Treatment method of crystallization mother liquor in adipic acid crystallization refining process

A processing method and technology for crystallization mother liquor, which can be used in organic chemistry methods, separation/purification of carboxylic acid compounds, organic chemistry, etc., and can solve problems such as difficulty in processing crystallization mother liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Get 100g adipic acid crystallization mother liquor, by weight, the typical composition of described crystallization mother liquor is adipic acid (15%), glutaric acid (30%), water (40%), other impurity (15%), Other impurities are mainly succinic acid, esters, polymers, catalysts and other reaction by-products or impurities such as catalysts entrained in the mother liquor, add 10g of methanol, stir evenly, stand at 20°C for 20min, then separate layers, and obtain a light liquid in the upper layer after liquid separation Phase 93g and lower heavy liquid phase 17g.

[0040] The above-mentioned light liquid phase was evaporated under reduced pressure, with an evaporation rate of 40%, to obtain 37.2g of condensate, which was crystallized at 20°C for 40 minutes, and solid-liquid separation obtained 41g of mixed crystals of adipate and glutaric acid, and the impurity content was 0.5w% according to liquid chromatography analysis. The steam condensate can recover methanol and wat...

Embodiment 2

[0043] Take 100g of adipic acid crystallization mother liquor, in parts by weight, the composition of the crystallization mother liquor is the same as that of Example 1, add 20g of methanol, stir evenly, leave to stand at 5°C for 5min and then separate layers, after liquid separation, 102g of the upper light liquid phase and the lower layer are obtained. Heavy liquid phase 18g.

[0044] The above-mentioned light liquid phase was evaporated under reduced pressure, the evaporation volume was 55%, and 56.1 g of condensate was obtained, which was crystallized at 5° C. for 15 minutes, and 44 g of mixed crystals of adipic acid and glutaric acid were obtained by solid-liquid separation. According to liquid chromatography analysis, the impurity content was 0.4w%. The steam condensate can recover methanol and water.

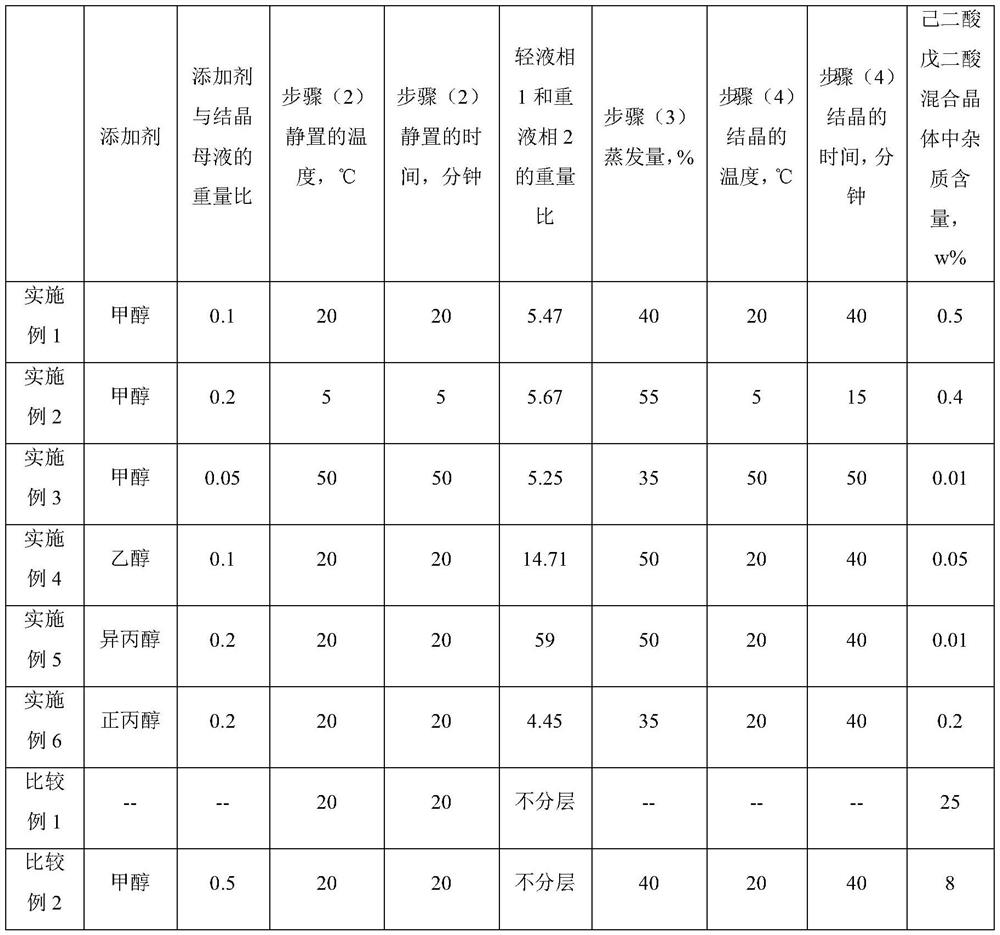

[0045] For the convenience of comparison, the main process conditions and experimental results are listed in Table 1.

Embodiment 3

[0047] Take 100g of adipic acid crystallization mother liquor, in parts by weight, the composition of the crystallization mother liquor is the same as that of Example 1, add 5g of methanol, stir evenly, leave to stand at 50°C for 50min, then separate layers, and obtain 84g of the upper light liquid phase and the lower layer after liquid separation Heavy liquid phase 16g.

[0048] The above-mentioned light liquid phase was evaporated under reduced pressure, with an evaporation rate of 35%, to obtain 29.4g of condensate, crystallized at 50°C for 50min, and obtained 20g of adipate-glutaric acid mixed crystals by solid-liquid separation, and the impurity content was 0.01w% according to liquid chromatography analysis. The steam condensate can recover methanol and water.

[0049] For the convenience of comparison, the main process conditions and experimental results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com