Patents

Literature

104 results about "Tert-Butyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tert-Butyl acetate, t-butyl acetate or TBAc is a colorless flammable liquid with a camphor- or blueberry-like smell. It is used as a solvent in the production of lacquers, enamels, inks, adhesives, thinners and industrial cleaners. It has recently gained EPA volatile organic compound (VOC) exempt status.

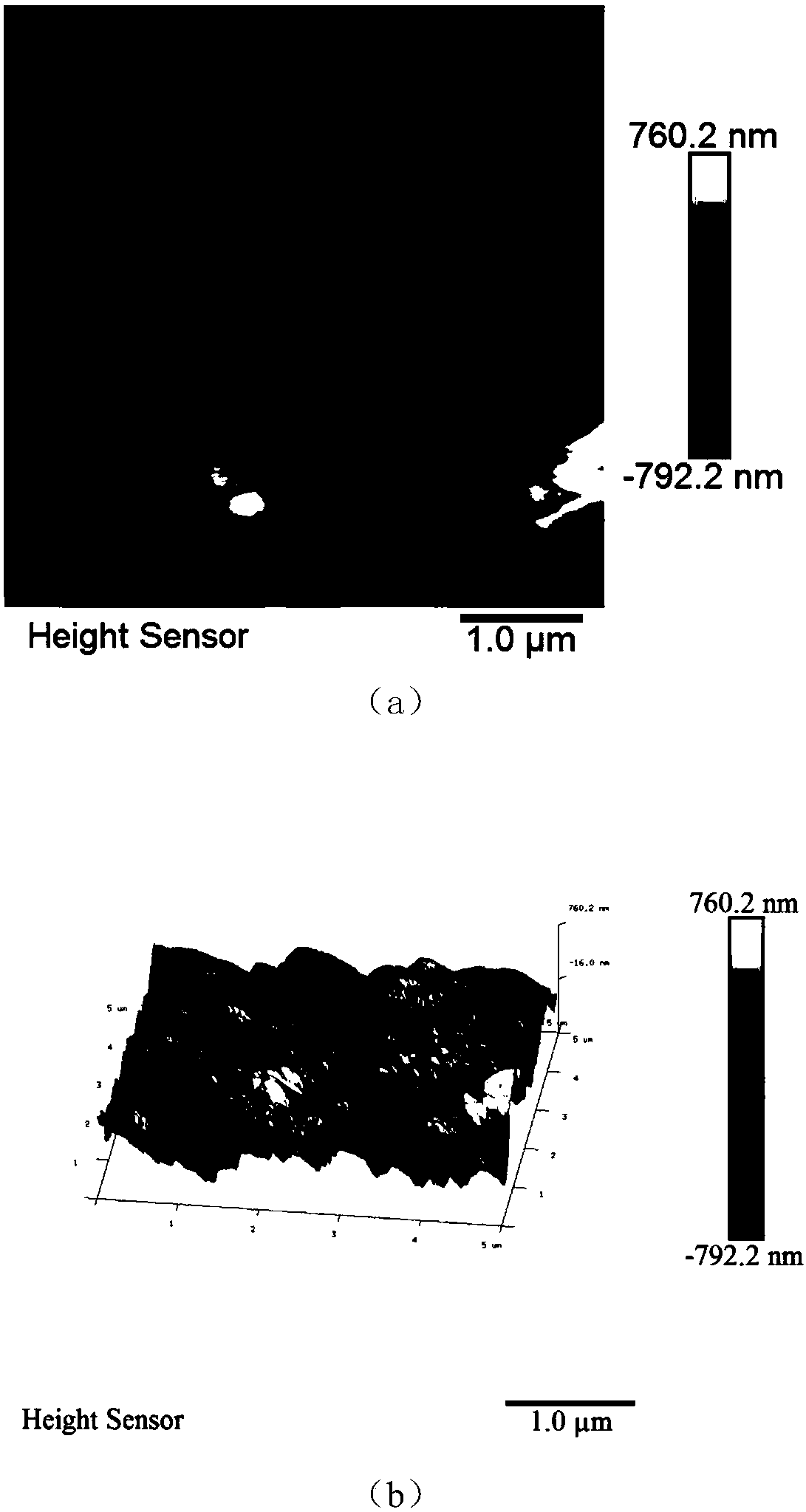

Bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and preparation method and application thereof

The invention discloses a bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and a preparation method and application thereof. The preparation method comprises the following steps: 1) performing synergistic modification treatment on two or more nanoparticles to obtain modified blended particles; 2) adding the blended modified particles into a dispersing solvent, performing ultrasonic dispersion for 1 to 2 hours and then mechanically stirring; 3) adding a certain amount of tert-butyl acetate into fluoro-siloxane resin and performing shearing dispersion to obtain substrate material emulsion; 4) mixing the blended modified particle turbid liquid in the step 2 and the substrate material emulsion in the step 3, adding a coupling agent, heating, stirring anddispersing, and performing dispersion by a high-speed shearing dispersing machine to obtain super-amphiphobic coating; and 5) stirring the super-amphiphobic coating uniformly, spray-coating the surface of an object with the super-amphiphobic coating and drying at room temperature for 10 to 30 minutes to successfully prepare the wear-resistant integrated super-amphiphobic coating. The wear-resistant super-amphiphobic organic-inorganic hybrid coating is obtained by connecting a fluorine-silicon substrate and the blended modified particles through chemical grafting copolymerization reaction.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

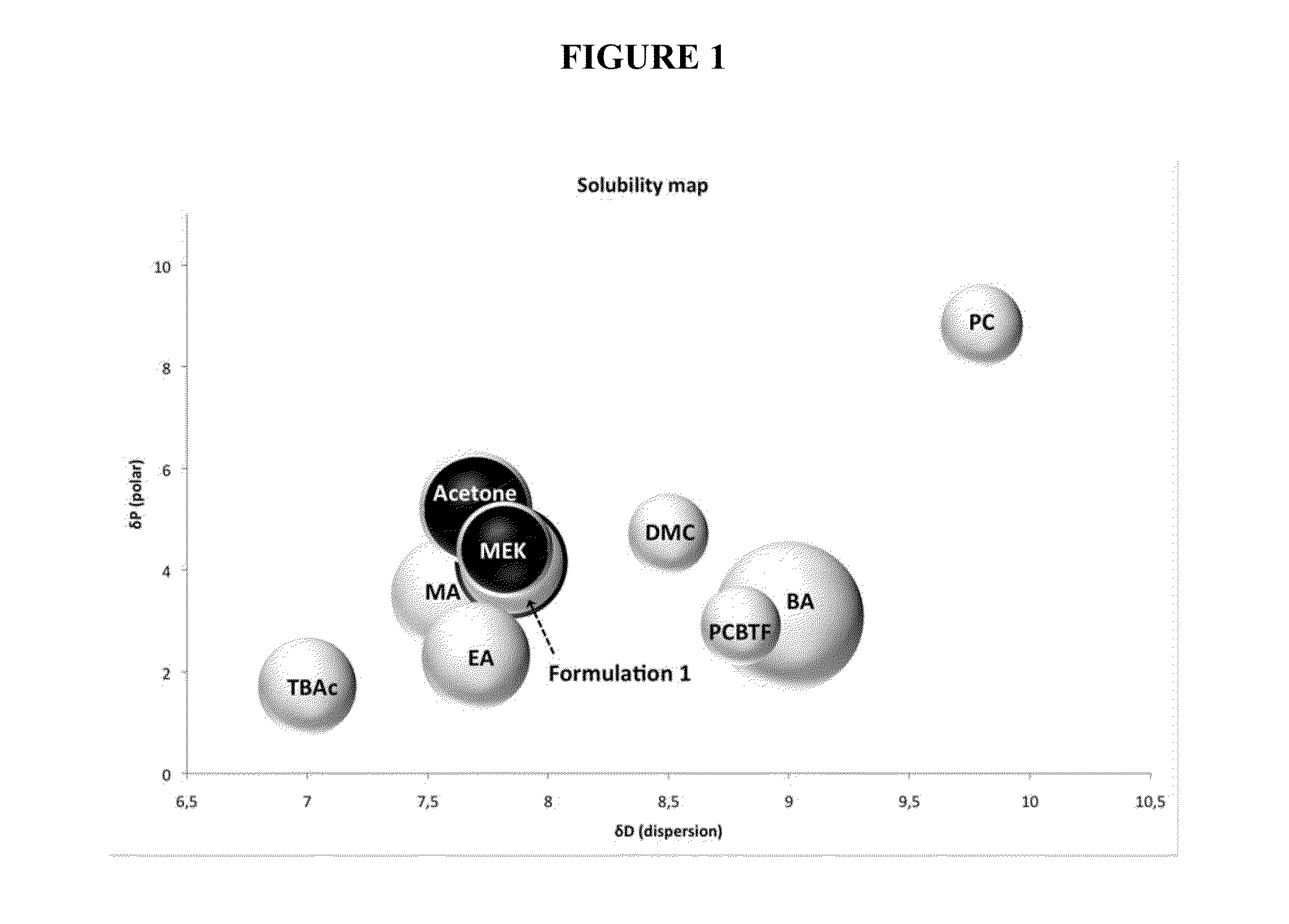

Solvent formulations

ActiveUS20140255326A1Low toxicityCosmetic preparationsOrganic chemistryTert-Butyl acetateCarbonate ester

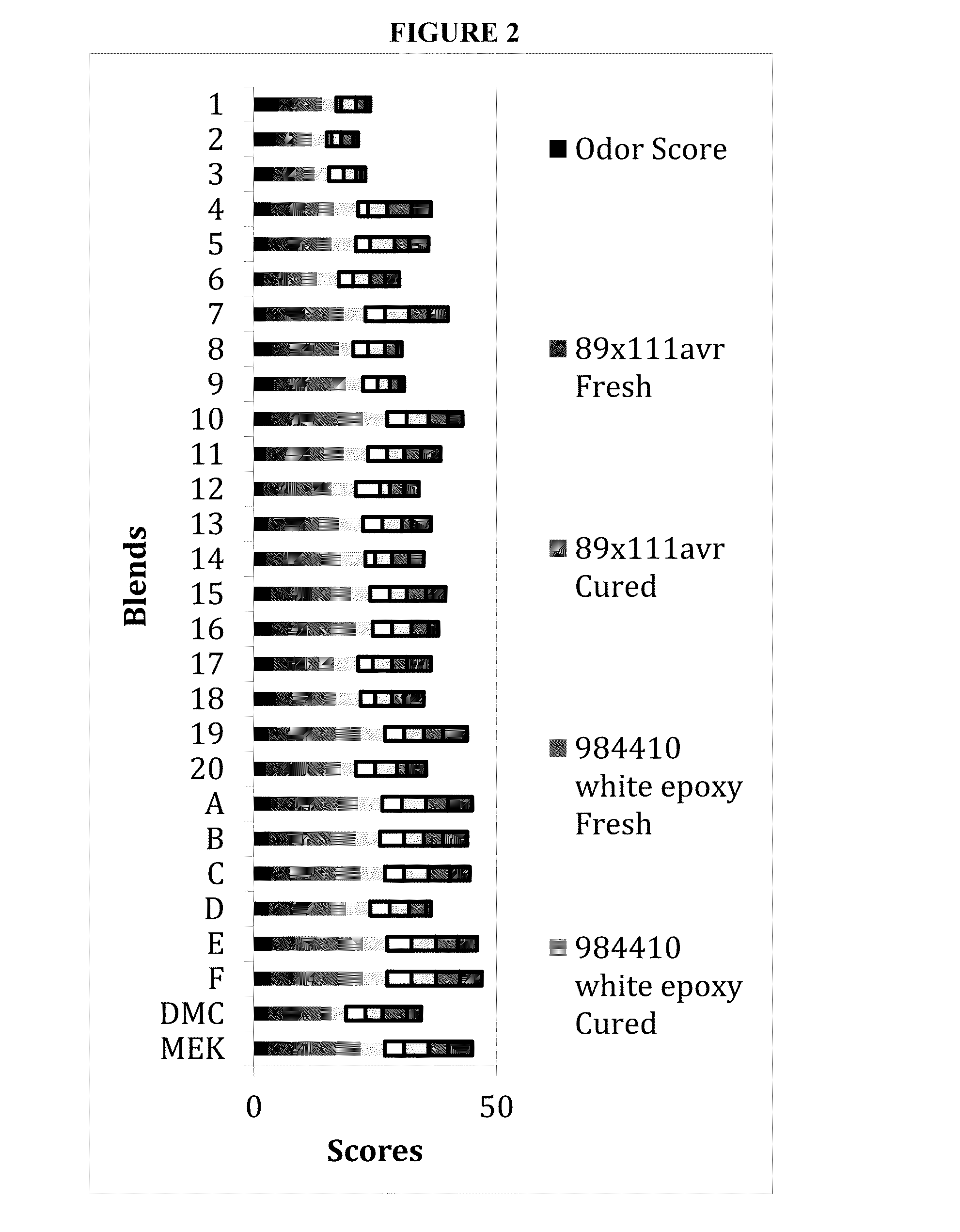

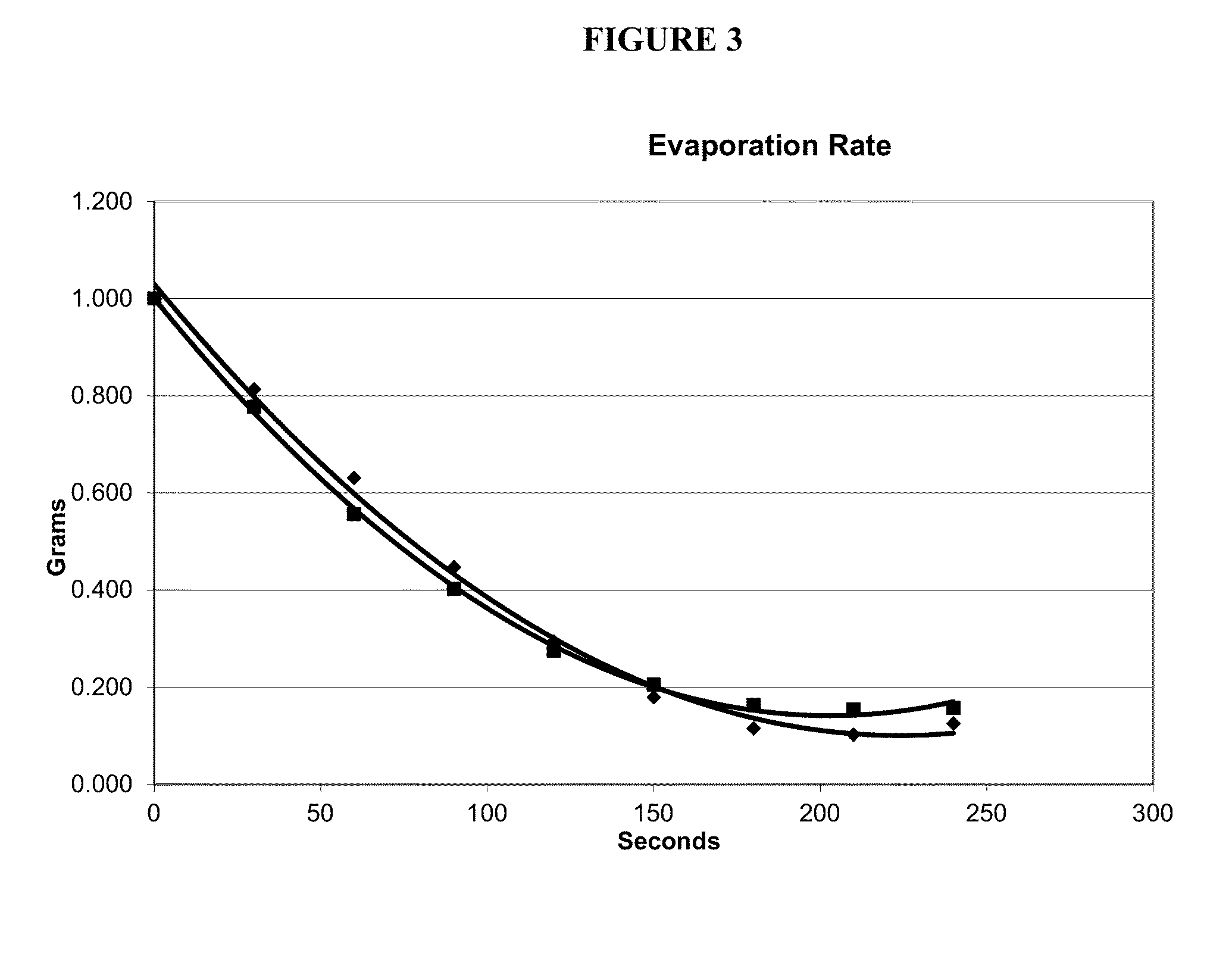

The present disclosure provides, in part, a solvent composition including an an acetic acid alkyl (C1-C4) ester (e.g., methyl acetate (MA), ethyl acetate (EA), or tert-butyl acetate (TBAc)) and a carbonate ester (e.g., dimethyl carbonate, or propylene carbonate)

