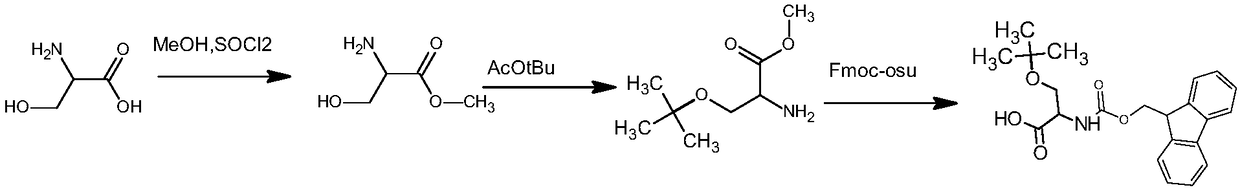

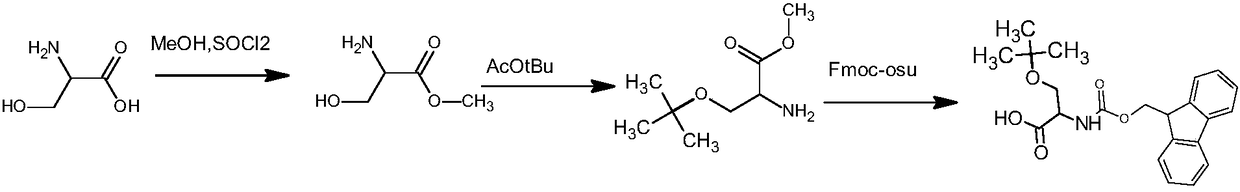

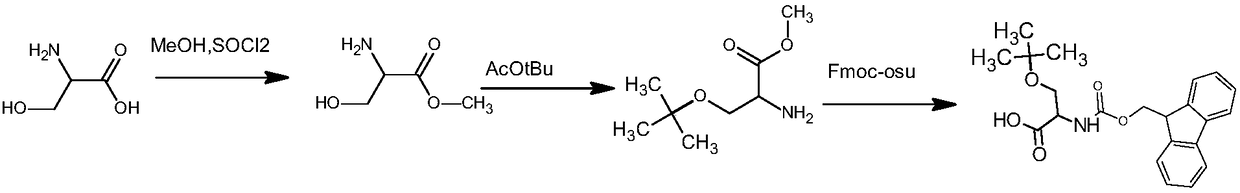

Preparation method of fmoc-O-tert-butyl-L-serine

A technology of fluorenylmethoxycarbonyl and tert-butyl, applied in the field of preparation of N--O-tert-butyl-L-serine, can solve the problems of difficult drying of water, low purity, long preparation time, etc., and achieve reduction Requirements for production equipment, a wide range of applications, and the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 20g of L-serine and 600g of methanol into the reaction flask, and add 28g of SOCl dropwise to the reaction flask under stirring 2 , use reflux reaction, and use TLC to detect the reaction solution in the reaction bottle. If there is no L-serine in the reaction bottle, the reaction is complete; The solution obtained L-serine methyl ester hydrochloride solid 29g, wherein the yield of L-serine methyl ester hydrochloride was 98%;

[0027] Get a new reaction flask, add 410g tert-butyl acetate, 50g perchloric acid (analytical pure), 29g L-serine methyl ester hydrochloride successively in this reaction flask, then add 10g H 2 SO 4 (analytically pure), at room temperature, stirred and reacted for 3 days, when TLC detection (thin-layer chromatography) detected that there was substantially no L-serine methyl ester hydrochloride in the reaction system, 50g of water was added to the reaction bottle, and the reaction was adjusted with NaOH solution The PH in the bottle is 8, l...

Embodiment 2

[0032] Add 20 g of L-serine and 600 g of methanol into the reaction flask, and add 30 g of SOCl dropwise to the reaction flask under stirring 2 , use reflux reaction, and use TLC to detect the reaction solution in the reaction bottle. If there is no L-serine in the reaction bottle, the reaction is complete; The solution obtained L-serine methyl ester hydrochloride solid 29g, wherein the yield of L-serine methyl ester hydrochloride was 98%;

[0033] Get a new reaction flask, add 410g tert-butyl acetate, 52g perchloric acid (analytical pure), 29g L-serine methyl ester hydrochloride successively in this reaction flask, then add 12g H 2 SO 4 (analytical pure), at room temperature, stirred and reacted for 4 days, when TLC detection (thin layer chromatography) detects that there is substantially no L-serine methyl ester hydrochloride in the reaction system, add 60g water in the reaction flask, adjust the reaction with NaOH solution The pH in the bottle is 9, let stand to separate th...

Embodiment 3

[0037] Add 10 g of L-serine and 300 g of methanol into the reaction flask, and add 14 g of SOCl dropwise to the reaction flask under stirring 2 , use reflux reaction, and use TLC to detect the reaction solution in the reaction bottle. If there is no L-serine in the reaction bottle, the reaction is complete; The solution obtained L-serine methyl ester hydrochloride solid 15g, wherein the yield of L-serine methyl ester hydrochloride was 98.6%;

[0038] Get a new reaction flask, add about 210g tert-butyl acetate, 25g perchloric acid (analytical pure), 15g L-serine methyl ester hydrochloride successively in this reaction flask, then add 5g H 2 SO 4 (analytically pure), at room temperature, stirred and reacted for 4 days, when TLC detection (thin layer chromatography) detects that there is substantially no L-serine methyl ester hydrochloride in the reaction system, add 30g water in the reaction bottle, adjust the reaction with NaOH solution The pH in the bottle is 9, let stand to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com