Preparation method of magnesium oxide modified carbon nanotube material and application of magnesium oxide modified carbon nanotube material in phosphorus adsorbing and recovery

A carbon nanotube, multi-walled carbon nanotube technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effects of promoting adsorption, good selective adsorption, and efficient adsorption and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

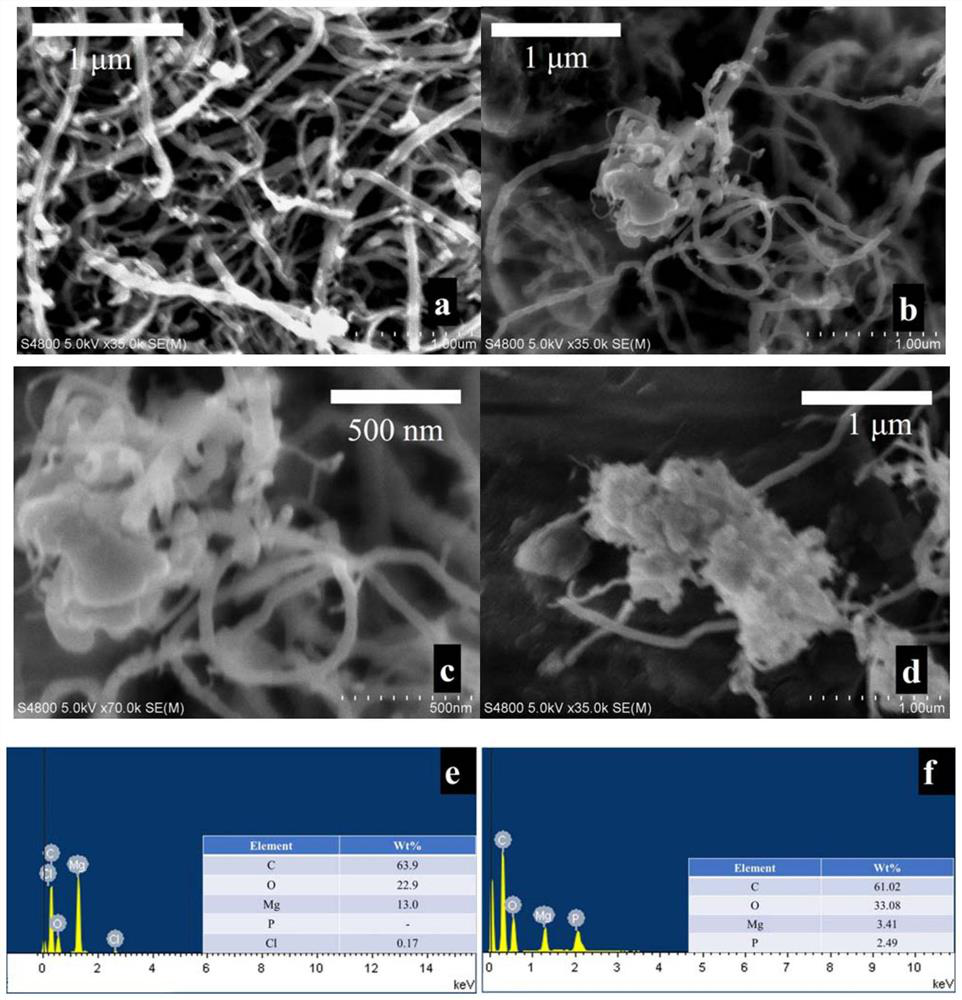

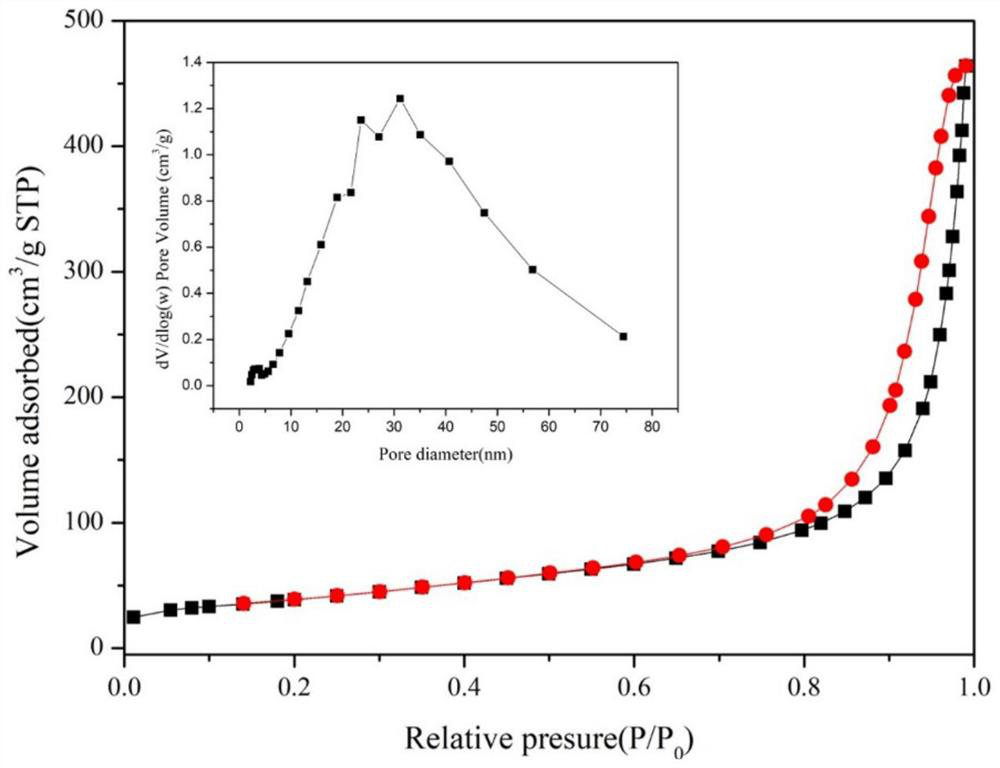

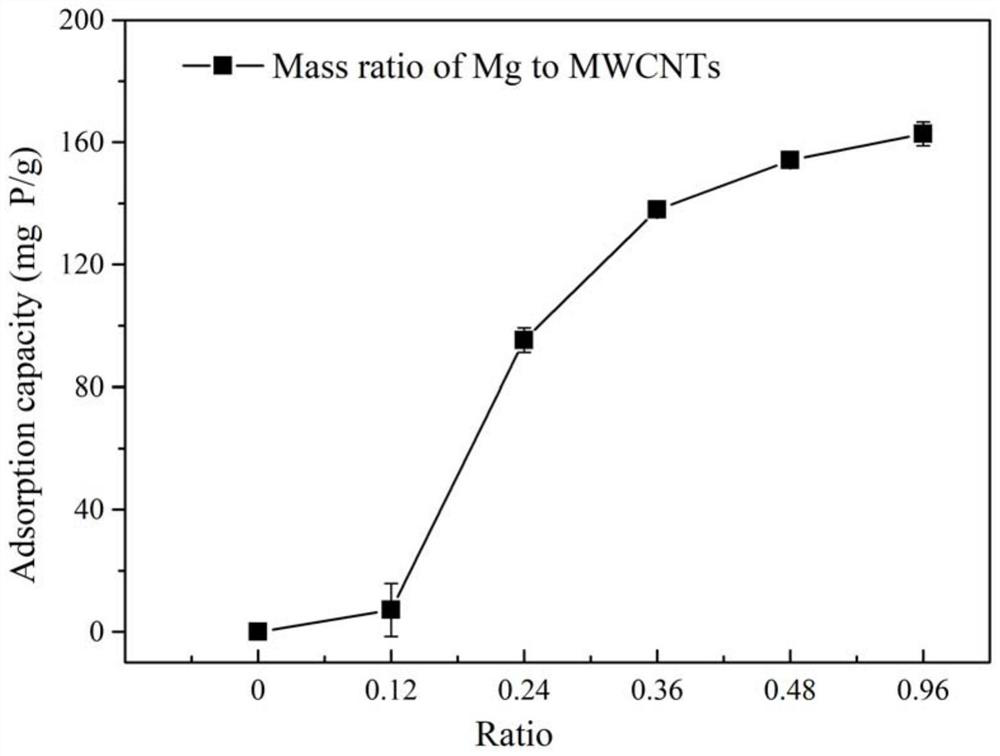

Embodiment 1

[0049] Add 1 g of purchased multi-walled carbon nanotubes (with a particle size range of 60 to 100 nm) into 100 ml of MgCl 2 ·6H 2 In O solution, the mass ratio of Mg element to carbon nanotube is 0.12. After 24 hours of magnetic stirring at 120 rpm at room temperature, the mixture was dried in a 388.15K blast oven for 24 hours. Under nitrogen protection, the dried mixture was calcined in a high temperature tube furnace. Adjust the nitrogen flow rate to 60mL / min, keep it for 20 minutes, and exhaust the oxygen in the high temperature tube furnace. Set the initial temperature to 50°C, raise the temperature to 600°C at a rate of 5°C / min, and keep it for 2 hours. After the temperature was cooled to room temperature, the obtained product was washed with deionized water several times to remove impurities, dried in an oven at 65°C to constant weight, fully ground with an agate mortar and then transferred to a polyethylene tube for sealing to obtain Magnesium oxide modified carbon...

Embodiment 2

[0051] Example 1 was repeated with the same steps, except that the mass ratio of Mg element to carbon nanotube was 0.24.

Embodiment 3

[0053] Example 1 was repeated with the same steps, except that the mass ratio of Mg element to carbon nanotube was 0.36.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com