Owner:TBF ENVIRONMENTAL TECH

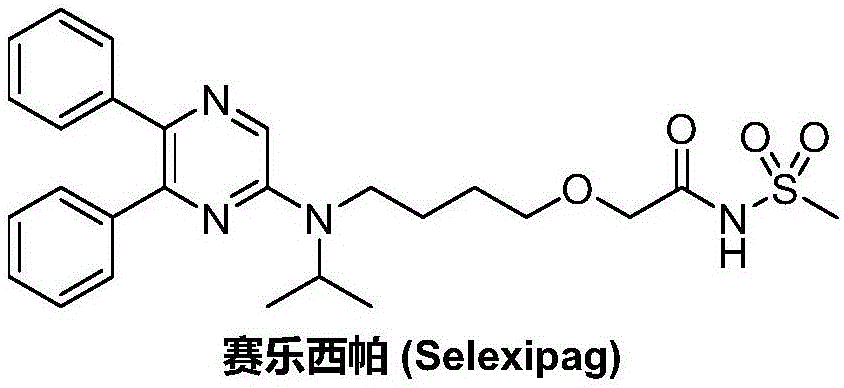

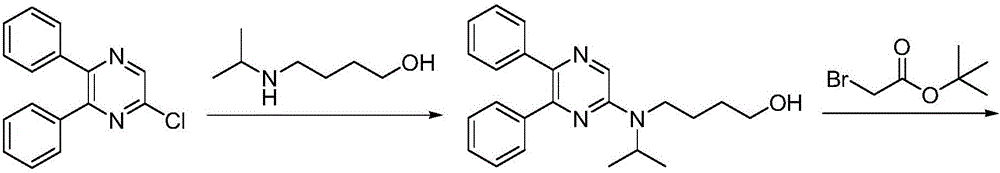

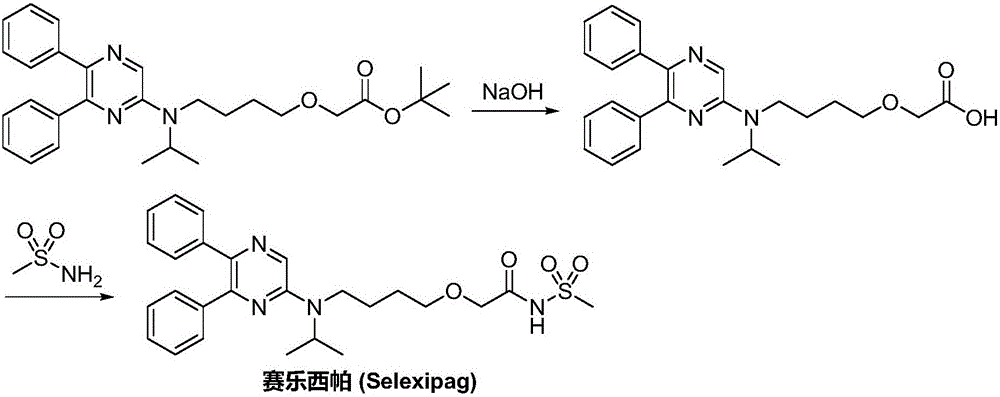

Synthetic method of selexipag

The invention discloses a synthetic method of selexipag. According to the method, 4-[(t-butyloxycarboryl)(isopropyl) amino]-1-butanol and tert-butyl bromoacetate are subjected to a condensation reaction, and obtained 4-[(t-butyloxycarboryl)(isopropyl) amino butoxyl] tert-butyl acetate is subjected to a hydrolysis reaction under an alkaline reaction; obtained 4-[(t-butyloxycarboryl)(isopropyl) amino butoxyl] acetic acid and methanesulfonamide are subjected to a condensation reaction; obtained 2-[4-[(t-butyloxycarboryl)(isopropyl) amino butoxyl]-N-(methylsulfonyl) acetamide is subjected to a deprotection reaction under an acid condition, obtained 2-[4-(isopropyl) amino butoxyl]-N-(methylsulfonyl) acetamide and 5-chloro-2,3-diphenyl pyrazine are subjected to a substitution reaction, and the finished product selexipag is obtained. The method has a reasonable and concise process route and is environment-friendly and suitable for industrial production, the operation is simplified, and the cost is relatively low.

Owner:湖南欧亚药业有限公司

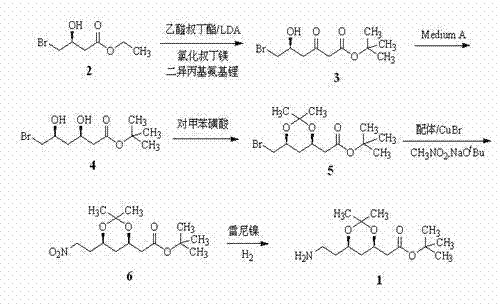

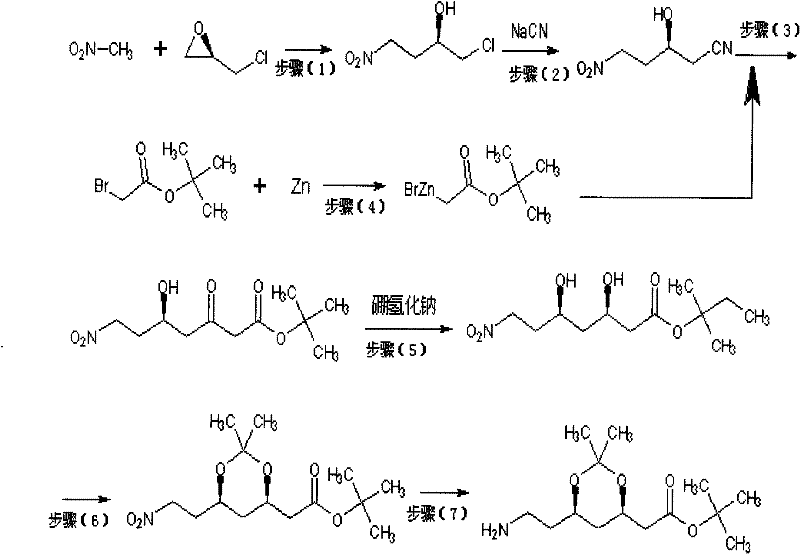

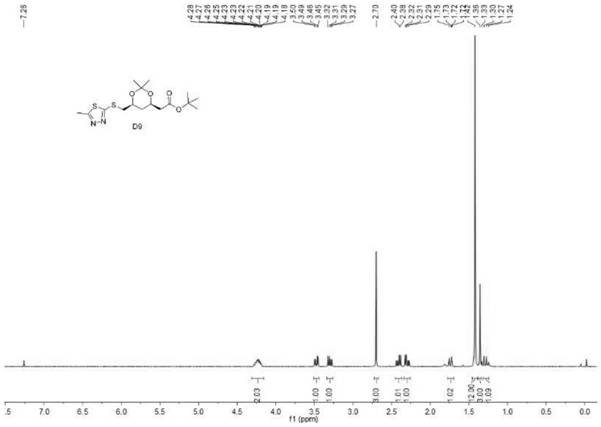

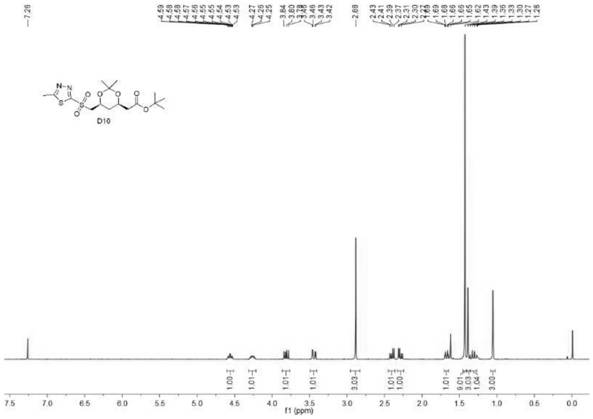

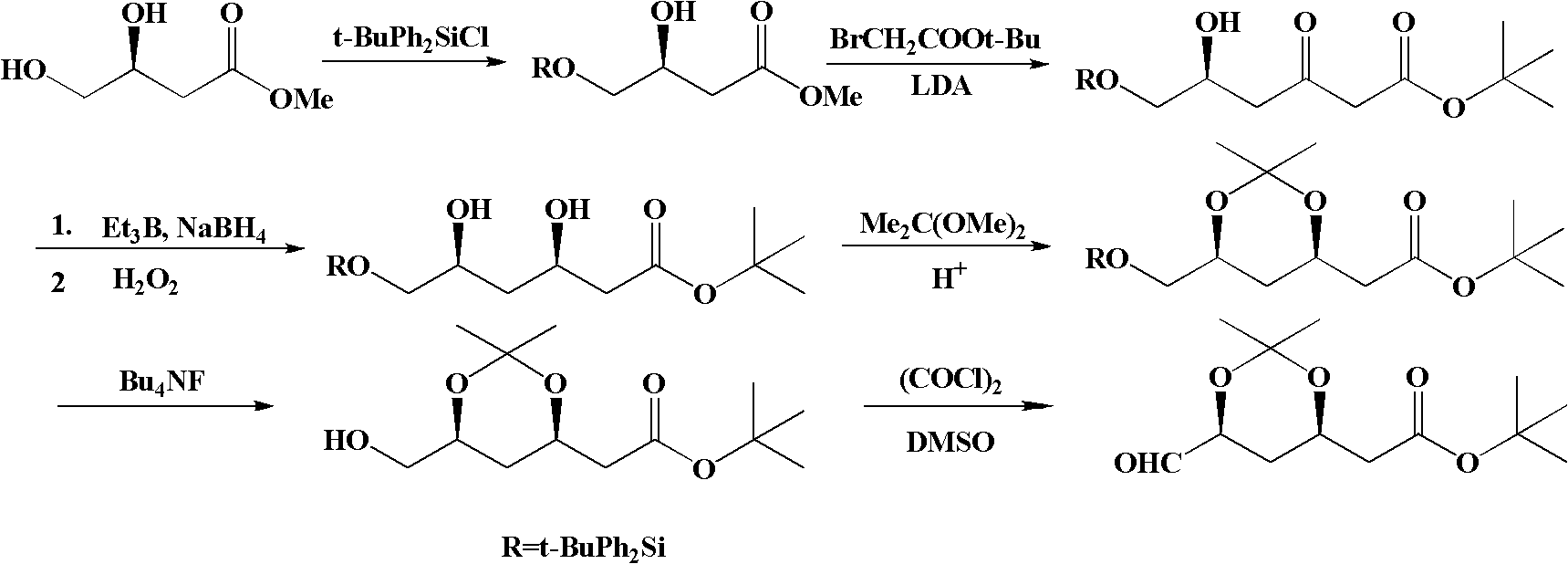

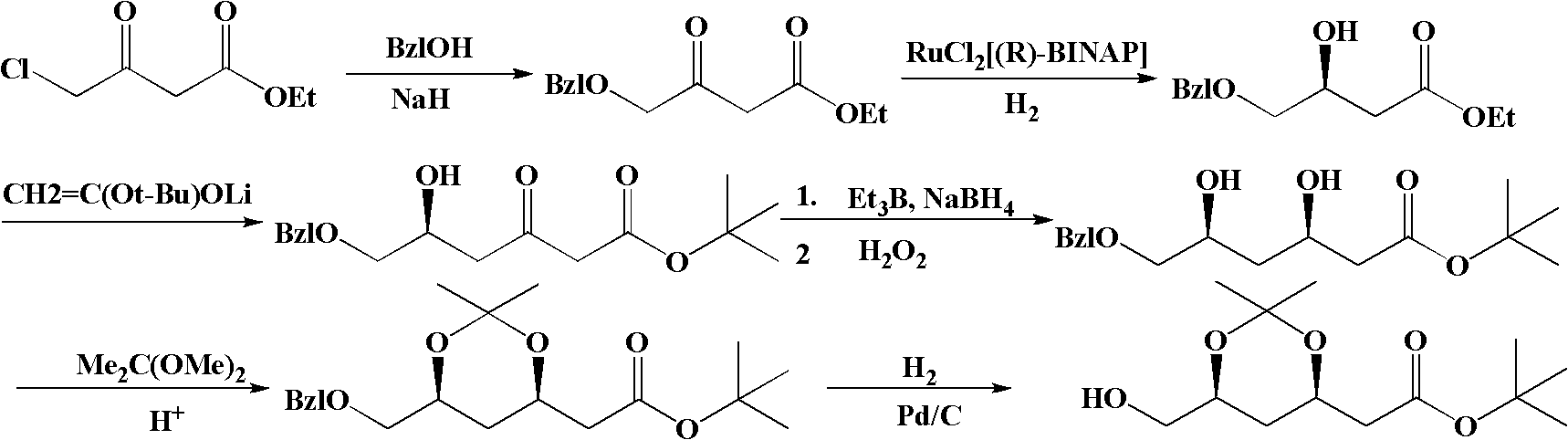

Synthetic method of atorvastatin calcium intermediate

InactiveCN103614430AFew stepsLow costOrganic chemistryMicroorganism based processesEthyl groupNitromethane

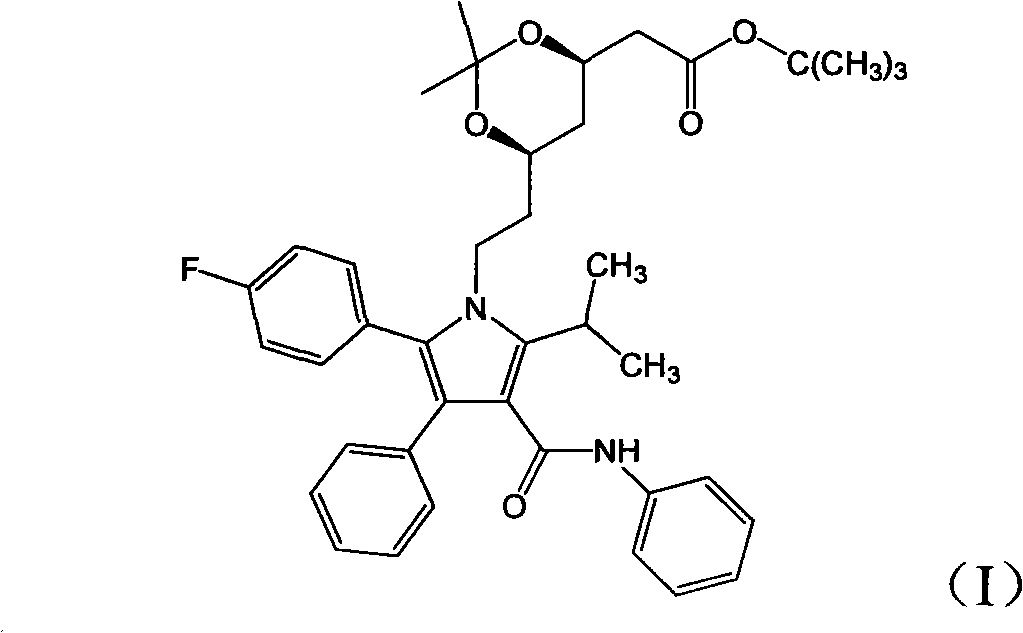

The invention discloses a synthetic method of an atorvastatin calcium intermediate. The synthetic method comprises the following steps: preparing [(4R, 6S)-6- brooethyl-2,2-diemthyl-1,3-dioxane-4-group] tert-butyl acetate (5) by (3S)-4-bromine-3-hydroxyl ethyl butyrate through condensation, asymmetric biological catalytic reduction and hydroxyl protection; and preparing an atorvastatin calcium intermediate [(4R, 6S)-6-(2-aminoethyl)-2,2-dimethyl-1,3-dioxane-4-group] tert-butyl acetate through catalytic hydrogenation reduction of raney nickel after 5 is condensed with nitromethane under action of cuprous bromide and a nitrogen-containing compound ligand. According to the synthetic method disclosed by the invention, steps are shortened, cost is lowered, and therefore, the synthetic method is more suitable for large-scale preparation.

