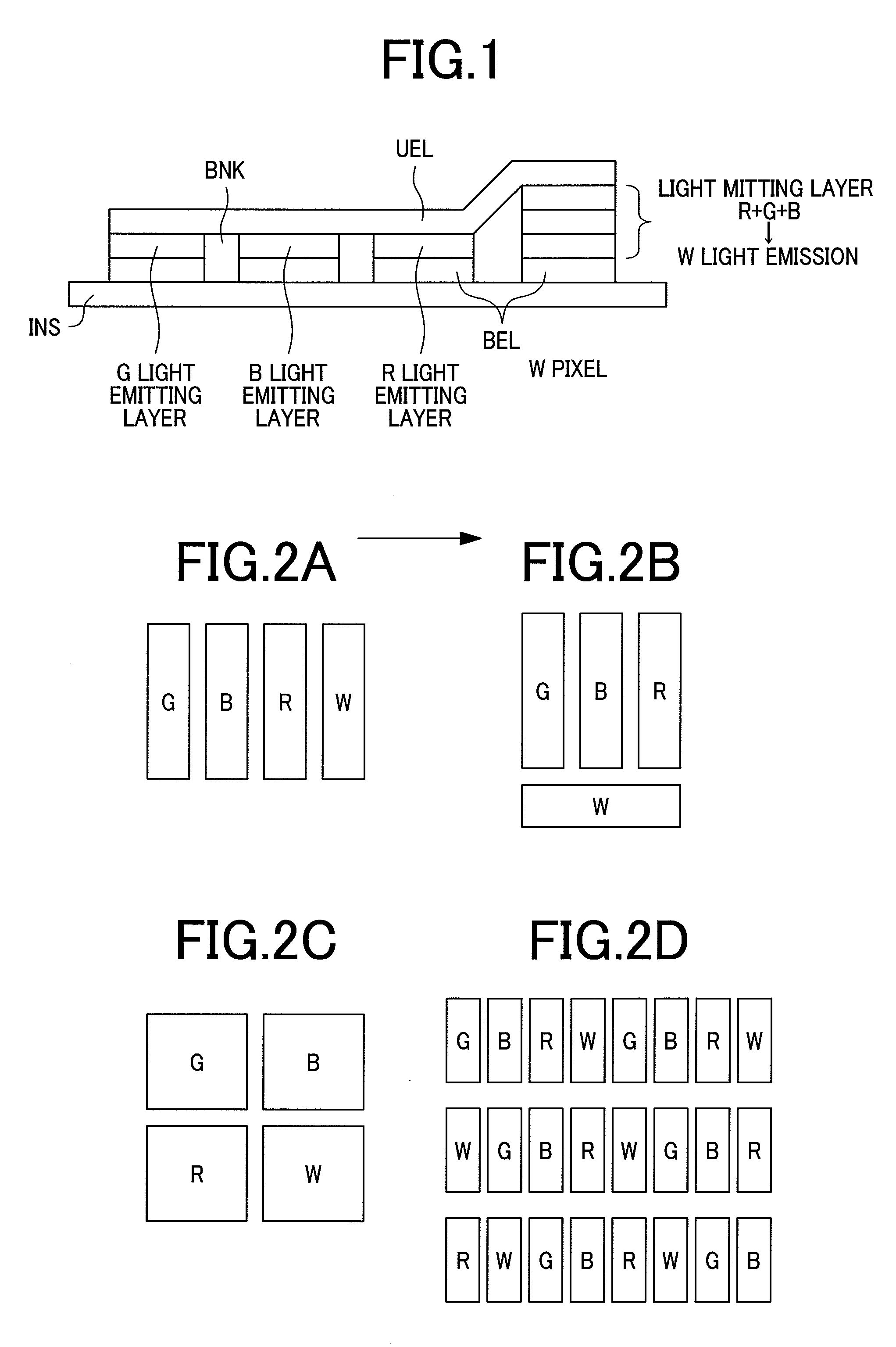

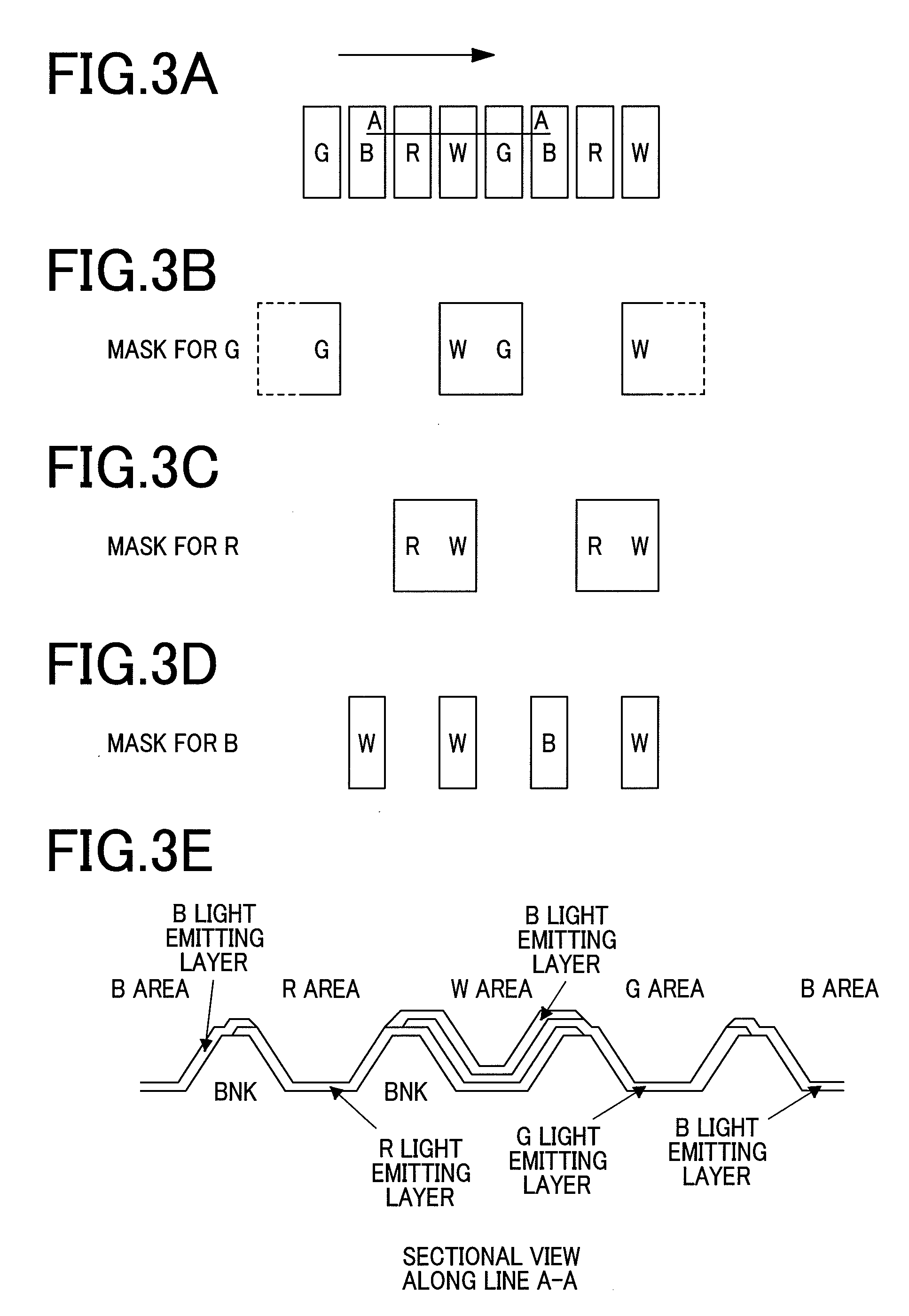

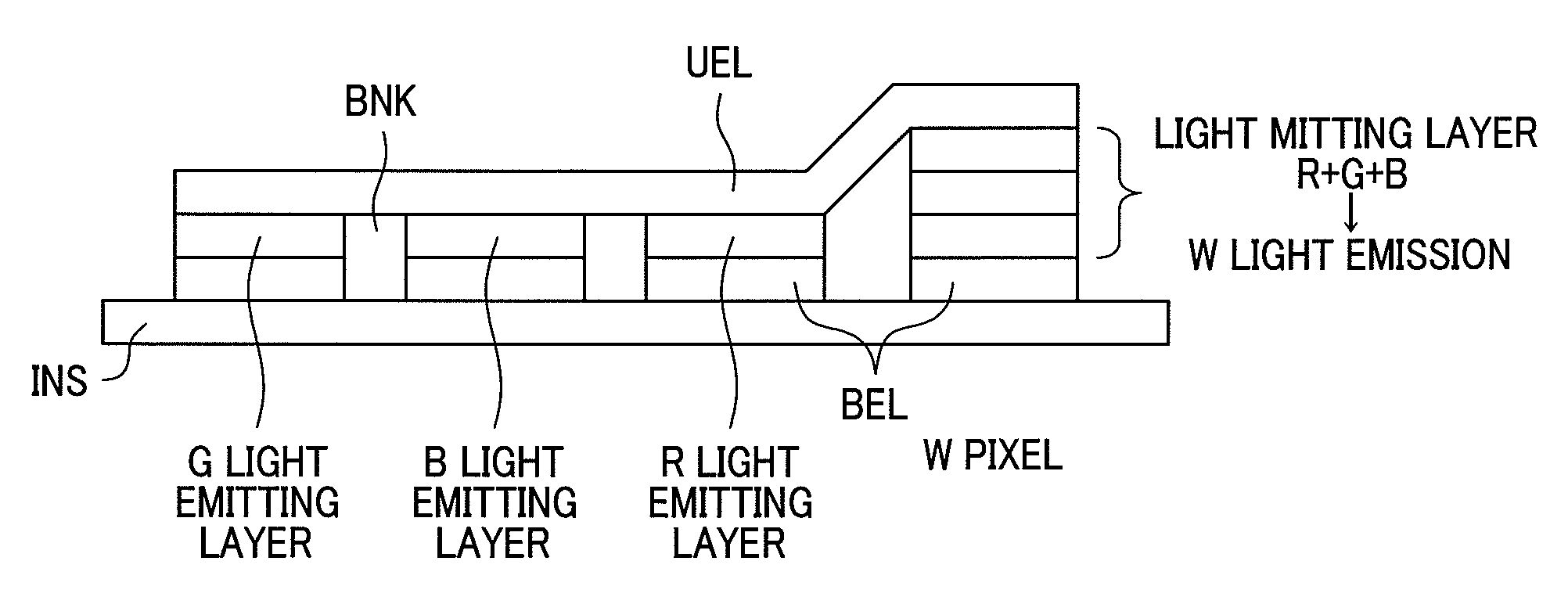

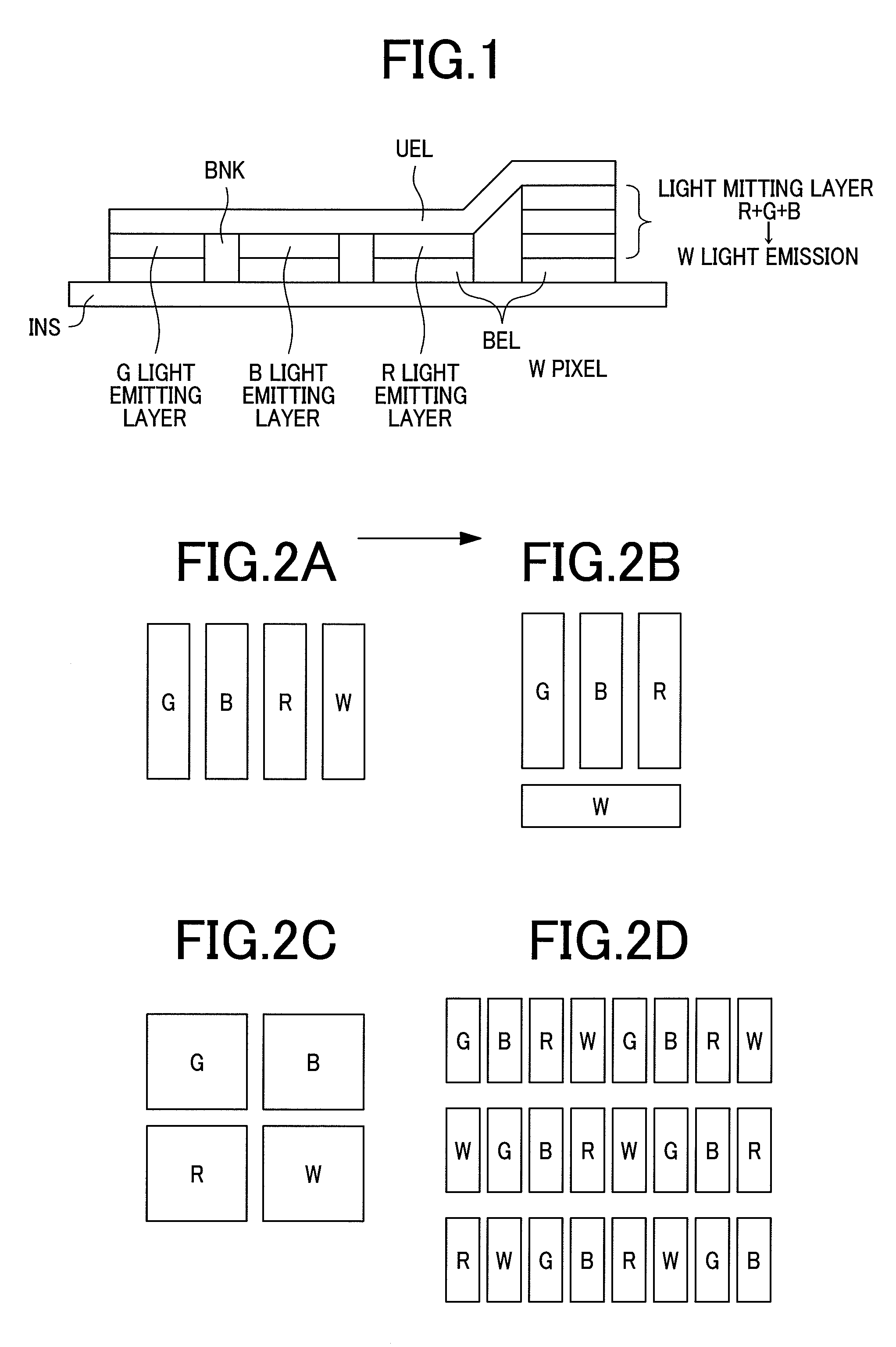

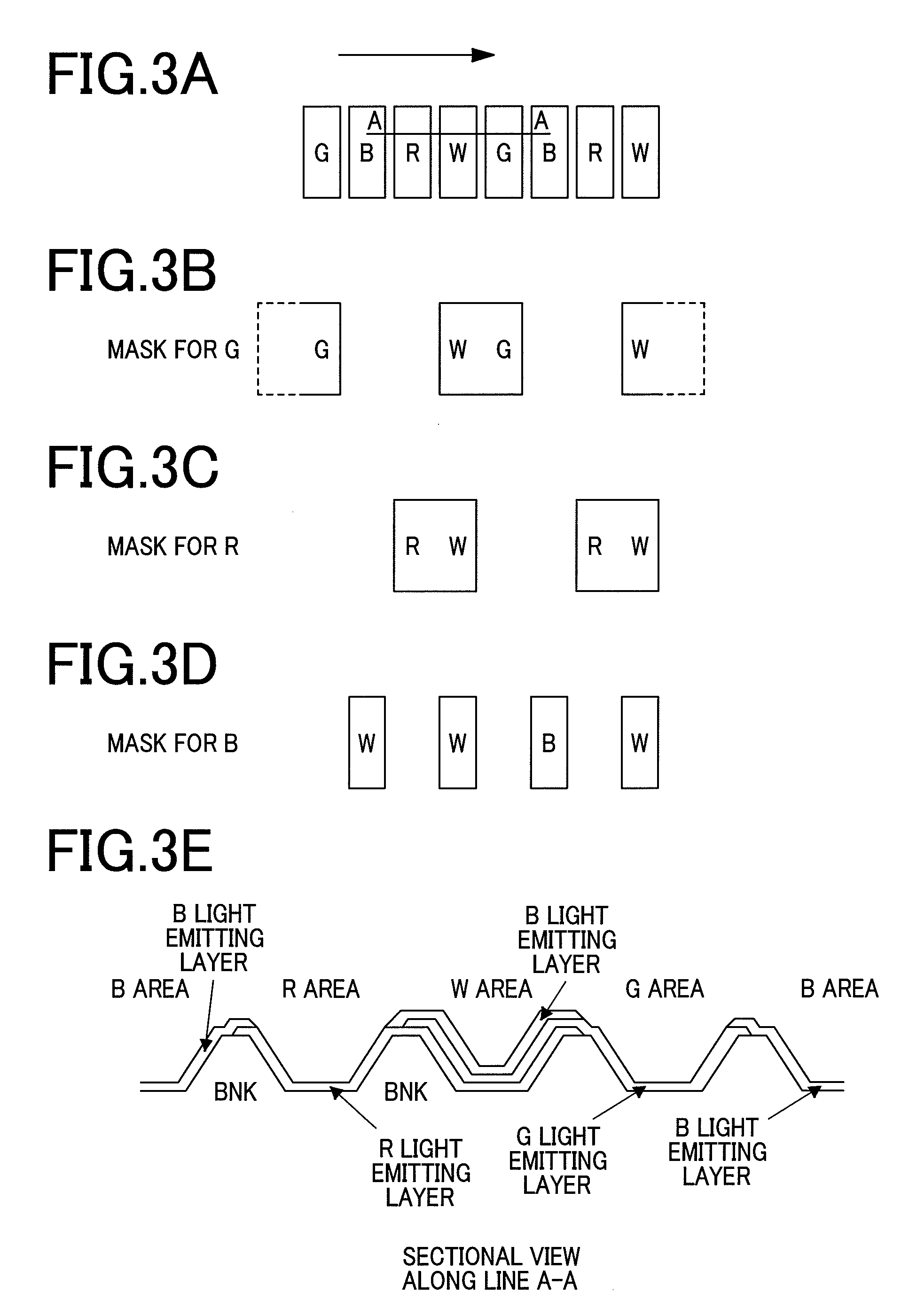

Organic electroluminescence display device

ActiveUS20070200495A1Increase pixel formation processColor purity can be easilyDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceGreen-light

The recent invention provide an organic electroluminescence display device with color purity adjustment, particularly white purity increased, without increasing formation processes. For each of unit pixels formed on an insulating film INS formed on a principal surface of a glass substrate, a bank BNK is provided on a bottom electrode BEL being a pixel electrode. The bank BNK has the shape of a bank that surrounds a pixel concerned, for each of pixels, and an organic electroluminescence light emitting layer is charged within a region surrounded by the banks BNKs. Between the banks BNKs, a green light emitting layer (G light emitting layer), a blue light emitting layer (B light emitting layer), and a red light emitting layer (R light emitting layer) are provided. At the same time as the formation of these color light emitting layers, light emitting layers of three colors, the green light emitting layer (G light emitting layer), the blue light emitting layer (B light emitting layer), and the red light emitting layer (R light emitting layer) are stacked on a region of a white pixel to form a white light emitting layer (G+B+R). An upper electrode UEL is formed over the green light emitting layer (G light emitting layer), the blue light emitting layer (B light emitting layer), the red light emitting layer (R light emitting layer), and the white light emitting layer (G+B+R light emitting layer).

Owner:SAMSUNG DISPLAY CO LTD +1

Method for producing cyclic organic silicon compound and organic silicon resin having alcoholic hydroxyl group

