Composite material for in-situ growth of ternary cobalt nickel molybdenum oxide on graphene and two-step synthesis method thereof

A nickel-molybdenum oxide, in-situ growth technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problem that the performance of electrode materials cannot meet the requirements of life and capacity at the same time, to avoid invalid quality, avoid agglomeration, and facilitate uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

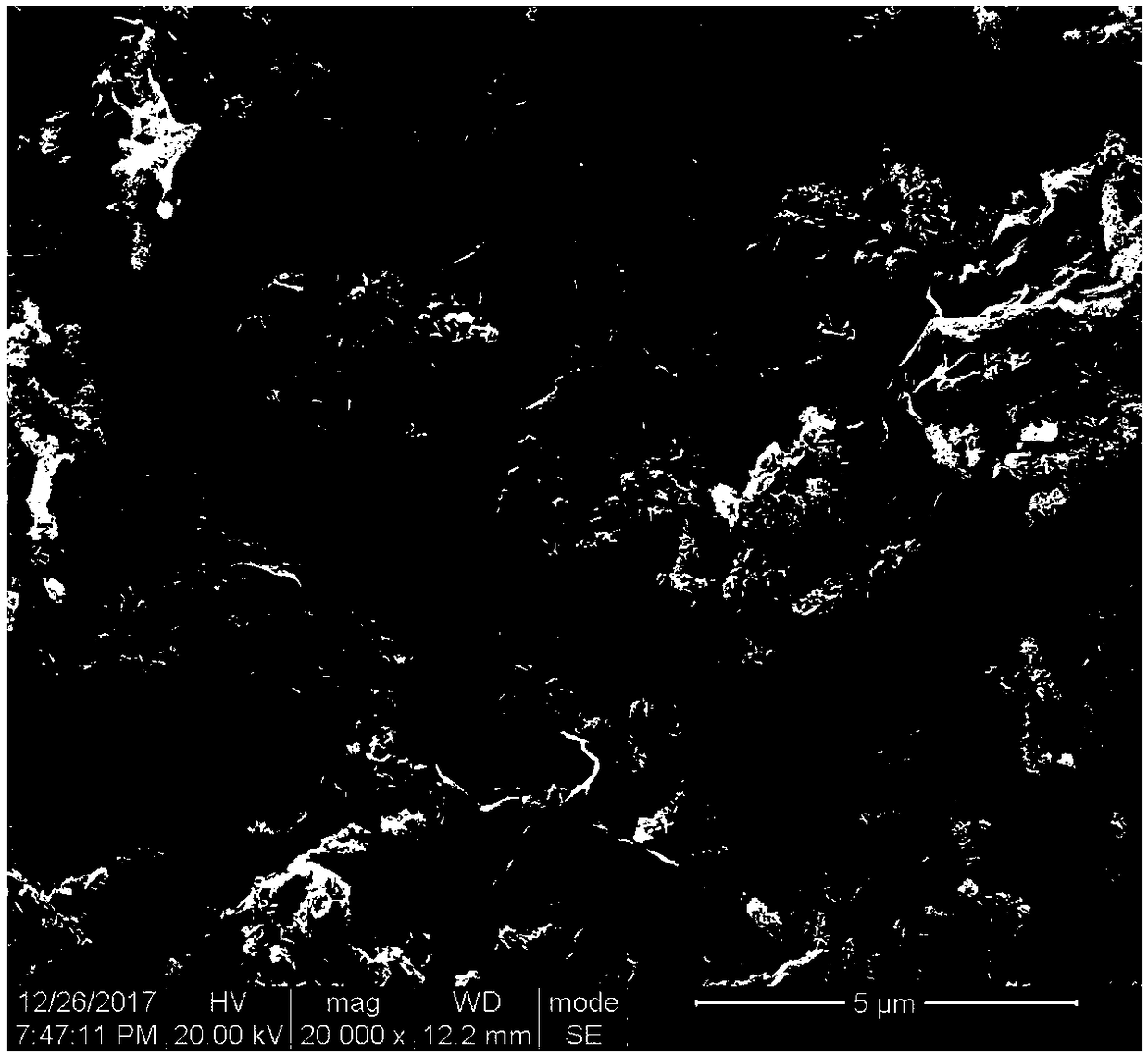

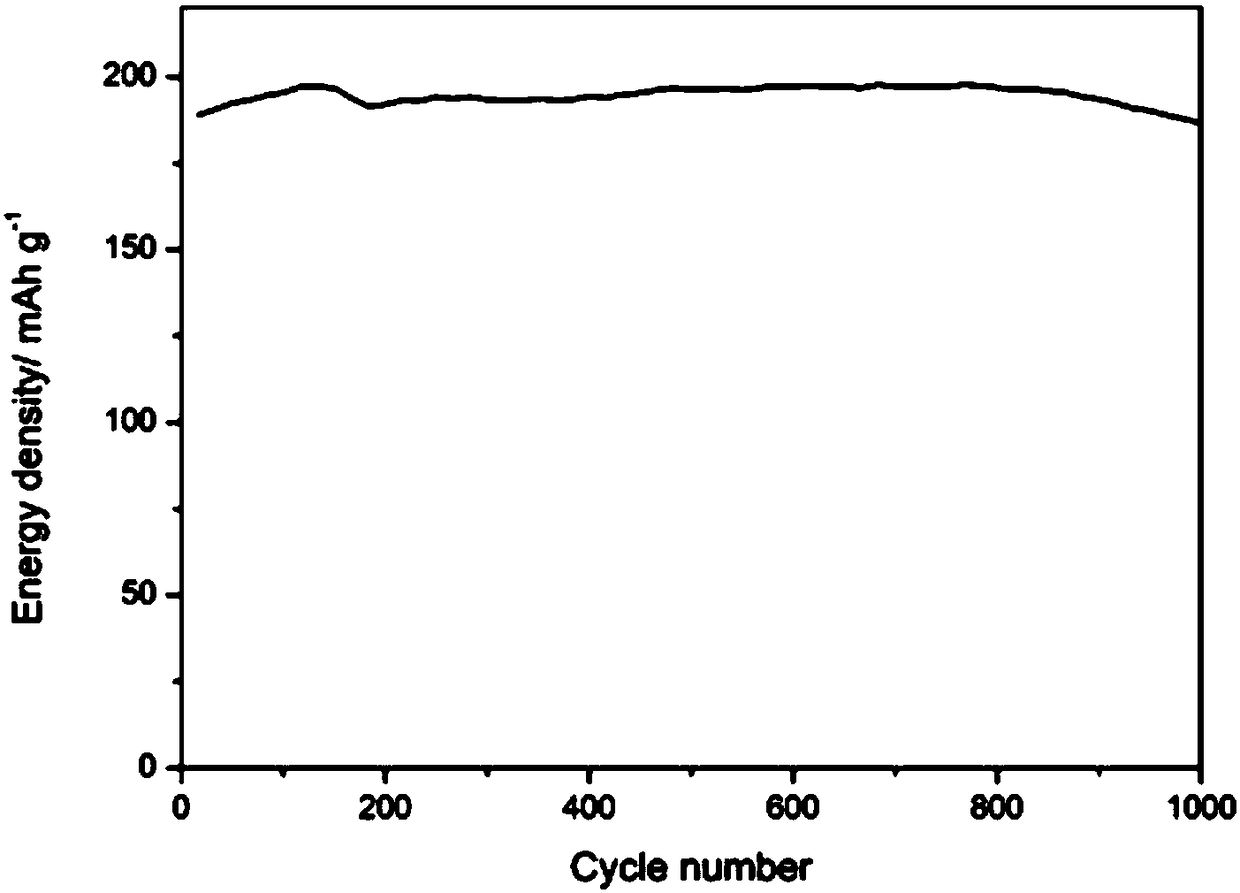

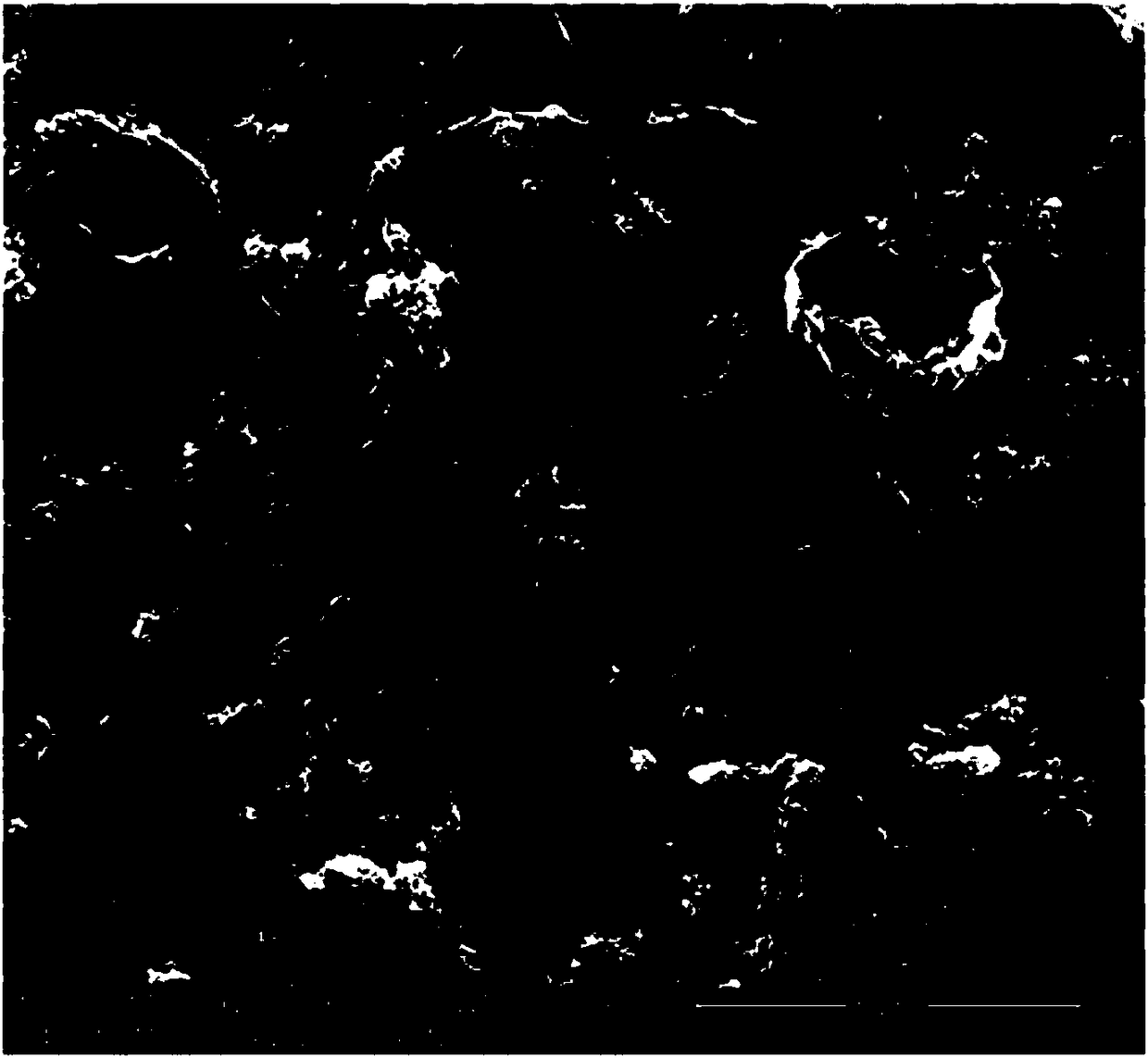

Image

Examples

Embodiment 1

[0049] 1) Weighing 10 mg of graphene, fully stirring and ultrasonic;

[0050] 2) Weigh 1g of Co(NO 3 ) 2 , 50mg of urea and 50mg of NH 4 F powder is added to the graphene solution that has been sonicated, and stirred for 5 minutes;

[0051] 3) Weigh 20 mg of polyvinylpyrrolidone (PVP) powder and add it to the mixture, and stir for 5 minutes;

[0052] 4) react at 100°C for 6 hours;

[0053] 5) After the reaction is over, take the precipitate and wash it centrifugally with water and ethanol;

[0054] 6) Stir the washed precipitate with deionized water;

