Biological method for preparing gamma-aminobutyric acid

A technology of aminobutyric acid and aminobutyric acid clear solution, which is applied in the field of preparation of γ-aminobutyric acid, can solve the problems of cumbersome separation and purification process, restriction of industrial production, and complex components of fermentation broth, so as to improve product purity, low cost, Post-processing simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Bacteria culture

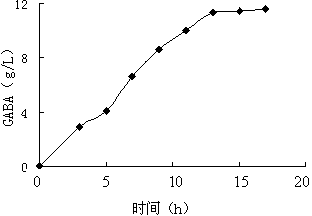

[0033] After the lactic acid bacteria strains are activated, the first-level seed culture, the second-level seed culture, and finally enter the fermenter culture, the inoculation amount is 3% (V / V, seed liquid / fermentation liquid), 30 ℃ static culture for 16 hours, the fermentation process The pH is controlled by adding lye, so that the pH of the fermentation broth is maintained in the range of 4.5-7.0, and the bacteria are collected by filtration through a 0.6 μm ceramic membrane.

[0034] Seed medium raw materials in g / L: glucose 10, yeast extract 5, peptone 5, sodium acetate 0.5, disodium hydrogen phosphate (or dipotassium hydrogen phosphate) 1, magnesium sulfate 1, manganese sulfate 1, PPE polyether defoaming Agent 0.1 (but not limited to this defoamer, any defoamer that can be used in the fermentation industry can be used).

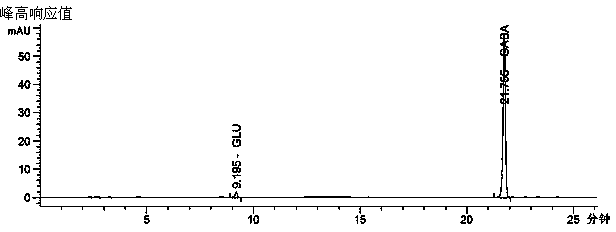

[0035] Fermentation medium formula in g / L: glucose 10, yeast extract 5, peptone 5, sodium acetate 0.5, sodium glutamat...

Embodiment 2

[0053] A method for preparing gamma-aminobutyric acid by a biological method, comprising the following steps:

[0054] (1) Cell preparation:

[0055] Add sodium glutamate to the medium, and add 1-30g / L (for example, 1 g / L, 15 g / L, 30 g / L) as an inducer to induce enzyme production and insert it into the producing cells The strain of glutamic acid decarboxylase is cultivated; the culture conditions are: culture temperature 25-35°C (for example, 25°C, 30°C, 35°C), pH control is carried out by adding lye during the fermentation process, so that the pH of the fermentation broth is maintained at Within the range of 4.5-7.0, the culture time is 8 to 24 hours (for example, 8h, 16h, 24h); the bacterial liquid is obtained after the culture;

[0056] (2) Collection of bacterial cells by ceramic membrane filtration: filter the bacterial liquid obtained in step (1) through a ceramic membrane to collect bacterial cells with a membrane pore size of 0.05-1 μm (for example, 0.05 μm, 0.5 μm, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com