Preparation method of nanoscale molecular sieve@ graphene oxide coupled material

A nano-molecular sieve, nano-scale technology, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of high price, difficult to occupy pores, pollute the environment, etc., and achieve easy availability of reagents, short gas diffusion paths, The effect of large effective specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

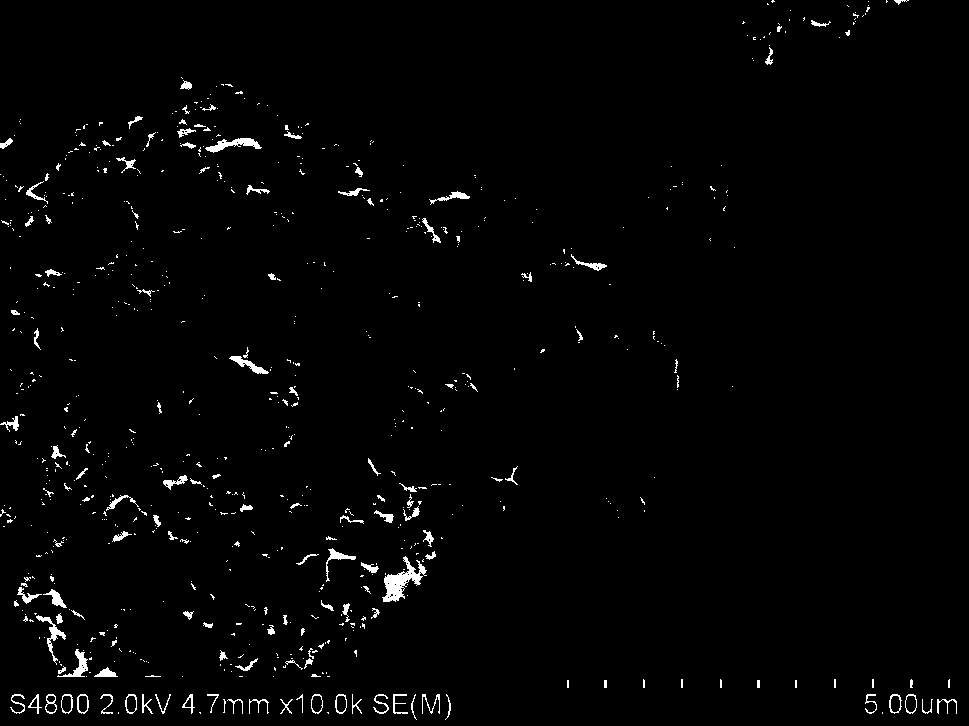

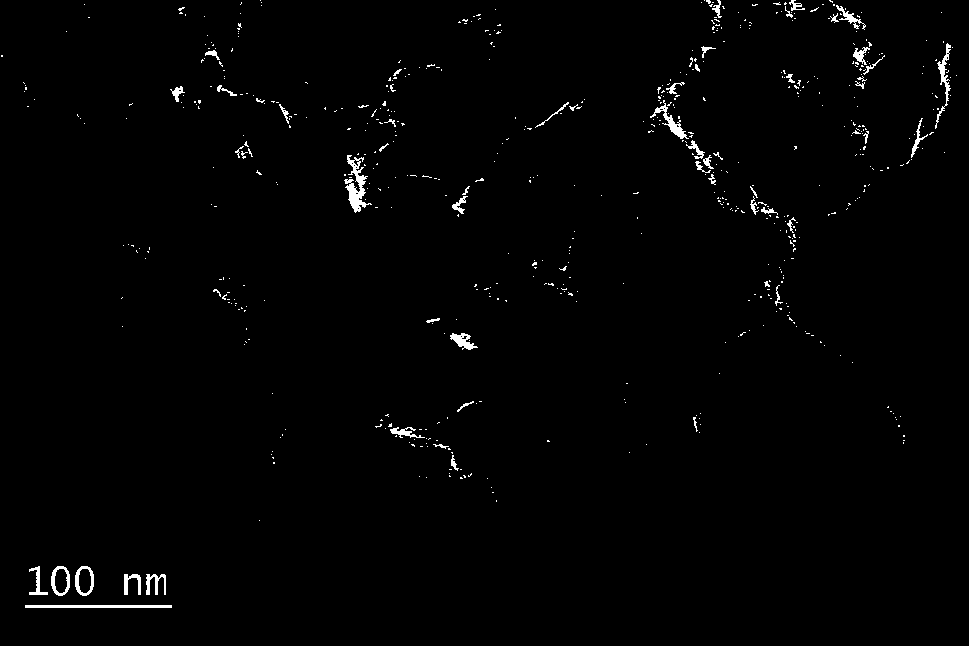

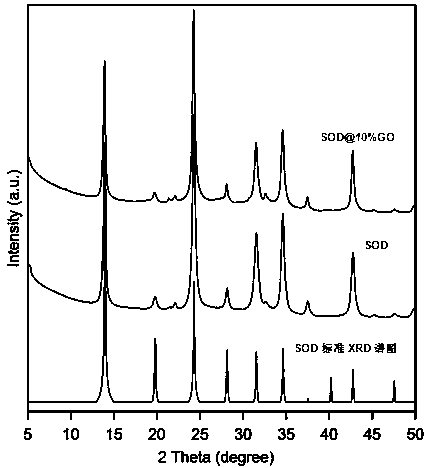

[0020] Example 1, a preparation method of a nanoscale molecular sieve@graphene oxide coupling material mentioned in the present invention, comprising the following steps:

[0021] At room temperature, mix silica sol, sodium hydroxide and deionized water to prepare silicon source solution, the mass fraction of silica sol is 22%, and the mass fraction of sodium hydroxide is 21%; mix aluminum powder, sodium hydroxide and deionized water to prepare Aluminum source solution, the mass fraction of aluminum is 3.4%, and the mass fraction of sodium hydroxide is 32%. Place the silicon source and aluminum source solutions in a mixture of ice and water until the two solutions reach 0°C, add the aluminum source solution to the silicon source solution drop by drop, and stir for 24 hours at a speed of 800 rps. The mixed solution was centrifuged and washed to pH=8, and freeze-dried to obtain the molecular sieve amorphous precursor product. The obtained amorphous precursor was stirred and mix...

Embodiment 2

[0023] Example 2, a preparation method of a nanoscale molecular sieve@graphene oxide coupling material mentioned in the present invention, comprising the following steps:

