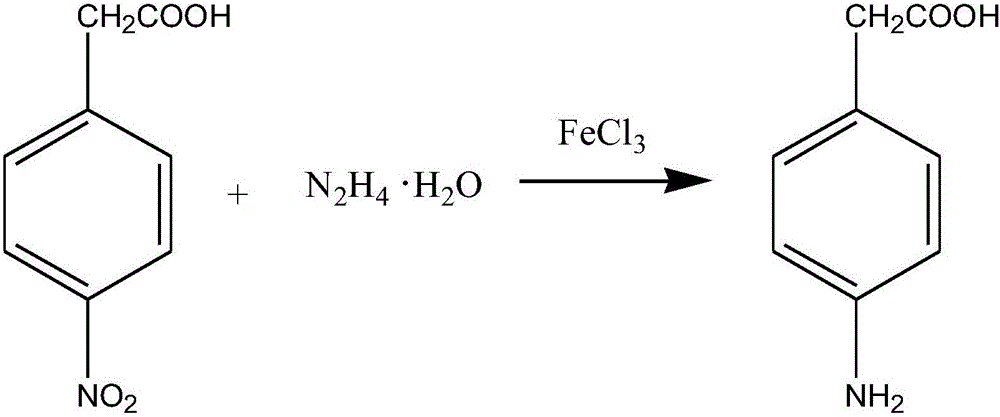

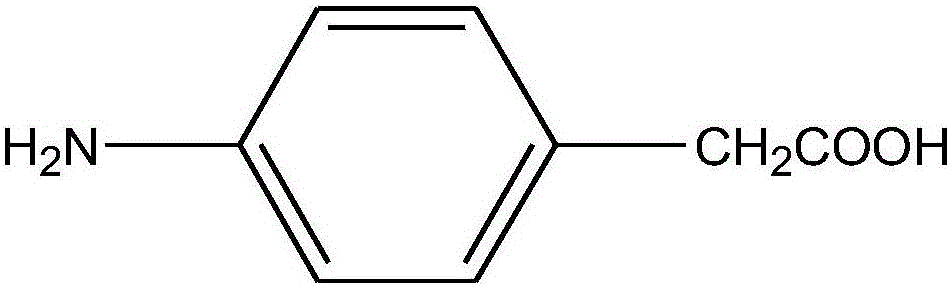

Preparation method of p-aminophenylacetic acid

A technology of p-aminophenylacetic acid and p-nitrophenylacetic acid, which is applied in the field of p-aminophenylacetic acid preparation, can solve the problems of difficult solid waste, low product yield, backward technology, etc., and achieve good purity, high yield, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method for p-aminophenylacetic acid, comprising the steps of: mixing water, ferric chloride, and p-nitrophenylacetic acid, heating up to 60°C under a nitrogen atmosphere, adding an aqueous solution of hydrazine hydrate dropwise, keeping the temperature for 2 hours, and cooling down to 20°C. ℃ to crystallize, filter to take the filter cake, wash with water, and dry to obtain p-aminophenylacetic acid, wherein the weight ratio of water, ferric chloride, p-nitrophenylacetic acid, and hydrazine hydrate is 10:0.05:1:0.45, wherein, for The amount of water used to wash the filter cake is not included.

Embodiment 2

[0024] A preparation method for p-aminophenylacetic acid, comprising the steps of: mixing water, ferric chloride, and p-nitrophenylacetic acid evenly, heating up to 90°C under a nitrogen atmosphere, adding an aqueous solution of hydrazine hydrate dropwise, keeping the temperature for 1 hour, and cooling down to 5 ℃ to crystallize, filter to take the filter cake, wash with water, and dry to obtain p-aminophenylacetic acid, wherein the weight ratio of water, ferric chloride, p-nitrophenylacetic acid, and hydrazine hydrate is 10:0.2:1:1, wherein, for The amount of water used to wash the filter cake is not included.

Embodiment 3

[0026] A preparation method for p-aminophenylacetic acid, comprising the steps of: mixing water, ferric chloride, and p-nitrophenylacetic acid, heating up to 70°C under a nitrogen atmosphere, adding hydrazine hydrate aqueous solution dropwise, keeping the temperature for 1.8h, and cooling down to Crystallize at 15°C, filter the filter cake, wash with water, and dry to obtain p-aminophenylacetic acid, wherein the weight ratio of water, ferric chloride, p-nitrophenylacetic acid, and hydrazine hydrate is 10:0.2:1:0.55, wherein, use The amount of water used to wash the filter cake is not included.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com