Preparation method for dihydrostreptomycin sulphate

A technology of dihydrostreptomycin sulfate and streptomycin sulfate, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of low utilization rate of reducing agent, high consumption of oxalic acid, and unstable quality and other problems, to achieve the effect of increasing the amount of decolorizing agent, high purity, and reasonable reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

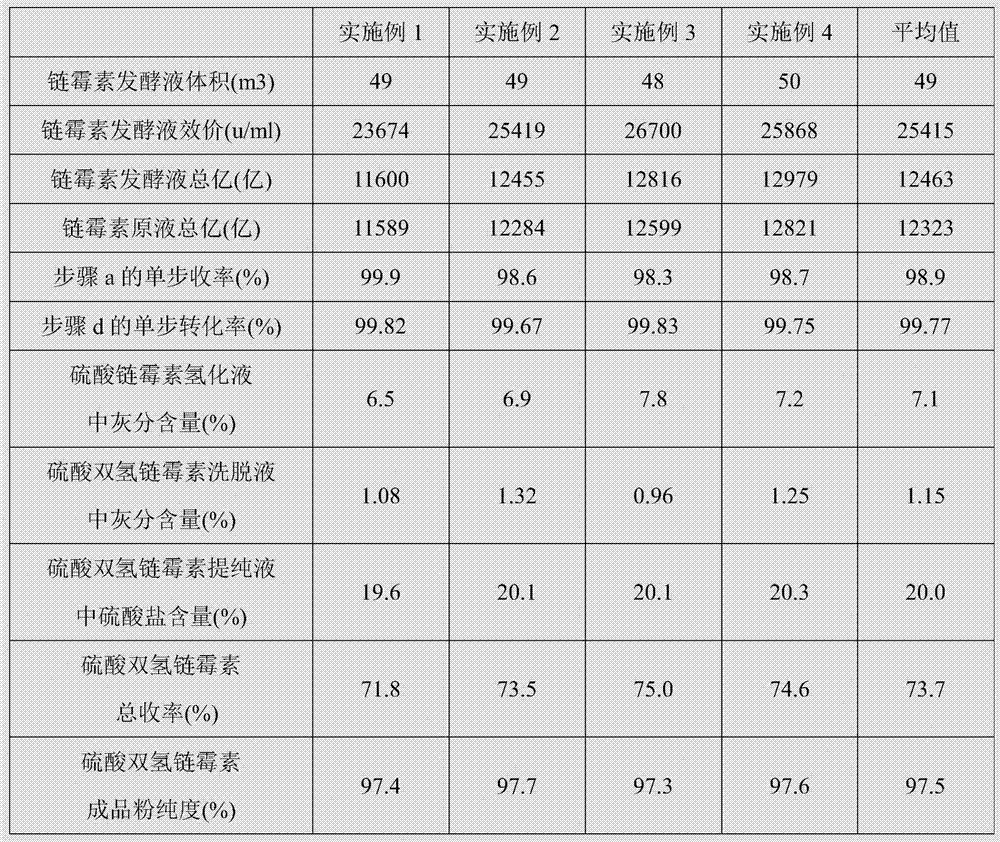

Examples

preparation example Construction

[0041] A kind of preparation method of dihydrostreptomycin sulfate of the present invention, its specific implementation steps are as follows:

[0042] a. According to 6 ~ 16kg / m 3 Add oxalic acid to the streptomycin fermentation broth, then adjust the pH to 2.5-3.5 with sulfuric acid, heat to 60-85°C, remove insoluble matter by centrifugation or filtration, and then adjust the pH to 7.0-8.5 with sodium hydroxide, Prepare streptomycin stock solution;

[0043] b. Adsorb and saturate the streptomycin stock solution with sodium type 110 resin, D152 resin or D150 resin, wash with soft water, anhydrous salt water or purified water, and then elute with 5.0-6.5% dilute sulfuric acid to obtain streptomycin sulfate eluent;

[0044] c. Adsorb and saturate the streptomycin eluate with macroporous primary amine-based resin D303, wash with anhydrous brine or purified water and press dry, and then use 7.0-9.0% dilute sulfuric acid to circulate and analyze to obtain streptomycin sulfate a...

Embodiment 1

[0054] A kind of preparation method of dihydrostreptomycin sulfate of the present embodiment, its specific implementation steps are as follows:

[0055] a. According to 6kg / m 3 Add oxalic acid to streptomycin fermentation broth, then adjust pH to 2.5 with sulfuric acid, heat to 60°C, remove insoluble matter by centrifugation or filtration, and then adjust pH to 7.0 with sodium hydroxide to obtain streptomycin stock solution ;

[0056] b. After the streptomycin stock solution is adsorbed and saturated with sodium type 110 resin, it is washed with soft water and pressed dry, and then eluted with 5.0% dilute sulfuric acid to obtain a streptomycin sulfate eluent;

[0057] c. Absorb and saturate the streptomycin eluate with macroporous primary amine-based resin D303 or D318, wash with purified water, and then analyze with 8.0% dilute sulfuric acid to obtain a streptomycin sulfate analysis solution;

[0058] d. After adjusting the pH of the streptomycin sulfate analysis solution t...

Embodiment 2

[0067] A kind of preparation method of dihydrostreptomycin sulfate of the present embodiment, its specific implementation steps are as follows:

[0068] a. According to 16kg / m 3 Add oxalic acid to streptomycin fermentation broth, then adjust pH to 3.5 with sulfuric acid, heat to 85°C, remove insoluble matter by centrifugation or filtration, and then adjust pH to 8.5 with sodium hydroxide to obtain streptomycin stock solution ;

[0069] b. After the streptomycin stock solution is adsorbed and saturated with sodium D152 resin, it is washed with anhydrous brine and eluted with 5.0% dilute sulfuric acid to obtain a streptomycin sulfate eluent;

[0070] c. After the streptomycin eluate is absorbed and saturated with macroporous primary amine-based resin D318 resin, it is washed with anhydrous brine and pressed dry, and then analyzed with 6.0% dilute sulfuric acid to obtain a streptomycin sulfate analysis solution;

[0071]d. After adjusting the pH of the streptomycin sulfate anal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com