ActiveUS20070055036A1High puritySecondary reaction can be suppressedSilicon organic compoundsPolymer sciencePtru catalyst

The object of the present invention is to provide a production method wherein synthesis of a cyclic organic silicon compound similar to oxa-silacyclopentanes is completed in a single-step reaction. It is also to provide an organic silicon resin having an alcoholic hydroxyl group, which is capable of easily controlling its construction and is longitudinally stable. The means for solving is to produce the cyclic organic silicon compound represented by the formula (3) below by reacting an olefin represented by the formula (1) below and an alkoxysilane represented by the formula (2) below in the presence of a catalyst comprising a transition metal. (In the formula, Z is alkenyl group having carbon atoms from 2 to 5 where the terminal carbon atom forms a C═C bond, R is methyl group or hydrogen atom, and Me is methyl group.) (In the formula, R1 is alkyl group or alkoxyl group, having carbon atoms from 1 to 3, and R2 is alkyl group having carbon atoms from 1 to 3.) (In the formula, Z′ is alkylene group having carbon atoms from 2 to 5.) And it is an organic silicon resin having an alcoholic hydroxyl group obtained by performing hydrolysis and condensation of a cyclic organic silicon compound represented by the formula (3) above, or of a mixture of this and a polyfunctional alkoxysilane.

Owner:TOAGOSEI CO LTD

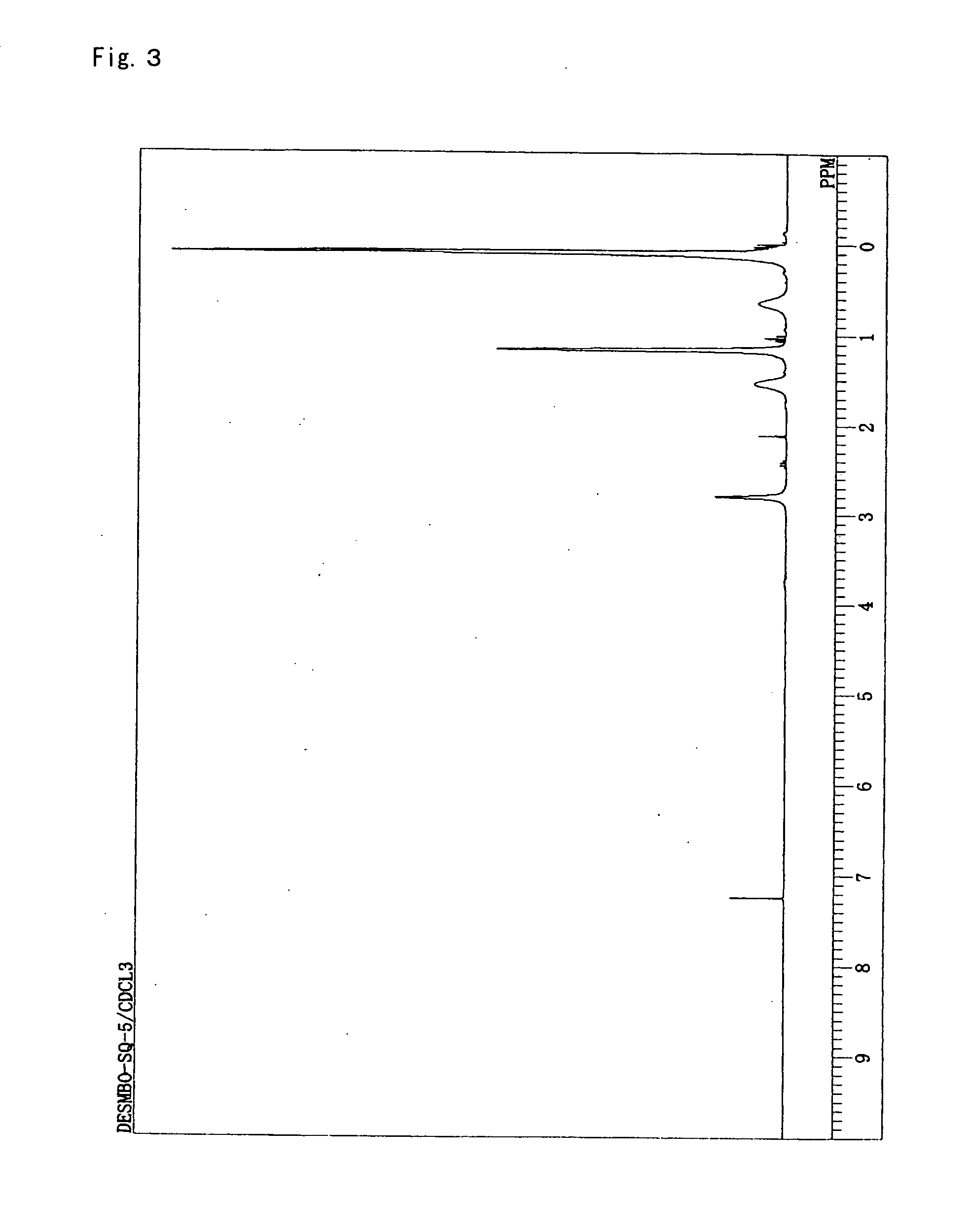

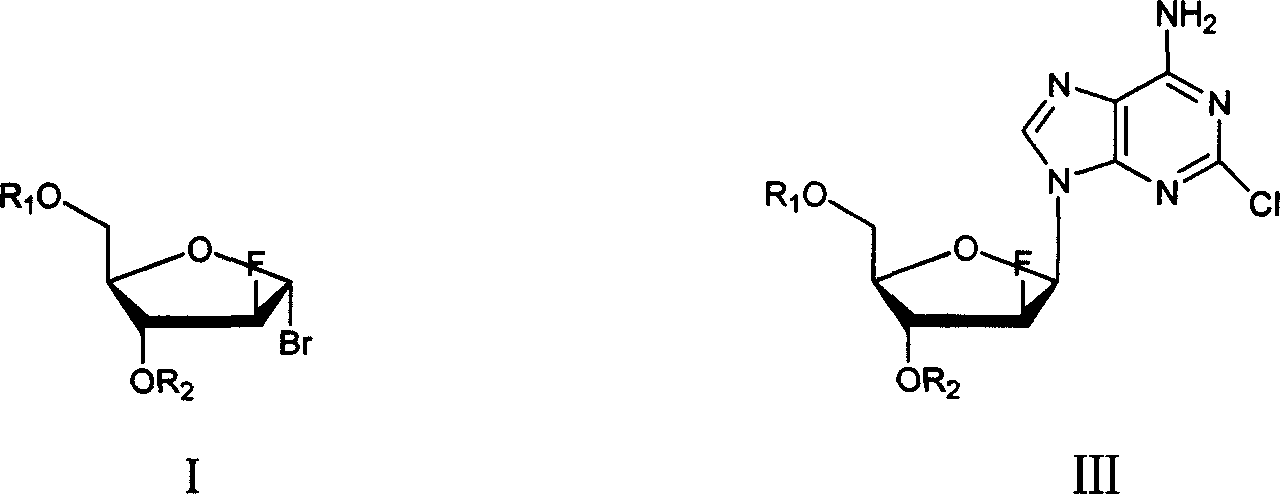

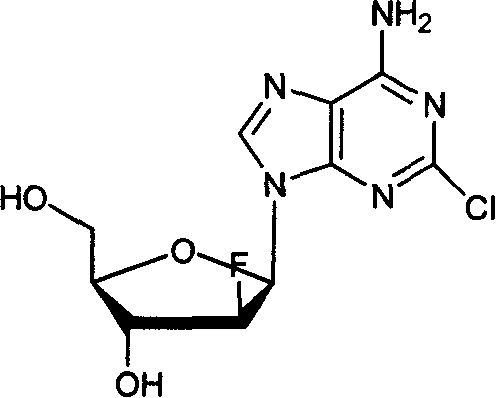

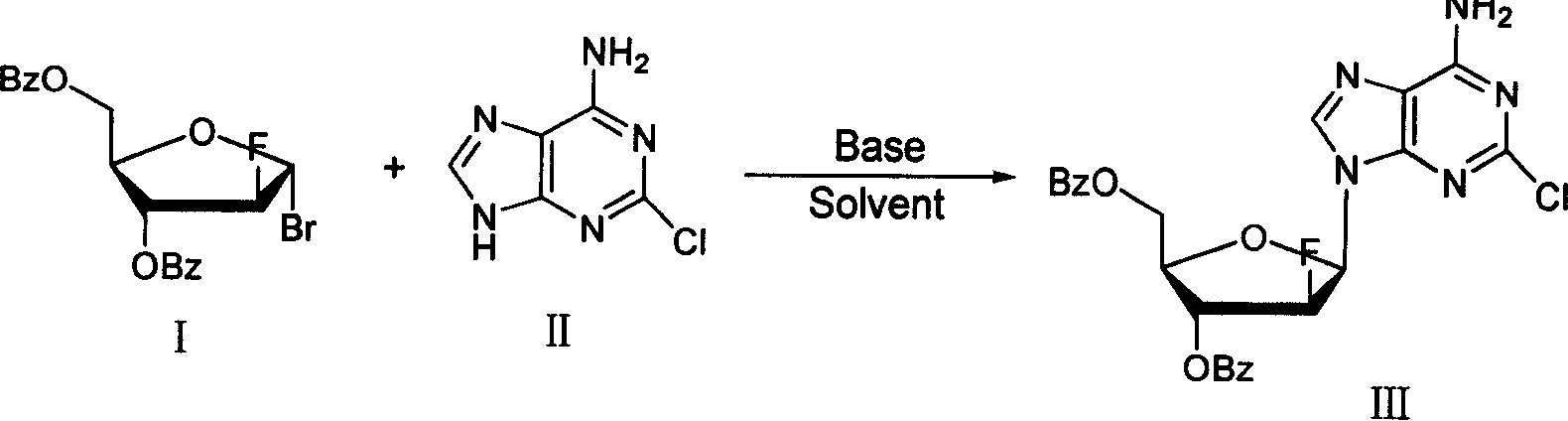

Method of producing high purity clofarabine

The present invention relates to a preparation method of clofarabine, comprising mixture of 2-adenine chlorine and the compound of formula I. the reaction is done under mild conditions and an appropriate temperature; the basically pure compound of the formula III can be prepared after separation. The high-purity clofarabine can be got through hydrolysis under alkaline conditions.