Owner:SUZHOU HEALTH COLLEGE

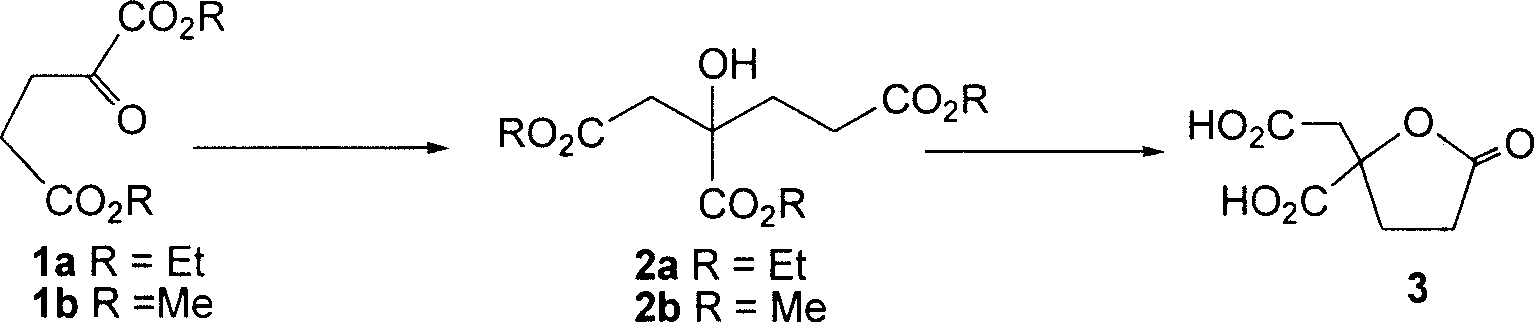

Preparation method for tert-butyl acetate

InactiveCN102115443AIncrease contentHigh mechanical strengthOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidNaphtha

The invention provides a method of preparing tert-butyl acetate by reacting an alkene compound with acetate, wherein the number of the carbon atoms of the alkene compound is four.In particular, the alkene compound with four carbon atoms is obtained from the naphtha cracking process, wherein the volume percentage of isobutene in the above compound is 30-60%.During the reaction of the above alkene compound with acetate, isobutene is selected to be subject to the reaction to obtain tert-butyl acetate of high purity.According to the preparation method, the concentration of 1-butylene in the above alkene mixture is improved and 1-butylene is more easily to be separated in subsequent processes.Index words: alkene esterification reaction, tert-butyl acetate, alkene mixture and solid acid.

Owner:SK INNOVATION CO LTD +1

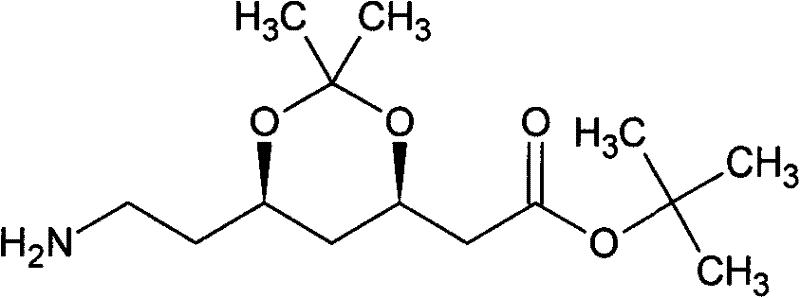

Preparation method of atorvastatin intermediate (3R, 5S)-7-amino-3,5-O-isopropylidene-3,5-dyhydroxyl heptylic acid tert-butyl acetate

The invention discloses a preparation method of an atorvastatin intermediate (3R, 5R)-7-amino-3,5-O-isopropylidene-3,5-dyhydroxyl heptylic acid tert-butyl acetate. The method comprises the following steps of: reacting (R)-epichlorohydrin and nitromethane to generate 1-chlorine-4-nitryl-(R)-2-butanol, and reacting with sodium cyanide to obtain (R)-3-hydroxyl-5-nitryl-valeronitrile; dropwise adding the product into a tert-butyl bromoacetate zinc reagent to generate 7-nitryl-5-hydroxyl-3-carbonyl-heptylic acid tert-butyl acetate; reacting with sodium borohydride to generate 7-nitryl-3,5-dyhydroxyl-heptylic acid tert-butyl acetate; reacting with 2,2-dimethoxypropane, acetone and methanesulfonic acid to obtain 7-nitryl-3,5-O-isopropylidene-3,5-dyhydroxyl-heptylic acid tert-butyl acetate; and obtaining (3R, 5R)-7-amino-3,5-O-isopropylidene-3,5-dyhydroxyl heptylic acid tert-butyl acetate by hydrogen reduction. The yield of the product is 80-86%, and the purity of the product is greater than or equal to 99.0%.

Owner:湖北楚维药业有限公司 +1

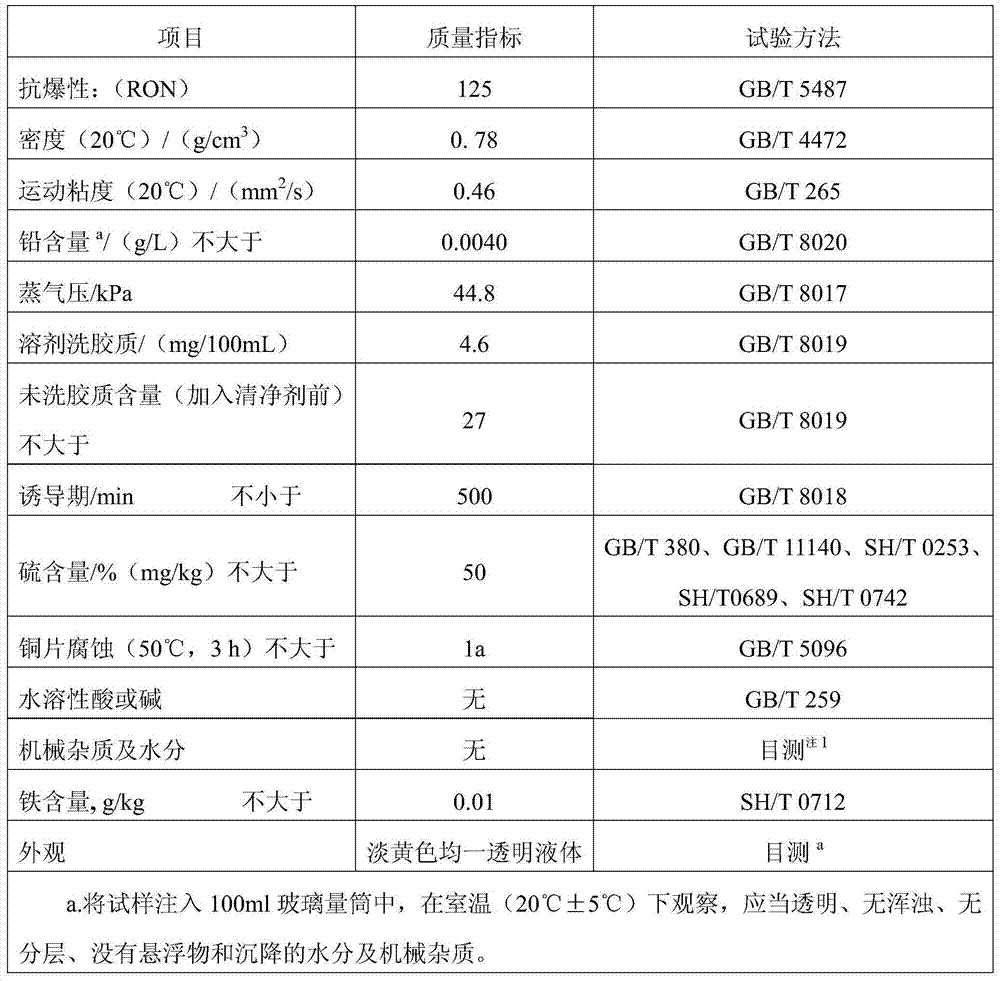

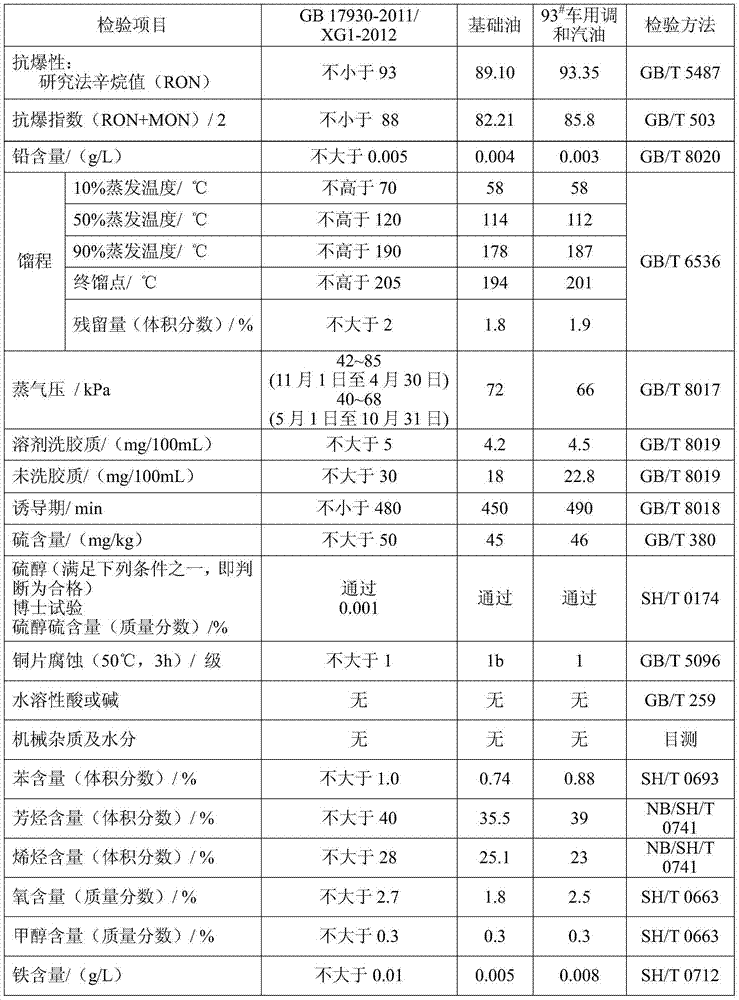

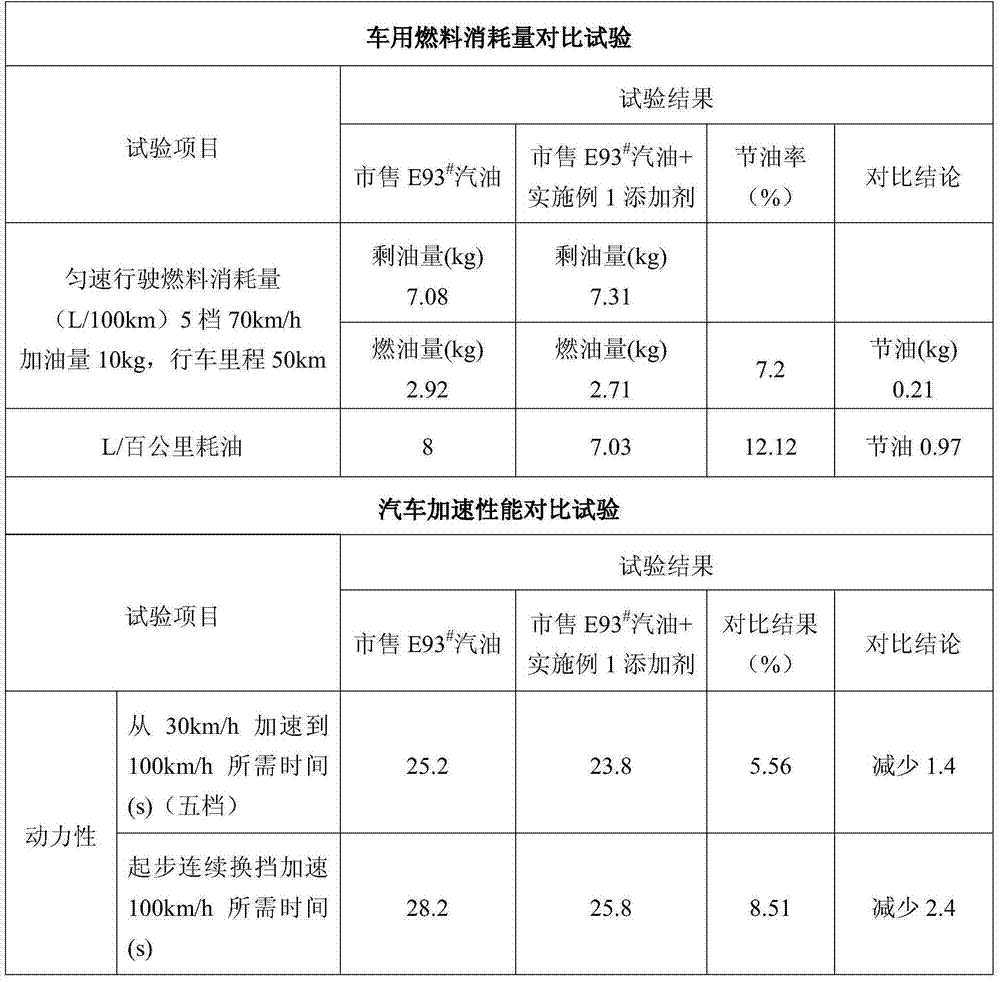

Composite additive for producing National Standard IV 93# gasoline from refinery base oil

InactiveCN104119967AIncrease powerIncrease torqueLiquid carbonaceous fuelsFuel additivesMass ratioMethyl carbonate

The invention provides a vehicle fuel oil composite additive which comprises the following components in percentage by mass: 35-80% of octane number enhancer, 15-38% of combustion improver and 5-27% of assistant. The octane number enhancer is composed of ethanol, tert-butyl acetate, methyl tert-butyl ether, cyclopentane and polymethoxy dimethyl ether in a mass ratio of 40:10:40:7:3; the combustion improver is composed of diisopropyl ether, dimethyl carbonate, nitromethane, acetone and glycol dimethyl ether in a mass ratio of 45:30:10:5:10; and the assistant is composed of isoamyl alcohol, isopropanol, 2-ethylhexanol, dipolylinoleic acid, metal passivator and antioxidant in a mass ratio of 20:60:8:10:0.4:1.6.When being applied to vehicle fuel oil, the composite additive can reduce or eliminate knocking, enable the fuel oil to have high octane number performance and ensure the fuel in the cylinder to be combusted completely, so that both the exhaust emission and fuel consumption are lowered, and the power and torsion of the engine are enhanced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

