Method for preparing tert-butyl acetate

A technology of tert-butyl acetate and acetic acid, which is applied in the field of preparing tert-butyl acetate, can solve the difficulties of separation and purification of tert-butyl acetate, and does not involve olefin polymerization inhibition, etc., and achieves selectivity improvement, self-polymerization inhibition, and extreme solution The effect of easy polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

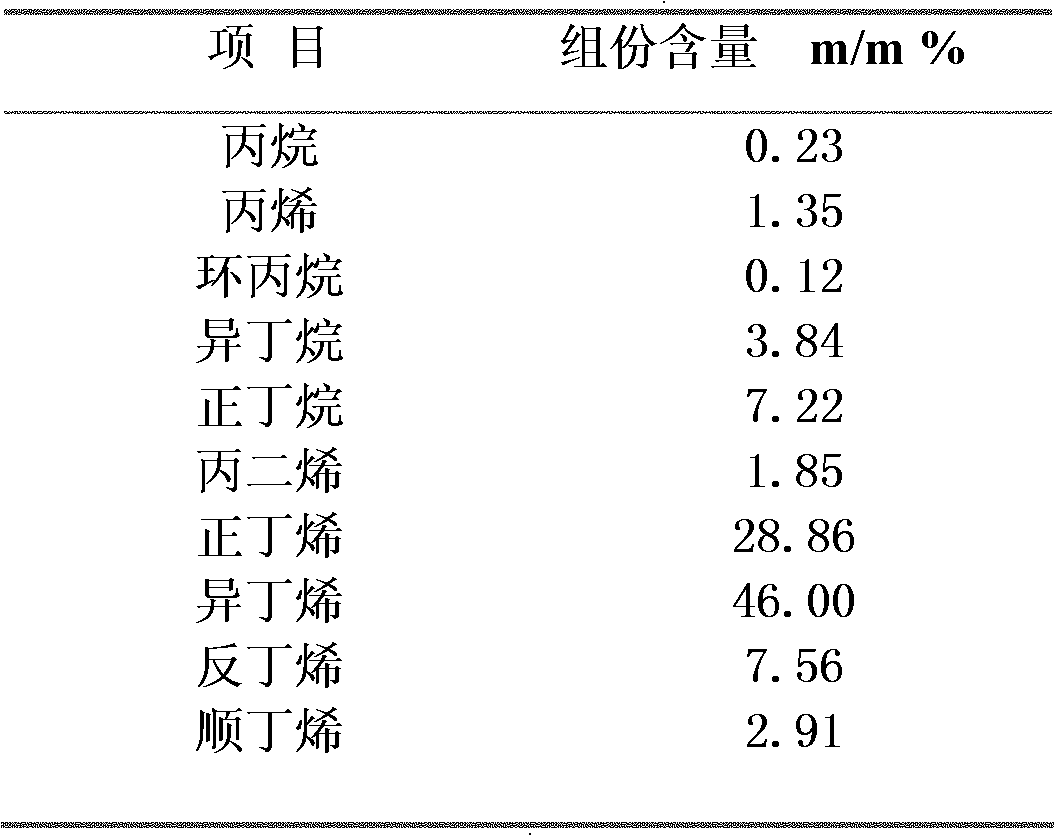

[0022] Embodiment 1 does not use a polymerization inhibitor, and embodiments 2 to 4 use different single polymerization inhibitors. 90g acetic acid, 9g strong acid type ion exchange resin catalyst and 0.08g polymerization inhibitor join in the 500ml stainless steel autoclave that has cooling coil pipe, after sealing, pressurize to 1.0MPa with nitrogen and blow several times, to remove air, then in Heat the mixture to 60°C with stirring, and pressurize with nitrogen to make 166gC 4 The liquid phase feed was added to the kettle, and the pressure was increased to 1.4MPa with nitrogen, and the reaction time was 1h. Table 1 is the mixed raw material C used 4 composition, and the results are shown in Table 2.