Owner:BEIJING D VENTUREPHARM TECH DEV

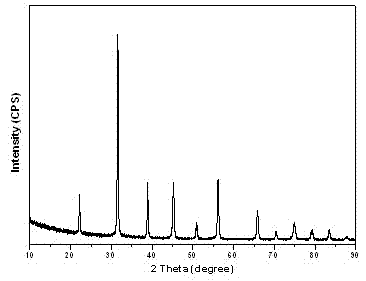

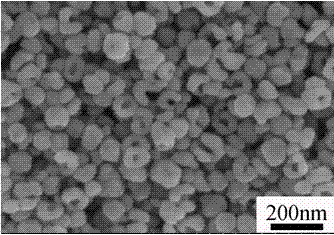

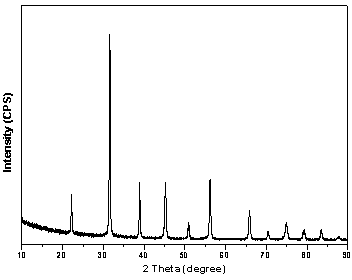

Preparation method of tetragonal-phase barium titanate (BaTiO3) hollow nanocrystal

ActiveCN102887705AEasy purityA simple solvothermal method prepared high-purityBarium titanatePotassium hydroxide

The invention discloses a preparation method of a tetragonal-phase barium titanate (BaTiO3) hollow nanocrystal. The preparation method comprises the following steps of: using barium acetate and tetrabutyl titanate as raw materials, adding deionized water, adding potassium hydroxide of an appropriate amount to promote crystallization, and carrying out hydrothermal reaction at the temperature of 110-240 DEG C so as to prepare the tetragonal-phase barium titanate (BaTiO3) hollow nanocrystal. The preparation method is simple in technical process, easy in control, low in cost and easy in scale production. The prepared product is high in purity, good in crystallinity, good in dispersivity and narrow in particle size distribution. The product has wide application prospects in the fields of microelectronic devices, high-capacity capacitors, sensors, storage materials, piezoelectric ceramics, filters and the like.

Owner:ZHEJIANG UNIV

Method for preparing lithium hexafluorophosphate by using composite solvent

InactiveCN102491305ALow boiling pointResidue reductionSecondary cellsPhosphorus compoundsDistillationEvaporation

The invention relates to a safe and reliable method for preparing lithium hexafluorophosphate by using a composite solvent. The technical steps of the method are simple. The method comprises steps that: anhydrous phosphoric acid, calcium fluoride and sulfur oxide are subject to a reaction, such that PF5 gas is obtained by evaporation; the evaporated PF5 gas is dehydrated, such that a high-purity anhydrous PF5 product is obtained; diethyl ether and anhydrous methyl cyanide are respectively dehydrated, such that high-purity diethyl ether and anhydrous methyl cyanide are obtained; high-purity lithium fluoride is added to the diethyl ether solution; methyl cyanide is added to the obtained solution; the PF5 gas is slowly delivered into the solution while stirring; when a reaction is finished, high-purity nitrogen is delivered into the solution, such that displacement is carried out until no PF5 gas is remained in a vessel; a dry product Li(CH3CN)4PF6 obtained through distillation is heatedand decomposed, such that LiPF6 is prepared; LiPF6 is dissolved under room temperature, such that a solution with a concentration of 1M is obtained; the solution is filtered by using a precise filterwith a specification of 0.2mum, such that a clarified solution is obtained; the solution is dried, such that a pure LiPF6 product is obtained.

Owner:山东省智能光电新能源研究院

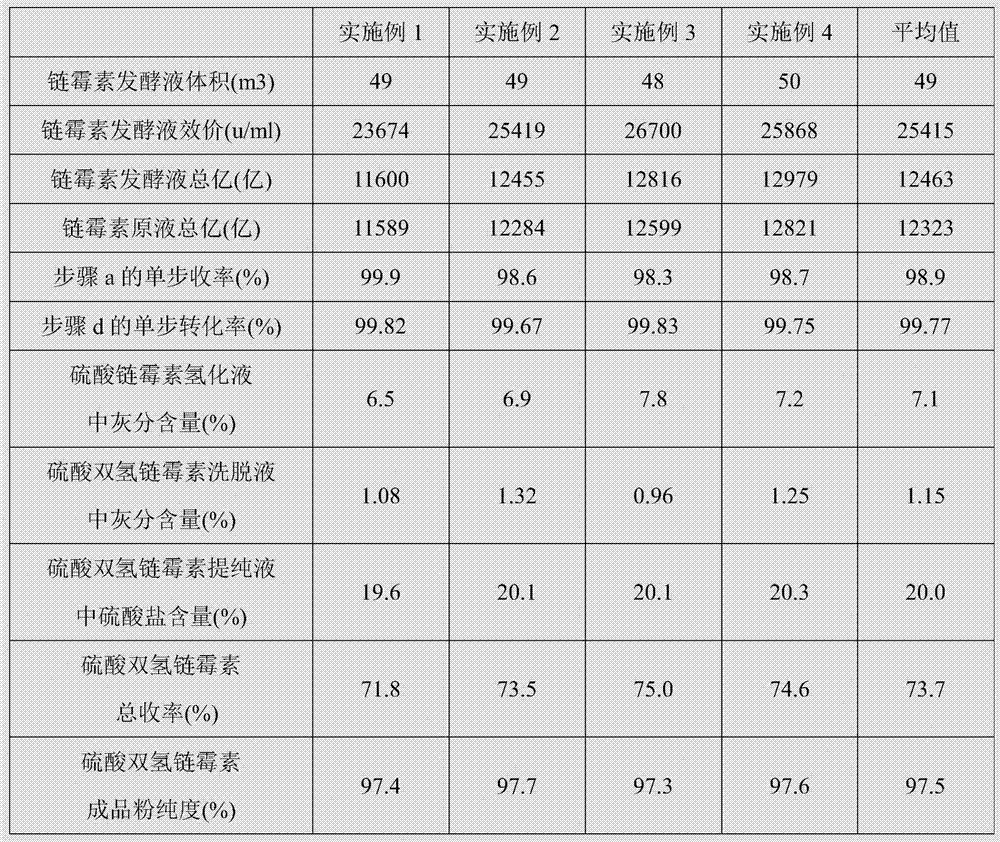

Preparation method for dihydrostreptomycin sulphate

ActiveCN106928288AHigh purityImprove pass rateSugar derivativesSugar derivatives preparationUltrafiltrationIon exchange

The invention discloses a preparation method for dihydrostreptomycin sulphate and belongs to the production preparation technology of semi-synthesis antibiotics. The method comprises the following steps: treating with acid; performing ion exchange; adsorbing with large-pore amino resin; hydrogenating; performing secondary ion exchange; purifying by a mixed bed; treating with activated carbon; concentrating through a nanofiltration membrane; decolorizing by activated carbon; and treating with an ultrafiltration membrane and performing spray drying. According to the invention, the dosage of oxalic acid in a preparation process is reduced, the use ratio of the reducing agent is increased, the production cost is lowered, the production efficiency is increased, the method can meet the industrial production requirement and the product purity, quality yield and total recovery of the dihydrostreptomycin sulphate are increased.

Owner:华北制药华胜有限公司

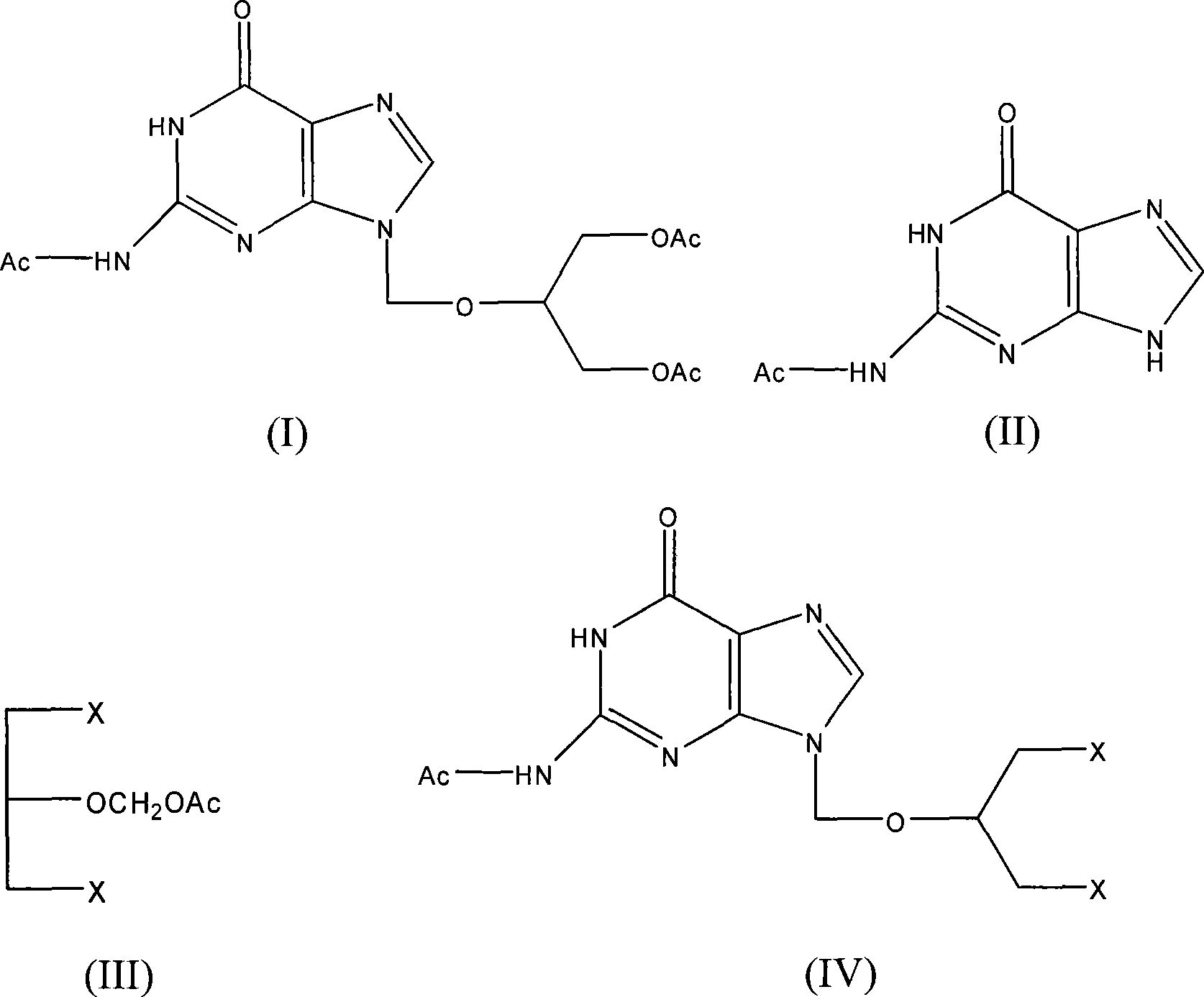

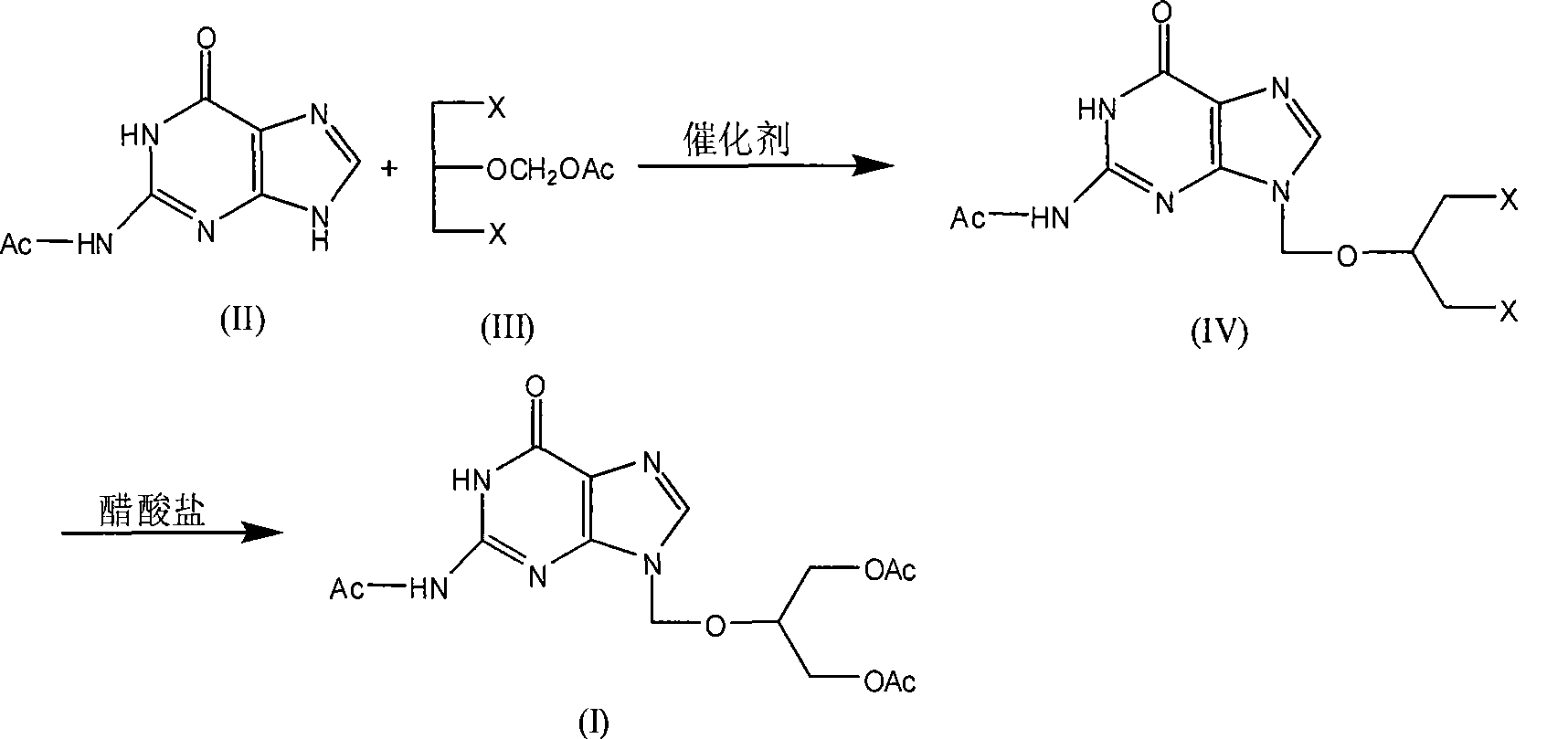

Chemical synthesis of triacetylganciclovir

The invention discloses a chemical synthesis method for triacetylganciclovir of a structural formula (I). The synthesis method comprises that: monoacetylguanine of a structural formula (II) and 1,3-dihalo-2-(acetoxylmethoxy) propane of a structural formula (III) are used raw materials to be reacted in a solvent A at 100 to 150 DEG C in the presence of a catalyst to form dihalo-2- acetyl- ganciclovir; the dihalo-2- acetyl- ganciclovir and an acetate are completely reacted in an organic solvent B at 70 to 150 DEG C; and the triacetylganciclovir is obtained after post treatment. The invention is reasonable in process, high in reaction yield, high in product purity and low in production cost and has good process application value.