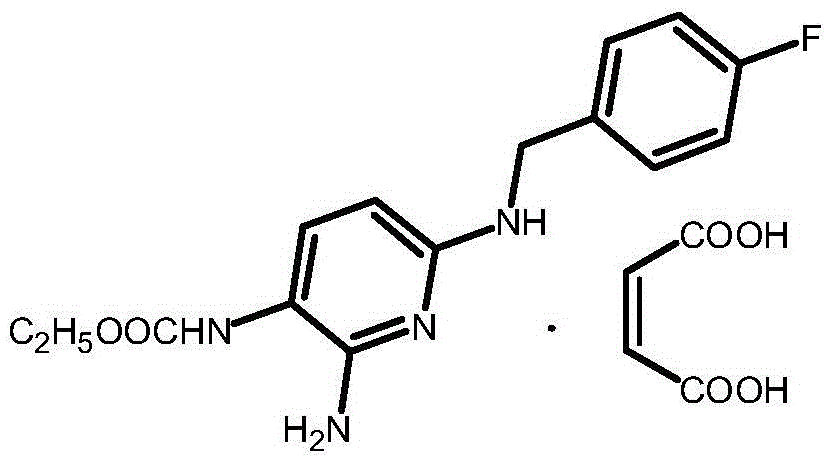

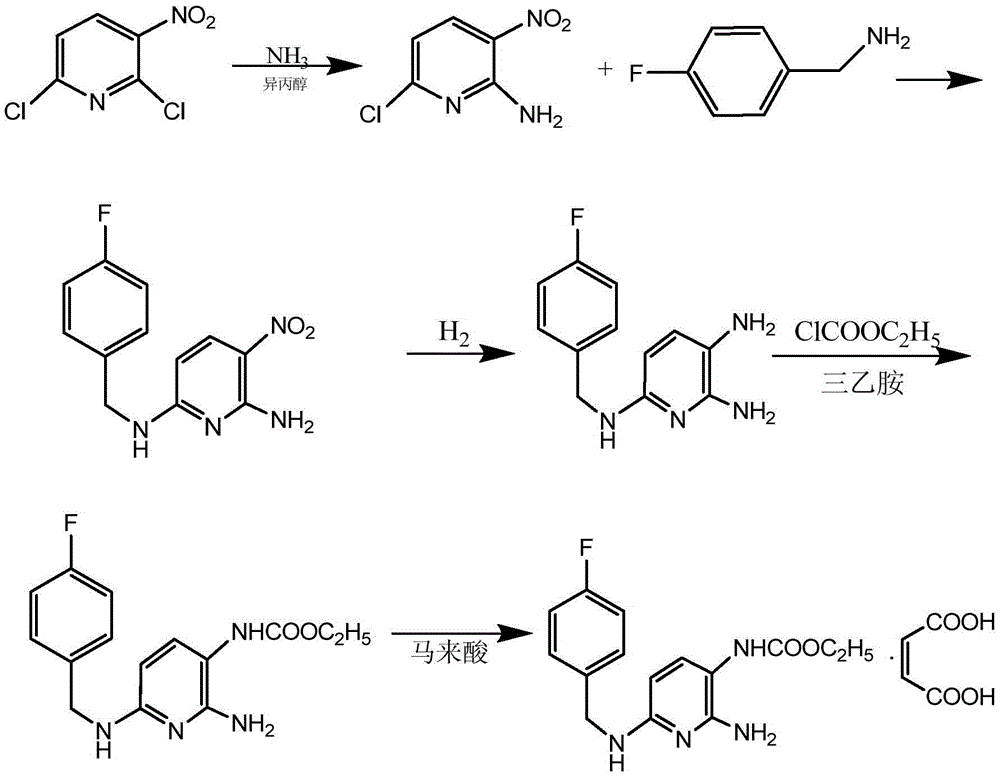

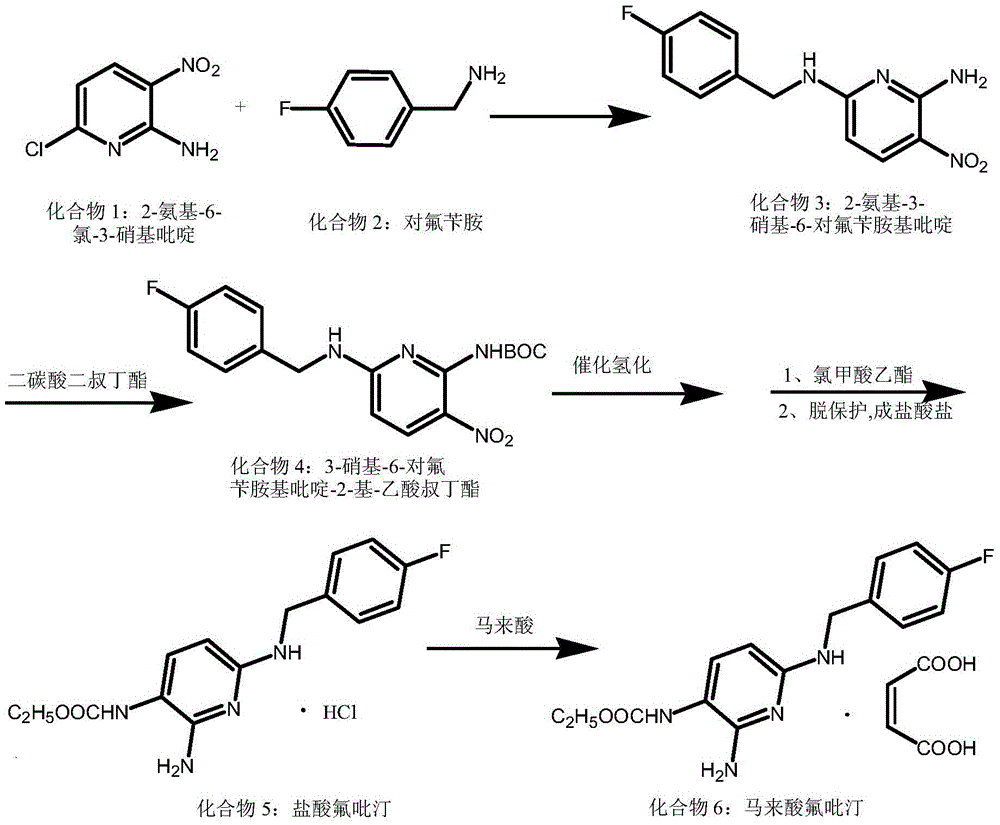

Synthesis method for flupirtine maleate compound

ActiveCN105541705AReduce manufacturing costReduce the possibilityOrganic chemistryEthyl chloroformateSynthesis methods

The invention discloses a synthesis method for a flupirtine maleate compound. The method comprises the steps that 2-amino-3-nitro-6-chloropyridine (a first compound) is used as a starting material to react with fluorobenzylamine (a second compound) to generate 2-amino-3-nitro-6-p-fluorobenzylamine pyridine (a third compound), the third compound is processed through di-tert-butyl dicarbonate ester protection to obtain 2-amino-3-nitro-6-p-fluorobenzylamine pyridine-3-based-tert-butyl acetate (a fourth compound), the fourth compound is processed through hydrogenation reduction and then react with ethyl chloroformate, after reacting is finished, deprotection is performed to obtain flupirtine hydrochloride (a fifth compound), and the fifth compound is salified with maleic acid to obtain flupirtine maleate (the sixth compound). According to the synthesis method, the starting material is cheap and easy to obtain, byproduct generation is avoided through amino protection, therefore, the impurity content is decreased, and the product quality is improved; catalytic reduction is performed by adopting palladium chloride, the reaction condition is mild, the reaction process is easy to operate, and the method is suitable for industrial production.

Owner:SHANDONG LUOXIN PHARMA GRP HENGXIN PHARMA CO LTD

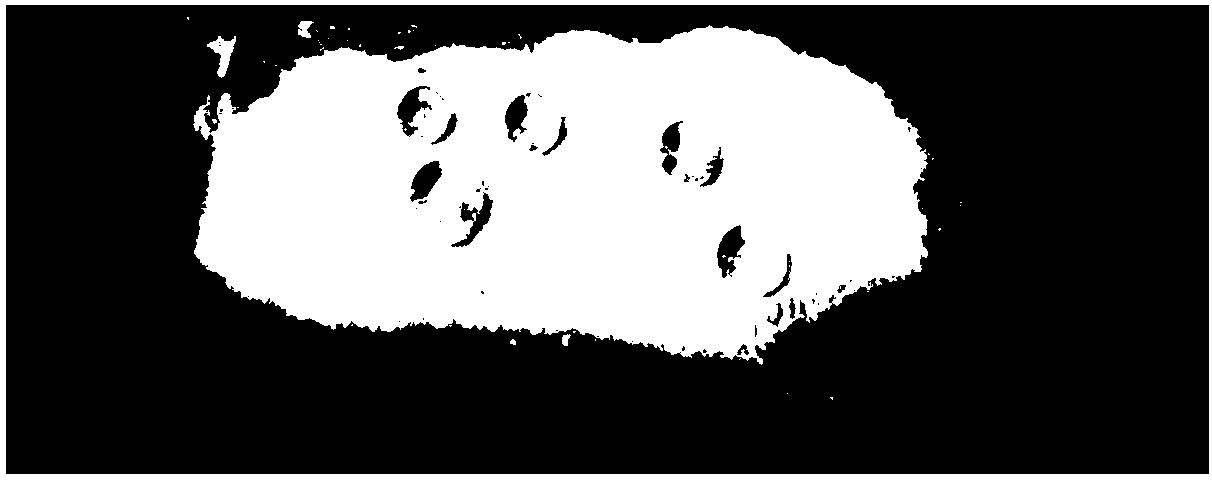

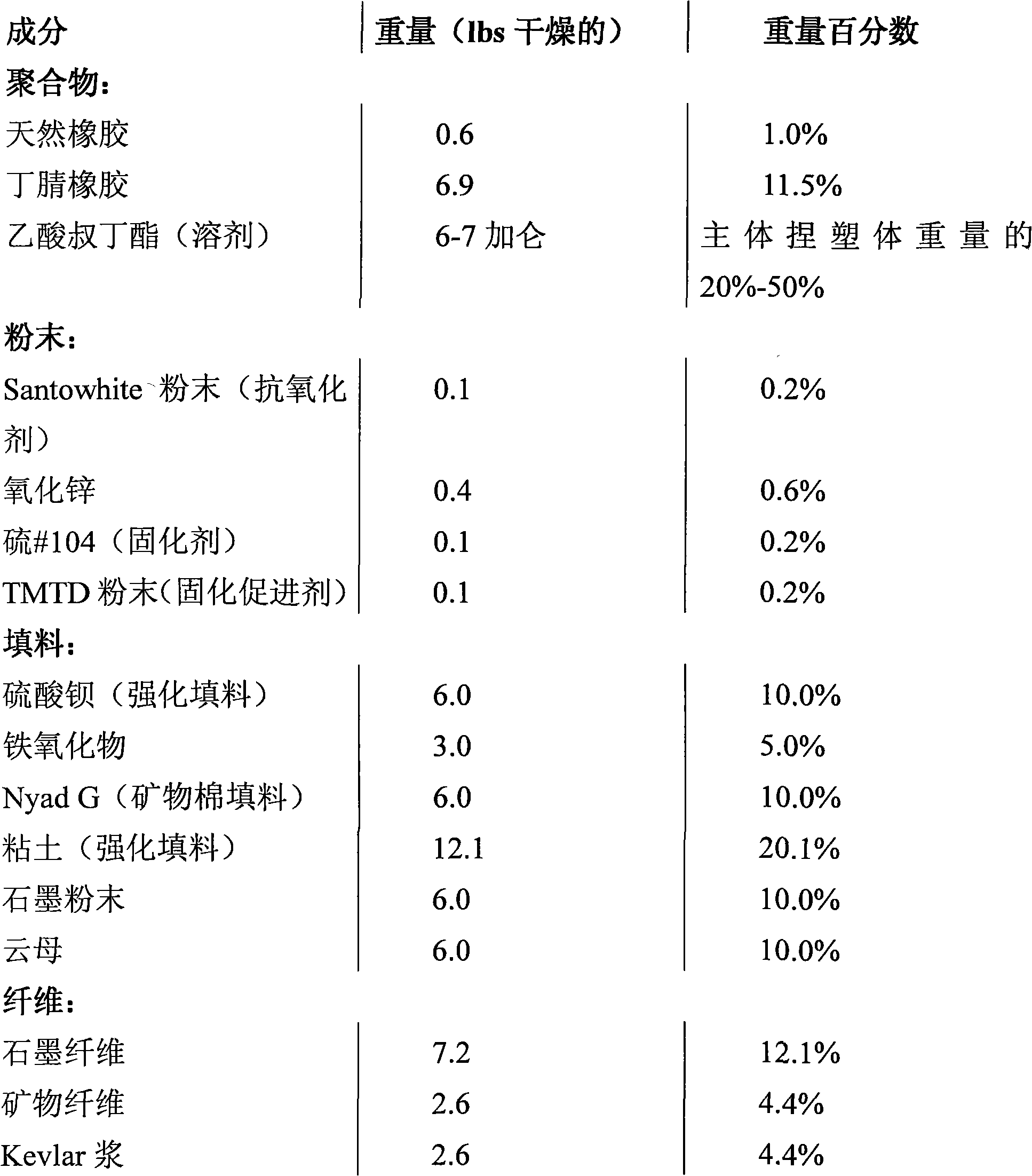

Process for making high-pressure sheet gasketing materials

InactiveCN101528880AObvious advantageObvious featuresOther chemical processesVehicle sealing arrangementsElastomerFiber

A method for making high-pressure sheet gasketing material is provided that employs an elastomer, such as natural rubber and / or acylonitrile-butadiene rubber. Tert-butyl acetate is added to dissolve the elastomer. Other components may then be mixed with the dissolved elastomer and may include, for example, antioxidants, colorants, curing agents, curing accelerators, reinforcing fillers, and fibers such as organic and / or mineral fibers. The resulting dough may be formed into a high-pressure sheets, for use as gasketing material, using a two-roll sheeter machine, or the like.

Owner:GARLOCK SEALING TECH LLC (US)

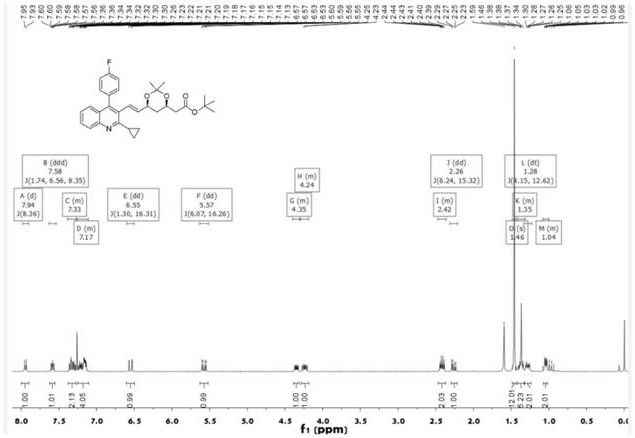

Synthetic method of pitavastatin tert-butyl ester

ActiveCN111875538AHigh stereoselectivityHigh purityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystQuinoline

The invention discloses a synthesis method of pitavastatin tert-butyl ester, which comprises the following steps: carrying out a reaction on (4R-Cis)-6-chloromethyl-2,2-dimethyl-1,3-dioxolane-4-tert-butyl acetate with a substance A under the action of a first base catalyst to obtain a substance B; oxidizing the substance B with an oxidizing agent to obtain a substance C; carrying out a reaction with 2-Cyclopropyl-4-(4-fluorophenyl)-quinoline-3-formaldehyde under the action of a second base catalyst to obtain a substance D; and finally, performing acid deprotection to obtain the pitavastatin tert-butyl ester. The method has the advantages of mild and controllable reaction conditions, wherein the reaction conditions of Julia olefination are free of requirement of ultralow-temperature reaction, so that the synthesis method has advantages of convenience and simplicity in operation, good stereoselectivity and high yield, and the synthesized pitavastatin tert-butyl ester is completely free of cis-isomer and high in purity.

Owner:ANHUI QINGYUN PHARMA & CHEM

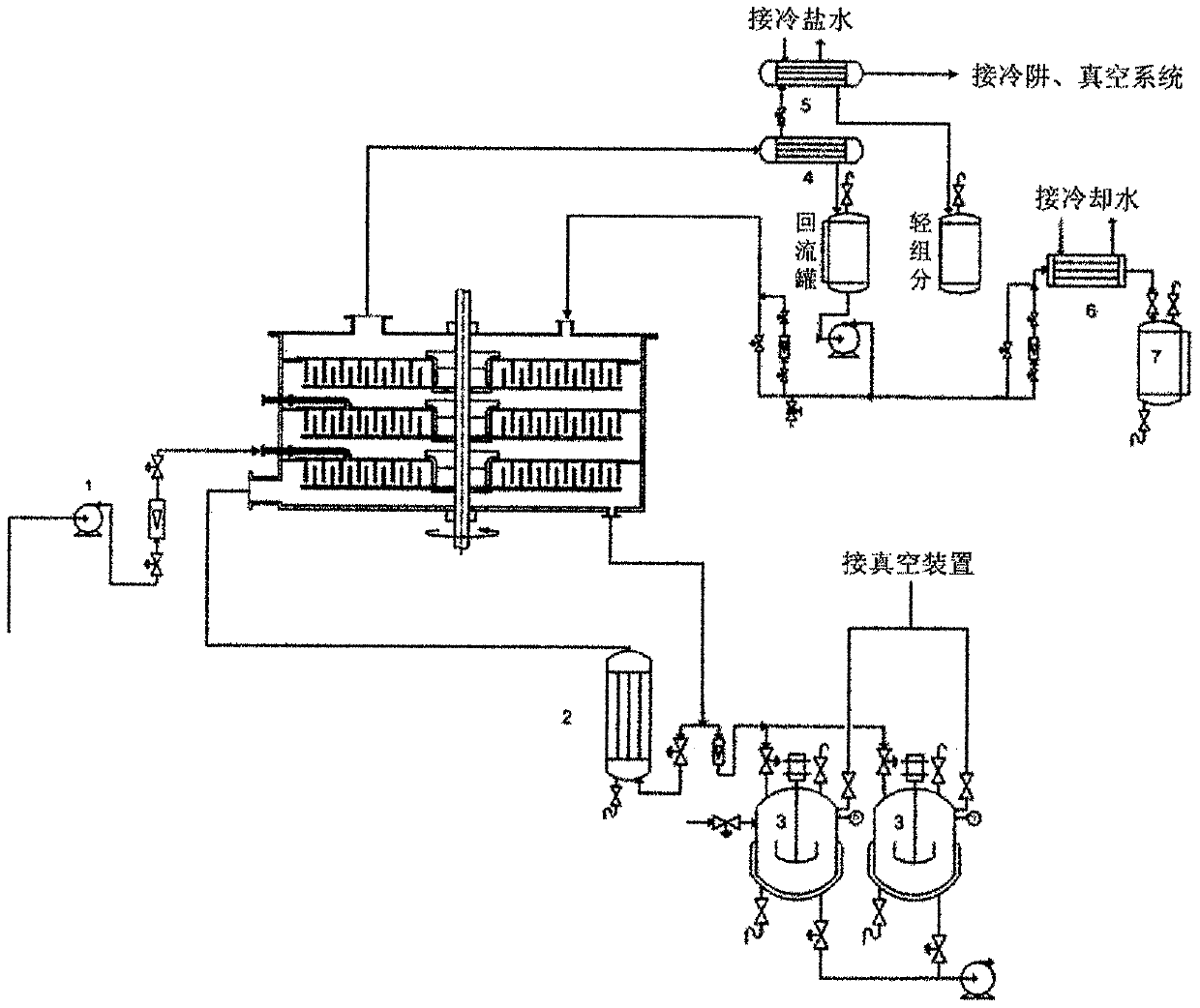

Process for separating tert-butyl acetate in medicine waste solvent through vacuum rectification by using super-gravity bed

InactiveCN107827750AReduce manufacturing costImprove recycling ratesOrganic compound preparationVacuum distillation separationAcetic acidReflux

The invention relates to a vacuum rectification method using a super-gravity bed as core separating equipment, and discloses a process for separating and recycling a waste solvent in the synthetic process of statins or other medicines and recovering tert-butyl acetate in the solvent. During operation, the waste solvent enters from a place located between the two-layer and three-layer rotors of thesuper-gravity bed, wherein the rotating speed is 1000r / min, the reflux ratio is 4-10, the vacuum degree at the top of a tower is 20kPa-70kPa, and the temperature of a tower kettle is controlled at 70DEG C-85 DEG C, a tert-butyl acetate product with higher purity can be recovered in the tower kettle, the purity can reach 95% or more, the residual amount of isoprene is less than 1%, and the moisture content is less than 1000ppm, thereby fully meeting the requirements of recycling; and compared with traditional tower-type rectification operation, the process provided by the invention has the advantages of having a simple technological procedure, low energy consumption, a small occupied area of equipment, and high recovery rate of the product tert-butyl acetate, and being capable of effectively improving economic benefits.