[0023] Table 1 Raw Material C 4 composition

[0024]

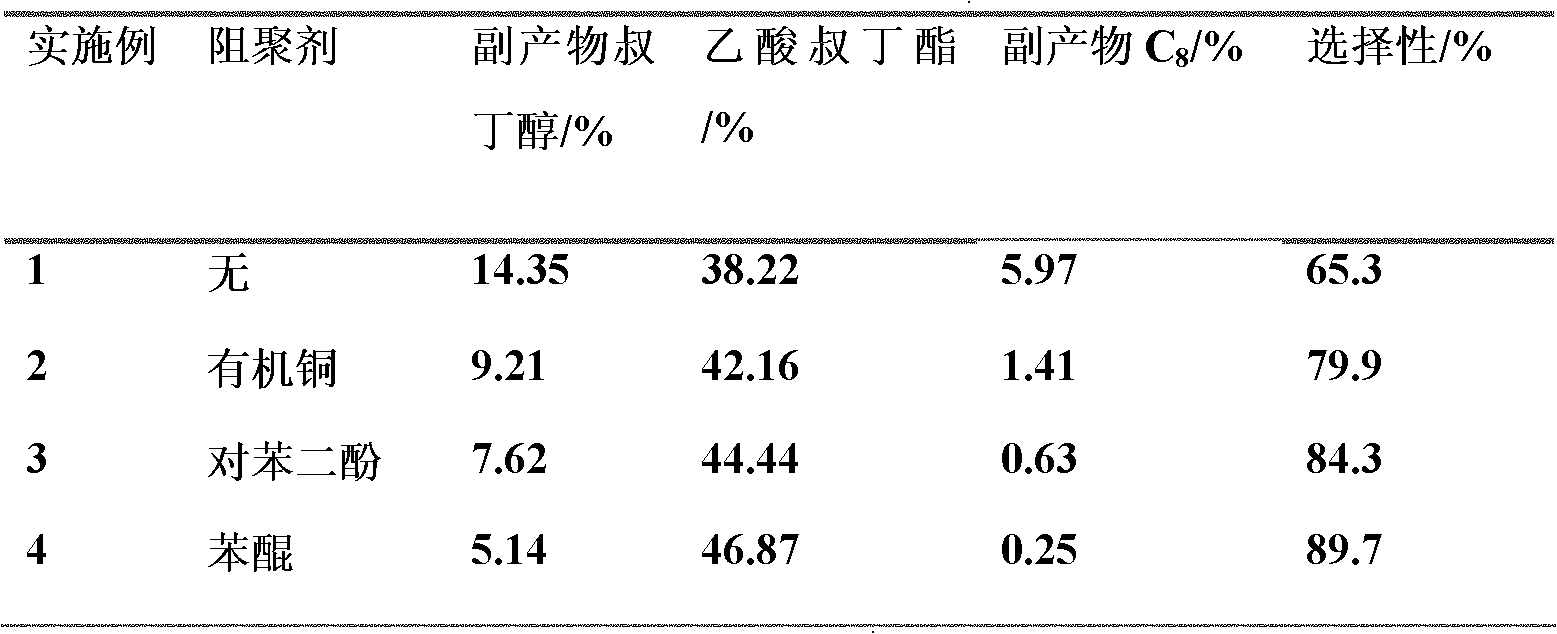

[0025] Table 2 Effect of using a single polymerization inhibitor

[0026]

[0027] As can be seen from Table 2, in acetic acid and containing isobutylene C 4 In the process of synthesizing tert-butyl acetate, ...

