Super-hydrophobic electroactive anti-pitting coating capable of being solidified under normal temperature and preparation method thereof

A room temperature curing, super-hydrophobic technology, applied in coatings, conductive coatings, anti-corrosion coatings, etc., to achieve the effects of improving mechanical properties and mechanical properties, high effective specific surface area, and high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] FEVE selects chlorotrifluoroethylene-alkyl vinyl ester, TDI is selected as the curing agent, and a super-hydrophobic electroactive coating with anti-pitting performance is prepared on the iron plate. The hydrophobicity of the coating is tested during the friction process. Anti-corrosion performance of coatings in alkali and high-concentration saline environments.

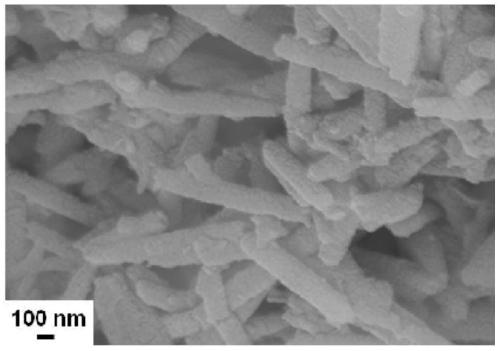

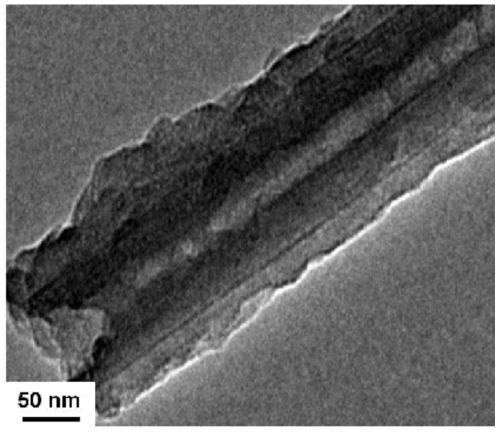

[0051] (1) Preparation of polyaniline / halloysite conductive composite

[0052] The halloysite nanotubes were ultrasonically dispersed in 0.5 mol / L sulfuric acid, and aniline monomer and ammonium persulfate initiator were added sequentially, in which the concentrations of aniline, ammonium persulfate and halloysite nanotubes were 1.86 g / L and 4.65 g / L, respectively. g / L and 0.4 g / L; after the mixed solution was stirred ultrasonically for 30 min, the chemical oxidation polymerization was carried out at 0-3 °C for 24 h.

[0053] Wash with deionized water and ethanol to remove unreacted aniline monomer and forme...

Embodiment 2

[0069] FEVE uses tetrafluoroethylene-alkyl vinyl ether copolymer, HDI trimer is used as the curing agent, and the super-hydrophobic electroactive anti-pitting corrosion coating is prepared on the aluminum plate.

[0070] Prepare coating according to the step of embodiment 1 and carry out performance test, and the difference with embodiment 1 is:

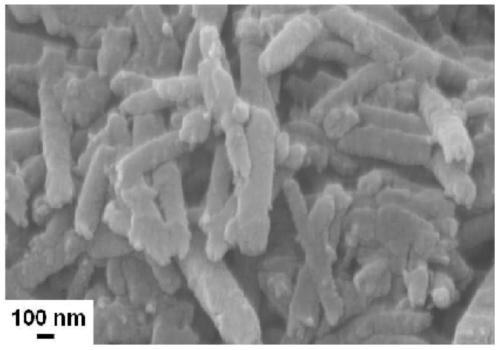

[0071] In step (1), the inorganic acid was phosphoric acid with a concentration of 0.4 mol / L, and the concentrations of aniline, ammonium persulfate and halloysite nanotubes were 2.79 g / L, 6.98 g / L and 1.12 g / L, respectively.

[0072] In step (2), the mass of halloysite nanotubes was 1.5 g, the amount of tetraethylorthosilicate was 18 mL, and the amount of perfluorodecyltriethoxysilicon was 2 mL.

[0073] In step (3), an 8 cm × 8 cm aluminum plate was selected and polished to the St3 standard with 360-mesh, 600-mesh and 1000-mesh sandpaper, respectively. After polishing, the samples were ultrasonicated with deionized water and ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com