Owner:张小顺 +1

Method for co-producing high-purity heparin sodium and dermatan sulfate from pig lungs

The invention provides a method for co-producing high-purity heparin sodium and dermatan sulfate from pig lungs. According to the method, the pig lungs are adopted as a raw material for producing high-purity heparin sodium and high-purity dermatan sulfate through enzymolysis, ion exchange, classified elution, concentration and ethanol precipitation. Specifically, the method comprises the steps of obtaining two steps of eluate through substep elution with ion exchange, removing salt and concentrating by using an ultrafiltration method, and further performing alcohol precipitation, thereby obtaining the heparin sodium and dermatan sulfate. In elution of ion exchange resin, a gradient sodium chloride solution is adopted for elution, so that heparin sodium and dermatan sulfate can be separated in eluate of different concentrations, the separation of heparin sodium from dermatan sulfate is achieved, the purity of heparin sodium and dermatan sulfate is respectively improved, the titer of heparin sodium and dermatan sulfate is also improved, and the purity, the titer and the optical rotation of heparin sodium and dermatan sulfate all meet the requirements of a pharmacopeia. The method is simple in process, low in cost and high in yield, and the economic benefits of product can be greatly increased.

Owner:CHONGQING DOUHAO BIOTECH

Organic electroluminescence display device having red, green, blue and white pixels

ActiveUS7714507B2Broaden the formation processHigh purityDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceOrganic electroluminescence

The recent invention provide an organic electroluminescence display device with color purity adjustment, particularly white purity increased, without increasing formation processes. For each of unit pixels formed on an insulating film INS formed on a principal surface of a glass substrate, a bank BNK is provided on a bottom electrode BEL being a pixel electrode. The bank BNK has the shape of a bank that surrounds a pixel concerned, for each of pixels, and an organic electroluminescence light emitting layer is charged within a region surrounded by the banks BNKs. Between the banks BNKs, a green light emitting layer (G light emitting layer), a blue light emitting layer (B light emitting layer), and a red light emitting layer (R light emitting layer) are provided. At the same time as the formation of these color light emitting layers, light emitting layers of three colors, the green light emitting layer (G light emitting layer), the blue light emitting layer (B light emitting layer), and the red light emitting layer (R light emitting layer) are stacked on a region of a white pixel to form a white light emitting layer (G+B+R). An upper electrode UEL is formed over the green light emitting layer (G light emitting layer), the blue light emitting layer (B light emitting layer), the red light emitting layer (R light emitting layer), and the white light emitting layer (G+B+R light emitting layer).

Owner:SAMSUNG DISPLAY CO LTD +1

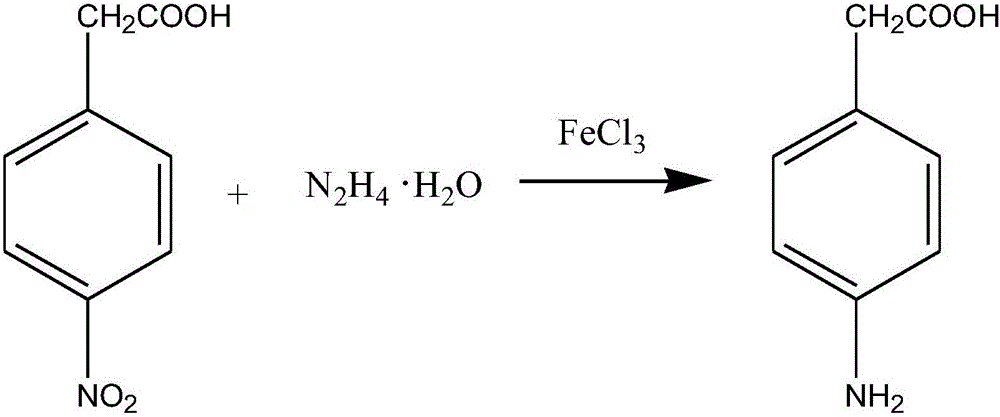

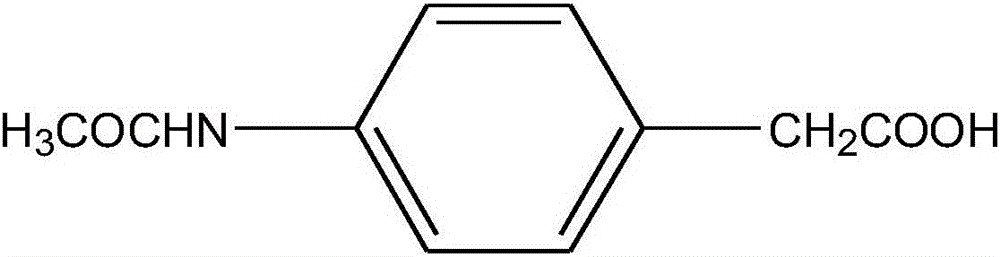

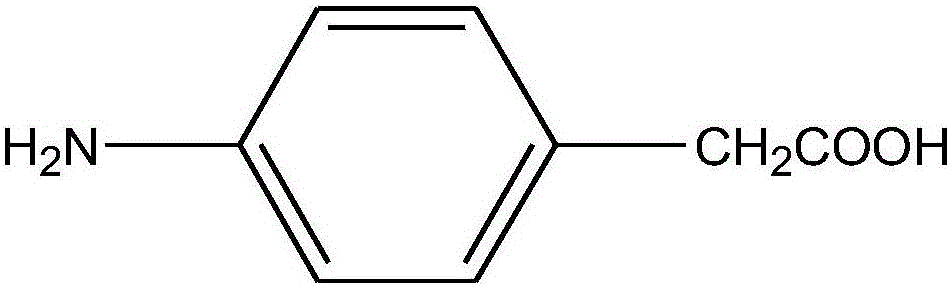

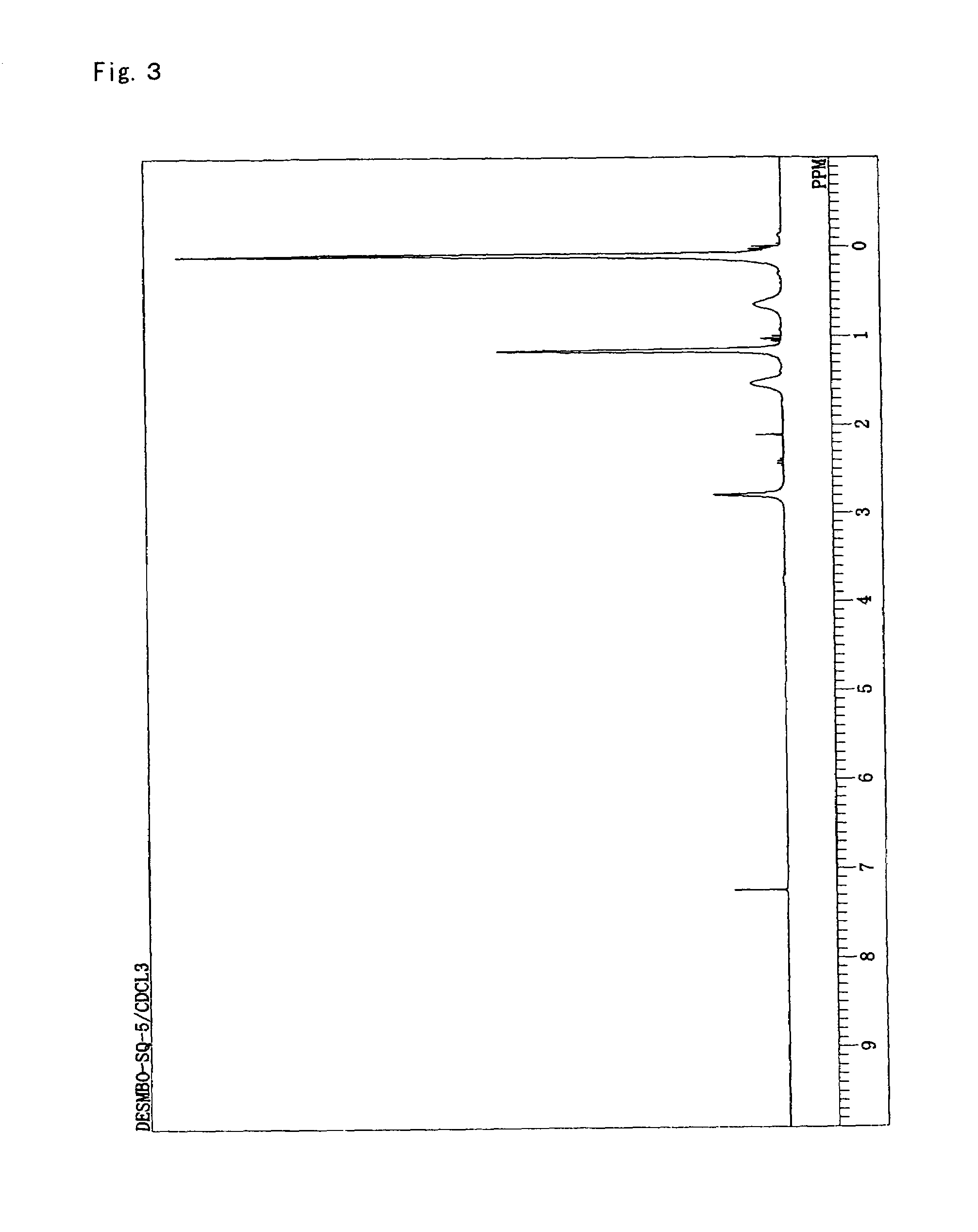

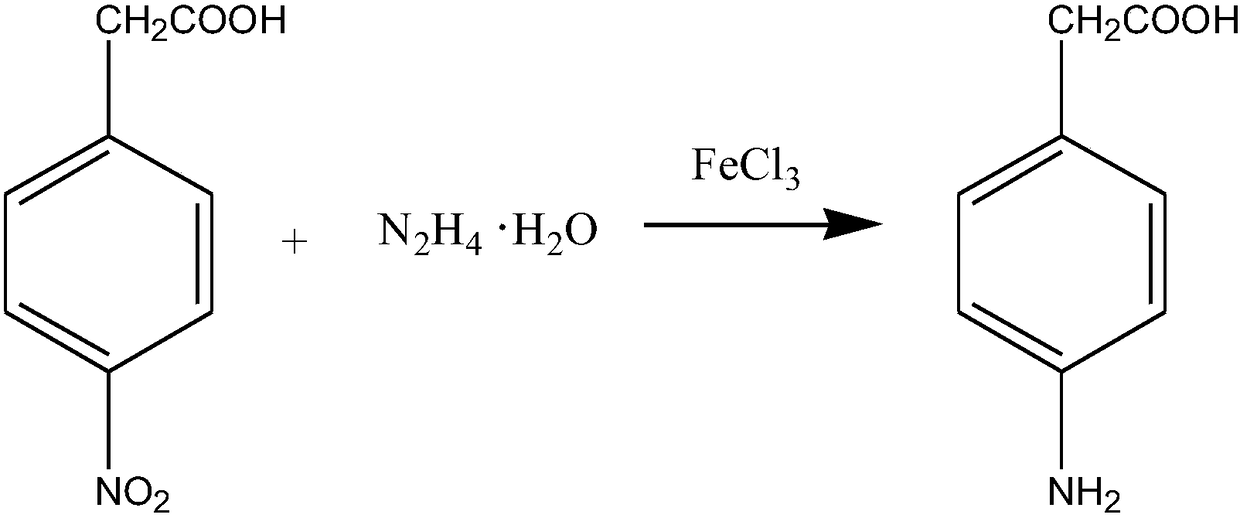

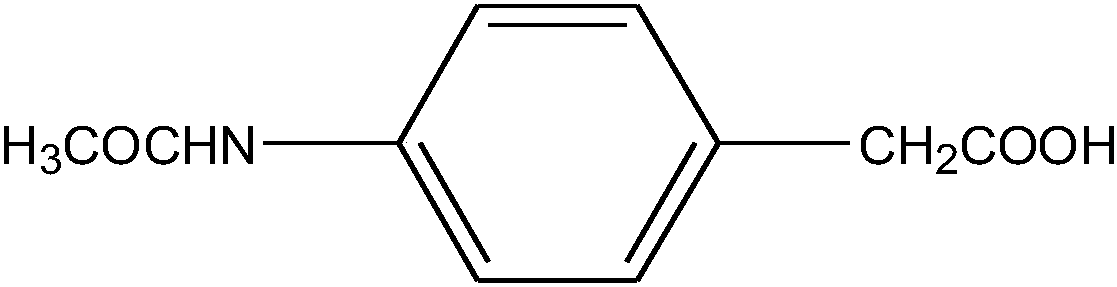

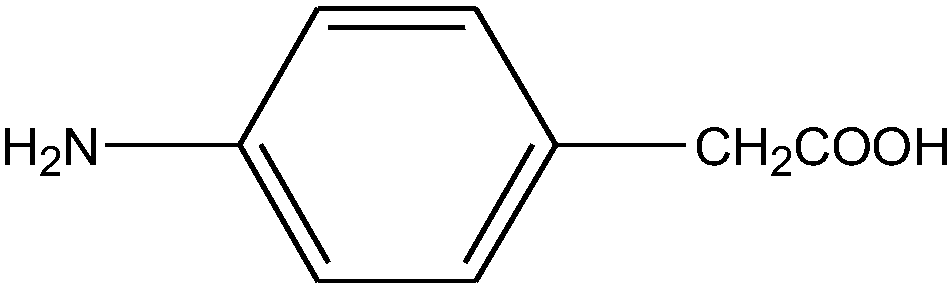

Preparation method of p-aminophenylacetic acid

ActiveCN106083631AProtect environmentOperations to Avoid Recycling SolventsOrganic compound preparationAmino-carboxyl compound preparationNitrogen atmosphereAqueous solution

The invention discloses a preparation method of p-aminophenylacetic acid. The method comprises the following steps: uniformly mixing water, iron chloride and p-aminophenylacetic acid, heating the materials to the temperature of 60-90 DEG C under nitrogen atmosphere, dropping a hydrazine hydrate aqueous solution, insulating for 1-2 hours, cooling the material for crystallization, filtering the material to take a filter cake, washing the filter cake, and drying the product to obtain p-aminophenylacetic acid. According to the method, a difficulty processed solid waste is not generated, an organic solvent is not required, the environment is protected, the reaction condition is mild, operation is simple, and the method is suitable for industrial production, yield is high, the purity of the prepared p-aminophenylacetic acid is good, and the method provides the help for normal and stable production for actarit.

