Process for separating tert-butyl acetate in medicine waste solvent through vacuum rectification by using super-gravity bed

A technology of tert-butyl acetate and vacuum distillation, applied in the preparation of carboxylate, the preparation of organic compounds, the separation/purification of carboxylate, etc., can solve the loss of tert-butyl acetate and the utilization rate of tert-butyl acetate. and recovery rate is reduced, can not get tert-butyl acetate solution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

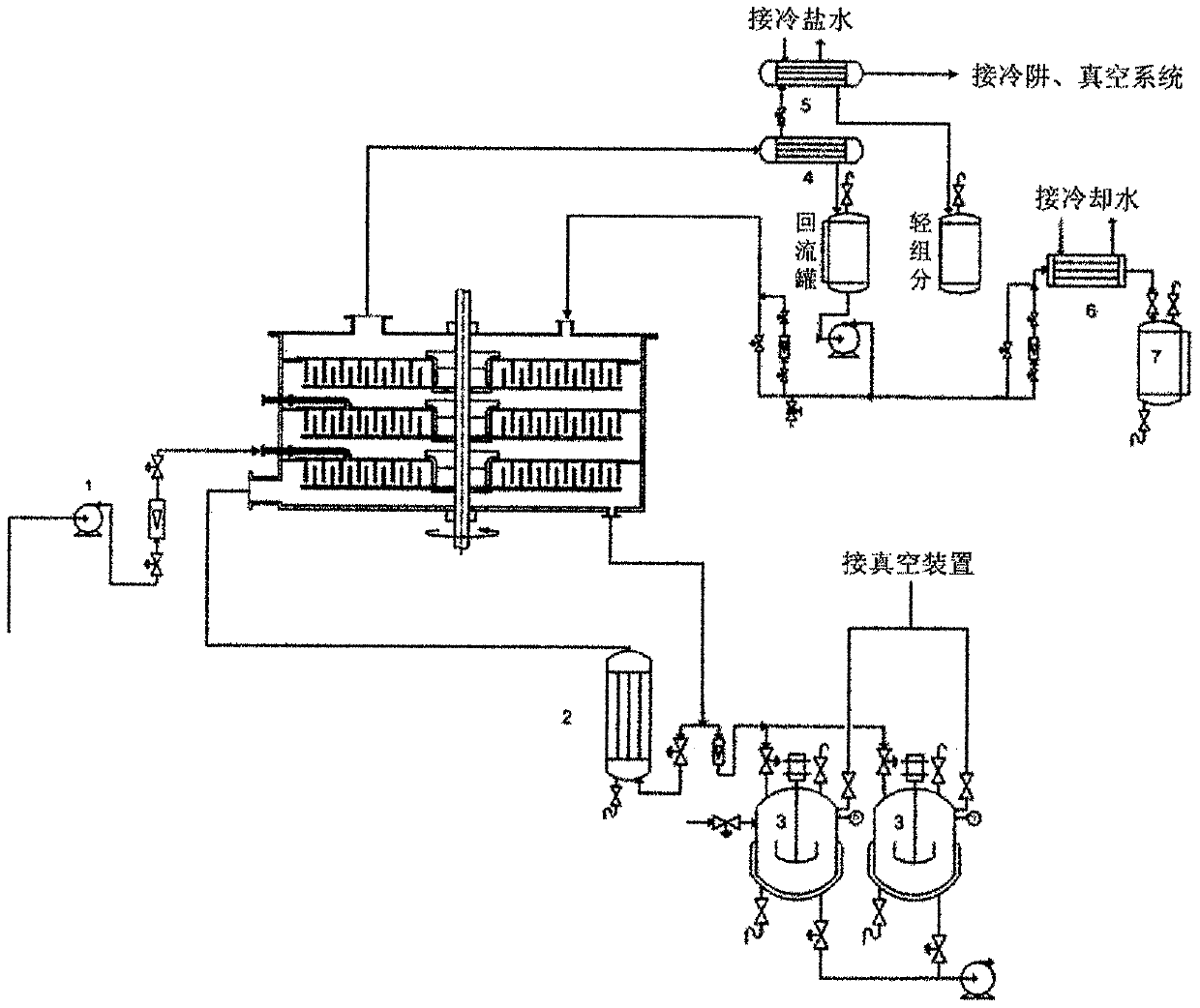

[0024] In this embodiment, the high-gravity bed is used as the vacuum distillation process of the core separation equipment to recover and reuse tert-butyl acetate in waste solvents in the synthesis process of statins and other drugs. Its specific process implementation steps are described as follows:

example 1

[0026]A batch of 45,000 kg of waste solvent contained 11.3% isoprene, 4.3% methyl tert-butyl ether, 16.2% tetrahydrofuran, 65.0% tert-butyl acetate and 3.2% impurities as determined by gas chromatography. The moisture meter determines that it contains 7500ppm of moisture. At a feed rate of 650kg / h, the raw material is pumped from the transitional raw material tank to between the second and third layer rotors of the supergravity bed. The speed of the turntable is 1000r / min, the reflux ratio is controlled to be 6-10, the vacuum at the top of the tower is 32kPa, and the operating temperature of the tower kettle is 82°C. After the operation is stable, a high-purity tert-butyl acetate product can be obtained in the tower kettle. As determined by gas chromatography, the purity of tert-butyl acetate in the product is 97.2%, and the content of isoprene is 0.9%, which is less than 1%. According to the requirements, tetrahydrofuran contains 0.9%, the rest is impurities, which is 1.0%, ...

example 2

[0028] There is a batch of 48,000 kg of waste solvent, which contains 10.7% isoprene, 5.0% methyl tert-butyl ether, 16.1% tetrahydrofuran, 63.7% tert-butyl acetate, and 4.5% impurities as determined by gas chromatography. The moisture meter determined that it contained 8070ppm of moisture. At a feed rate of 720kg / h, the raw material is pumped from the transition raw material tank to between the second and third layer rotors of the supergravity bed. The speed of the turntable is 1000r / min, the reflux ratio is controlled to be 4-8, the vacuum at the top of the tower is 40kPa, and the operating temperature of the tower kettle is 78°C. After the operation is stable, a high-purity tert-butyl acetate product can be obtained in the tower kettle. As determined by gas chromatography, the purity of tert-butyl acetate in the product is 95.6%, and the isoprene content is 0.8%, which is less than 1%. According to the requirements, tetrahydrofuran contains 1.0%, the rest is impurities, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com