Anion coating solution for air purification

A technology of air purification and negative ions, applied in the field of negative ion coating liquid for air purification, can solve the problems of chemical and microbial pollution that are difficult to purify, cannot be quickly resolved and eliminated, and cannot be converted, so as to eliminate formaldehyde without dead ends and avoid harming the human body. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

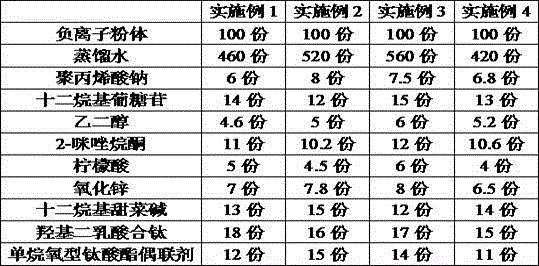

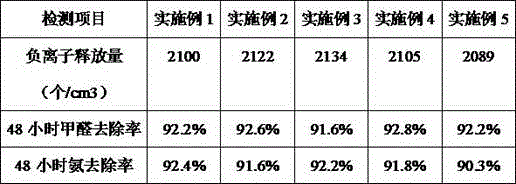

[0028] Embodiment 1~4: a kind of negative ion coating solution for air purification is made up of the following components by weight, as shown in table 1:

[0029] Table 1

[0030]

[0031] 100 parts of the negative ion powder, 400-600 parts of distilled water, 6-8 parts of sodium polyacrylate, 12-15 parts of dodecyl glucoside, 4-6 parts of ethylene glycol, 10-12 parts of 2-imidazolidinone 4~6 parts of citric acid, 6~8 parts of zinc oxide, 12~15 parts of lauryl betaine, 15~18 parts of titanium hydroxydilactate and 10~15 parts of monoalkoxy titanate coupling agent After mixing and soaking the parts for 2 to 3 days, put them into a ball mill for low-speed ball milling for 2 to 3 hours, and then high-speed ball milling for 40 to 60 minutes to obtain the anion coating solution for air purification;

[0032] The negative ion powder is obtained through the following steps:

[0033] Step 1. Add nano-tourmaline powder, nano-titanium dioxide powder, sodium silicate, methanol and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com