Owner:HEFEI PINGGUANG PHARMA

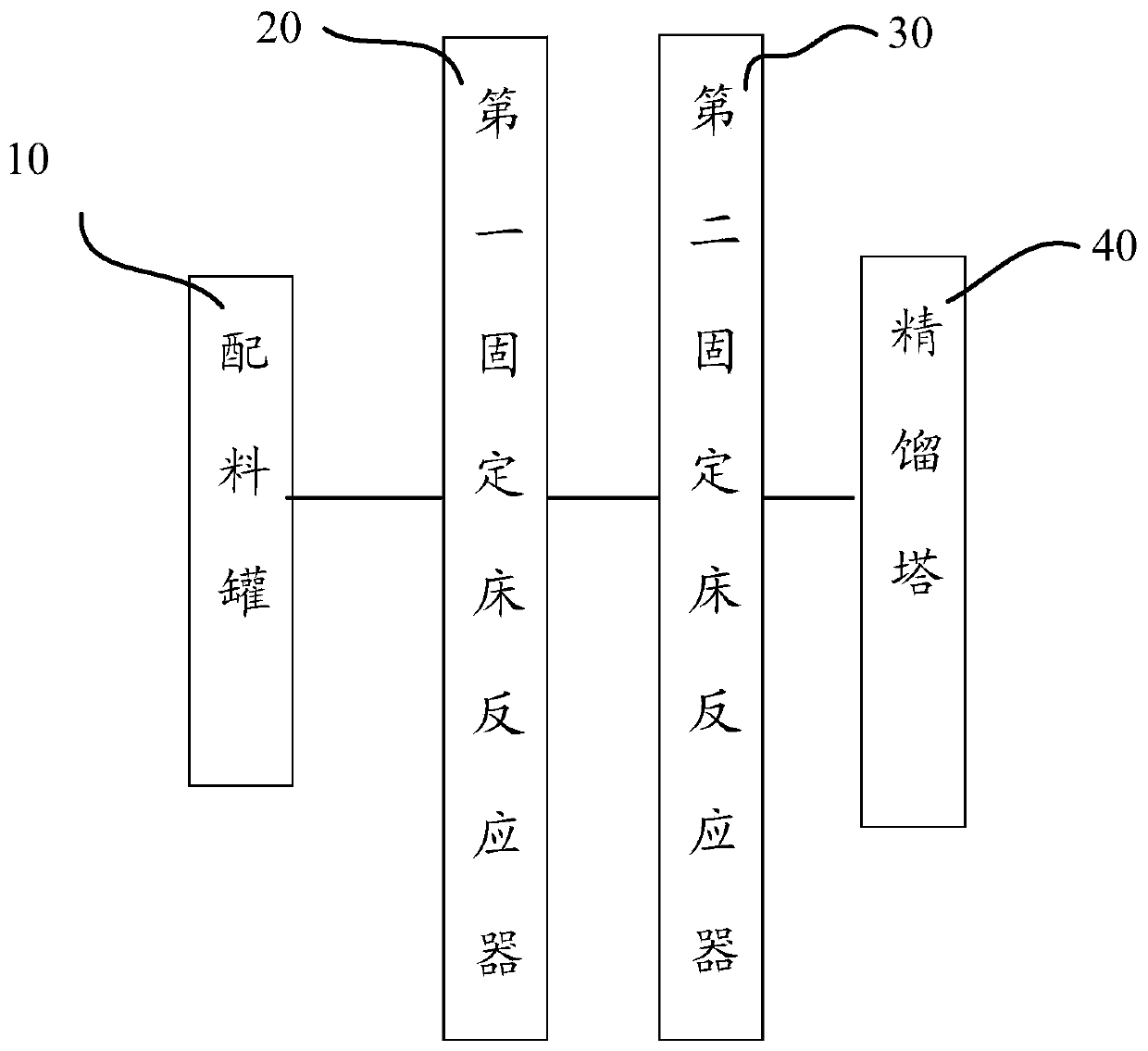

Preparation method of ethyl 3-ethoxypropionate

PendingCN111004123AImprove conversion ratePromote regenerationOrganic compound preparationCarboxylic acid esters preparationChemical industryPtru catalyst

The embodiment of the invention discloses a preparation method of ethyl 3-ethoxypropionate, and relates to the technical field of chemical industry synthesis. According to the scheme, low-acidity absolute ethyl alcohol and ethyl acrylate are subjected to an addition reaction under the catalytic action of a strongly basic ion exchange resin to prepare ethyl 3-ethoxypropionate, wherein the acidity of the reactant is within 10ppm and cannot affect the catalyst, so that the conversion rate of the catalyst is high so as to achieve high yield (the conversion rate and the yield of the scheme are morethan 98%). According to the invention, the method has the advantages of simplicity, mild conditions, few side reactions and easy regeneration of the catalyst; and the product easily achieves the purity of more than 99.8%, can be further processed into an electronic grade, can be used in photoelectric industry, greatly simplifies the separation process, and is convenient for continuous production.

Owner:SHENZHEN PRECHEM FINE CHEM CO LTD

Method for extracting taurine from marine food product leftovers

InactiveCN109053502AEasy purityHigh purityOrganic chemistryOrganic compound preparationUltrafiltrationStrong acids

The invention discloses a method for extracting taurine from marine food product leftovers. The method comprises the following steps: S1, crushing the marine food product leftovers into granular powder through a crusher; S2, adding water to the powder prepared in S1 to dilute; heating for 30min to obtain a mixed solution; digesting the mixed solution for 20min, and removing solid impurities; and S3, adding hydrochloric acid to the mixed solution prepared in S2 to remove protein. According to the method, the marine food product leftovers are fully utilized to extract taurine; and sea cucumber intestine extracting liquid extracted with hot water cannot be concentrated or subjected to salt removing through ultrafiltration or strong acid cation exchange resin, the salt is completely removed byelectrodialysis, and then most of the impurities can be removed by ultrafiltration through an ultrafiltration membrane. Therefore, the technical steps are simplified; the purity of the taurine in crystallizing is increased, and the recrystallizing times are decreased; the purity of the taurine extracted and separated by the technical method is beyond 90%; the processes are simple; and the equipment input is low.

Owner:东山县东盛食品有限公司

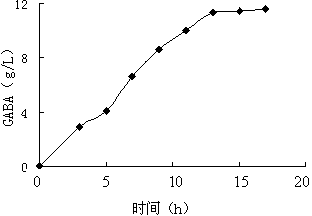

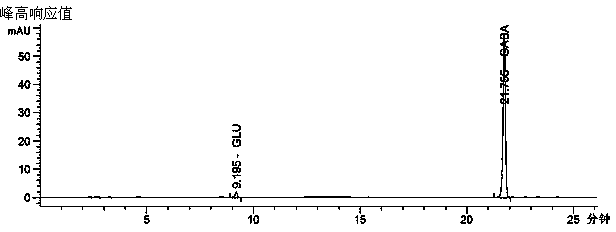

Biological method for preparing gamma-aminobutyric acid

ActiveCN102796779BIncrease productionLow costOrganic compound preparationMicroorganism based processesPresent methodElectrodialysis

Owner:南通励成生物技术有限公司

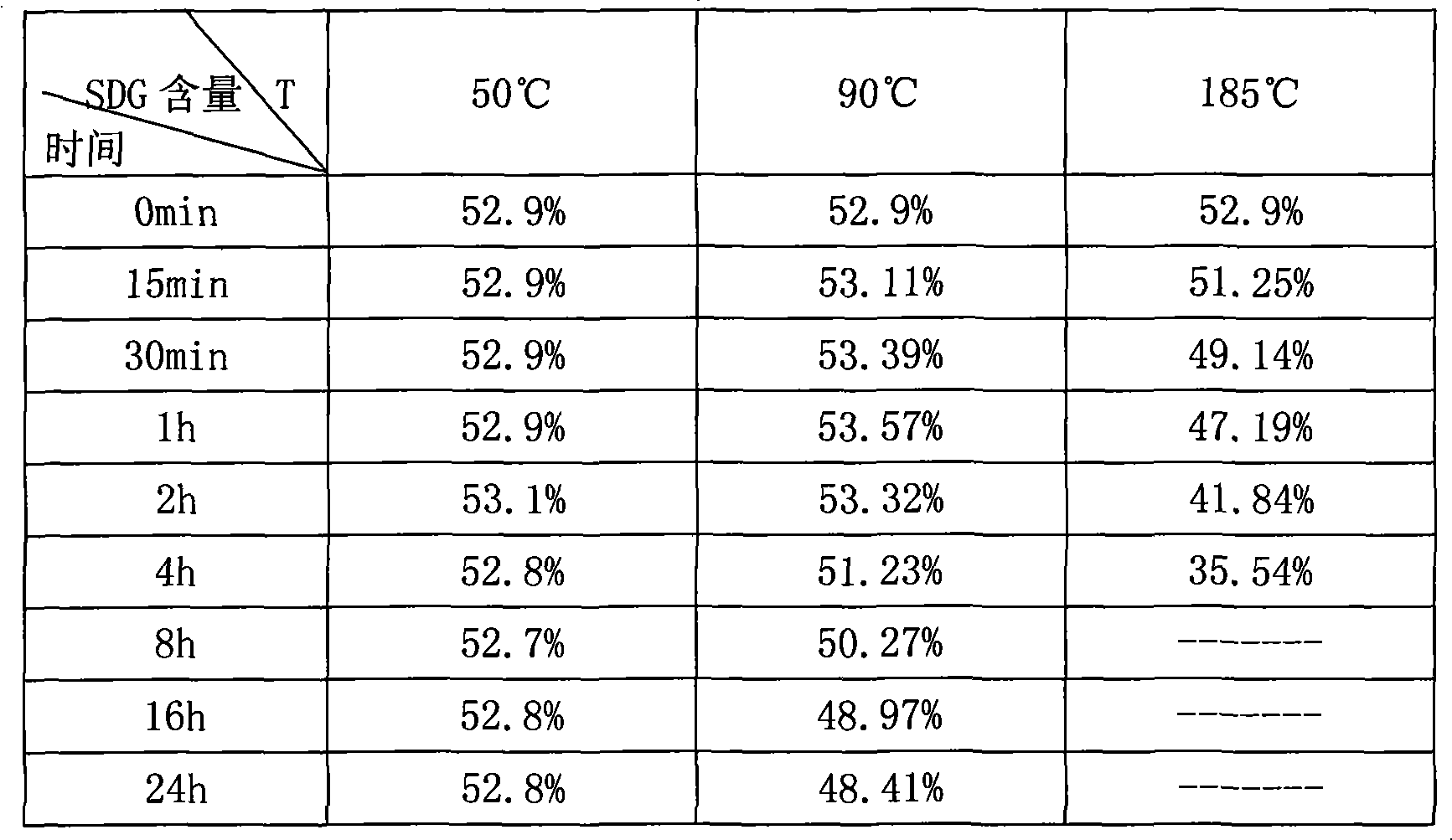

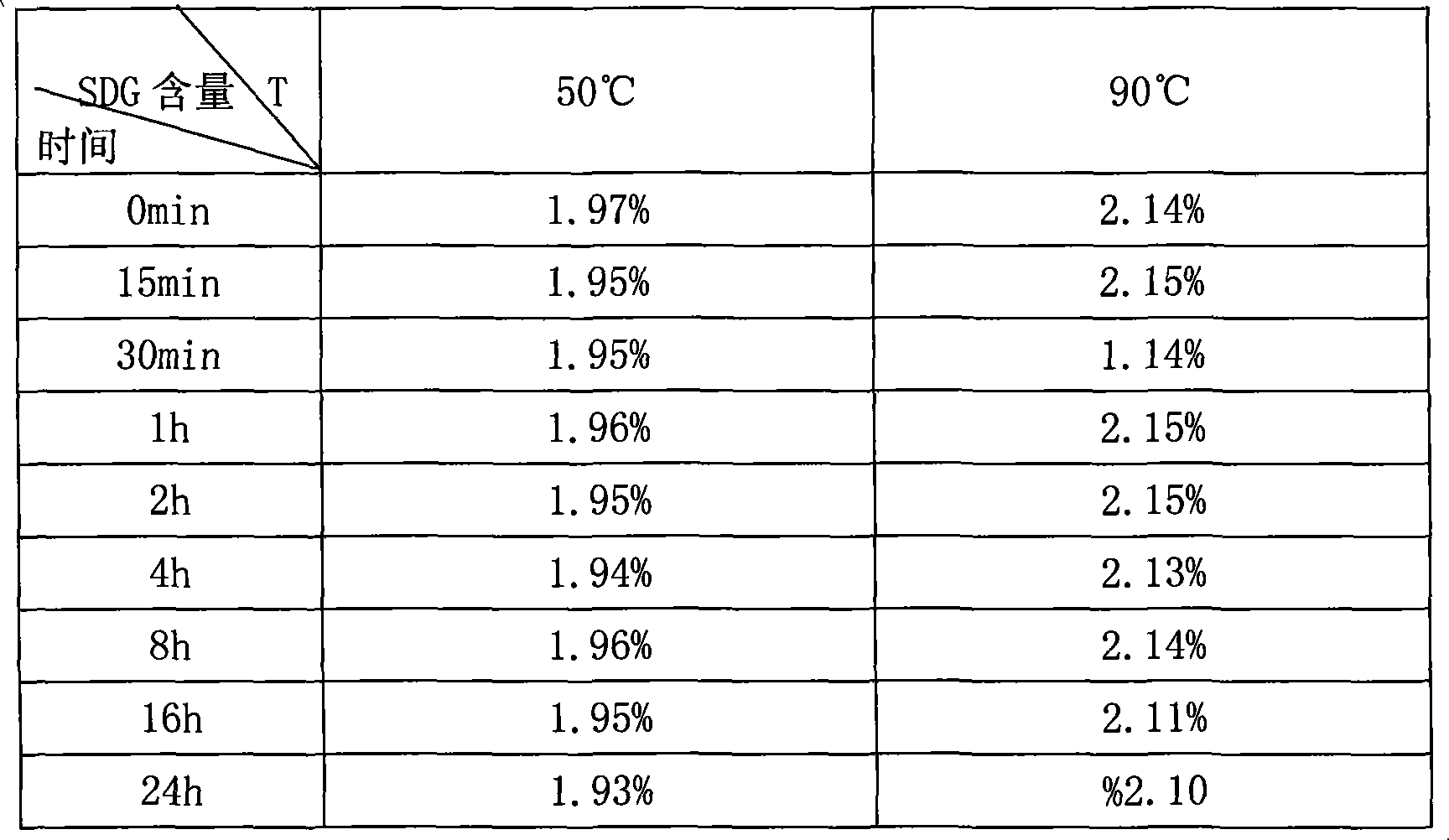

Method for preparing flax lignins

Owner:成都圆大生物科技有限公司

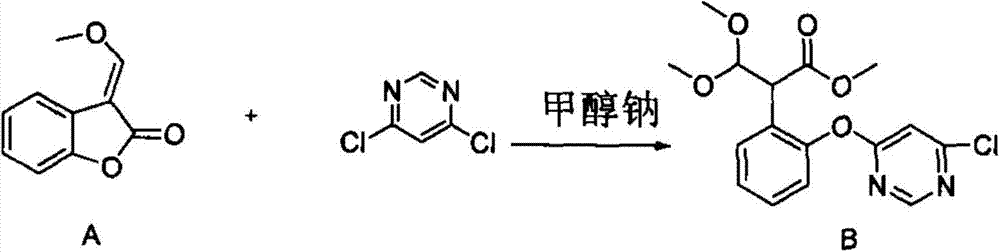

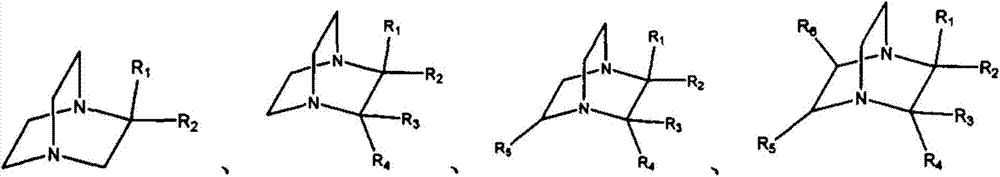

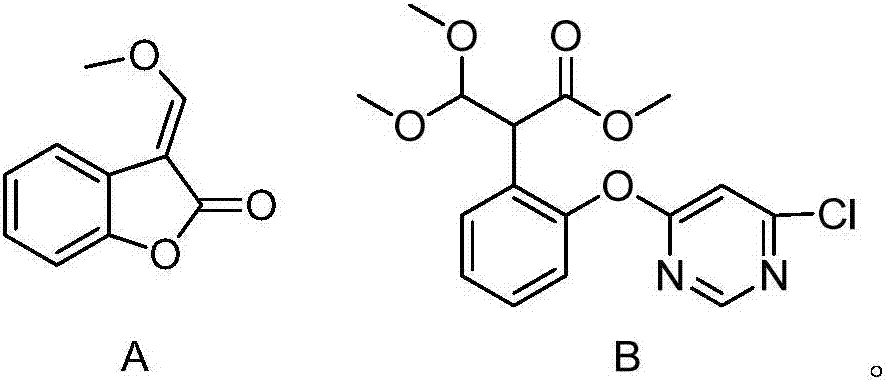

A kind of preparation method of azoxystrobin intermediate

ActiveCN104725321BHigh purityEasy purityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSodium methoxideAzoxystrobin

