Preparation method of crystal form I linezolid

A linezolid, type I technology, applied in the field of organic compound synthesis technology, can solve the problems of large environmental pollution, recrystallization, large amount of solvent, etc., and achieves the effects of less environmental pollution, mild conditions, and small amount of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

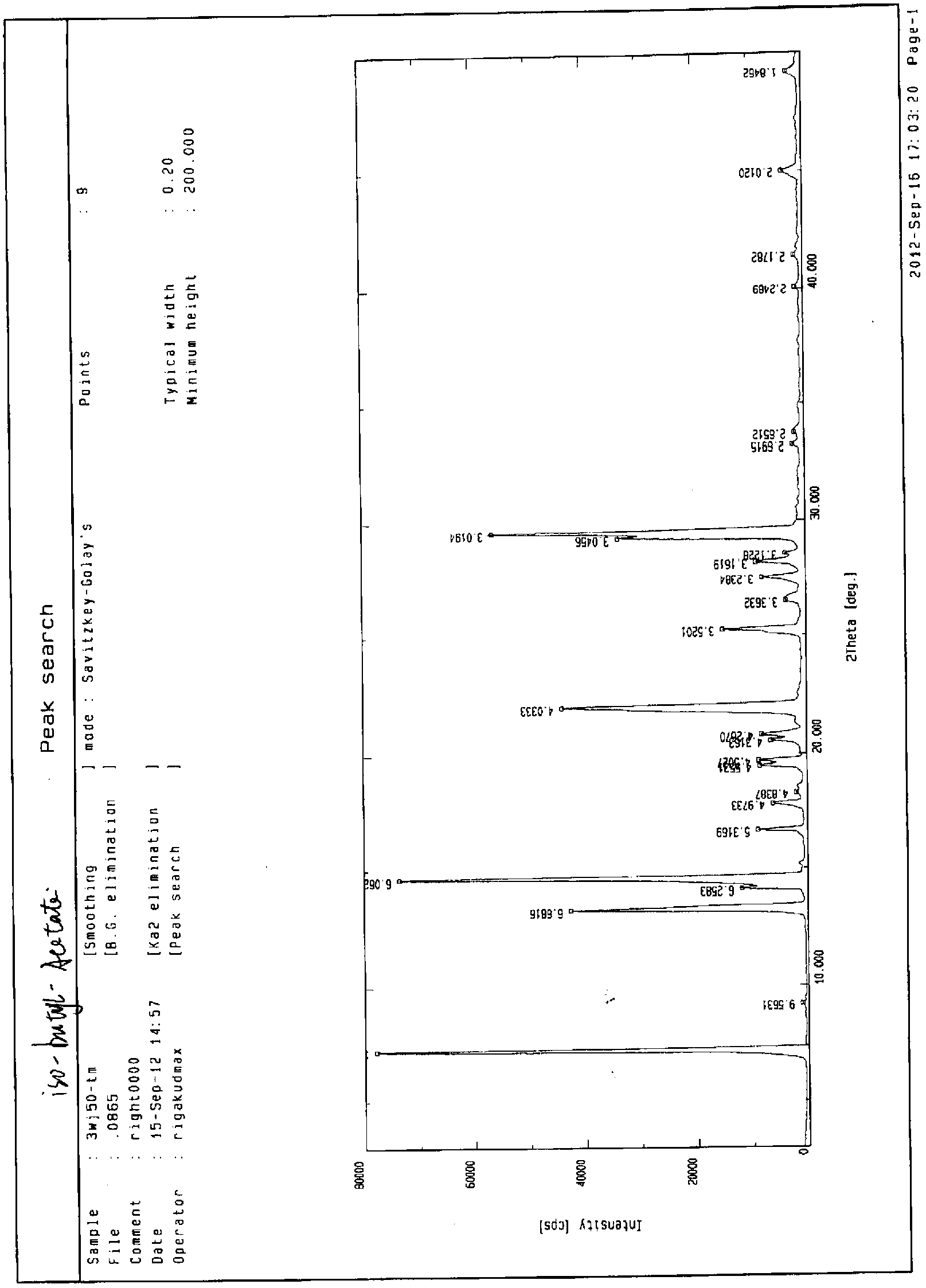

[0017] Add 6.5g of linezolid crude product into a 250mL four-necked bottle, add 150mL of isobutyl acetate, stir and heat to 120-130°C, after the crude linezolid is completely dissolved, cool to room temperature (20-25°C) under slow stirring , to precipitate crystals, filter, wash the filter cake with 20 mL of isobutyl acetate, and dry at 40° C. to obtain 5.6 g of crystalline form I linezolid, with a yield of 86.2%. Its X-ray powder diffraction (PXRD) pattern is shown in figure 1 . Its 2θ characteristic peaks are 7.3, 9.2, 13.2, 14.1, 14.6, 16.6, 17.8, 19.5, 19.7, 20.8, 22.0, 25.3, 29.3, 29.6±0.2, and it is the Form I crystal form of linezolid.

Embodiment 2

[0019] Add 5g of linezolid crude product into a 250mL four-neck flask, add 120mL of tert-butyl acetate, stir and heat to 100-110°C, after the crude linezolid is completely dissolved, cool to room temperature (20-25°C) under slow stirring, The precipitated crystals were filtered, the filter cake was washed with 20 mL of tert-butyl acetate, and dried at 40° C. to obtain 4.2 g of crystalline form I linezolid with a yield of 85%.

Embodiment 3

[0021] Add 5g of linezolid crude product into a 250mL four-neck flask, add 160mL of isopropyl acetate, stir and heat to 90-100°C, after the crude linezolid is completely dissolved, cool to room temperature (20-25°C) under slow stirring, The precipitated crystals were filtered, the filter cake was washed with 30 mL of isopropyl acetate, and dried at 40° C. to obtain 3.8 g of crystalline form I linezolid with a yield of 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com