Method for detecting residues on a component

A technology for detecting components and residues, applied in the direction of optical testing for defects/defects, etc., can solve problems such as high equipment costs, and achieve the effect of simplifying detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

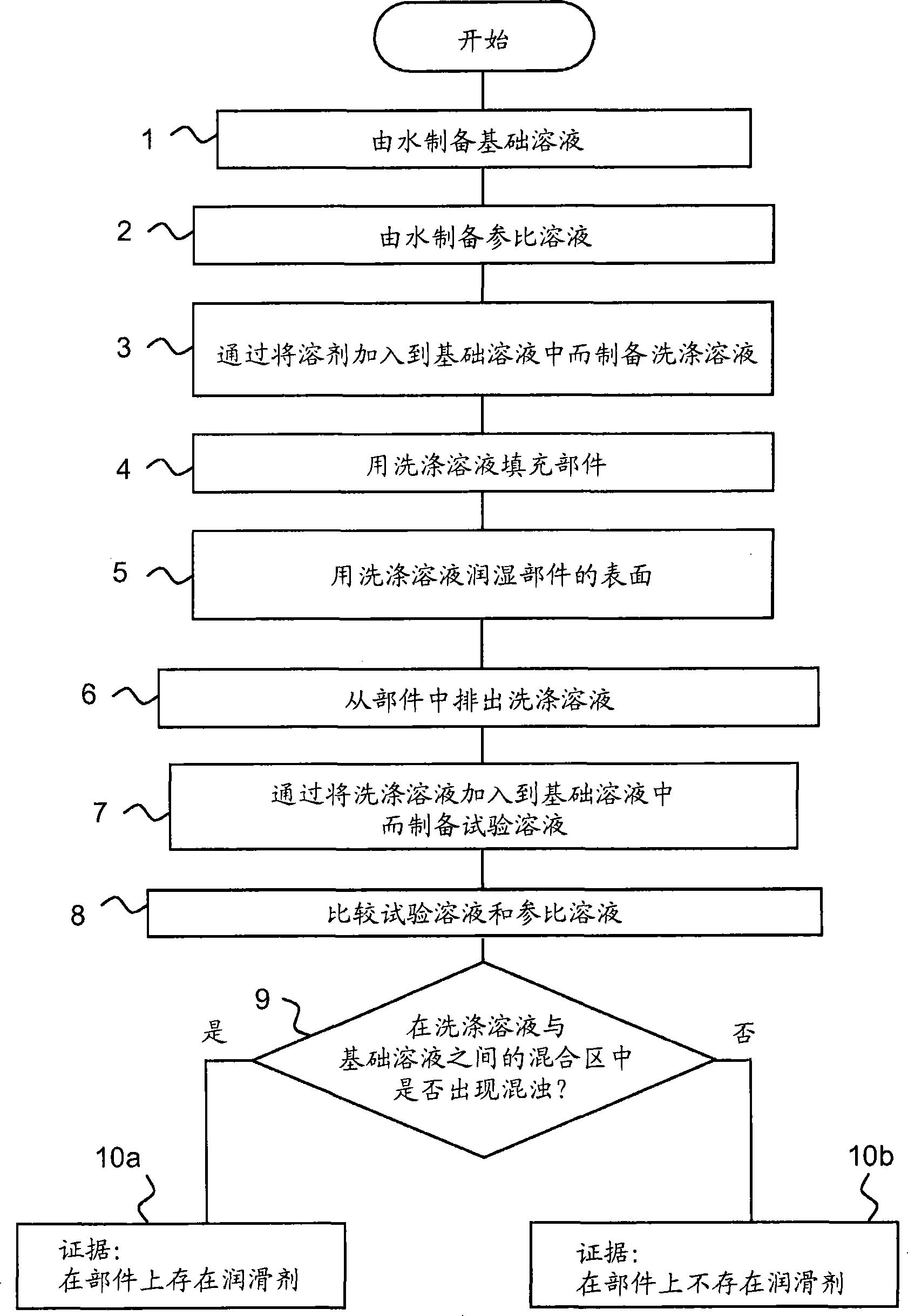

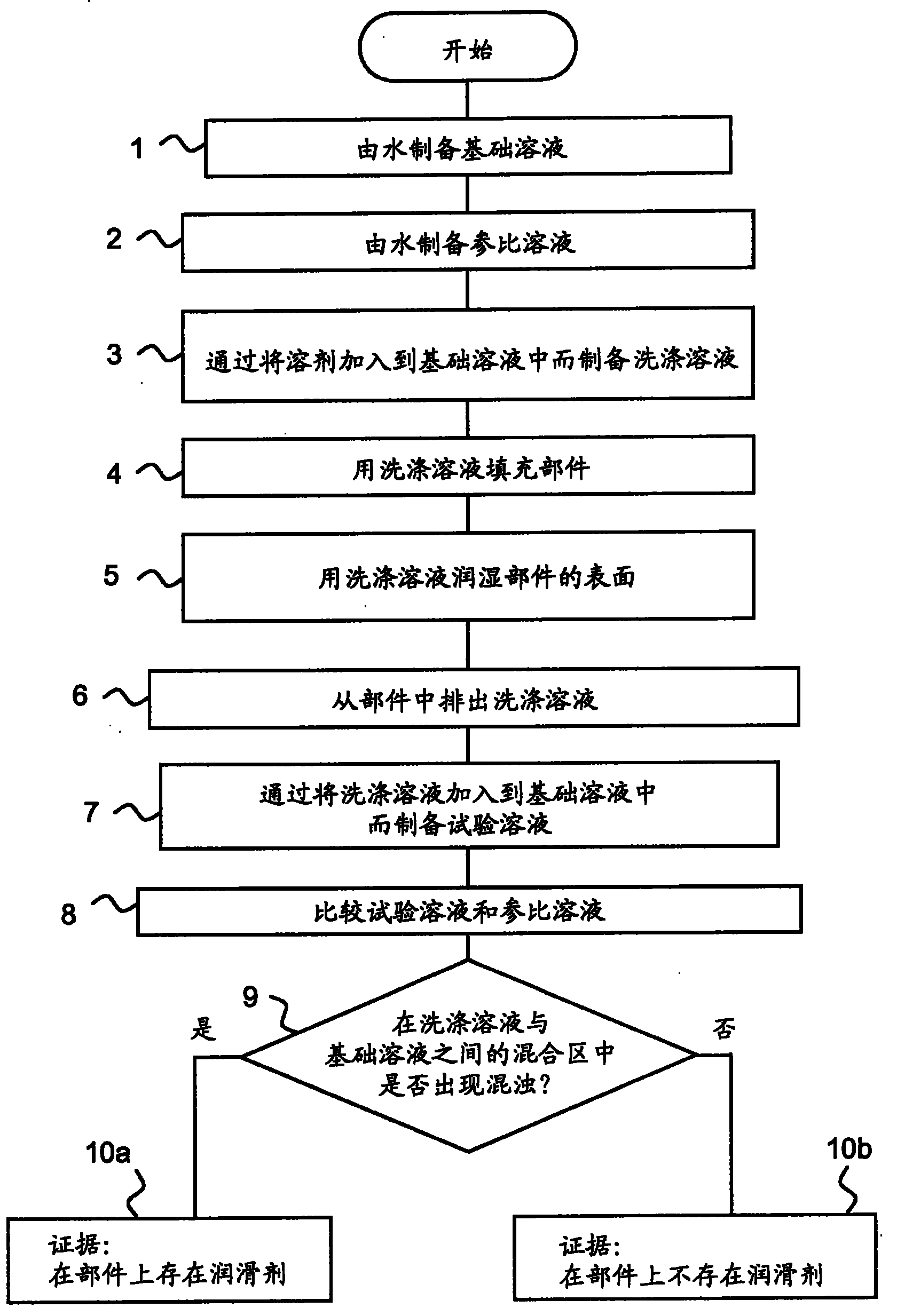

[0035] In the method according to the invention, the procedure is shown in figure 1 In step 1, place 9 ml of deionized or distilled water as a base solution in a test tube. In step 2 parallel thereto, a reference sample (also called blind or blank sample) of the same composition is prepared, ie as 9 ml of deionized or distilled water in a test tube.

[0036] To prepare the actual wash solution, in step 3, fresh solvent is added to a clean Pasteur pipette in such a way that the solvent-water mixing zone appears in the upper region of the tube filling. The amount of solvent is preferably 1 ml. During mixing, a change in clarity may occur due to a change in the refractive index of the mixture, however it does not indicate cloudiness and disappears within a minute. If persistent turbidity develops, the solvent and / or water is contaminated and should not be used for testing. The water and solvent are then replaced with fresh material.

[0037] In step 4, the part to be inspecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com