Owner:SHANGHAI TAIHE INT TRADE CO LTD +1

In-vitro propagation method of tuberose virus

The invention relates to a method for propagating tuberose virus in vitro, which belongs to the technical field of plant virus propagation and comprises following steps: preparing culture medium, culturing tissues of a drug source tuberose, checking virus, and propagating the drug source tuberose virus in vitro. The method of the invention has the advantages that a plant tissue culture technique is utilized to propagate the tuberose virus in vitro, the tuberose virus can be propagated without limit, and the original infecting potential is maintained, which not only solves the problem that thedrug source is captured in imported virus disease quarantine, but also greatly simplifies the steps of propagation and drug source storage, the work for seeding differential hosts repeatedly, for reviving the drug source repeatedly, for transferring repeatedly, and for disinfecting soil before seeding to store some drug source is saved, the working efficiency is increased in times, and infectioustiter is easily extracted and prepared, which provides the virus with high purity for preparing virus detection antiserum.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Preparation method of tetragonal-phase barium titanate (BaTiO3) hollow nanocrystal

ActiveCN102887705BEasy purityA simple solvothermal method prepared high-purityBarium titanatePotassium hydroxide

Owner:ZHEJIANG UNIV

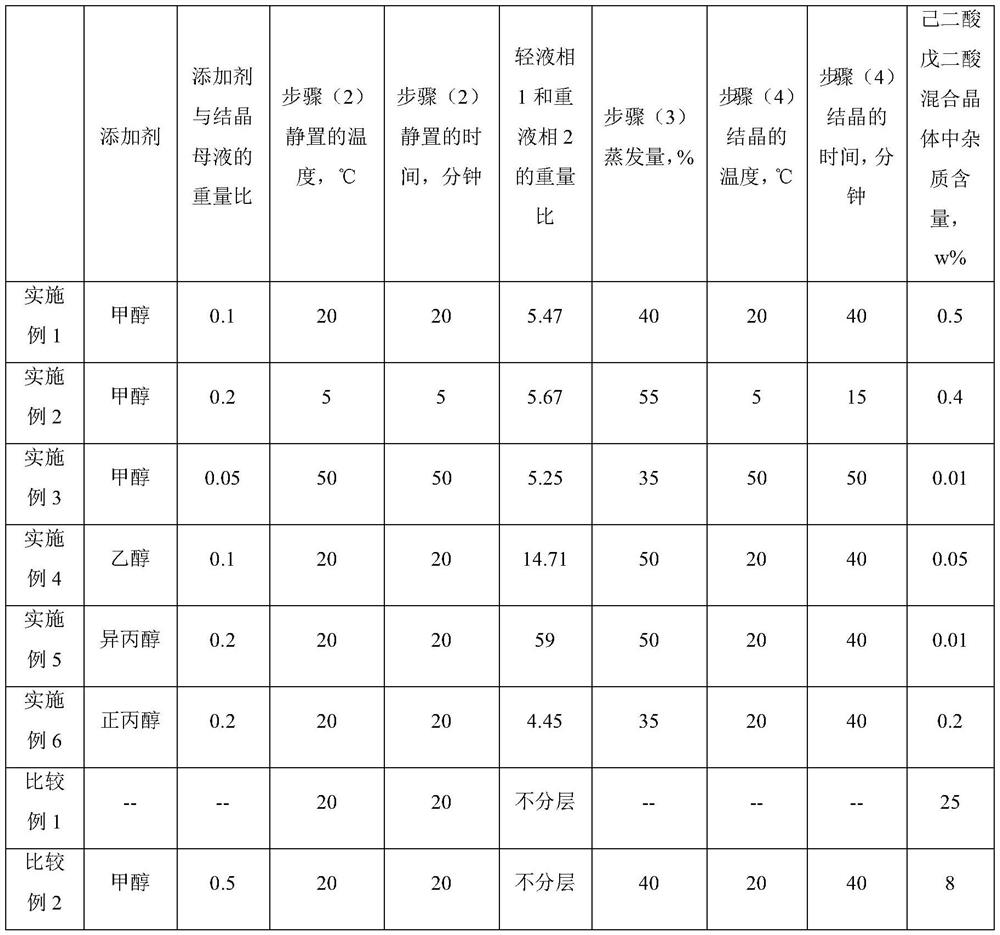

Treatment method of crystallization mother liquor in adipic acid crystallization refining process

PendingCN112441915AGuaranteed purityEasy purityOrganic chemistry methodsCarboxylic compound separation/purificationPolymer scienceGlutaric acid

In order to solve the problem that the crystallization mother liquor is difficult to treat in the adipic acid crystallization refining process in the prior art, the invention provides the treatment method of the crystallization mother liquor in the adipic acid crystallization refining process. The method can effectively remove other impurities in the mixture of adipic acid and glutaric acid in thecrystallization mother liquor. According to the technical schemes, the treatment method of the crystallization mother liquor in the adipic acid crystallization refining process comprises the following steps of: (1) mixing the crystallization mother liquor with an additive; (2) performing still standing and layering to obtain a light liquid phase 1 and a heavy liquid phase 2; (3) evaporating the light liquid phase 1 to obtain a material 3; and (4) crystallizing and separating the material 3 to obtain adipic acid and glutaric acid mixed crystals and mother liquor 4. According to the method, a solvent in the crystallization mother liquor is water or basically water, the additive comprises C1-C3 alcohol, and the weight ratio of the additive to the crystallization mother liquor is greater than0 and less than 0.3.

Owner:CHINA PETROLEUM & CHEM CORP +1

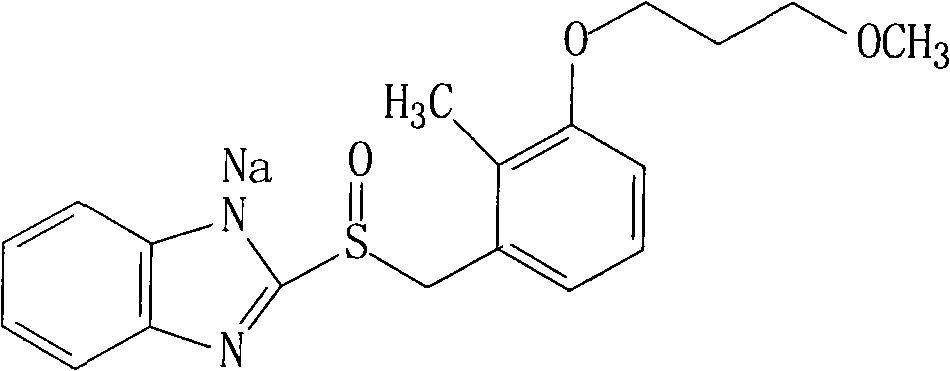

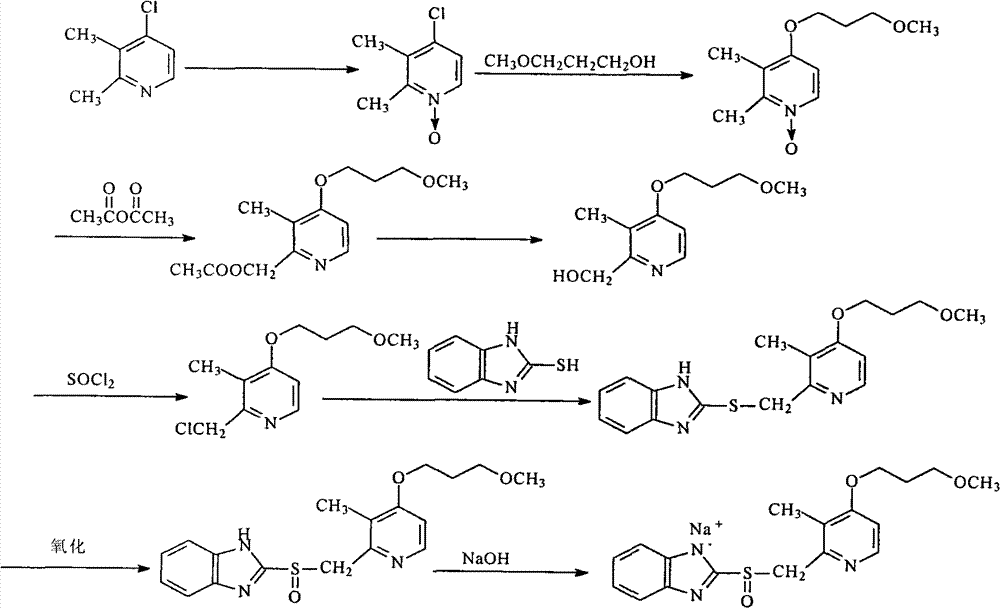

Rabeprazole sodium compound and novel preparation method thereof

The invention aims at providing a novel rabeprazole sodium compound and a novel preparation method thereof. A novel oxidizing agent of trichloroisocyanuric acid is adopted for controlling the oxidization from thioether into sulfoxide, and the oxidization from the thioether into the sulfoxide is perfectly controlled. Because the invention shortens the reaction steps, and few other impurities are introduced in the process of synthesizing chiral rabeprazole sodium, so the purification process is easier, the purity and the yield of obtained finally products are high, and the invention is applicable to large-scale industrial production.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

Method of synthesizing tetraalkyltin

The invention relates to a preparation method of an organotin product, in particular to a method of synthesizing tetraalkyltin through two-step method, belonging to the technical field of the chemical engineer. The method adopts a two-step method and the method comprises the following steps: firstly adopting metal magnesium, solvent and a small number of the prepared Grignard reagent to react andsynthesize Grignard reagent, and then dropwise adding stannic chloride to perform an alkylation reaction and obtain tetraalkyltin, wherein the added solvent is butyl ether solution, the Grignard reaction is performed at 55-75 DEG C for 2-4h under the nitrogen protective atmosphere, and the alkylation reaction is performed at 80-100 DEG C for 1-3h under the nitrogen protective atmosphere. Comparedwith the current one-step reaction, the method avoids the generation of the side reaction so that the Grignard exothermic reaction can be performed safely and stably and the reaction is easy to control. Compared with the traditional two-step method, the method solves the problems that the boiling point of the solvent is low, the solvent is volatilizable, the explosive risk is high, and the solvent is harmful to human body and the like.