[0055] 7) Weigh 200mg of Ni(NO 3 ) 2 , 200 mg Na 2 MoO 4 The solid was added to the above solution and stirred;

[0056] 8) Measure 5mL of ethanol, add it dropwise to the mixture, and stir;

[0057] 9) Transfer to a polytetrafluoroethylene reactor and react at 100°C for 5 hours;

[0058] 10) After the reaction is over, take the precipitate and carry out centrifugal washing with water and ethanol;

[0059] 11) Dry in...

Embodiment 2

[0062] 1) Weighing 100mg of graphene and fully stirring and ultrasonic;

[0063] 2) Weigh 1g of Co(NO 3 ) 2 , 200mg of urea and 200mg of NH 4 F powder is added to the graphene solution that has been sonicated, and stirred for 5 minutes;

[0064] 3) Weigh 100 mg of polyvinylpyrrolidone (PVP) powder and add it to the above mixture, and stir for 5 minutes;

[0065] 4) react at 200°C for 12 hours;

[0066] 5) After the reaction is over, take the precipitate and wash it centrifugally with water and ethanol;

[0067] 6) Stir the washed precipitate with deionized water;

[0068] 7) Weigh 500mg of Ni(NO 3 ) 2 , 500mg Na 2 MoO 4 The solid was added to the above solution and stirred;

[0069] 8) Measure 15mL of ethanol, add it dropwise to the mixture, and stir;