[0024]At room temperature, mix silica sol, sodium hydroxide and deionized water to prepare silicon source solution, the mass fraction of silica sol is 66%, and the mass fraction of sodium hydroxide is 11%; mix aluminum powder, sodium hydroxide and deionized water to prepare Aluminum source solution, the mass fraction of aluminum is 3%, and the mass fraction of sodium hydroxide is 32%. Place the silicon source and aluminum source solutions in an ice-water mixture to 0°C, add the aluminum source solution to the silicon source solution dropwise, and stir for 96 hours at a speed of 700 rps. The mixed solution was centrifuged and washed to pH=8, and freeze-dried to obtain the molecular sieve amorphous precursor product. The obtained amorphous precursor and the graphene oxide suspension were stirred and mixed at...

Embodiment 3

[0025] Example 3, a preparation method of a nanoscale molecular sieve@graphene oxide coupling material mentioned in the present invention, comprising the following steps:

[0026] At room temperature, mix silica sol, sodium hydroxide and deionized water to prepare silicon source solution, the mass fraction of silica sol is 22%, and the mass fraction of sodium hydroxide is 21%; mix aluminum powder, sodium hydroxide and deionized water to prepare Aluminum source solution, the mass fraction of aluminum is 3.4%, and the mass fraction of sodium hydroxide is 32%. Place the silicon source and aluminum source solutions in an ice-water mixture, add the aluminum source solution dropwise to the silicon source solution, and stir for 24 hours at a speed of 600 rps. The mixed solution was centrifuged and washed to pH=8, and the obtained molecular sieve amorphous precursor product was freeze-dried. The obtained amorphous precursor was mixed with the graphene oxide suspension at room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com