Owner:云南锡业锡化工材料有限责任公司

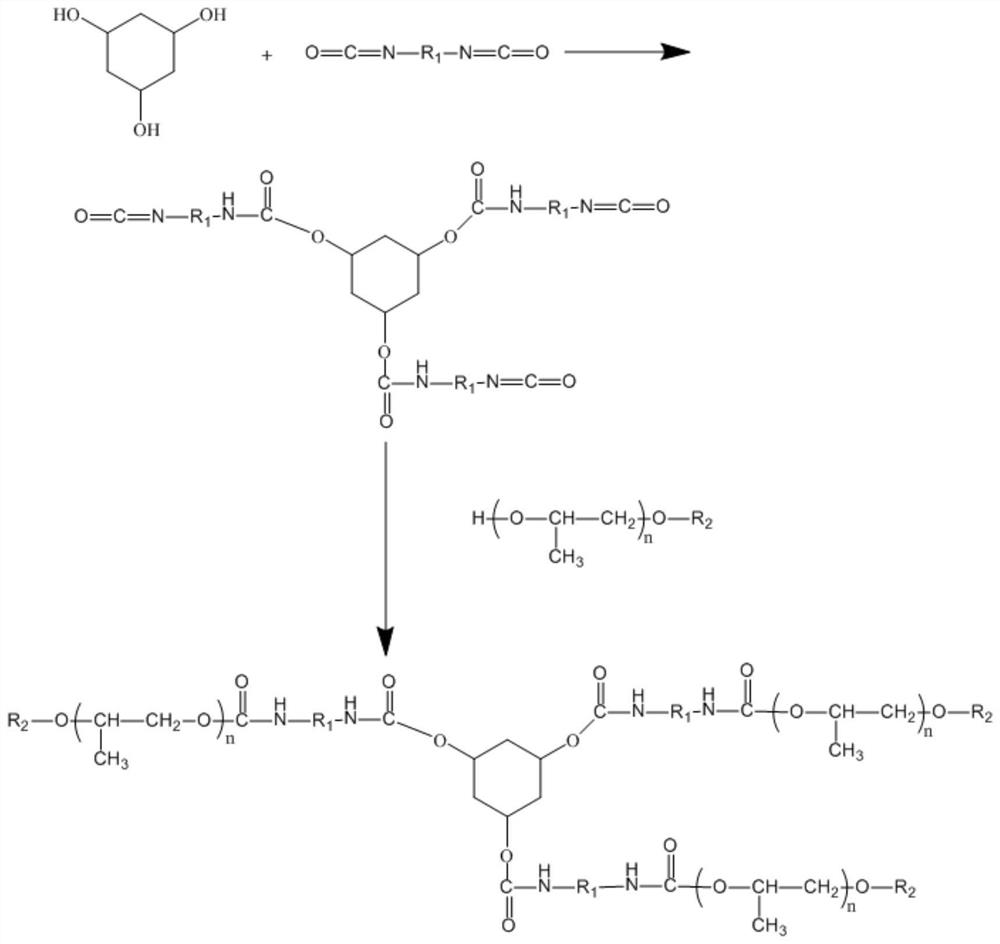

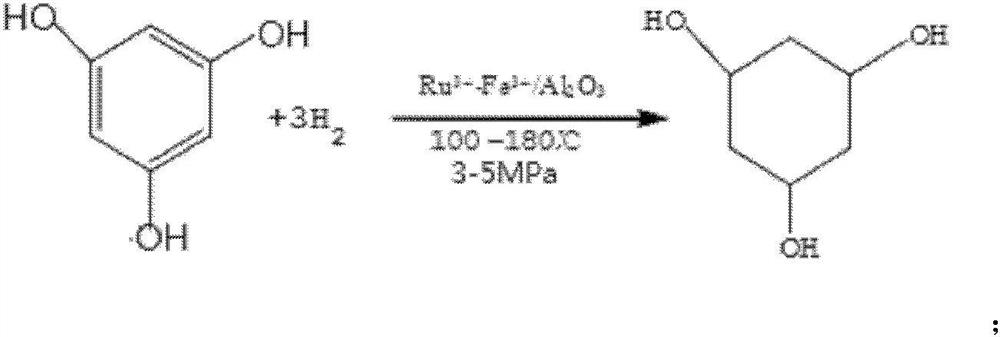

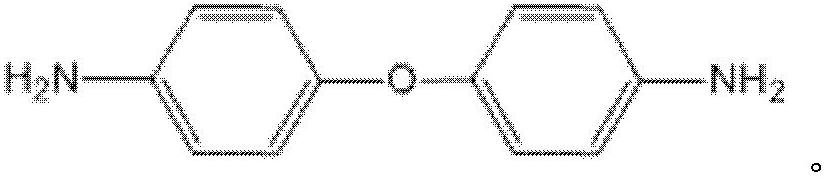

A kind of hyperbranched dispersant and preparation method thereof

Owner:英德侗富贵科技材料有限公司

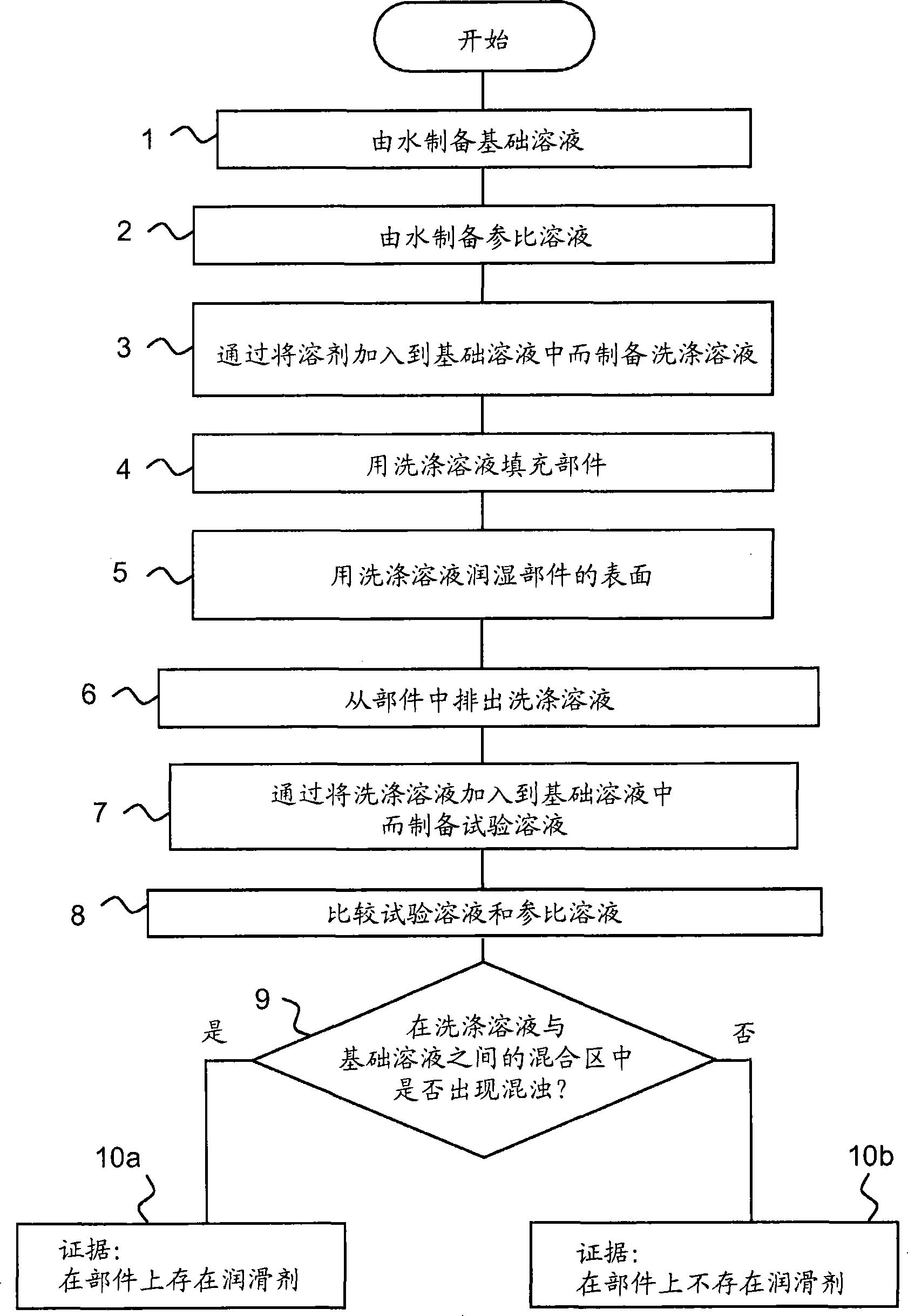

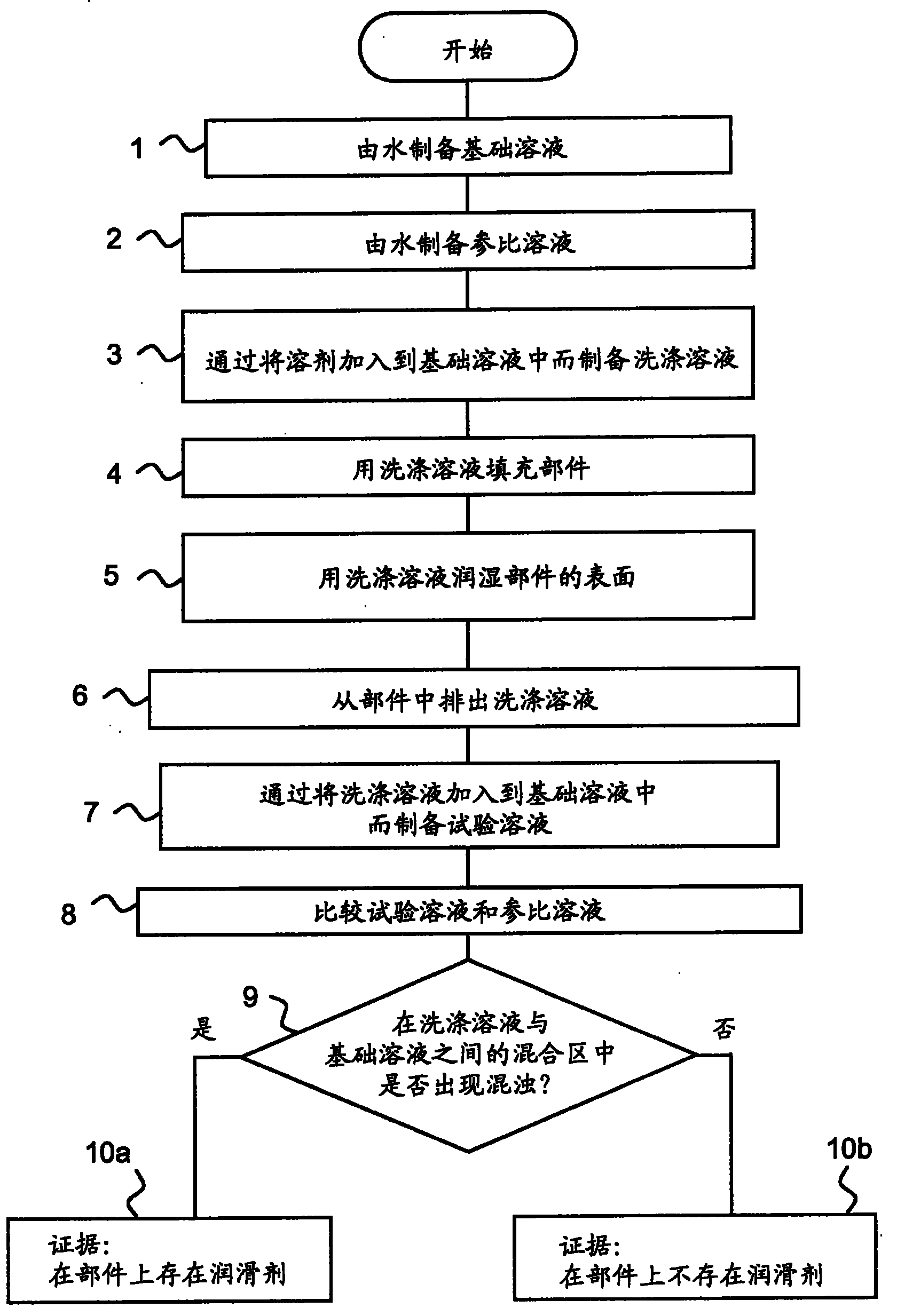

Method for detecting residues on a component

InactiveCN101283267BEasy purityAvoid chemical reactionsOptically investigating flaws/contaminationTurbiditySolvent

Owner:AIRBUS OPERATIONS GMBH

Method for removing phosphorus and boron from metallurgical-grade silicon

The invention provides a method for removing phosphorus and boron from metallurgical-grade silicon, which relates to the purification of metallurgical-grade industrial silicon. The provided method for removing the phosphorus and the boron from the metallurgical-grade silicon has the advantages of less investment, lower production cost, less environmental pollution and the like. The method comprises the following steps of: putting a bulk silicon material into a smelting furnace; smelting the bulk silicon material, and covering the bulk silicon material with a slag former to obtain a silicon block mixture; vacuumizing the smelting furnace until the pressure is between 800 and 1,200 Pa, and charging argon until the pressure is between 8,000 to 12,000 Pa; heating the silicon block mixture to be melted, introducing water vapor, pouring a melted mixture on a loading graphite crucible below a smelting crucible, and taking out the silicon material after being cooled; crushing and milling the silicon material after slag forming to obtain silicon powder; soaking the powdered silicon in hydrochloric acid; soaking the silicon powder after being soaked in the hydrochloric acid in dilute aqua regia; and soaking the silicon powder after being soaked in the dilute aqua regia in hydrofluoric acid to obtain the metallurgical-grade silicon without the phosphorus and the boron.

Owner:XIAMEN UNIV

Method for preparing lithium hexafluorophosphate by using composite solvent

InactiveCN102491305BLow boiling pointResidue reductionSecondary cellsPhosphorus compoundsDistillationEvaporation

The invention relates to a safe and reliable method for preparing lithium hexafluorophosphate by using a composite solvent. The technical steps of the method are simple. The method comprises steps that: anhydrous phosphoric acid, calcium fluoride and sulfur oxide are subject to a reaction, such that PF5 gas is obtained by evaporation; the evaporated PF5 gas is dehydrated, such that a high-purity anhydrous PF5 product is obtained; diethyl ether and anhydrous methyl cyanide are respectively dehydrated, such that high-purity diethyl ether and anhydrous methyl cyanide are obtained; high-purity lithium fluoride is added to the diethyl ether solution; methyl cyanide is added to the obtained solution; the PF5 gas is slowly delivered into the solution while stirring; when a reaction is finished, high-purity nitrogen is delivered into the solution, such that displacement is carried out until no PF5 gas is remained in a vessel; a dry product Li(CH3CN)4PF6 obtained through distillation is heatedand decomposed, such that LiPF6 is prepared; LiPF6 is dissolved under room temperature, such that a solution with a concentration of 1M is obtained; the solution is filtered by using a precise filterwith a specification of 0.2mum, such that a clarified solution is obtained; the solution is dried, such that a pure LiPF6 product is obtained.

Owner:山东省智能光电新能源研究院

Method for extracting taurine from sea cucumber sausage

InactiveCN104447427BEasy purityHigh purityOrganic chemistryOrganic compound preparationCentrifugationTaurine

A method for extracting taurine from sea cucumber intestines, which is characterized in that it consists of the following steps: (1) heating and extracting sea cucumber intestines in water, and collecting the sea cucumber intestine extract; (2) filtering the sea cucumber intestine extract through plate and frame or The supernatant is obtained by centrifugation in a decanter centrifuge, a disc centrifuge and a tube centrifuge in sequence; (3) The supernatant is electrodialyzed by an electric drive device, desalinated, and the conductance reaches 300-1000μS / cm to stop, and the desalinated supernatant is obtained. (4) The desalted clear liquid is ultrafiltered with a membrane with a molecular weight of 1000Da, and the filtrate is collected; (5) After the filtrate is concentrated under reduced pressure for 20-40 times the volume, ethanol with a concentration of more than 95% is added to make the final concentration When it reaches 50-60%, let it stand at 4°C, and collect the precipitate by suction filtration or centrifugation. (6) After the precipitate is dissolved in water, add ethanol with a concentration of more than 95% to make the final concentration reach 50-60%, carry out recrystallization, repeat this step once, and carry out recrystallization again to obtain pure taurine.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI

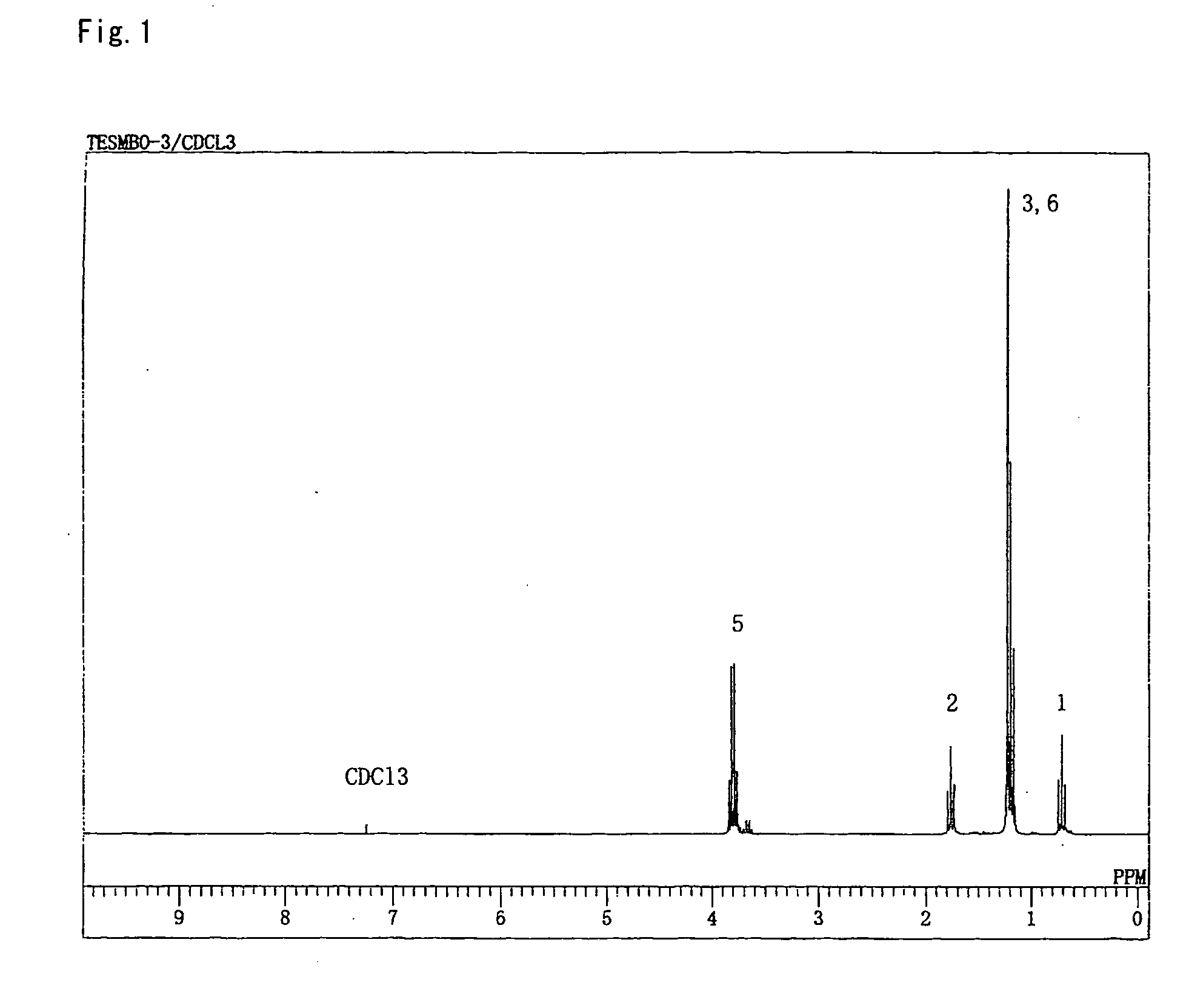

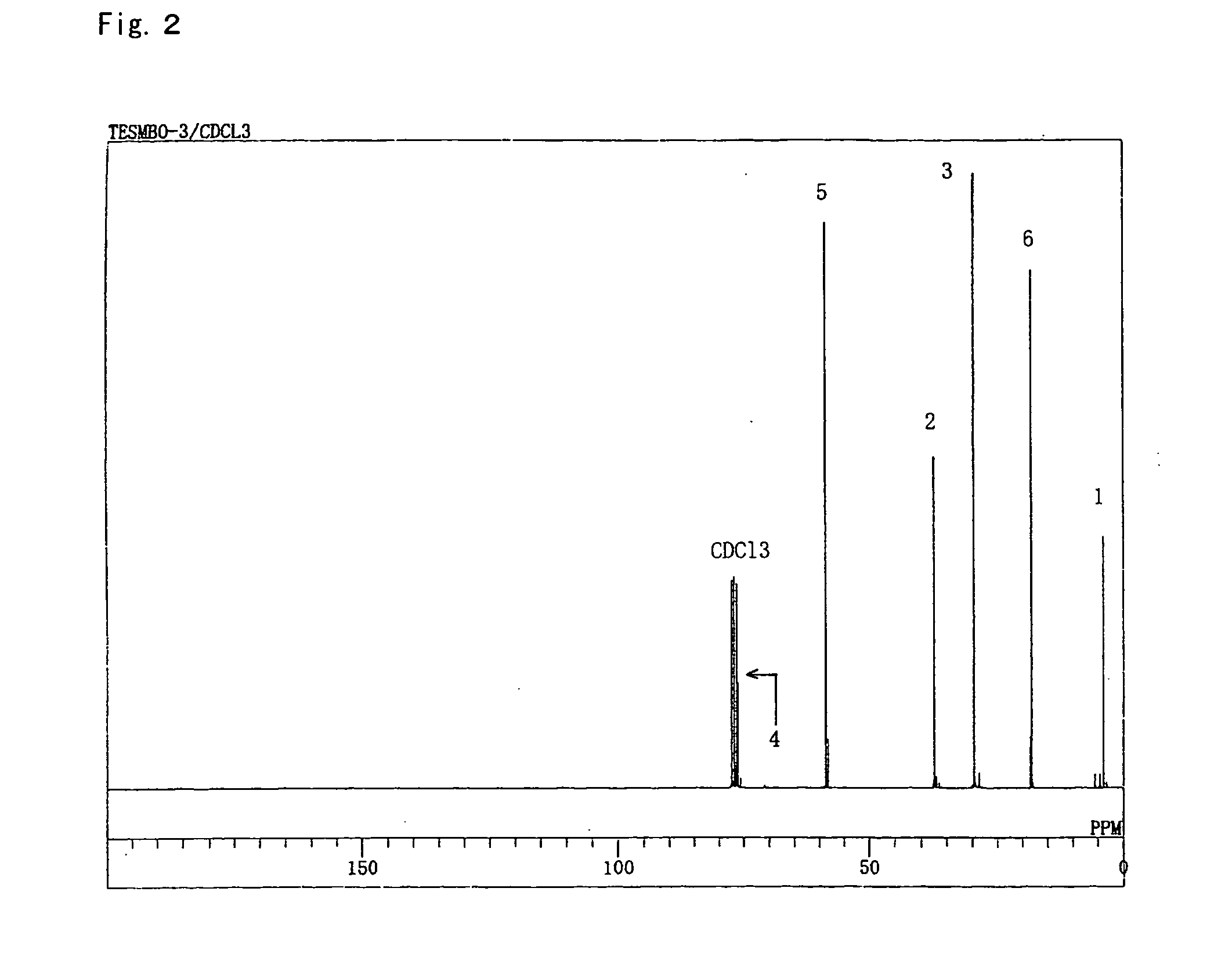

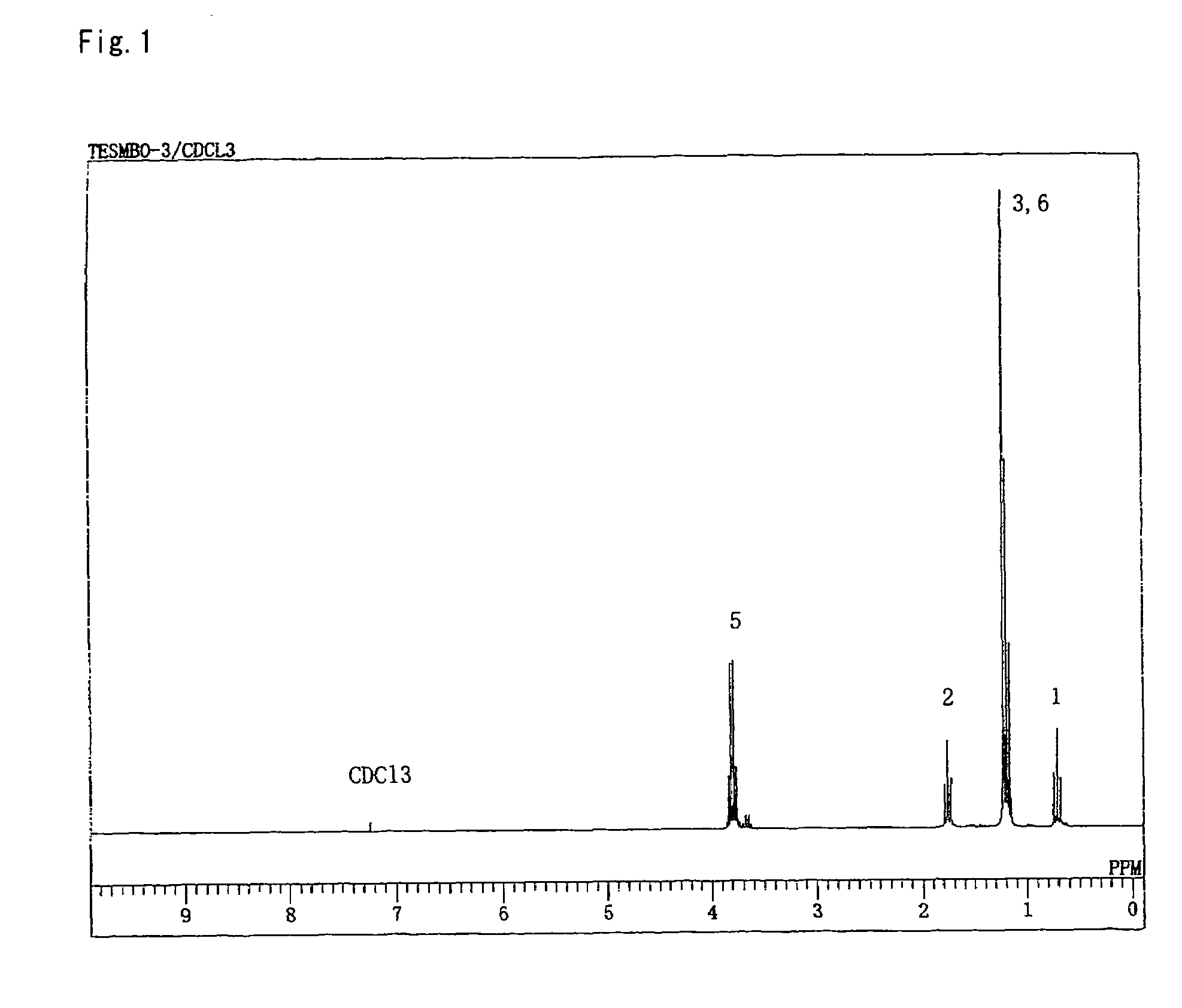

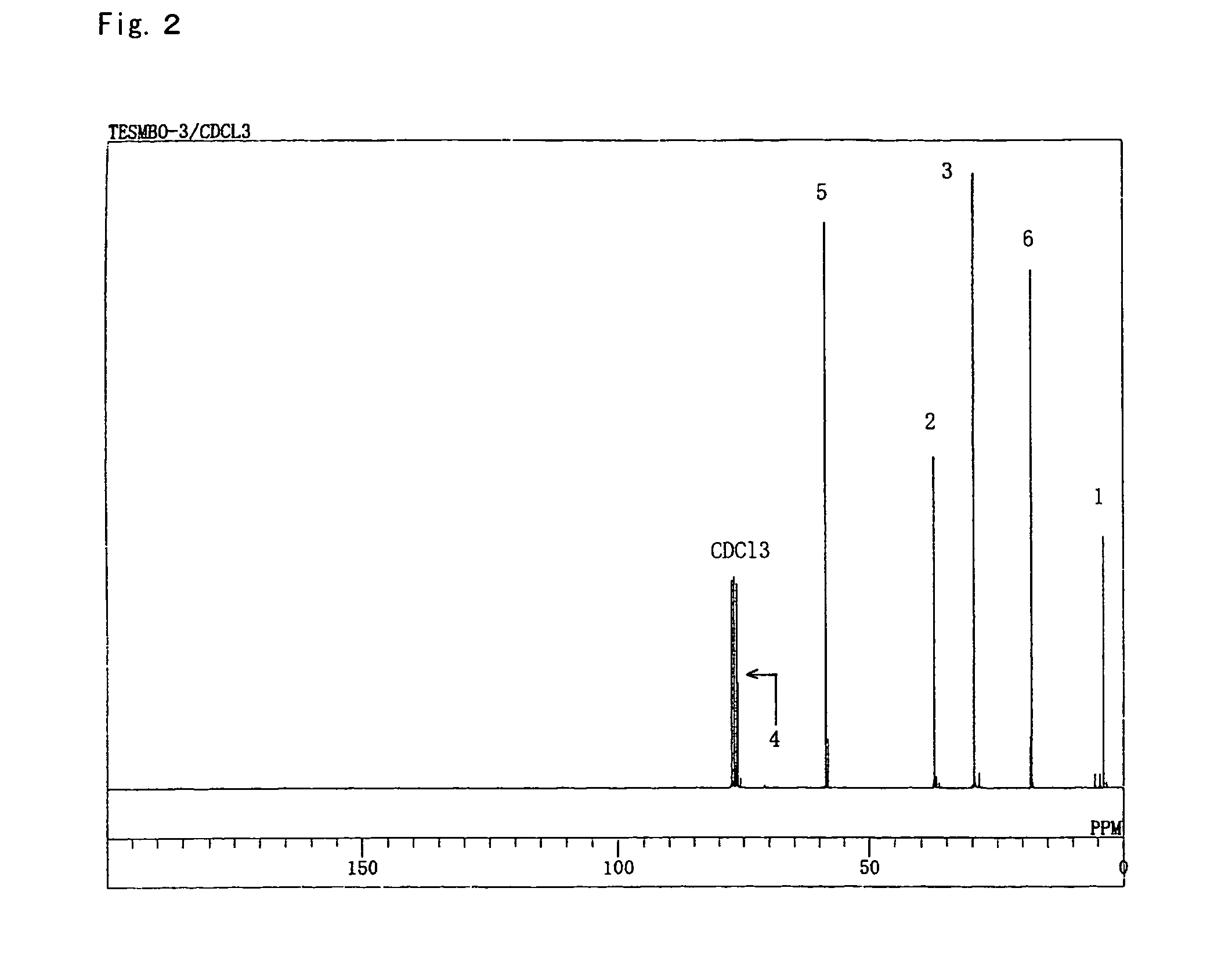

Method for producing cyclic organic silicon compound and organic silicon resin having alcoholic hydroxyl group

ActiveUS7402648B2High puritySecondary reaction can be suppressedSilicon organic compoundsMethyl groupHydrolysis

The object of the present invention is to provide a production method wherein synthesis of a cyclic organic silicon compound similar to oxa-silacyclopentanes is completed in a single-step reaction. It is also to provide an organic silicon resin having an alcoholic hydroxyl group, which is capable of easily controlling its construction and is longitudinally stable.The means for solving is to produce the cyclic organic silicon compound represented by the formula (3) below by reacting an olefin represented by the formula (1) below and an alkoxysilane represented by the formula (2) below in the presence of a catalyst comprising a transition metal.(In the formula, Z is alkenyl group having carbon atoms from 2 to 5 where the terminal carbon atom forms a C═C bond, R is methyl group or hydrogen atom, and Me is methyl group.)(In the formula, R1 is alkyl group or alkoxyl group, having carbon atoms from 1 to 3, and R2 is alkyl group having carbon atoms from 1 to 3.)(In the formula, Z′ is alkylene group having carbon atoms from 2 to 5.)And it is an organic silicon resin having an alcoholic hydroxyl group obtained by performing hydrolysis and condensation of a cyclic organic silicon compound represented by the formula (3) above, or of a mixture of this and a polyfunctional alkoxysilane.

Owner:TOAGOSEI CO LTD

A kind of preparation method of dihydrostreptomycin sulfate

ActiveCN106928288BFast decolorizationHigh puritySugar derivativesSugar derivatives preparationUltrafiltrationIon exchange

The invention discloses a preparation method for dihydrostreptomycin sulphate and belongs to the production preparation technology of semi-synthesis antibiotics. The method comprises the following steps: treating with acid; performing ion exchange; adsorbing with large-pore amino resin; hydrogenating; performing secondary ion exchange; purifying by a mixed bed; treating with activated carbon; concentrating through a nanofiltration membrane; decolorizing by activated carbon; and treating with an ultrafiltration membrane and performing spray drying. According to the invention, the dosage of oxalic acid in a preparation process is reduced, the use ratio of the reducing agent is increased, the production cost is lowered, the production efficiency is increased, the method can meet the industrial production requirement and the product purity, quality yield and total recovery of the dihydrostreptomycin sulphate are increased.

Owner:华北制药华胜有限公司

A kind of preparation method of p-aminophenylacetic acid

ActiveCN106083631BDoes not affect purityEasy purityOrganic compound preparationAmino-carboxyl compound preparationPhenylacetic acidOrganosolv

Owner:HEFEI PINGGUANG PHARMA

High-purity sodium rabeprazole compound

The invention relates to a high-purity sodium rabeprazole compound, belonging to the technical field of medicine. The method includes the following steps: dissolving crude sodium rabeprazole synthesized by the reaction of rabeprazole and sodium hydroxide in water, adjusting pH value to be faintly acid to neutral by using solid acid salt, and collecting precipitated solid; after dissolving the solid with organic solvent, conducting elution and purification by using eluting agent through macroporous adsorption resin, and collecting eluent; and adjusting the pH value of the eluent to be alkaline, and collecting the precipitated solid to obtain the pure sodium rabeprazole.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com