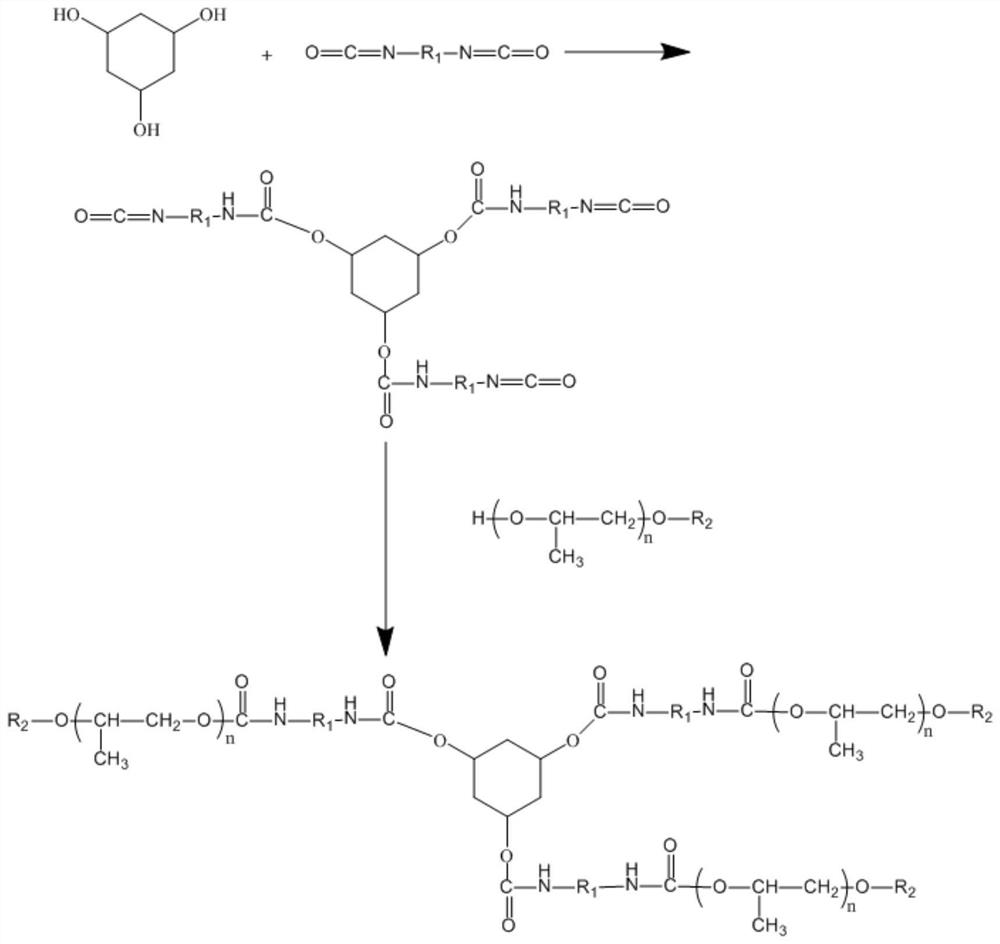

A kind of hyperbranched dispersant and preparation method thereof

A technology of hyperbranched dispersant and catalyst, which is applied in the direction of coating, etc., can solve the problems of high price of hyperdispersant, affect the performance of hyperbranched dispersant, complex central atomic structure, etc., and achieve excellent color development and versatility , simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

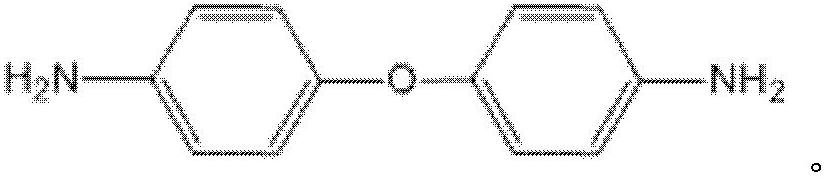

Method used

Image

Examples

Embodiment 1

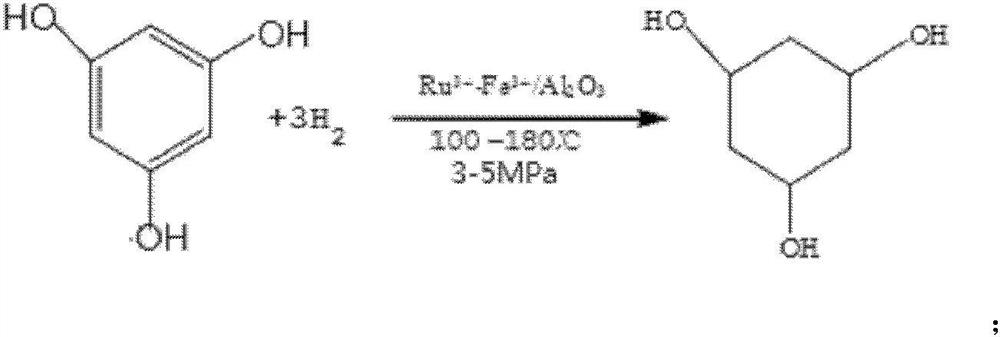

[0060] The embodiment of the present invention provides a kind of preparation method of hyperbranched dispersant, comprises the following steps:

[0061] (1) Weigh 7.847g of RuCl 3 ·3H 2 O (261.57, 0.03mol), 2.705g FeCl 3 ·6H 2 O (270.5, 0.01mol) was added into 200mL of double distilled water, stirred and added dropwise with 5% hydrochloric acid to make the pH of the solution 3, after stirring and dissolving, 100g of dry γ-Al 2 o 3 Slowly immerse in the above solution, stir and mix, put it into a constant temperature 50°C electric blast drying oven, let it stand for 72h, filter, wash, and dry to obtain the catalyst precursor.

[0062] (2) Soak the catalyst precursor obtained in step (1) in distilled water, cool down to 15°C, and use 5% hydrochloric acid to adjust the pH value of the solution to 3, then add 15% NaBH dropwise under stirring conditions 4 When the alkali solution does not have hydrogen and heat to be emitted in the solution, filter, wash, put into a vacuum ov...

Embodiment 2

[0067] The embodiment of the present invention provides a kind of preparation method of hyperbranched dispersant, comprises the following steps:

[0068] (1) Weigh 7.847g of RuCl 3 ·3H 2 O (261.57, 0.03mol), 2.705g FeCl 3 ·6H 2 O (270.5, 0.01mol) was added into 200mL of double distilled water, stirred and added dropwise with 5% hydrochloric acid to make the pH of the solution 3, after stirring and dissolving, 100g of dry γ-Al 2 o 3 Slowly immerse in the above solution, stir and mix, put it into a constant temperature 50°C electric blast drying oven, let it stand for 72h, filter, wash, and dry to obtain the catalyst precursor.

[0069] (2) Soak the catalyst precursor obtained in step (1) in distilled water, cool down to 15°C, and use 5% hydrochloric acid to adjust the pH value of the solution to 3, then add 15% NaBH dropwise under stirring conditions 4 When the alkali solution does not have hydrogen and heat to be emitted in the solution, filter, wash, put into a vacuum ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Branching factor | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com