Preparation method of glutamic acid-5-benzyl ester-1-tert-butyl ester hydrochloride

A technology of tert-butyl acetate and glutamic acid, which is applied in the field of preparation of glutamic acid-5-benzyl ester-1-tert-butyl ester hydrochloride, can solve problems such as difficulty in production and operation, achieve higher yield, Avoid overly acidic, high-safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

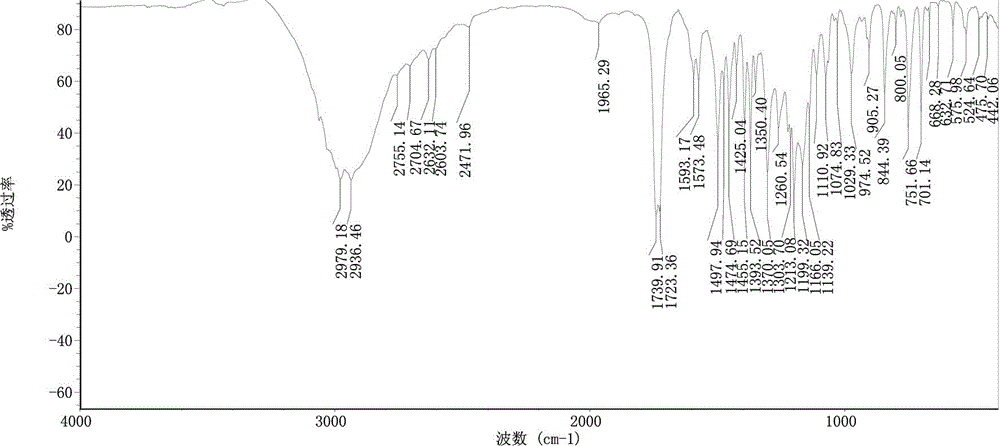

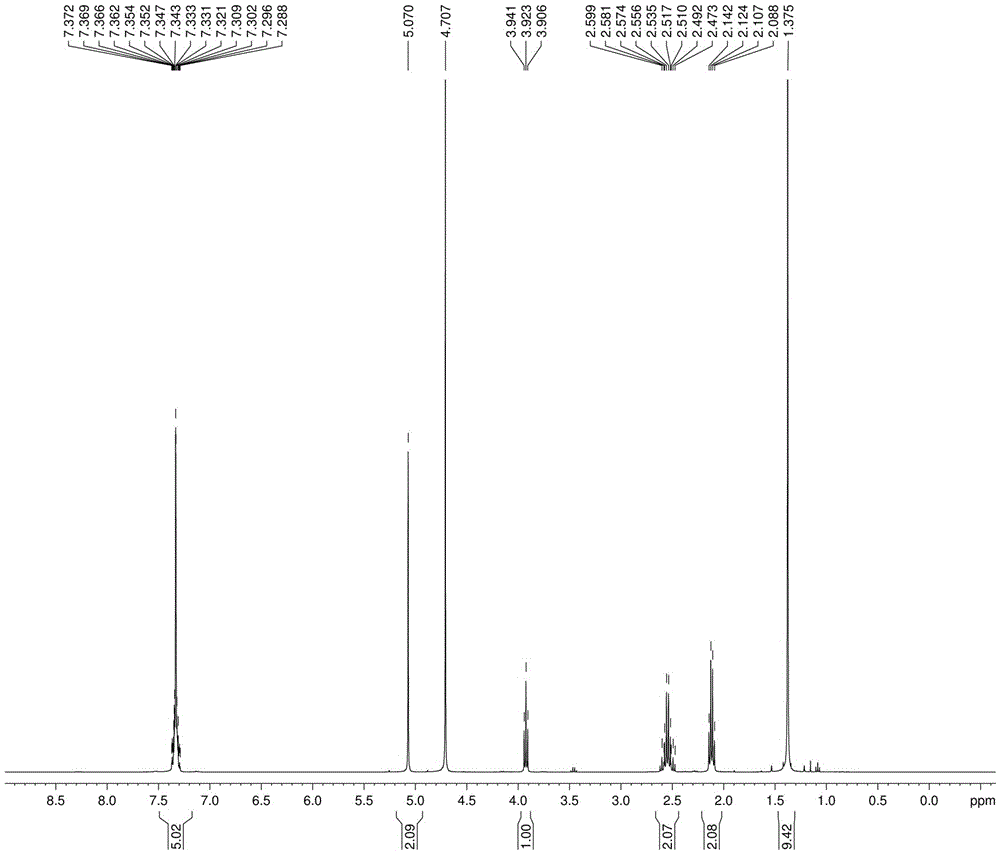

[0017] Example 1: Add 34ml of concentrated sulfuric acid dropwise to 340ml of ether, keep below 10°C, add 340ml of benzyl alcohol, stir for 15 minutes, evaporate the ether under reduced pressure at room temperature, add 50g of L-glutamic acid and stir for 20 hours. Adjust pH to 7-8 with ethylamine, filter and dry to obtain 75g of L-glutamate-5-benzyl ester; add 75g of L-glutamate-5-benzyl ester to 750ml of tert-butyl acetate, cool with ice water for external use, T figure 1 , 2 .

Embodiment 2

[0018] Example 2: Add 34ml of concentrated sulfuric acid dropwise to 340ml of ether, keep below 10°C, add 340ml of benzyl alcohol, stir for 15 minutes, evaporate the ether under reduced pressure at room temperature, add 50g of L-glutamic acid and stir for 20 hours. Adjust pH to 7-8 with ethylamine, filter and dry to obtain 75g of L-glutamate-5-benzyl ester; add 75g of L-glutamate-5-benzyl ester to 750ml of tert-butyl acetate, cool with ice water for external use, T figure 1 , 2 .

Embodiment 3

[0019] Example 3: Add 34ml of concentrated sulfuric acid dropwise to 340ml of ether, keep below 10°C, add 340ml of benzyl alcohol, stir for 15 minutes, evaporate the ether under reduced pressure at room temperature, add 50g of L-glutamic acid and stir for 20 hours. Adjust pH to 7-8 with ethylamine, filter and dry to obtain 75g of L-glutamate-5-benzyl ester; add 75g of L-glutamate-5-benzyl ester to 750ml of tert-butyl acetate, cool with ice water for external use, T figure 1 , 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com