Owner:南京揽博环境技术有限公司 +1

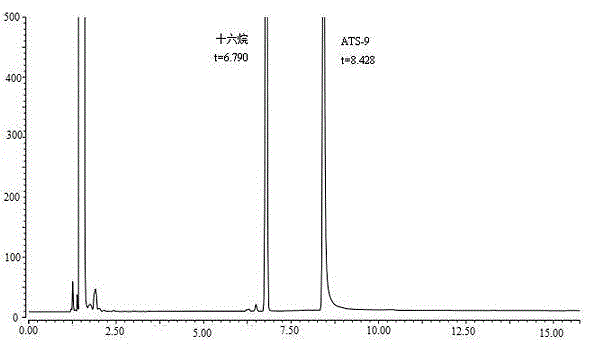

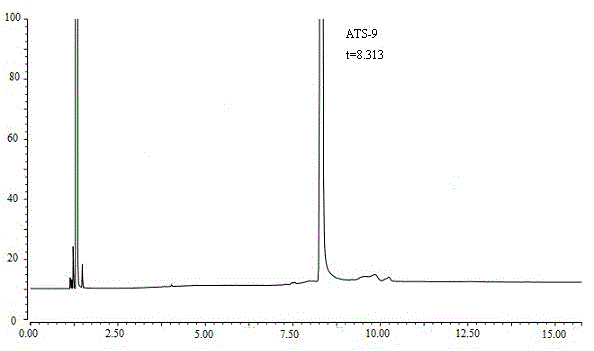

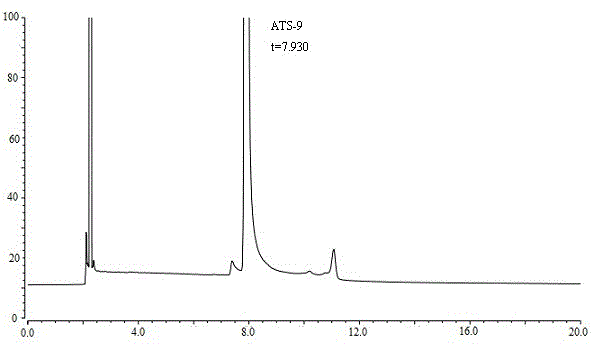

Method for determining (4R, 6R) -6-aminoethyl-2,2-dimethyl-1,3-dioxane-4- tert-butyl acetate content

ActiveCN105136921AAccurate contentAccurate detectionComponent separationCapillary gas chromatographyN-hexadecane

The present invention discloses a method for determining (4R, 6R) -6--aminoethyl-2,2-dimethyl-1,3-dioxane-4- tert-butyl acetate content. The method is as follows: ATS-9 is diluted with 1,2-dichloroethane, an Agilent DB-624 capillary gas chromatography column is used, a hydrogen flame ionization detector is used, appropriate temperature programing, vaporization chamber temperature and detector temperature are set, nitrogen is used as a carrier gas, n-hexadecane is used as an internal standard for detection, and ATS-9 content in a to-be-tested solution can be calculated by internal standard method according to the gas chromatogram. The ATS-9 and related substances and the internal standard can be effectively separated, and the method is rapid, accurate, simple and well reproducible, and lays the foundation for the establishment of ATS-9 quality standards.

Owner:HENAN ZHIWEI BIOMEDICINE CO LTD

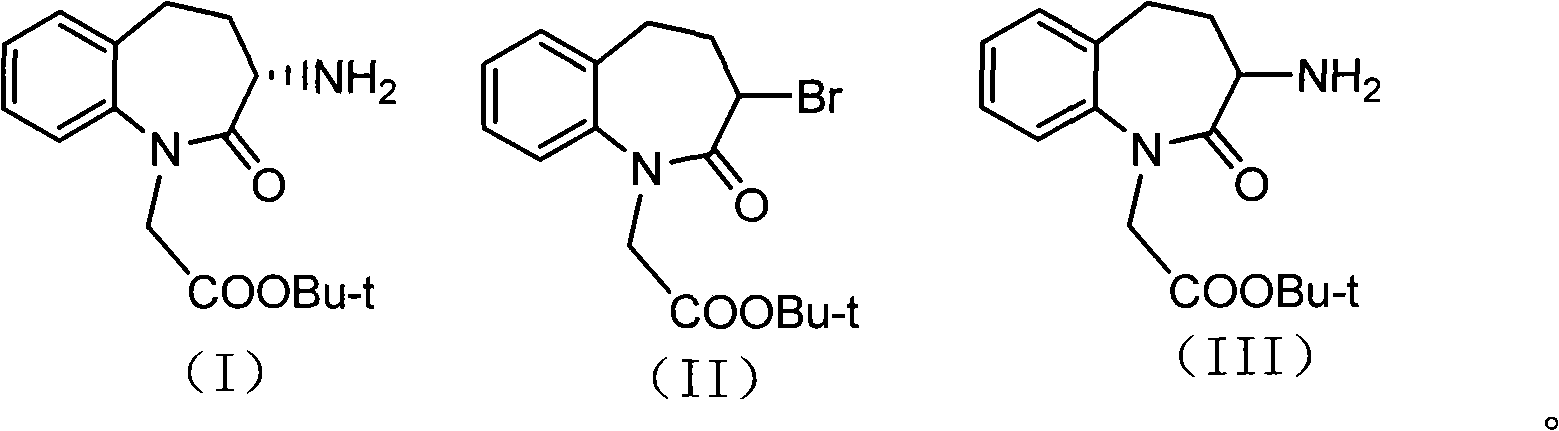

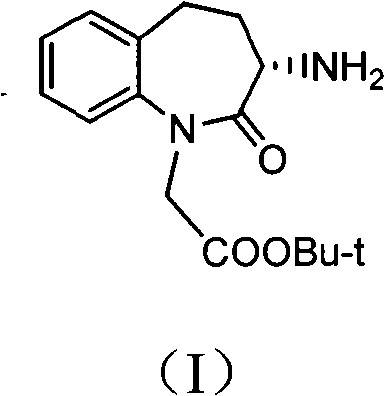

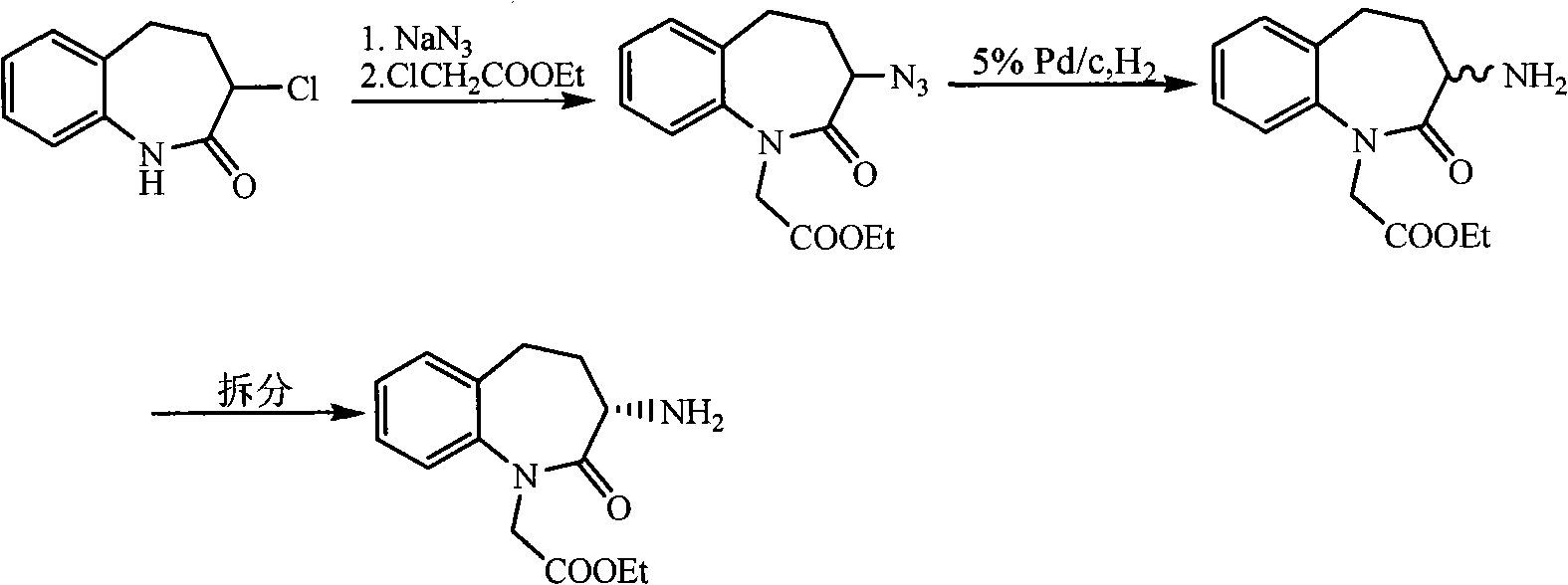

Synthetic method of Benazepril key intermediate S-amino substance

ActiveCN101538242AImprove conversion rateReduce pollutionOrganic-compounds/hydrides/coordination-complexes catalystsOptically-active compound separationReaction temperatureOxygen

The invention discloses a synthetic method of Benazepril key intermediate S-amino substance, comprising the following steps of: (1) amination: in a sealed reaction vessel, introducing ammonia gas to 3-bromine-2, 3, 4, 5-tetrahydrogen-2-oxygen-1H-1-benzoaza-1-tert-butyl acetate shown as formula (II) with the existence of a cupric salt catalyst and an organic solvent until the reaction pressure is 2.0MPa to 5.0MPa, evenly mixing, raising the temperature to 50 to 120 DEG C, reacting for 1 to 5 hours, and after the reaction is finished, obtaining 3-amino group-2, 3, 4, 5-tetrahydrogen-2-oxygen-1H-1-benzoaza-1-tert-butyl acetate with the (S, R) configuration after the post-treatment of the reaction solution; and (2) resolving reaction: stirring the product obtained in step (1) at the reaction temperature of 30-70 DEG C for 0.5 to 8 hours in amino acid resolving agent and resolving solvent, and after the reaction is finished, obtaining optically pure (S)-3-amino group-2, 3, 4, 5-tetrahydrogen-2-oxygen-1H-1-benzoaza-1-tert-butyl acetate by the separation treatment of reaction products. The method takes the cupric salt as the catalyst, and the amination is executed under normal medium pressure, therefore, the conversion rate is high and the pollution is light.

Owner:ZHEJIANG UNIV OF TECH +1

Preparation method of alkyl furanone

The invention relates to a preparation method of alkyl furanone. The preparation steps are as follows: dripping acetyl tert-butyl acetate into absolute aether containing sodium metal until aether reflow, maintaining reflux after finishing dripping to obtain mixed solution A; dripping alpha-bromo-propionyl chloride into mixed solution A at 12-15 DEG C, maintaining the temperature after finishing dripping, standing at room temperature, precipitating the organic phase and washing with water, extracting the aqueous layer with aether, merging the organic phase and drying to obtain mixed solution B; evaporating mixed solution B out of aether, carrying out reduced pressure reaction on the residual liquid to obtain mixed solution C; and refining mixed solution C, blending with water, regulating pH value with sodium hydroxide solution to 7.9-8, adding hydrogen peroxide, regulating pH value of the product with hydrochloric acid solution to 1-2, extracting with aether, drying extract, removing aether and carrying out reduced pressure evaporation to obtain pale yellow oil-solid mixture, i.e. finished product of alkyl furanone. The preparation method has short technique period, simple operation, satisfactory yield, and good color, scent and flavor of the finished product.

Owner:TIANJIN CHEM REAGENT RES INST

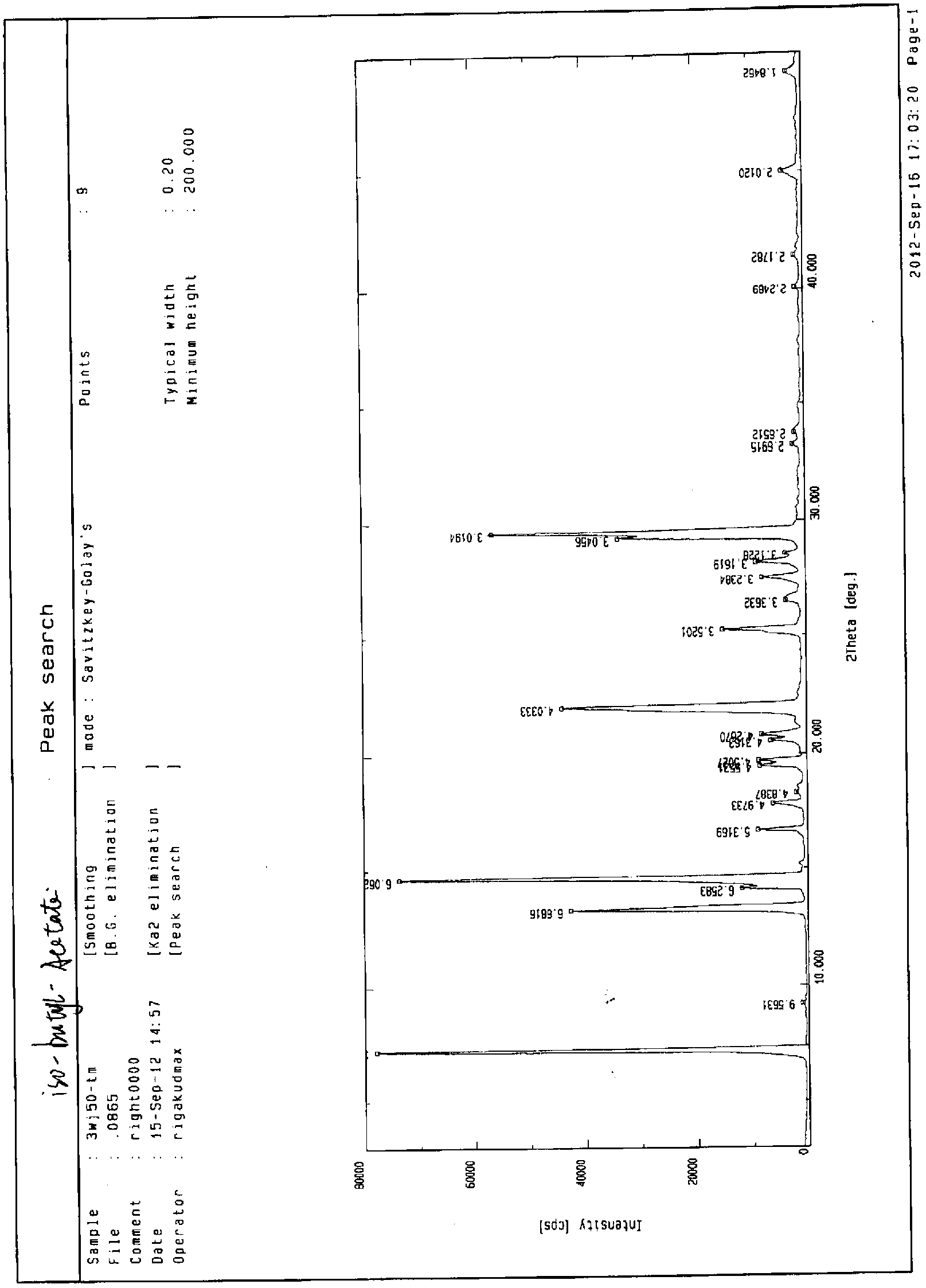

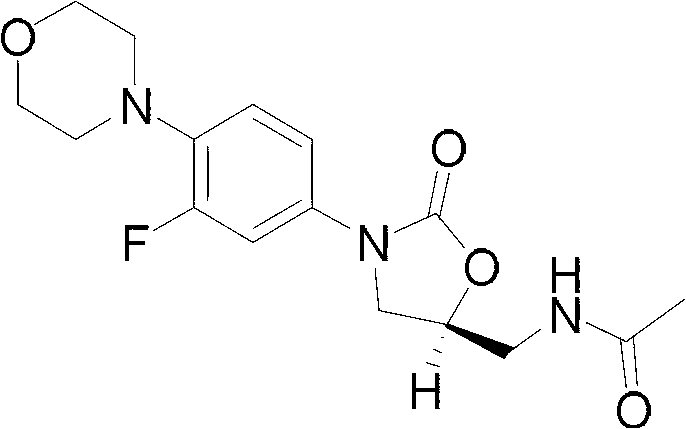

Preparation method of crystal form I linezolid

InactiveCN102850290AReduce pollutionMixed crystal is effectiveOrganic chemistryAcetic acidOrganic solvent

The invention relates to a preparation method of crystal form I linezolid. The method comprises the steps of: adding a linezolid crude product, non-crystal form I linezolid or mixed linezolid crystal into an ester or toluene solvent, wherein the ester solvent is any one selected from ethyl acetate, acetic acid isobutyl ester, tert-butyl acetate, acetic acid isopropyl ester, isopropyl formate, or ethyl formate, and the amount ratio of the ester or toluene solvent to the linezolid crude product, the non-crystal form I linezolid or the mixed linezolid crystal is (5-40mL): 1g; heating and dissolving the linezolid crude product, the non-crystal form I linezolid or the mixed linezolid crystal into the solvent, and cooling to separate out crystal; filtering the mixed liquid; and finally, washing a filter cake by an organic solvent and drying to obtain the crystal form I linezolid. The preparation method of the crystal form I linezolid is less in solvent amount, does not need crystal nucleus induction, only needs dissolving by heating, cooling and filtering, and is simple and convenient to operate and mild in conditions, thus the preparation method is suitable for industrial production; meanwhile, the method is high in yield.