[0070] 9) Transfer to a polytetrafluoroethylene reactor and react at 200°C for 10 hours;

[0071] 10) After the reaction is over, take the precipitate and carry out centrifugal washing with water and ethanol;

[00...

Embodiment 3

[0075] 1) Weighing 50mg of graphene, fully stirring and ultrasonic;

[0076] 2) Weigh 1g of Co(NO 3 ) 2 , 150mg of urea and 150mg of NH 4 F powder is added to the graphene solution that has been sonicated, and stirred for 5 minutes;

[0077] 3) Weigh 50 mg of polyvinylpyrrolidone (PVP) powder and add it to the mixture, and stir for 5 minutes;

[0078] 4) react at 150°C for 24 hours;

[0079] 5) After the reaction is over, take the precipitate and wash it centrifugally with water and ethanol;

[0080] 6) Stir the washed precipitate with deionized water;

[0081] 7) Weigh 300mg of Ni(NO 3 ) 2 , 300mg Na 2 MoO 4 The solid was added to the above solution and stirred;

[0082] 8) Measure 10mL of ethanol, add it dropwise to the mixture, and stir;

[0083] 9) Transfer to a polytetrafluoroethylene reactor and react at 150°C for 6 hours;

[0084] 10) After the reaction is over, take the precipitate and carry out centrifugal washing with water and ethanol;

[0085] 11) Dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com