Embodiment 5~8

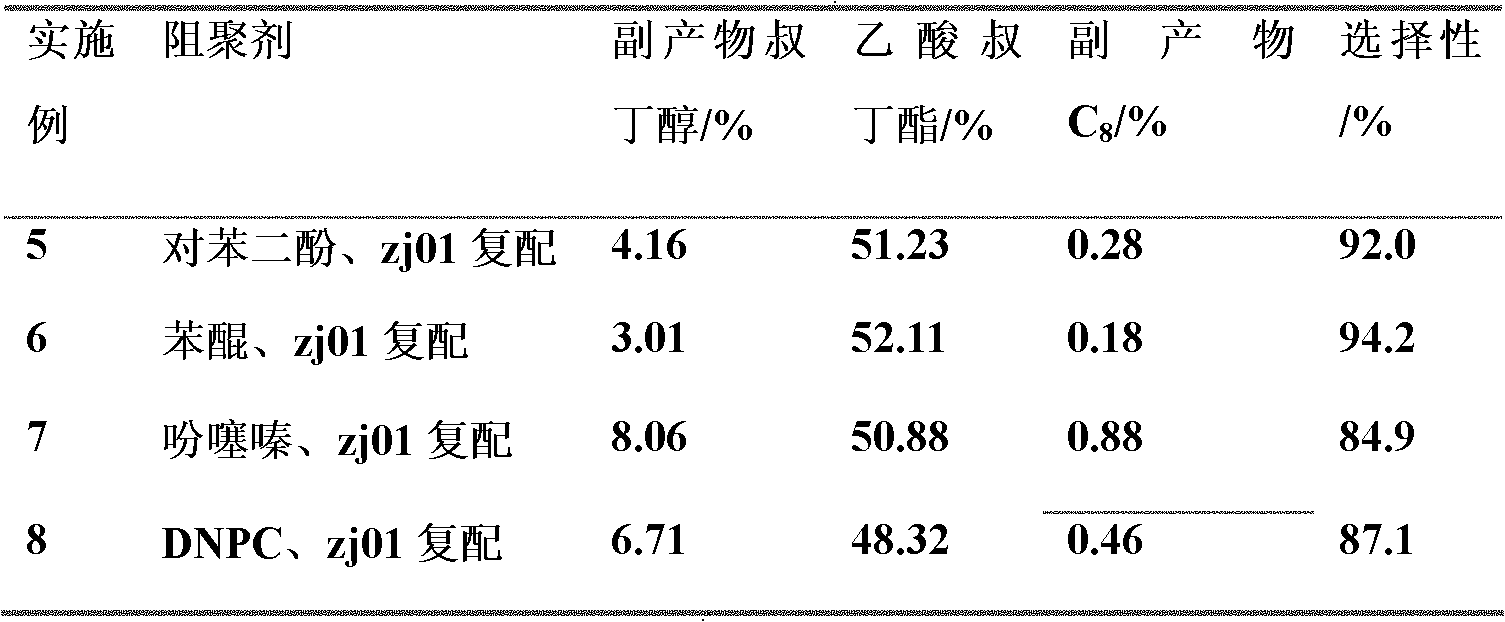

[0029] Embodiments 5-8 use compounded polymerization inhibitors, which are respectively hydroquinone, benzoquinone, phenothiazine, 2,6-dinitro-p-cresol (DNPC) and piperidinol compound zj01 in a ratio of 3:1 Composite, other reaction conditions such as polymerization inhibitor adding total amount are the same as embodiment 1~4. The results are shown in Table 3.

[0030] Table 3 The use effect of compound polymerization inhibitor

[0031]

[0032] As can be seen from Table 3, in acetic acid and containing isobutylene C 4 In the process of synthesizing tert-butyl acetate, the effect of using the compounded polymerization inhibitor (Example 6) of benzoquinone and piperidinol compound zj01 is obviously better than that of using hydroquinone, phenothiazine, DNPC and piperidinol compound zj01 complex polymerization inhibitor (embodiment 5, 7 or 8).

Embodiment 9~11

[0034] Use benzoquinone and zj01 (2,2,6,6-tetramethyl-4-hydroxyl-piperidinyl oxygen free radical) composite polymerization inhibitor to compare the use effects of different proportions, and other reaction conditions are the same as in Example 1~ 4. The results are shown in Table 4.

[0035] Table 4 The effect of using different proportions of compound inhibitors

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com