Owner:TIANJIN WEIJIE TECH

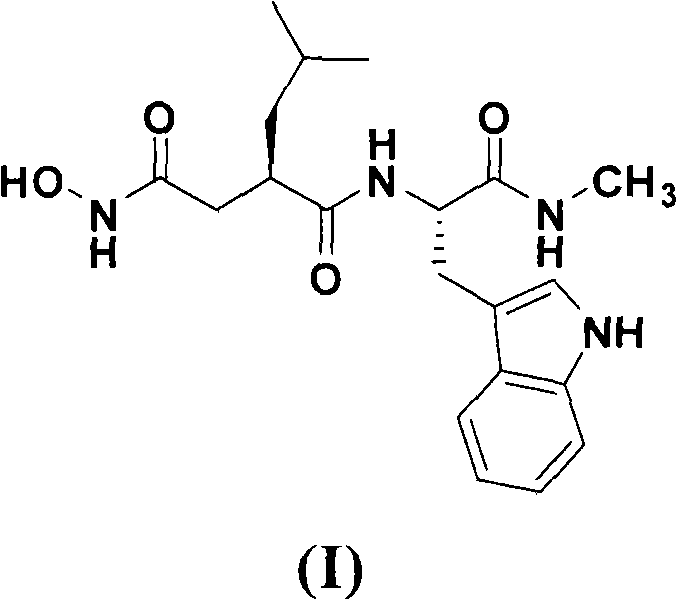

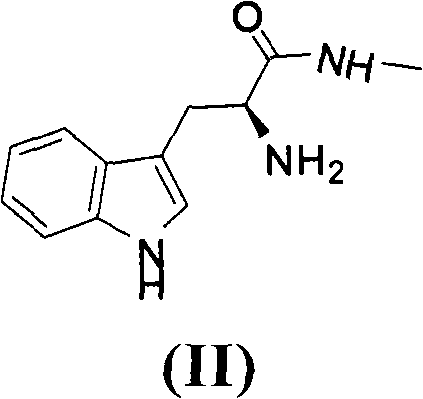

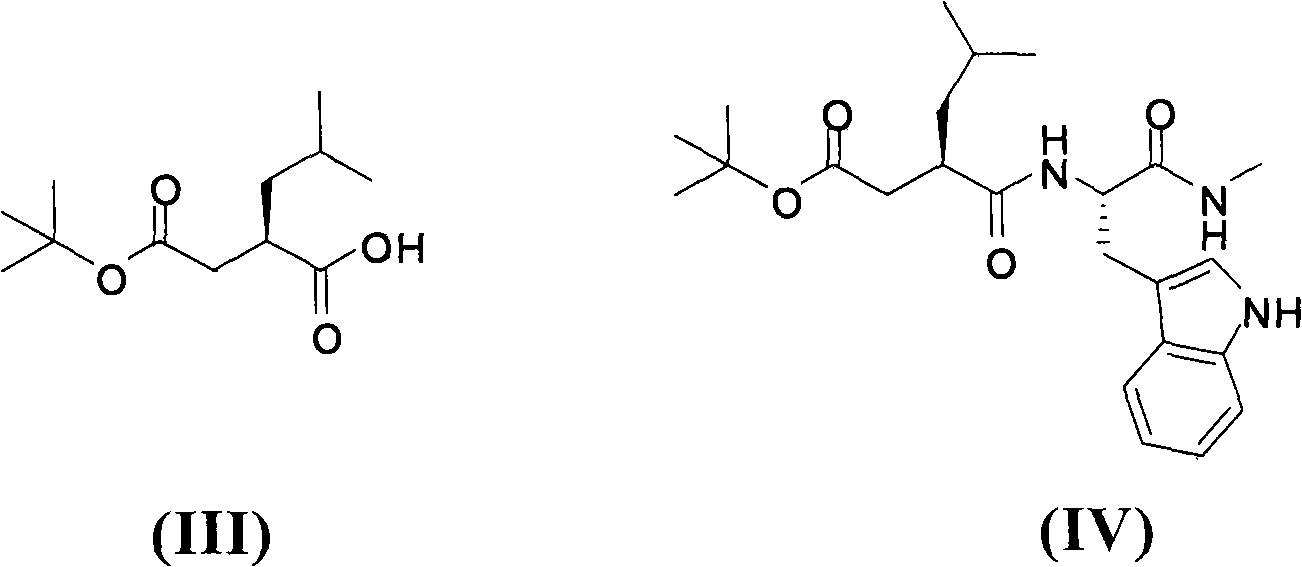

Method for preparing ilomastat

The invention relates to a new method for preparing ilomastat, which comprises the following steps of: reacting a tryptophan methyl ester hydrochloride with a methylamine to prepare tryptophanyl methylamine; performing a condensation reaction between the tryptophanyl methylamine and a tert-butyl acetate succinate derivative to prepare a midbody of a formula (IV); removing the tert-butyl from the midbody of formula (IV) to form a midbody of a formula (V); and performing a condensation reaction between the midbody of formula (V) and a free hydroxylamine to form the ilomastat. The method of the invention is simple in the process and low in the cost.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

Heat-resistant filter paper and preparation method thereof

InactiveCN103437250AIncrease dosagePerformance is not affectedNon-macromolecular organic additionFiltration separationPolyesterGlycerol

The invention relates to heat-resistant filter paper and a preparation method thereof. The heat-resistant filter paper disclosed by the invention is composed by the following raw materials by weight: 52-60 parts of hardwood pulp, 42-52 parts of calcium carbonate powder, 10-18 parts of carboxymethyl cellulose, 12-13 parts of polyester fiber, 3-4 parts of trimethylolpropane, 1-2 parts of hydroxyl silicone oil, 2-3 parts of nanometer bentonite, 1-2 parts of celestite powder, 1-2 parts of sodium persulfate, 1-2 parts of antimonous oxide, 1-2 parts of lauryl dimethyl amine oxide, 2-4 parts of sodium dodecyl sulfate, 2-3 parts of triethylene glycol, 0.6-1 part of gamma-aminopropyl triethoxysilane, 3-4 parts of a wet strength agent, 2-4 parts of rosin, 4-5 parts of aluminum hydroxide powder, 3-4 parts of glycerin, 5-7 parts of absolute ethyl alcohol, 0.1-0.3 part of peroxide tert-butyl acetate, 0.2-0.4 part of dodecyl alkylphenol polyoxyethylene ether and a proper amount of water. By adding a great amount of calcium carbonate powder as a raw material, the heat resistance of the filter paper is greatly improved.

Owner:BENGBU PIONEER FILTER

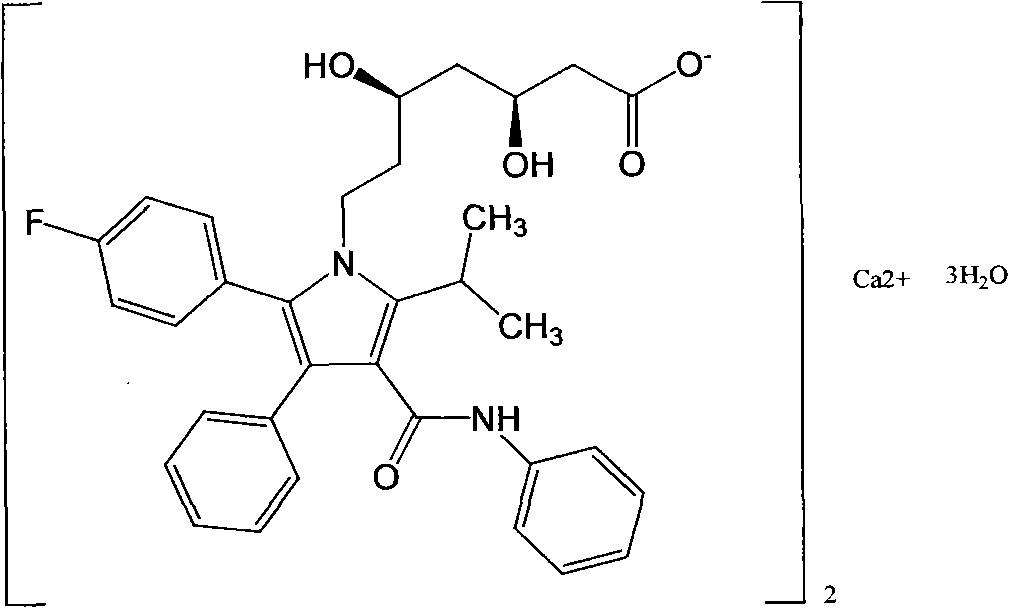

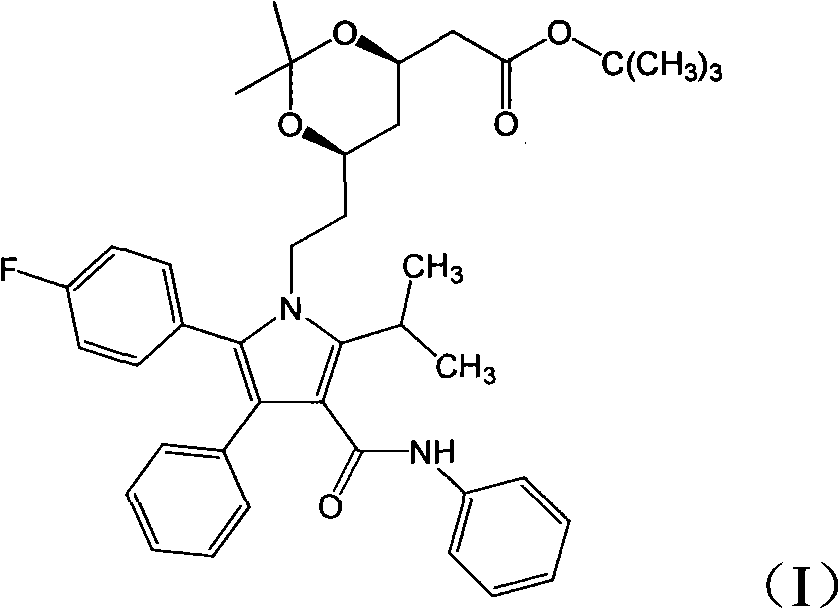

Method for preparing atorvastatin calcium

The invention relates to a method for preparing Atorvastatin calcium. In the method, (4R-cis)-6-[2-[2-(4-fluorophenyl)-5-(1-isopropyl)-3-phenyl-4-[(aniline)carbonyl]-1H-pyrrole-1-group] ethyl]-2, 2-dimethyl-1, 3-dioxolane-4-tert-butyl acetate is used as an initial raw material for preparing the Atorvastatin calcium by a one-pot method.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD +1

Acetone-based solution of a vinyl resin

InactiveUS20110201721A1Improve propertiesWiden the optionsAntifouling/underwater paintsPretreated surfacesDiacetone alcoholSolubility

Disclosed in this specification is a method and composition for producing a coating of a poly(vinyl chloride) (PVC) resin from an acetone-based solution. The solution includes a coating facilitator with terpineol and / or tertbutyl acetate. The coating facilitator also includes a second compound with a boiling point of at least 100° C. that acts to promote the solubility of the PVC resin. Also disclosed is an acetone-based solvent system that includes an additive selected from a terpene, diacetone alcohol and t-butyl acetate.

Owner:TARKSOL

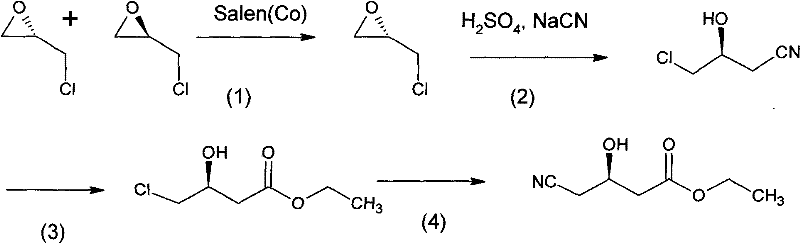

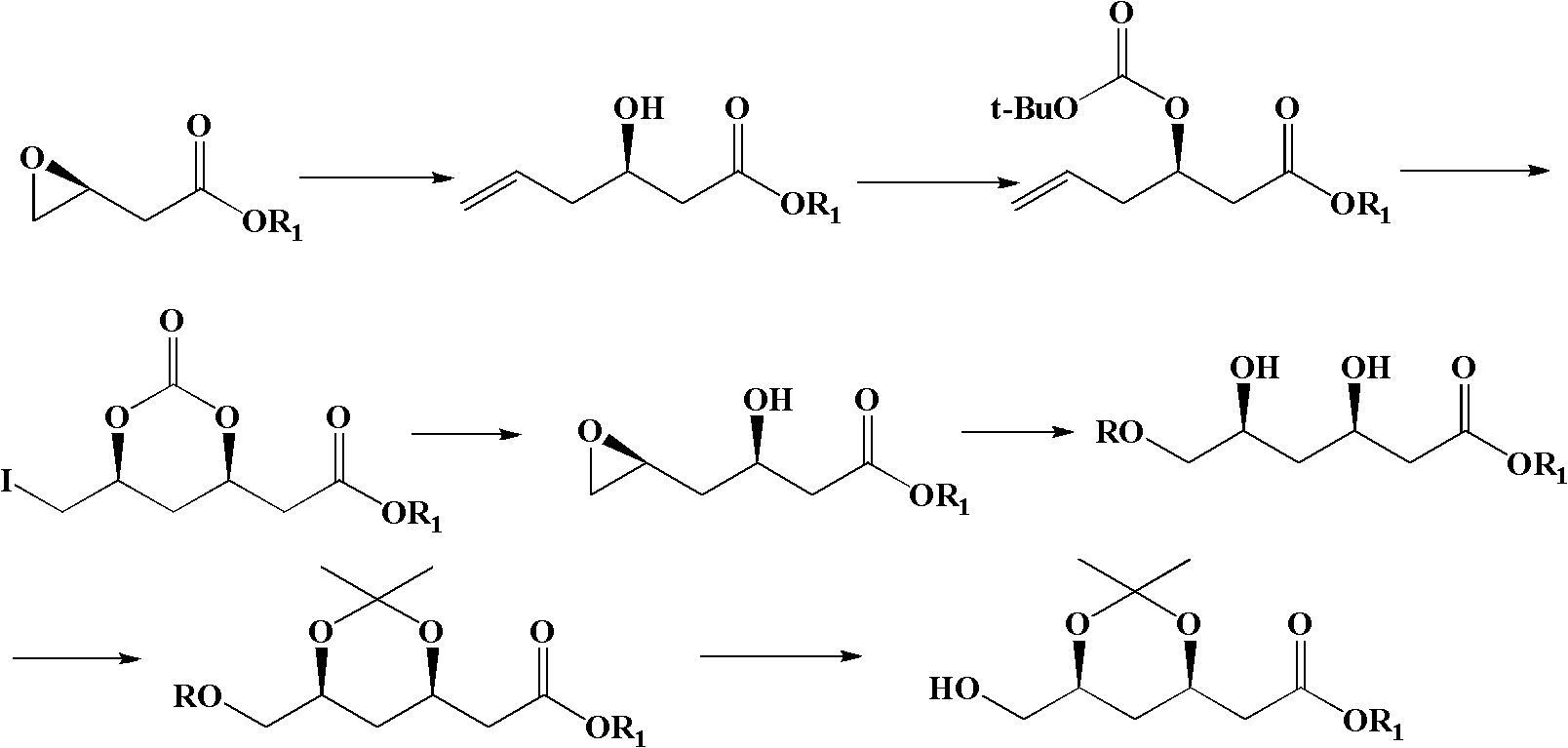

Method for preparing (4R-cis)-6-substituted-2,2-dimethyl-1,3-dioxane-4-tert-butyl acetate

ActiveCN102180862BHigh yieldLow costOrganic chemistryBulk chemical productionBlaise reactionAcetic acid

The invention relates to a method for preparing (4R-cis)-6-substituted-2,2-dimethyl-1,3-dioxane-4-tert-butyl acetate with a structural formula (VIII) shown in the specifications. In the formula, R is formaldehyde or methanol. In the preparation method, Blaise reaction is used for replacing complicated Claisen ester condensation reaction with a large number of side reactions, the aim of growing a carbon chain is fulfilled under the mild condition, and expensive lithium diisopropylamide (LDA) and a low-temperature environment is avoided; and a complicated route of oxidizing alcohol into aldehyde is avoided in the process of generating the compound VIII.

Owner:VALIANT CO LTD

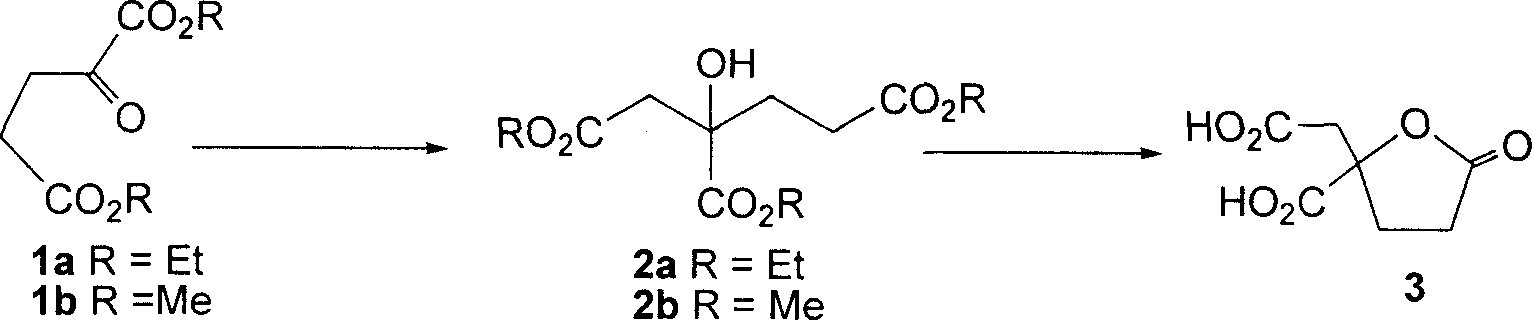

Preparation method of racemic homocitric acid lactone

The present invention relates to homocitric lactone, and is especially the simple large scale process of preparing racemic homocitric lactone with facile cheap 2-keto glutaric ester as material. The preparation process includes the reaction of 2-keto glutaric ester with negative ion in solvent, extraction, concentration and chromatographic column purification to form one intermediate compound; and the refluxing of the intermediate compound in formic acid, acetic acid and / or trifluoroacetic acid to obtain homocitric lactone. The negative ion is formed with one kind of ester selected from ethyl acetate, methyl acetate and tert-butyl acetate, and one kind of alkali selected from hexamethyl disilicoamido lithium formed with n-butyl lithium and hexamethyl disilane and diisopropylamino lithium formed with n-butyl lithium and diisopropylamine.

Owner:XIAMEN UNIV

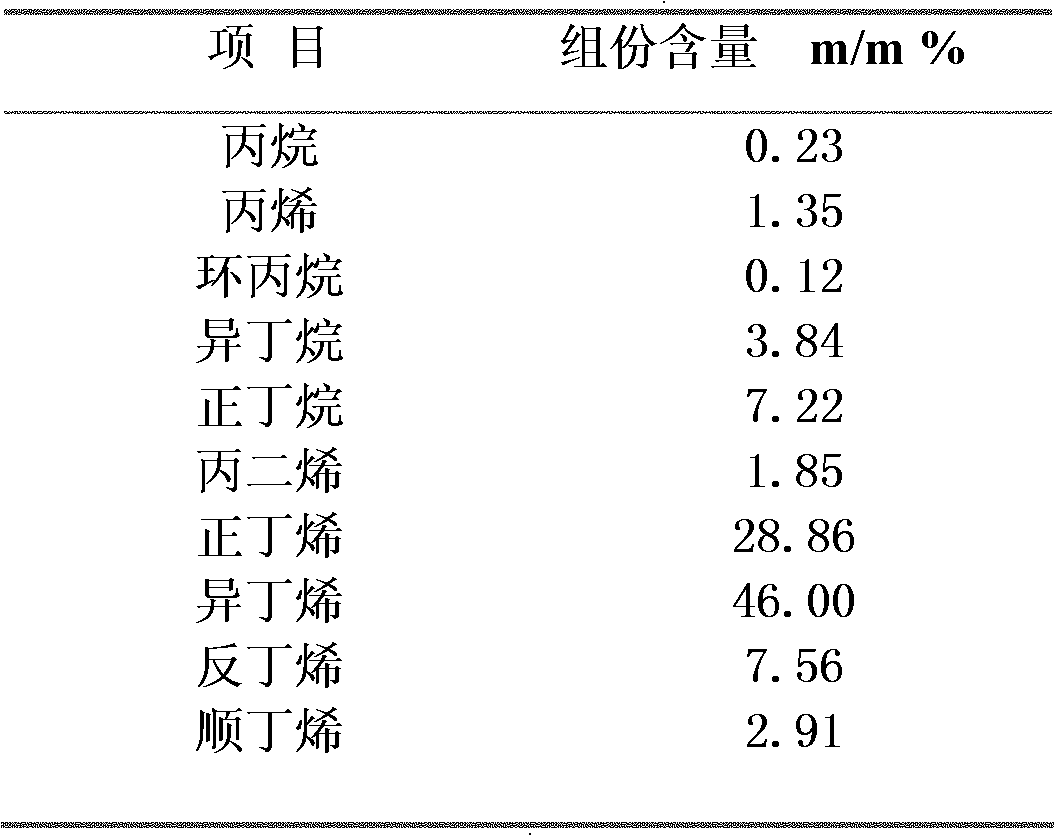

Method for preparing tert-butyl acetate

InactiveCN102372628ASolve the problem of easy aggregationSelf-polymerization inhibitionOrganic compound preparationCarboxylic acid esters preparationAcetic acidTert-Butyl acetate

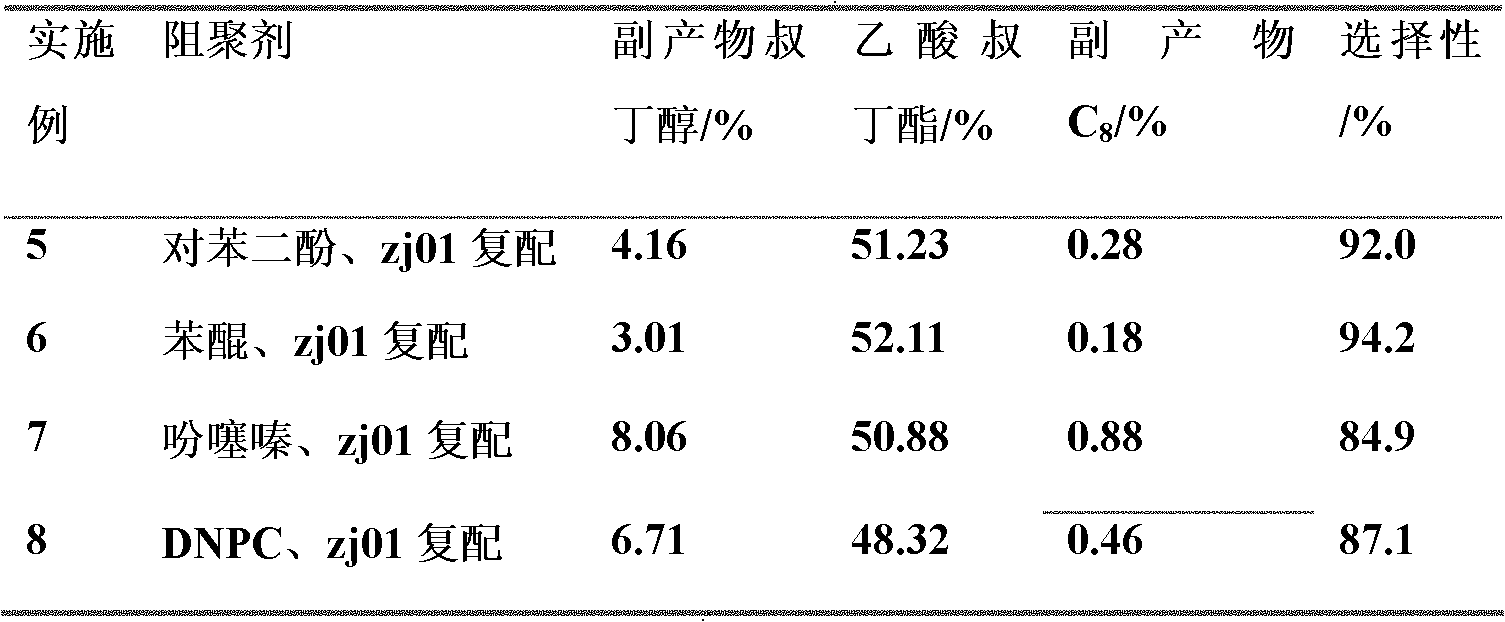

The invention relates to a method for preparing tert-butyl acetate, and in particular relates to a method for preparing tert-butyl acetate based on acetic acid and isobutene-containing C4 as raw materials. The method is characterized by adding a polymerization inhibitor in a reaction process, wherein the polymerization inhibitor is a component A or a component B or a mixture of the components A and B, wherein the component A is selected from phenols, diphenols, benzoquinone and derivatives thereof or phenothiazine compounds, and the component B is a hydroxylamine compound or piperidine derivative. By adopting the method provided by the invention, the self-polymerization reaction of isobutene can be well inhibited, the selectivity of tert-butyl acetate is greatly improved, and separation process is simplified.

Owner:CHINA PETROLEUM & CHEM CORP

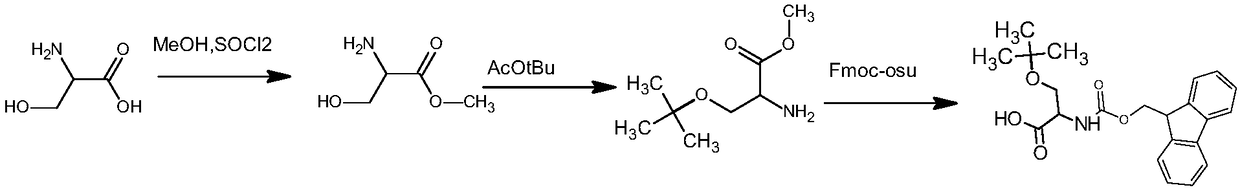

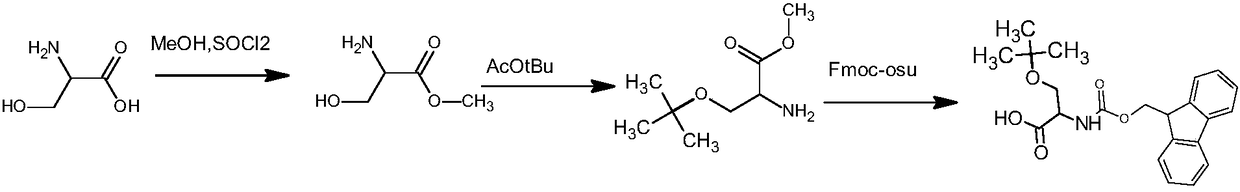

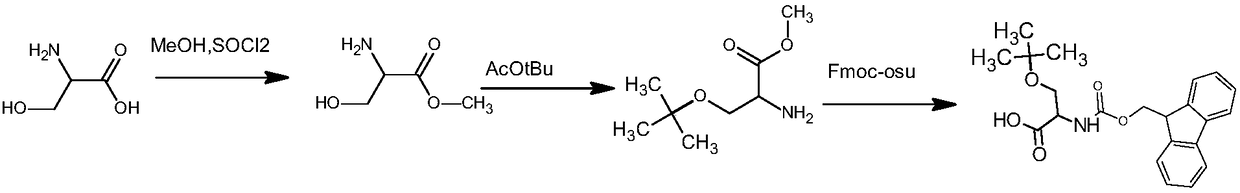

Preparation method of fmoc-O-tert-butyl-L-serine

InactiveCN109265370ALow toxicityLow priceCarbamic acid derivatives preparationOrganic compound preparationSerine methyl esterTert butyl

The invention discloses a preparation method of fmoc-O-tert-butyl-L-serine. The method comprises the steps that 1, L-serine and a methanol solution are added into a reaction container, and under stirring, SOCl2 is added dropwise for reflux reaction to obtain L-serine methyl ester hydrochloride; 2, the L-serine methyl ester hydrochloride is added into tert-butyl acetate, and a catalyst is added forreaction to obtain O-tert-butyl-L-serine methyl ester; 3, the O-tert-butyl-L-serine methyl ester is added into alkaline liquid for saponification reaction to obtain an O-tert-butyl-L-serine aqueous solution; 4, an organic solvent and NaCO3 are added into O-tert-butyl-L-serine, then fmoc n-hydroxysuccinimide este is added to adjust a pH value to be 8-10, and extraction separation is conducted to obtain the fmoc-O-tert-butyl-L-serine. In the preparation method, the L-serine, methanol and SOCl2 are adopted as raw materials, and through the reflux reaction, the L-serine methyl ester hydrochlorideis prepared; the reaction is carried out in liquid phases respectively, and is safe and pollution-free.

Owner:四川什邡市三高生化实业有限公司

Environmental-friendly exempt solvent and preparation process thereof

InactiveCN106867302AIncrease stickinessConducive to labor protectionCoatingsMethyl carbonateMoisture resistance

The invention discloses an environmental-friendly exempt solvent which is prepared from the following components in parts by mass: 8-18 parts of tert-butyl acetate, 40-53 parts of dimethyl carbonate, 5-7 parts of methyl acetate and 23-30 parts of n-butyl acetate. The environmental-friendly exempt solvent disclosed by the invention is free of benzene, is beneficial to labor protection, is somehow low in cost when compared with that of benzene-containing diluents, is remarkable in universality, and is capable of diluting a nitrolacquer series, an alkyd paint series, an acrylic paint series, an epoxy paint series, a polyurethane paint series, a vinylidene chloride paint series, an acetal paint series and the like. The invention further discloses a preparation method of the environmental-friendly exempt solvent. The preparation method is simple in production process, free of wastewater or waste residue discharge in the production process, and small in gas volatilization which meets national discharge standards. Compared with conventional diluents, the environmental-friendly exempt solvent has the effects that a paint film on the surface of a product or a dried paint film can be relatively good in viscosity and the surface of the paint film can be relatively smooth when compared with that of a film formed by the benzene-containing diluents, and moreover relatively good moisture resistance can be achieved in the construction process.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Method for preparing tert-butyl acetate from acetic acid and iso-butane

ActiveCN105367422AHigh selectivityRaw materials are cheap and easy to getPreparation by caroxylic acid/anhydride-hydrocarbon reactionOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidTert-Butyl acetate

The invention provides a method for preparing tert-butyl acetate from acetic acid and iso-butane. The method includes the steps that acetic acid and iso-butane are reacted in the presence of a catalyst and an oxidizing agent, and tert-butyl acetate is produced. The method for preparing tert-butyl acetate from acetic acid and iso-butane overcomes the defects of the prior art, raw materials are cheap and easy to get, energy consumption is low, the selectivity of tert-butyl acetate is high, and economic benefits are more remarkable.

Owner:HUNAN ZHONGCHUANG CHEM

Preparation method of glutamic acid-5-benzyl ester-1-tert-butyl ester hydrochloride

InactiveCN105541649AAvoid decompositionImprove securityOrganic compound preparationAmino-carboxyl compound preparationBenzeneTert-Butyl acetate

A preparation method of glutamic acid-5-benzyl ester-1-tert-butyl ester hydrochloride mainly solves the problem of operation difficulty in the synthesis method of the prior arts. A technical scheme is as below: the preparation method of glutamic acid-5-benzyl ester-1-tert-butyl ester hydrochloride comprises the steps of: esterifying a starting material of glutamic acid with benzyl alcohol, and purifying to obtain glutamic acid 5-benzyl ester; conducting a transesterification reaction on glutamic acid 5-benzyl ester and tert-butyl acetate under catalysis to obtain glutamic acid-5-benzyl ester-1-tert-butyl ether; and finally controlling the atmosphere with ether hydrochloric acid to an acidic state to obtain the glutamate 5-benzyl-1-t-butyl ester hydrochloride. The product can be used for the field of peptide synthesis.

Owner:GL BIOCHEM SHANGHAI +1

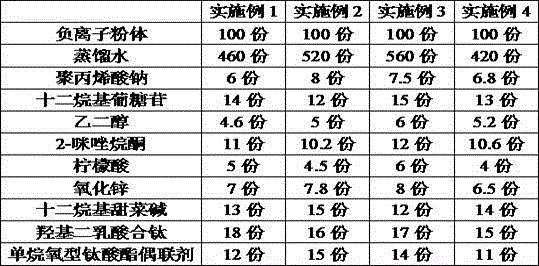

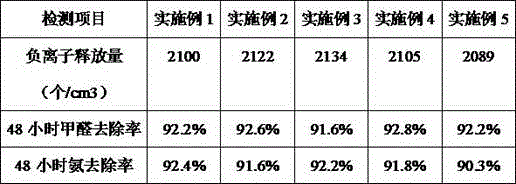

Anion coating solution for air purification

InactiveCN106334436AAvoid harmDirect fusionGas treatmentDispersed particle separationSlurryHigh pressure

The invention discloses an anion coating solution for air purification. The anion coating solution is prepared from, by weight, anion powder, distilled water, sodium polyacrylate, lauryl glucoside, glycol, 2-imidazolidone, citric acid, zinc oxide, lauryl betaine, tert-butyl acetate and a monoalkoxy-titanates coupling agent; nanoscale tourmaline powder, nanometer titania, sodium silicate, methyl alcohol and 2-alkyl acetamido ethyl imidazoline are added into a high pressure reaction kettle, the mass ratio of the nanoscale tourmaline powder to the nanometer titania, sodium silicate to the sodium silicate to the methyl alcohol to the 2-alkyl acetamido ethyl imidazoline is 1:(3-5):(1.5-2):(2-4):(3-5), and the prepared slurry mixed solution is subjected to a hydrothermal reaction. The anion coating solution can be thoroughly attached to the surfaces of pollutants, no dead corner exists during formaldehyde removal, the using effect is more obvious and more direct, the interfacial effect is larger, the toxic gas adsorption rate is further increased, the adsorptivity is stronger, and a formed nanometer film and the surface of an object are fused more directly.

Owner:昆山倍善环保实业有限公司

Environmental-friendly energy-saving gasoline standard increasing agent

InactiveCN104419478AReasonable formulaLow costLiquid carbonaceous fuelsAcetic acidTert-Butyl acetate

The invention relates to the technical field of gasoline standard increasing agents and in particular relates to an environmental-friendly energy-saving gasoline standard increasing agent. The gasoline standard increasing agent consists of the following materials in percentage by weight: 15-30 percent of ethyl aniline, 10-20 percent of acetone, 5-20 percent of chlorinated paraffin, 1-10 percent of tert-butyl acetate, 5-25 percent of methanol and 10-25 percent of isoamylene. The invention aims to provide an environmental-friendly energy-saving gasoline standard increasing agent which is prepared from readily available raw materials and is low in cost and reasonable in formula.

Owner:章成荣

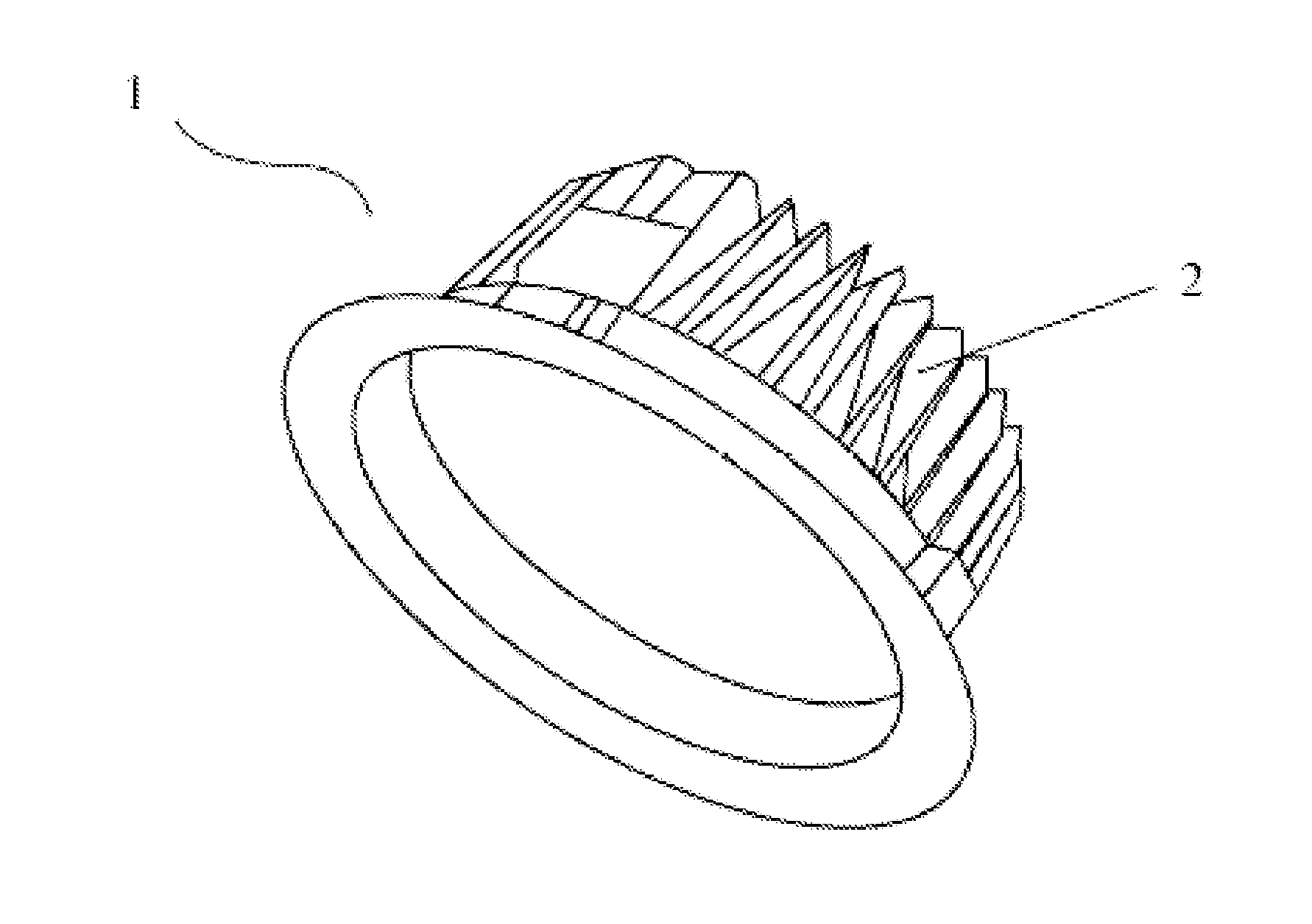

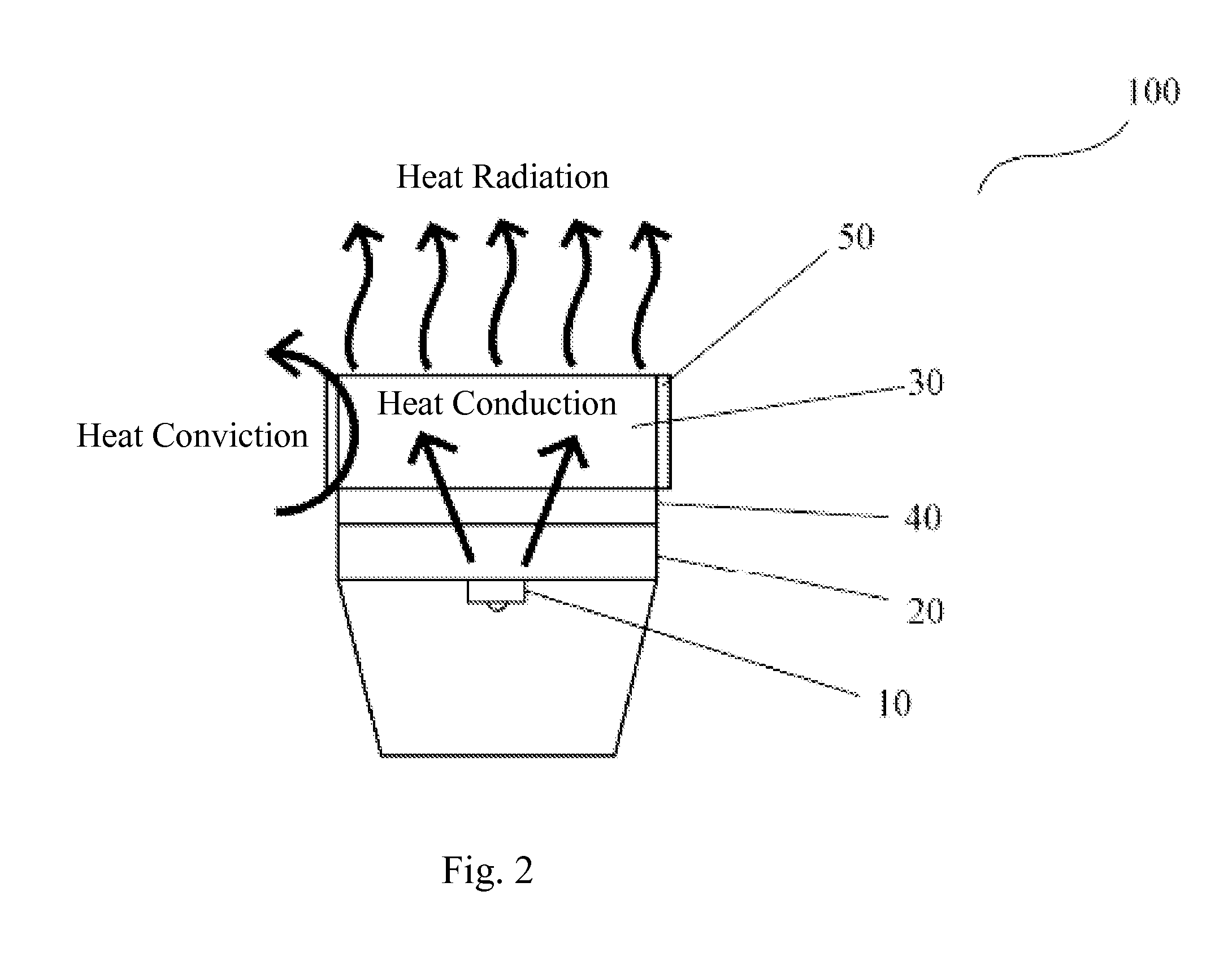

Heat-conducting and heat-dissipating nano-materials, preparing method thereof and heat-dissipating system

InactiveUS20140152167A1Facilitate conductionImprove the heating effectElectric discharge tubesLighting heating/cooling arrangementsTert-Butyl acetateHeat conducting

The invention provides a heat-conducting and heat-dissipating nano-material, a method for preparation thereof and a heat-dissipating system. The method comprises the following steps: i) mixing a complex formed by a high molecular material and a substance having heat conduction and heat dissipation properties with tert-butyl acetate and 4-Chlorobenzotrifluoride, wherein the complex is of nano scale in particle size; and ii) placing a mixture obtained from step i) into water and stirring the mixture in water for a period of time to afford the heat-conducting and heat-dissipating material. Application of the heat-conducting and heat-dissipating material in a heat-dissipating system of LED light may simplify the manufacturing process, save raw materials used and reduce weight and size of heat sink of the heat-dissipating system.

Owner:GREEN FORMULA

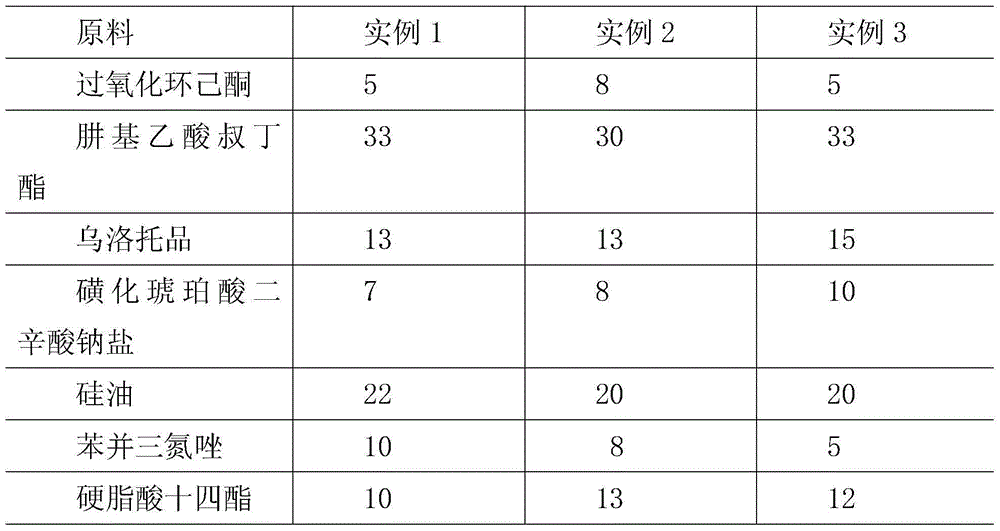

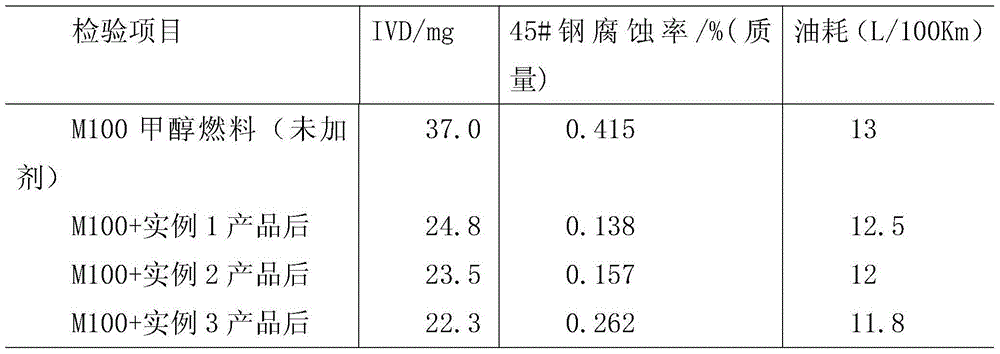

Methanol fuel additive and preparation method thereof

InactiveCN104449892AImprove combustion effectImprove detergencyLiquid carbonaceous fuelsCyclohexanoneInlet valve

The invention discloses a methanol fuel additive and a preparation method thereof. The methanol fuel additive comprises the following components in parts by weight: 5-10 parts of cyclohexanone peroxide, 30-35 parts of hydrazino tert-butyl acetate as well as 10-15 parts of an intermediate used for mainly improving the heat value of combustion, 5-10 parts of an antioxidant corrosion inhibitor used for auxiliarily improving the heat value of combustion, 5-15 parts of an oxygen-containing compound serving as a combustion improver of methanol combustion, 20-25 parts of a silicone oil serving as a stabilizing accelerator and 5-10 parts of sodium diethylhexyl sulfosuccinate serving as an emulsifying agent. By the methanol fuel additive, the combustion of the methanol fuel burnt in methanol cars is greatly improved, the methanol fuel additive has a good cleaning effect on carbon deposit and gum in intake valve deposits and the phenomenon that the power of an engine is affected by the reduction in gas-charging coefficient of blended gasoline due to the increase in intake resistance of the engine is avoided; the corrosion rate of methanol to a metal is decreased and the service life of the car is prolonged; and meanwhile, the problems of incomplete combustion of methanol fuel, power shortage, high fuel consumption and lighting of engine failure lamps are effectively solved.

Owner:陕西宝姜新能源技术研发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com